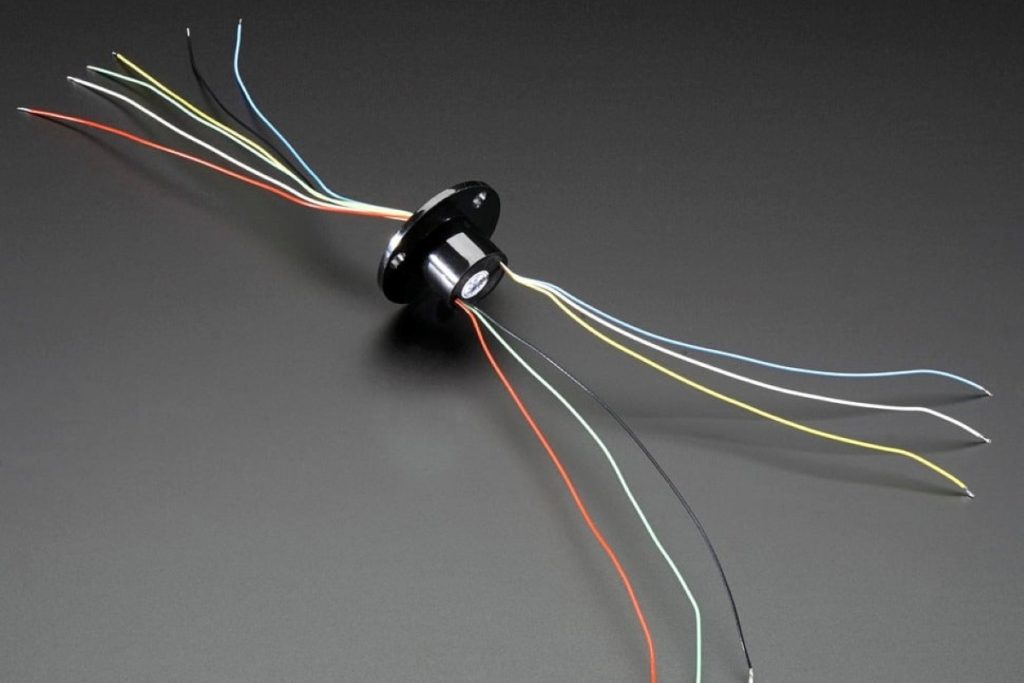

A slip ring can reach 2000 rpm and work stable, even above 4000 rpm.

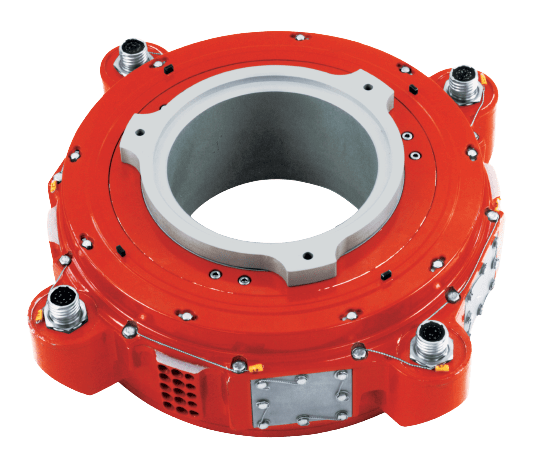

A high-speed slip ring is a type of slip ring that is designed to operate at higher rotational speeds and transmit power and electrical signals from a stationary structure to a rotating one. These slip rings are typically utilized in industries like manufacturing, aerospace, defense, and robotics.

The design of high-speed slip rings often allows for rotational speeds of up to 20,000 revolutions per minute (rpm). This capability is essential in high-speed applications, such as aircraft propulsion systems, instrumentation, test benches, and turbines.

So, to sum up, high-speed slip rings are specially designed slip rings that can handle high rotational speeds, making them integral components in a variety of demanding applications.