This comprehensive guide delves into the world of electrical slip ring, uncovering their fundamental principles, varied types, and extensive applications across diverse fields. From the basic mechanics of how they transmit power and signals to the maintenance practices ensuring their longevity, each section is designed to enhance understanding and facilitate the optimal use of slip rings. The exploration extends to breakthrough technologies and upcoming trends, aiming to provide a thorough grasp of slip rings’ critical role in innovation and technological advancement.

Introduction: The Essential Role of Electrical Slip Ring

In the dynamic world of rotating electromechanical systems, the need for a reliable method of transmitting power and data between stationary and rotating platforms is paramount. Step into the sphere of electrical slip rings, the unsung heroes ensuring seamless rotation without entanglements or disruptions. At their core, electrical slip rings are electromechanical devices that allow the transmission of power and electrical signals from a stationary to a rotating structure. Imagine the face of a clock, with its sweeping second hand: if the central part needed to remain stationary while the outer circle needed electrical power or data to rotate continuously, how could this be achieved without tangling wires? The answer lies in the ingenious application of slip rings.

The Quintessence of Electrical Slip Ring

Electrical slip rings have quietly revolutionized numerous applications by offering an elegant solution to a complex problem. Comprising stationary brushes that gently make contact with a rotating ring, these devices facilitate the uninterrupted flow of electricity and signals, ensuring that systems like wind turbines, medical equipment, and industrial machinery operate efficiently. Picture a wind turbine, its blades continuously turning to harness the power of the wind. Inside the rotor hub, slip rings transmit control signals and power to pitch control systems, allowing the blades to adjust and optimize their angle to the wind—maximizing energy generation. This scenario underscores the crucial role slip rings play in renewable energy, a sector where reliability and efficiency are not just desired but required.

Lighting the Path: The Importance of Slip Rings

Electrical slip rings are indispensable across numerous sectors, highlighting their versatility and critical importance. In the medical field, slip rings are pivotal in advanced diagnostic equipment like CT scanners, enabling the rotational movement necessary for capturing detailed images of the human body. Meanwhile, in the realm of entertainment, slip rings contribute to the magic of theatrical productions and theme park rides, facilitating the complex movements of stage equipment and rotating sets. Each application showcases the adaptability of slip rings to various technical demands, underlining their indispensable nature.

Moreover, the evolution of slip rings has kept pace with technological advancements. Modern slip rings incorporate cutting-edge materials and engineering to minimize noise and wear while maximizing signal integrity and reliability. This evolution ensures that slip rings remain an essential component of both current and future innovations.

As we delve deeper into the chapters that follow, we will explore the myriad types of slip rings, their applications, considerations for selection, and best practices for maintenance. Through real-world examples and case studies, the significance of slip rings in our everyday lives and the technological sphere will be illuminated further. Whether in the high-tech corridors of aerospace or the bustling production lines of manufacturing, electrical slip rings play a pivotal role in bringing dynamic systems to life, propelling us toward a future where possibilities are as limitless as the rotations they facilitate.

The Basics of Electrical Slip Ring

Understanding the fundamental principles and components of electrical slip rings is essential for appreciating their pivotal role in various electromechanical systems. This chapter lays the foundation by defining electrical slip rings, dissecting their key components, and elucidating the principles that allow for the efficient transfer of power and signals.

Unraveling Electrical Slip Rings

At its simplest, an electrical slip ring is a device designed to transmit power and electrical signals from a stationary structure to a rotating one, enabling uninterrupted rotation. The basic concept of a slip ring could be likened to a rotating bridge that connects two different territories—where one territory is a static source of power or data, and the other is a moving recipient requiring that power or data to perform its function.

To illustrate, imagine a large radar antenna steadily rotating to scan the horizon for incoming weather patterns. For the antenna to rotate continually while still receiving power and transmitting data back to a stationary computer, an electrical slip ring is implemented within its base. This ensures continuous operation without limiting the antenna’s rotational capability.

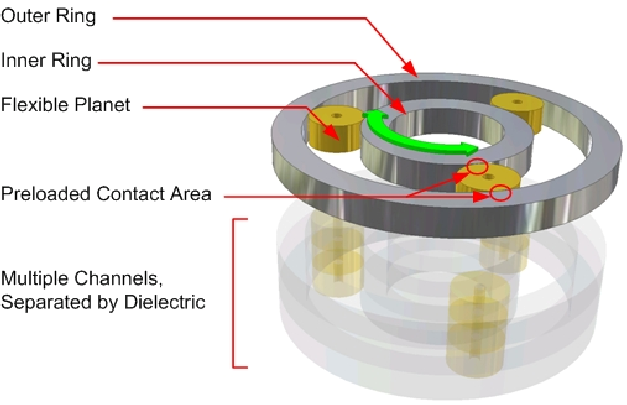

Components of a Slip Ring Assembly

A typical slip ring assembly comprises two main components: the rotor, which is connected to and rotates with the moving part, and the stator, which remains stationary and is connected to the source of power or data. The magic happens through the contact interfaces between these two components, usually in the form of metal brushes (stator) that lightly touch a rotating metal ring (rotor). This contact allows electrical currents and signals to pass through despite the movement.

- Rotors and Stators: The heart and soul of the slip ring, facilitating the physical connection and disconnection necessary for rotation.

- Brushes: Usually made of a conductive material, these maintain a gentle yet constant connection with the rotating ring, ensuring transmission.

- Housing: Protects the internal components from external elements and is often designed to suit specific environmental conditions.

The Principle of Transmission

The principle behind an electrical slip ring’s function hinges on the continuous contact between the stator’s brushes and the rotor’s ring. As the rotor spins, the brushes remain in contact, maintaining a static electrical connection. This allows for the flow of electrical currents and signals across the rotating interface.

Imagine a subway system where the train (rotating part) needs to collect passengers (electrical signals or power) from the station (stationary part) at every stop without pause. The slip ring, in this case, acts as the train doors that open (make contact) to let passengers in at every rotation or station.

In real-world applications, this principle allows for the control and operation of complex machinery such as wind turbines, where slip rings transfer power and data to the rotating blades, enabling precise control over blade pitch for optimal wind capture.

Addressing Common Questions

A common misconception about slip rings is that they are prone to rapid wear and maintenance challenges due to constant physical contact. However, advancements in materials and engineering have significantly enhanced their durability and operational lifespan, making them more reliable than ever.

In Practice

A compelling example of slip ring application is found in modern wind turbines. These giants of renewable energy rely on slip rings to manage blade adjustments, ensuring they capture the optimal amount of wind energy. The slip rings inside enable a constant flow of data and power to the turbine’s control systems, even as the nacelle rotates to align with wind directions—showcasing the slip ring’s critical role in efficient energy production.

Electrical slip rings serve as a cornerstone technology in bridging the gap between stationary and rotating systems. By understanding the basics of how they work, their components, and the principles behind their operation, we can appreciate their significance in a myriad of applications. As we move forward, technological advancements continue to push the boundaries of what slip rings can achieve, solidifying their role in the future of innovative engineering solutions.

Key Types and Configurations of Electrical Slip Ring

The versatility of electrical slip rings in bridging the electrical gap between stationary and rotating structures is facilitated by the variety of types and configurations available. Different applications demand specific features from slip rings, tailored to meet the requirements of power, signal fidelity, size constraints, and environmental conditions. This chapter delves into the common types of slip rings—capsule, through-bore, and pancake—and explores how their distinct designs serve various applications.

Capsule Slip Rings: Compact Solutions

Capsule slip rings are characterized by their compact, cylindrical design, making them the go-to choice for applications where space is at a premium. Encased in a small, round housing, the wires from the stationary part of the assembly weave through the capsule to make contact with the rotating part. This configuration is ideal for transmitting low to moderate power and data signals with high integrity.

Real-World Application: A quintessential example of capsule slip rings at work can be found in security cameras. These devices often need to pan or rotate 360 degrees to monitor their surroundings effectively. The compact size of capsule slip rings facilitates this continuous rotation, providing a seamless power supply and data transmission without hindering the camera’s motion.

Through-Bore Slip Rings: The Central Approach

Through-bore slip rings feature a hollow shaft at their core, allowing for the passage of other components, such as fluid lines or shafts. This design not only accommodates rotational electrical connectivity but also integrates the mechanical assembly, thereby optimizing space and functionality. Through-bore slip rings can handle a larger power capacity compared to capsule types and are suitable for applications requiring the transmission of multiple signals or higher currents.

Real-World Application: Consider the application in medical CT (Computed Tomography) scanners. The hollow center of the through-bore slip ring allows it to fit around the central axis of the scanner, facilitating the data transmission necessary for producing detailed body images while simultaneously supporting the rotation of the scanner’s components.

Pancake Slip Rings: The Low-Profile Choice

Pancake slip rings, as the name suggests, have a flat, disc-like configuration. This design minimizes the axial length but increases the diameter, making pancake slip rings ideal for applications where height is limited but there is enough radial space. Though they may suffer from higher capacitance due to their layout, which can affect signal quality, advancements in material science and engineering have somewhat mitigated these issues.

Real-World Application: In satellite dishes or wind turbine pitch control systems, where the assembly might be broad but flat, pancake slip rings ensure that power and data can be reliably transmitted without compromising the system’s structural integrity or functionality.

Tailored Configurations for Diverse Applications

The adaptability of slip rings extends beyond their basic types to include configurations like hybrid models, which can carry both power and high-speed data simultaneously, and Ethernet slip rings, designed specifically for uninterrupted high-speed data transmission.

Furthermore, manufacturers often offer customization options to meet the unique demands of specific applications, whether that involves altering materials for extreme environments, integrating additional features for signal integrity, or scaling the size to fit precise dimensional requirements.

Addressing Common Concerns

A misconception about the versatility of slip rings is that one type fits all applications, which is far from the truth. Each configuration has been developed to solve specific challenges, and selecting the wrong type could result in suboptimal performance or even failure. Consulting with manufacturers and engineers during the design phase is crucial to identify the most suitable slip ring for the application at hand.

The diversity of electrical slip rings in types and configurations underscores their importance in a wide array of applications, from everyday gadgets to sophisticated industrial machinery. By understanding the unique advantages and applications of capsule, through-bore, and pancake slip rings, designers and engineers can better harness these devices’ capabilities, ensuring that rotating systems perform seamlessly, regardless of their specific requirements. As technologies evolve and demand for more complex systems increases, the innovation in slip ring designs and configurations will undoubtedly continue, pushing the boundaries of what is possible in electromechanical design.

Applications of Electrical Slip Ring

Electrical slip rings may not be household items, but their pervasive presence in various applications is undeniable. From enabling the awe-inspiring rotations of industrial machines to facilitating the delicate maneuvers of medical equipment, these slip ring’s impact is profoundly felt. In this chapter, we shall explore diverse applications of electrical slip rings, including industrial machinery, wind turbines, robotics, medical equipment, and camera systems. We’ll highlight specific use cases to illustrate the integral role of slip rings in these everyday applications.

Industrial Machinery: The Powerhouse of Production

In industrial settings, the ability of machines to continuously rotate without disrupting power supply or communication is vital. Whether it’s in rotating assembly lines, packaging systems, or wind turbines, electrical slip rings are the unsung heroes enabling these systems to operate non-stop.

Real-World Example: Take a bottling plant, for instance—an environment where conveyor belts continually move and rotary machines fill, cap, and label bottles. Without slip rings, the machinery would struggle to retain the power supply during rotation, hampering productivity.

Wind Turbines: Harnessing Energy Efficiently

Wind turbines use slip rings to transfer power and control signals to the rotating blades, adjusting their pitch based on wind force and direction. This constant adjustment guarantees optimal power generation, regardless of how the wind blows.

Real-World Example: Modern wind turbines employ advanced ‘pitch control systems’. These systems require the continuous rotation of turbine blades in precise alignment with wind direction. Through-bore slip rings underpin this process, allowing for constant power supply and communication which is essential for the successful function of the turbines.

Robotics: Supporting Precision and Efficiency

In robotics, slip rings provide a reliable solution for transmitting power and control signals between stationary bases and moving parts. This is crucial in robotic arms, which must move freely while maintaining a steady flow of electrical information and power.

Real-World Example: Take a robotic manufacturing arm used in car assembly lines that’s required to rotate and articulate in several directions while welding car parts. The arm’s continuous rotating motion would be impossible to maintain without the presence of electrical slip rings, which enable the necessary power supply and communication.

Medical Equipment: Ensuring Life-saving Precision

Within the healthcare sector, various medical devices depend on the seamless operation of slip rings. They play a pivotal role in medical imaging machines that require rotating parts to capture patient data from several angles.

Real-World Example: In a CT scanner, a slip ring allows for the continuous rotation needed to create cross-sectional images of the body. The slip ring not only provides the necessary power for spinning the scanner but also transmits the large amount of data collected by the scanner to the stationary computer system, which interprets the information into interpretable images.

Camera Systems: Providing Uninterrupted Views

For camera systems designed to provide a 360-degree view, slip rings are essential. Space constraints within such systems often require compact solutions like capsule slip rings.

Real-World Example: Take a CCTV camera used for security surveillance. These cameras need to rotate continuously to monitor a wide area. Electrical slip rings inside the camera allow for an uninterrupted power supply and signal transmission, facilitating constant rotation and real-time imaging.

Addressing Common Misconceptions

Given the behind-the-scenes nature of electrical slip rings, many may underestimate their relevance in everyday applications. However, from the subtle rotation of surveillance cameras to the sturdy movement of industrial machinery, and the precise adjustments in medical equipment, these devices are indeed ubiquitous and fundamentally keep our world turning – quite literally.

Electrical slip rings’ range of applications reflects their immense versatility and indispensability. These devices’ ability to facilitate smooth and uninterrupted operation in a multitude of settings underscores their significance in our increasingly electromechanical world. As the drive towards automation and efficiency continues, we can only expect the prominence of electrical slip rings in various sectors to further ascend. For those designing and engineering future technologies, understanding slip rings’ applications and capabilities is crucial to realizing new and ambitious systems that will shape the world of tomorrow.

Selecting the Right Electrical Slip Ring

Choosing the right electrical slip ring for a particular application is crucial, much like ensuring a puzzle piece fits perfectly. It’s a decision that can impact the efficiency, longevity, and reliability of a system. In this chapter, we delve into the essential factors to consider when selecting slip rings, alongside guidelines tailored for different applications. By exploring these considerations in depth, we’ll illuminate the path to finding the perfect slip ring match for any project.

Considering the Essentials

Selecting an electrical slip ring is not a one-size-fits-all process. Several key factors influence this decision, requiring a thoughtful evaluation of each.

Current and Voltage Requirements

The electrical load that a slip ring needs to handle is paramount. It’s essential to know the maximum current and voltage the system will carry. This guarantees the slip ring can handle the electrical demand without overheating or degrading prematurely.

Real-World Example: For heavy machinery in a manufacturing plant that operates on high power requirements, selecting slip rings capable of handling the specific current and voltage ensures machinery operates safely and efficiently.

Size Constraints and Signal Types

Space availability often dictates the size of the slip ring, while the nature of the signal (data or power, analog or digital) influences the type of slip ring needed. Capsule slip rings suit compact spaces, whereas through-bore slip rings might be preferred for applications requiring a central pass-through for other components.

Real-World Example: In miniature robotics used in medical procedures, capsule slip rings are often the go-to choice. Their small size does not impose on the limited space within the robot, yet they provide the necessary power and signal transmission to operate the device effectively.

Environmental Conditions

Slip rings operate in a variety of environments, each with its own challenges. Factors such as exposure to dust, moisture, high or low temperatures, and even explosive environments dictate the need for slip rings with specific protective features or certifications.

Real-World Example: In outdoor wind turbines, slip rings must withstand harsh environmental conditions like rain, dust, and fluctuating temperatures. Selecting slip rings designed with robust sealing and durable materials is crucial for the turbines’ operational longevity.

Guidelines for Different Applications

The vast range of applications for slip rings means that guidelines can vary significantly. Here we provide some actionable advice for common use cases.

Robotics and Automation

For robotics, prioritize compact, high-speed data transmission capable slip rings. Consider the range of motion and ensure the slip ring allows for the freedom of movement required by the robotic system.

Renewable Energy Systems

Wind turbines and other renewable energy systems often face harsh environmental conditions. Select slip rings that are robust, can handle the required electrical loads, and are designed for outdoor conditions, ensuring durability and reliability.

Medical Equipment

Medical applications demand slip rings with high precision and reliability. Opt for low electrical noise options to avoid interference with sensitive signals and ensure they meet medical-grade standards.

Heavy Machinery

In heavy industrial settings, choose slip rings that can handle high power loads and are resistant to environmental factors such as dust and debris. Through-bore slip rings might be advantageous for integrating with machinery’s central components.

Addressing Common Misconceptions

A common misconception is that a more significant, more expensive slip ring is always better. However, matching the slip ring to the specific needs of the application is far more important than opting for the largest or costliest model.

The journey to selecting the right electrical slip ring is nuanced, requiring a deep understanding of the application’s needs, environmental challenges, and the specific requirements of the system. By considering these essential factors and following the provided guidelines, one can confidently choose a slip ring that ensures optimal performance and reliability. This choice not only affects the system’s immediate functionality but its longevity and cost-effectiveness over time. Remember, when it comes to electrical slip rings, precision in selection pays long-term dividends.

Installation and Maintenance of Electrical Slip Rings

The journey of leveraging electrical slip rings to their fullest potential does not end with a successful selection; it merely begins. Proper installation and diligent maintenance are paramount to ensuring these devices serve their intended purpose efficiently and for an extended period. This chapter delves into the nuanced world of slip ring installation and maintenance, aiming to equip you with the knowledge necessary to maximize the functionality and longevity of these pivotal components.

Proper Installation: The Foundation of Performance

Correct installation of slip rings can vastly improve their performance and durability. Here, we explore essential installation tips and practices.

Understanding Installation Requirements

Each slip ring type may have unique installation requirements regarding alignment, mounting, and electrical connections. Thoroughly reading and understanding the manufacturer’s guidelines is crucial.

Real-World Example: Industrial slip rings used in cranes require accurate alignment to ensure smooth rotation and consistent electrical conductivity. Misalignment can lead to uneven wear and tear, decreasing the slip ring’s lifespan.

Securing and Protecting Connections

Ensuring that electrical connections are secure and well-insulated is critical to prevent power loss and short circuiting. Additionally, protecting these connections from environmental factors will enhance their reliability.

Real-World Example: In outdoor wind turbine applications, the electrical connections to the slip rings must be securely fastened and protected from the elements (rain, dust, etc.) to avoid corrosion and ensure uninterrupted operation.

Testing Before Full Operation

Conducting a series of tests before putting the slip ring into full operation can identify potential issues that might have been overlooked during installation. This includes testing for electrical continuity, insulation, and noise levels.

Maintenance Practices: Ensuring Longevity and Reliability

Regular maintenance helps in early detection of potential problems and keeps slip rings operating smoothly. Let’s explore some effective maintenance practices.

Routine Cleaning and Inspection

Regular cleaning prevents the build-up of dust and debris, which can lead to electrical disturbances. Periodic inspections can identify wear and tear, ensuring that issues are addressed promptly.

Real-World Example: In the printing industry, slip rings on rotary printing presses must be cleaned regularly to prevent ink and debris from causing signal interference or power disruptions.

Schedule Regular Maintenance Checks

Establishing a maintenance schedule based on the manufacturer’s recommendations and the operating environment of the slip ring aids in its upkeep. This might include more frequent checks in harsh environments.

Real-World Example: For slip rings in marine applications, where saltwater and humidity are constant threats, a more rigorous maintenance schedule is necessary to prevent corrosion and maintain functionality.

Replacement of Worn-Out Components

Components like brushes and contacts wear out over time and need replacing. Keeping spare parts on hand and replacing worn components promptly can prevent downtime.

Addressing Common Misconceptions

A prevalent misconception is that once installed, slip rings require little to no maintenance. However, like all mechanical and electrical components, slip rings benefit significantly from regular upkeep. Neglect can lead to performance degradation and shorter lifespans.

The installation and maintenance of electrical slip rings are as critical as their selection. Proper installation sets the stage for optimal performance and reliability, while regular maintenance ensures the slip ring can withstand the demands of its application over time. By adhering to the guidelines and practices outlined in this chapter, you can significantly extend the useful life of slip rings, thus safeguarding your investment and ensuring the smooth operation of your equipment. Remember, the efficiency and longevity of slip rings depend not just on their design and build quality but equally on how well they are installed and maintained.

Troubleshooting Common Issues with Electrical Slip Rings

Navigating the complexities of electrical slip rings requires not just an understanding of their operation but also an awareness of potential issues that may arise during their lifespan. This chapter zeroes in on common roadblocks such as noise, wear and tear, and signal interference, offering a roadmap to diagnose, remedy, and, ideally, prevent these challenges. By infusing the discussion with practical examples, we aim to arm you with the knowledge to ensure the smooth functioning of your slip rings, maintaining the integrity and efficiency of your systems.

Identifying Common Problems

Let’s explore some of the frequent issues encountered with electrical slip rings and how they manifest in various applications.

Noise in Electrical Signals

Electrical noise, characterized by unwanted disturbances in electrical signals, can degrade the quality of data transmission, leading to inaccuracies or failures in communication.

Real-World Example: In digital signage, electrical noise can disrupt the video signal, resulting in poor image quality or intermittent display issues.

Wear and Tear of Components

Regular use of slip rings inevitably leads to physical wear, impacting their effectiveness and lifetime.

Real-World Example: In manufacturing automation equipment, extensive use causes wear on the slip ring contacts, leading to a need for more frequent maintenance or part replacements.

Signal Interference

External factors can cause signal interference, affecting the stability and clarity of the transmitted data or power.

Real-World Example: In UAVs (Unmanned Aerial Vehicles), signal interference can impede the control signals, affecting the drone’s operation and the integrity of the data collected during flights.

Solutions and Preventative Measures

With an understanding of common issues, we can now delve into strategies to address and prevent them, ensuring the long-term functionality of slip rings.

Mitigating Electrical Noise

- Shielding and Grounding: Implement shielding techniques and proper grounding to protect against electromagnetic interference (EMI).

- Regular Maintenance: Maintain a clean contact surface to minimize resistance fluctuations that can create noise.

Actionable Tip: In sensitive applications like medical equipment, using slip rings with low electrical noise specifications and ensuring they are correctly grounded can significantly reduce the risk of signal corruption.

Addressing Wear and Tear

- Quality Materials: Opt for slip rings made from durable materials suited to your specific application needs.

- Scheduled Replacements: Establish a schedule for inspecting and replacing worn components before they fail.

Actionable Tip: For heavy-duty applications like cranes or wind turbines, choosing slip rings with easily replaceable parts can simplify maintenance and extend the operational life of the equipment.

Reducing Signal Interference

- Proper Installation: Ensure slip rings are installed away from sources of electromagnetic interference.

- Use of Filters: Implement filters to isolate and remove unwanted signals from affecting the system.

Actionable Tip: In environments prone to high levels of EMI, such as near powerful motors or generators, using slip rings with built-in EMI protection can help maintain signal integrity.

Addressing Common Questions

A common question is whether slip ring problems can be fixed in-house or require professional service. While routine maintenance can often be handled by the system operators, more complex issues, particularly those involving sophisticated equipment or signal integrity, might necessitate professional expertise.

Troubleshooting the common issues associated with electrical slip rings is an integral part of ensuring their efficient operation. By identifying potential problems early, applying the right solutions, and taking preventive measures, the lifespan of these critical components can be significantly extended. Just as the correct installation and maintenance practices are crucial, so too is an ability to effectively address and rectify the problems that slip rings may encounter. This proactive approach not only enhances the performance of the slip rings but also contributes to the reliability and success of the systems they support.

Conclusion

Throughout our in-depth exploration of electrical slip rings, we have unearthed a wealth of knowledge and insight critical to understanding both the current landscape and future directions of this pivotal technology. As we close this journey, let’s succinctly revisit the essential takeaways that are shaping the world of electrical slip rings.

Recap of Key Points

- Essentials of Slip Ring Mechanics: We delved into the foundational aspects of electrical slip rings, underscoring their role as enabling devices for power and signal transmission across rotating interfaces.

- Maintenance Best Practices: Regular inspection and maintenance were emphasized as vital for the longevity and reliability of slip rings, ensuring their efficiency and functionality in various applications.

- Troubleshooting Techniques: Common issues such as noise, wear, and signal interference were examined, along with practical solutions and preventative strategies to mitigate these concerns.

- Innovations on the Horizon: We looked ahead to the future, highlighting emerging technologies, advanced materials, and promising trends of wireless and contactless slip rings which may reshape traditional usage and functionality.

Encouragement to Further Exploration

Our today’s understanding of electrical slip rings is just the beginning. This technology harbors a treasure trove of potential to drive innovation across multiple fields—be it in renewable energy, where they enhance the efficiency of wind turbines; in medical technology, where their precision and reliability can improve patient outcomes; or in the realm of robotics and automation, where they ensure seamless operations.

I encourage you, the reader, to venture beyond the pages of this article. Step into the world of electrical slip rings with a curious mind and an innovative spirit. Investigate the latest developments, engage with case studies, and perhaps even contribute to the next breakthrough in slip ring technology.

Real-World Example: Imagine the possibilities in space exploration with the advent of more robust slip rings capable of withstanding the extreme conditions of outer space—furthering not just our understanding of our solar system, but enhancing the viability of long-term space missions.

Call to Action

The road to mastery and innovation is an ongoing pursuit. Let this article serve as a springboard for your continued learning and exploration. Whether you are an engineer, a technician, or simply an enthusiast, the world of electrical slip rings offers a unique opportunity to impact various sectors positively. Share your insights, join discussions, and collaborate on projects that could shape the future—we have only scratched the surface of what is possible with electrical slip rings.

In closing, I invite you to keep the curiosity alive. Stay informed, stay inspired, and most importantly, stay engaged with the technological evolutions that promise to redefine the capabilities of this unassuming yet indispensable component—the electrical slip ring.