This article offers a comprehensive exploration of laboratory slip rings, essential components that facilitate continuous electrical connectivity in rotating parts of laboratory equipment. Starting with a detailed introduction to what slip rings are and their critical importance in laboratory settings, the article delves into the technical functionality, addressing the unique electrical challenges they help overcome. It highlights key applications in both medical and research laboratories, providing insightful examples and case studies to illustrate slip rings in action. Furthermore, the piece reviews recent innovations in slip ring technology, emphasizing the impact of new materials and designs on their performance. A thorough examination of the types of slip rings available on the market, including their advantages and limitations, equips readers with the knowledge to select the right slip ring for their laboratory equipment. The article also covers practical guidance on installation, routine maintenance, troubleshooting common issues, and offers advice on locating reputable manufacturers and suppliers. Looking towards the future, it speculates on potential developments in the field and the emerging technologies poised to revolutionize slip ring functionality. Finally, the conclusion recaps the main points discussed and encourages further engagement with the topic, urging readers to remain proactive in keeping abreast of advancements in laboratory slip rings.

Introduction to Laboratory Slip Rings

In the bustling world of laboratory research and diagnostics, the humble slip ring plays an indispensable role, albeit often out of the spotlight. Laboratory slip rings are specialized electromechanical devices designed to transmit power and electrical signals from a stationary to a rotating structure, facilitating continuity and reliability in operations where a 360-degree rotation is required. Think of them as the unsung heroes ensuring that vital equipment operates seamlessly, from advanced imaging devices to intricate robotic arms.

The Essence and Functionality of Slip Rings in Laboratory Environments

At their core, laboratory slip rings solve a fundamental challenge: maintaining a continuous electrical connection between stationary and moving parts of machinery without limiting movement. This is crucial in laboratory settings where precision and reliability are paramount. For instance, in medical imaging equipment like MRI machines, slip rings enable the rotating part of the scanner to remain electrically connected to the rest of the device, ensuring the transfer of power and data in real-time without interruption.

Why Slip Rings are Indispensable in Labs

The importance of slip rings in these settings cannot be overstated. They not only allow for the complex movement of apparatus but also significantly enhance the capabilities of laboratory equipment, making possible the complex diagnostic and research tasks that modern science demands. Without slip rings, many of the advancements in fields like medical imaging, biotechnology, and materials science would be difficult, if not impossible, to achieve.

Where You’ll Find Slip Rings in Action

Beyond medical imaging, laboratory slip rings find applications in a myriad of devices and systems crucial for research and diagnostics. These range from centrifuges, used to separate substances of different densities rapidly, to automated sample handling systems which rely on slip rings to maintain functionality while processing hundreds of samples each day. The versatility and reliability of slip rings makes them an essential component in designing and executing experiments that push the boundaries of what’s possible within laboratory walls.

By integrating real-world applications and outlining the critical role of slip rings in advancing laboratory capabilities, we bring to light the integral part these devices play in the scientific world. Their contribution, though often operating unseen, is pivotal in the seamless execution of complex procedures that underpin research and diagnostic achievements. Thus, an understanding of laboratory slip rings not only enriches our appreciation of modern scientific endeavors but also highlights the importance of continued innovation in this critical field.

The Functionality of Laboratory Slip Rings

The world of laboratory instrumentation and machinery, with its reliance on seamless rotational movement and uninterrupted power and data transmission, owes much of its efficiency and effectiveness to the functionality of slip rings. These innovative components, though small and often hidden within the larger machinery, play a crucial role in the smooth operation of numerous laboratory devices. Understanding how laboratory slip rings work and the electrical connectivity issues they address can illuminate their significance in the scientific and medical fields.

Deciphering the Workings of Slip Rings

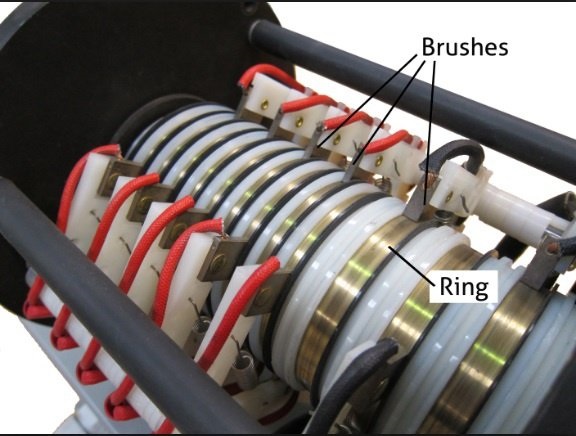

The principle behind the operation of slip rings is ingeniously straightforward yet vital for various applications. At its heart, a laboratory slip ring consists of stationary brushes that make constant contact with a rotating ring. As the ring turns, electrical signals and power are smoothly transferred through the brushes to the moving parts of the device or machinery. This continuous connection is maintained irrespective of the rotation angle, facilitating 360-degree movement without sacrificing the integrity of the signal or power supply.

Solving Connectivity Challenges in Dynamic Environments

One of the primary electrical connectivity challenges in laboratory environments involves maintaining a reliable connection between stationary and moving parts of equipment. Traditional wiring solutions are impractical for rotating parts, as they can easily become entangled, leading to signal loss or power disruptions. This is where slip rings come into play, offering a dynamic solution that ensures constant, uninterrupted electrical connectivity.

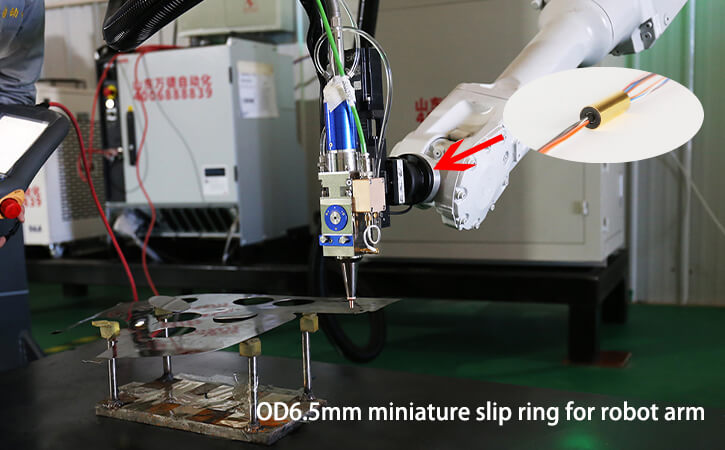

For instance, in the context of robotic arms used in automated laboratory processes, the arm’s rotation is essential for its operation. Slip rings installed within these arms allow for the transmission of control signals and power to the arm, regardless of its position or movement. This ensures that the robotic arm operates smoothly, accurately picking and placing samples or conducting precise measurements without the risk of data loss or power failure.

Real-World Impact and Addressing Misconceptions

A common misconception about slip rings is that their application is limited to large-scale or highly specialized equipment. However, their use extends beyond such confines, impacting a wide range of laboratory devices from simple mixers to sophisticated automated analytical instruments. The adaptability of slip rings to various operational needs — whether it’s transmitting low-level signals or handling high currents — underscores their versatility in solving connectivity challenges across different contexts.

The functionality of laboratory slip rings, with their ability to solve complex electrical connectivity issues, is pivotal in numerous laboratory settings. By facilitating uninterrupted power supply and signal transmission in rotating parts of equipment, slip rings not only enhance the reliability and efficiency of laboratory operations but also drive innovations in scientific research and diagnostics. Their behind-the-scenes role is critical in the seamless execution of experiments and processes that advance our understanding of the world.

Key Applications of Laboratory Slip Rings

The importance and utility of laboratory slip rings extend across a broad spectrum of applications, particularly making significant contributions in the realms of medical and research laboratories. These environments demand high precision, reliability, and often, the capability to support complex rotational movements in their equipment. This section delves into specific uses of slip rings in these settings, drawing on real-world examples and case studies to illuminate their critical role.

Innovating Medical Diagnostics: Slip Rings in MRI Machines

One of the quintessential examples of slip rings at work in medical laboratories is found within Magnetic Resonance Imaging (MRI) machines. These advanced diagnostic tools rely on the seamless rotation of the gantry – the part of the MRI machine into which a patient is inserted for scanning. Slip rings play a crucial role by ensuring an uninterrupted power supply and data transmission between the stationary and rotating parts of the gantry. This continuous connectivity allows for the capture of high-definition, 3D images of the patient’s body, crucial for diagnosing a wide range of conditions from injuries to tumors. The application of slip rings in MRI technology demonstrates their indispensable role in supporting medical diagnostics’ accuracy and reliability.

Revolutionizing Research: Slip Rings in Robotic Automation

In the field of scientific research, particularly in drug discovery and genetics, precision and efficiency are paramount. Here, slip rings are fundamentally changing the game by enabling the automation of labor-intensive processes. A case study worth highlighting involves the use of robotic arms equipped with slip rings to handle and analyze thousands of samples daily. The slip rings within these systems allow for the continuous transfer of electrical power and data signals as the arms rotate and maneuver samples between different stations for processing or analysis. This automation not only significantly increases throughput but also reduces the potential for human error, accelerating the pace of research and discovery in critical areas such as vaccine development and genomic sequencing.

Addressing Common Misconceptions

A prevalent misconception is that the utility of slip rings is restricted by their physical size or the environmental conditions of laboratories. On the contrary, today’s slip rings are designed to be highly adaptable, capable of functioning in various sizes and under different conditions, including those requiring sterile or highly controlled environments. Their versatility extends their application reach beyond traditional uses, facilitating innovation in experimental setups and equipment design across diverse scientific disciplines.

Providing Actionable Insights

For laboratories looking to integrate or upgrade equipment with slip ring technology, a key piece of advice is to partner with reputable manufacturers who understand the specific needs of lab-based applications. Doing so ensures access to slip rings that are not only of high quality but also customized for the unique demands of medical and research environments. Furthermore, regular maintenance and updates on these components can significantly enhance the longevity and performance of the laboratory equipment they support.

The key applications of laboratory slip rings in both medical and research laboratories underscore their critical role in driving advancements in diagnostics and scientific discovery. By enabling the seamless operation of complex and automated machinery, slip rings directly contribute to improving efficiency, reliability, and accuracy in these high-stakes environments. Their continued evolution and integration into laboratory equipment promise to further accelerate progress in the medical and scientific fields.

Innovations in Laboratory Slip Rings Technology

The domain of laboratory slip rings is marked by constant innovation and technological evolution, mirroring the dynamic nature of the scientific and medical fields they serve. Recent advancements in slip ring technology have been pivotal, bringing forth improvements that significantly enhance the performance and reliability of laboratory equipment. This section explores these technological leaps, focusing on the impact of new materials, designs, and their transformative potential in laboratory settings.

Breakthroughs in Slip Ring Technology

Recent years have witnessed remarkable progress in slip ring technology, with innovations focusing on increasing efficiency, reducing wear and tear, and minimizing electrical noise – factors that are crucial for the meticulous work conducted in laboratories. One notable advancement is the development of fiber optic slip rings, designed for high-speed data transmission without compromise in signal integrity. These slip rings use light instead of electrical currents, thereby eliminating electromagnetic interference, a common challenge in sensitive laboratory environments.

The Impact of Advanced Materials

The introduction of novel materials into the manufacture of slip rings has significantly uplifted their performance and durability. For instance, the use of gold-gold contact in the construction of slip rings has emerged as a game-changer. Gold, known for its excellent conductivity and resistance to corrosion, ensures a reliable electrical connection and a longer lifespan for slip rings, even under the strenuous conditions of continuous operation found in many laboratory applications.

Furthermore, the integration of composite materials has led to the development of slip rings that are both lighter and more robust, capable of withstanding environmental stressors without degradation in performance. These materials have also enabled the production of compact slip rings that are more adaptable to the constrained spaces of sophisticated laboratory instruments, without sacrificing their operational efficiency.

Redefining Designs for Enhanced Performance

The design innovations in slip rings technology are equally noteworthy. Modular slip rings, with their customizable design, allow for easy integration and scalability according to specific laboratory needs. This versatility facilitates seamless upgrades to equipment, catering to evolving research requirements without the need for complete overhauls, thus saving time and resources.

Moreover, the advent of wireless slip rings represents a radical redesign that promises to eliminate mechanical wear altogether, by using electromagnetic fields to transfer power and data. While still in the phases of development and refinement, these wireless systems could revolutionize equipment design and functionality in laboratories, offering a glimpse into the future of slip ring technology.

Addressing Misconceptions and Offering Guidance

A common misconception is that the integration of advanced slip ring technology is both complex and cost-prohibitive. However, the modular and customizable nature of many innovative slip ring designs allows for straightforward upgrades that can be adapted to suit a wide range of budgets and technical requirements. Collaboration with manufacturers during the design phase can ensure that the slip rings not only meet the operational demands of specific laboratory applications but also adhere to budgetary constraints.

The world of laboratory slip rings is one marked by continuous innovation, with recent advancements in materials, designs, and technology significantly enhancing the performance and reliability of these crucial components. As the scientific and medical fields continue to evolve, the demand for precision, efficiency, and adaptability in laboratory equipment will undeniably drive further innovations in slip ring technology. Keeping abreast of these developments is essential for laboratories aiming to leverage the full potential of their equipment and push the boundaries of research and diagnostics.

Types of Laboratory Slip Rings Available on the Market

The landscape of laboratory slip rings is as diverse as the myriad applications they empower. From the compact and simple to the complex and highly specialized, the variety available meets a broad spectrum of operational requirements. This section navigates through the different types of slip rings, shedding light on their unique advantages and the limitations they carry, and how these characteristics align with specific laboratory needs.

Mechanical Slip Rings

Overview

The most traditional form, mechanical slip rings, create an electrical connection through physical contact between a rotating and a stationary component. They are widely used for their straightforward design and reliability.

Advantages

- Versatility: Mechanical slip rings can be customized with various materials and specifications to suit a wide range of laboratory equipment.

- Cost-Effectiveness: Due to their simplicity, they are generally more affordable, making them accessible for a variety of budgets.

Limitations

- Wear and Tear: Physical contact leads to friction, resulting in wear over time, which can affect performance and durability.

- Electrical Noise: They can produce electrical noise, which may interfere with sensitive laboratory measurements.

Fiber Optic Slip Rings

Overview

Utilizing light to transfer data, fiber optic slip rings serve as a solution for high-speed communication without electrical interference, making them suitable for data-intensive applications.

Advantages

- High Data Rate: They support the transmission of large volumes of data at high speeds, essential for advanced diagnostics and research.

- Minimal Interference: The optical transmission eliminates electromagnetic interference, preserving the integrity of sensitive data.

Limitations

- Complexity and Cost: These slip rings are more complex to manufacture and install, reflecting in a higher cost compared to mechanical varieties.

- Specialized Handling: They require specialized knowledge for installation and maintenance, which may not be readily available in all laboratory settings.

Wireless Slip Rings

Overview

The newest entrants in slip ring technology, wireless slip rings, transmit power and data electromagnetically, eliminating the need for physical contact and, by extension, the associated wear and tear.

Advantages

- No Mechanical Wear: The absence of physical contact parts means there’s virtually no wear, significantly enhancing longevity.

- Flexible Design: Their design allows for more flexibility in equipment setup and can be particularly useful in applications requiring unhindered rotation.

Limitations

- Power Limitations: Currently, wireless slip rings may not support the high-power transmission needed for certain laboratory equipment.

- Emerging Technology: As a relatively new technology, wireless options may come with a higher cost and less established support infrastructure.

Addressing Common Questions and Offering Guidance

A frequent question concerns selecting the right slip ring for specific laboratory applications. The answer lies in a thorough analysis of the equipment’s operational requirements, considering factors like data transmission rates, environmental conditions, and budget constraints. Partnering with manufacturers can provide valuable insights, ensuring the selected slip ring optimally supports the laboratory’s current and future needs.

Moreover, it is crucial to dispel the misconception that all slip rings are created equal or that one type fits all scenarios. The diversity in slip ring technology means there is a tailored solution for nearly every application, but it requires a careful assessment to match with the right one.

The array of laboratory slip rings on the market caters to a wide swath of applications, each with its unique set of advantages and constraints. Understanding the nuances of mechanical, fiber optic, and wireless slip rings equips laboratory managers and researchers with the knowledge to make informed decisions, optimizing their equipment’s functionality and contributing to the advancement of scientific pursuits. Engaging in a dialogue with manufacturers, staying updated on technological advancements, and prioritizing both current and anticipated needs will pave the way for seamless integration of slip rings into laboratory settings, pushing the boundaries of what is achievable in research and diagnostics.

Selecting the Right Laboratory Slip Ring for Your Laboratory Equipment

The cornerstone of seamless laboratory operations lies in the judicious selection of components that form the backbone of its equipment. Slip rings, as pivotal elements in transmitting power and data in rotating systems, require careful consideration to align their capabilities with the needs of the laboratory. This section delves into the criteria essential for selecting the right laboratory slip ring, underpinning the discussion with factors such as size, signal type, and environmental conditions.

Understanding Selection Criteria

Selecting the appropriate slip ring is not a matter of chance but a calculated decision based on a thorough understanding of the equipment’s requirements and the working environment. The right slip ring can elevate the efficiency and reliability of laboratory operations, whereas an ill-suited one can lead to suboptimal performance or even failure.

Size and Installation Constraints

- Compactness vs. Functionality: Laboratories often grapple with space constraints. Compact slip rings that fit in tight spaces without compromising on the number or type of channels needed are crucial for such settings.

- Installation Flexibility: Consideration of the ease of installation is paramount. Modular slip rings, for example, offer a plug-and-play solution that can be easily integrated or upgraded.

Signal Integrity and Type

- Data and Power Transmission Needs: The nature of the signal (analog, digital, high-speed data, power) significantly influences slip ring selection. For data-intensive applications, fiber optic slip rings might be preferable for their high data rate capabilities and minimal interference.

- Signal Integrity: It’s essential to choose slip rings that ensure minimal signal loss or interference, especially in precision-critical laboratory operations.

Environmental Considerations

- Resistance to Contaminants: Laboratories often present challenging environments, with the presence of chemicals, dust, and other contaminants. Slip rings with a robust design and appropriate sealing are necessary to withstand such conditions.

- Adaptability to Temperature and Humidity: The operating environment’s temperature and humidity levels can affect slip ring performance. Selecting slip rings designed to operate within the specific parameters of your laboratory environment ensures reliability and longevity.

Navigating Selection with Real-world Examples

Consider the case of a pharmaceutical research laboratory where precision and data integrity are paramount. The laboratory’s equipment, used for drug efficacy testing, requires slip rings that can handle delicate signals without interference. Fiber optic slip rings emerge as the optimal choice, providing high-speed data transmission capabilities while maintaining signal integrity in a highly controlled environment.

Conversely, a geological research institute employing equipment in variable outdoor conditions might prioritize robust mechanical slip rings with high dust and moisture resistance, ensuring reliable data collection even in harsh environments.

Addressing Common Questions and Offering Guidance

A common query revolves around balancing cost against performance. It’s vital to view slip rings not just as a purchase but as an investment in the laboratory’s operational efficiency. Prioritizing quality and suitability can lead to greater savings in the long run through reduced maintenance and equipment downtime.

Additionally, the misconception that a more complex slip ring always equates to a better solution is widespread. However, understanding the specific needs of your laboratory equipment can reveal that sometimes, simplicity and reliability are more beneficial than complexity, especially in terms of ease of maintenance and overall cost-effectiveness.

The path to selecting the right laboratory slip ring is paved with a comprehensive assessment of your equipment’s needs, an understanding of the operational environment, and a clear vision of your research objectives. By carefully considering factors such as size, signal type, and environmental conditions, laboratories can ensure the integration of slip rings that enhance the performance and reliability of their equipment. Engaging with manufacturers, leveraging their expertise, and staying informed about the latest advancements in slip ring technology are actionable steps towards making informed selections that align with your laboratory’s specific requirements, thus fostering an environment where scientific exploration and discovery can thrive.

Installation and Maintenance of Laboratory Slip Rings

Proper installation and diligent maintenance are pivotal for maximizing the functionality and longevity of slip rings in laboratory settings. This section offers a detailed exploration into the best practices for installing slip rings and the maintenance routines that ensure their optimal operation over extended periods. By following these guidelines, laboratories can prevent frequent equipment failures and ensure consistent, reliable data collection and power transfer.

Best Practices for Slip Ring Installation

The installation process of slip rings can significantly influence their efficiency and durability. A meticulous approach to installation not only streamlines the setup but also safeguards the equipment from early wear and operational problems.

Pre-installation Planning

- Understanding Specifications: Thoroughly review the slip ring’s specifications and compatibility with the existing equipment. This prevents issues related to mismatched load capacities or connection types.

- Gathering Necessary Tools and Equipment: Assemble all necessary installation tools beforehand, which may include screwdrivers, torque wrenches, and multimeters for electrical testing.

Installation Process

- Environment Preparation: Ensure the installation environment is clean and free from any contaminants that could adhere to the slip ring surfaces.

- Alignment and Placement: Proper alignment of the slip ring is crucial. Misalignment can cause uneven wear and tear, and potentially lead to operational failures. Use precision tools to achieve accurate alignment.

- Secure Connections: All electrical and mechanical connections should be secured to prevent any loose ends that could lead to operational inconsistencies or safety hazards.

Case Study: Installing a High-Speed Data Slip Ring in a Robotics Laboratory

A robotics laboratory required a high-speed data slip ring for a new articulating arm used in precision assembly tasks. The slip ring needed to manage multiple data channels simultaneously with minimal signal interference. The installation team prioritized the alignment of the rotating and stationary components to avoid any data errors or mechanical resistance. Post-installation tests confirmed optimal performance, demonstrating the importance of meticulous installation practices.

Maintenance Routines to Extend Service Life

Regular maintenance of slip rings can forestall common issues like wear and electrical noise, thereby extending their service life and ensuring uninterrupted laboratory operations.

Routine Inspection and Cleaning

- Regular Inspections: Schedule routine inspections to check for signs of wear, corrosion, or damage. Early detection of these issues can prevent more severe problems down the line.

- Cleaning Practices: Keeping the slip rings clean is essential, especially in laboratories where contaminants are prevalent. Use appropriate cleaning agents and techniques depending on the type of slip ring and its exposure.

Lubrication and Part Replacement

- Appropriate Lubrication: Certain types of mechanical slip rings require lubrication to reduce friction and wear. Use the correct lubricant as specified by the manufacturer, applying it at regular intervals.

- Timely Replacement of Worn Parts: Replace worn or damaged components promptly to maintain the functionality and efficiency of the slip ring.

Addressing Common Maintenance Questions

A frequently asked question is how often slip rings require maintenance. This depends on the usage frequency, environmental conditions, and manufacturer’s recommendations. Establishing a maintenance schedule based on these factors can help in keeping the slip rings in optimal condition.

Moreover, there’s a common misconception that slip rings are ‘install and forget’ components. However, like all mechanical devices, they require periodic attention to ensure their longevity and reliability.

Proper installation and regular maintenance are crucial for the effective operation of slip rings in laboratory environments. By adhering to best practices for installation and establishing a consistent maintenance routine, laboratories can enhance the reliability and lifespan of their slip rings. Tailoring these practices to the specific type of slip ring and its application, backed by adherence to manufacturer guidelines and leveraging real-world insights, can significantly impact the productivity and efficiency of laboratory operations. Engaging with experienced technicians and continuously educating lab personnel on latest practices are proactive steps towards achieving this goal.

Troubleshooting Common Issues with Laboratory Slip Rings

Even with diligent installation and maintenance, slip rings in laboratory settings can encounter problems that disrupt their performance. Understanding common issues and knowing how to address them can help mitigate downtime and prevent damage to valuable laboratory equipment. This section explores the typical problems encountered with slip rings and guides on when professional intervention becomes necessary, ensuring that the pursuit of scientific discovery remains uninterrupted.

Common Problems and Their Solutions

Laboratory environments can be challenging for slip rings, resulting in several recurring issues. Identifying these problems early and applying the correct remedies can safeguard equipment function and integrity.

Electrical Noise and Signal Interference

- Symptoms: Fluctuating signals, data loss, or electrical noise.

- Solution: Check for loose connections or wear in the contact material. Ensuring a clean contact surface can also reduce electrical noise. In some cases, upgrading to slip rings with better shielding or noise suppression technologies might be required.

Physical Wear and Tear

- Symptoms: Increased resistance, overheating, or mechanical failures.

- Solution: Regularly inspect for any signs of physical degradation. Replacing worn-out parts or applying appropriate lubrication can mitigate these issues. In cases of severe wear, replacing the entire slip ring unit might be necessary.

Contamination

- Symptoms: Erratic performance, increased maintenance requirements.

- Solution: Implementing superior sealing solutions can prevent contaminants from affecting slip ring performance. Regular cleaning with recommended solvents or techniques tailored to the specific type of contamination can help maintain optimal function.

Case Study: Overcoming Signal Interference in an Analytical Chemistry Lab

An analytical chemistry laboratory faced recurrent data transmission issues with its slip ring-equipped centrifuge. The problem was traced to electrical noise due to inadequate shielding and contact wear. The lab technicians replaced the worn contacts and upgraded to a slip ring model with enhanced shielding capabilities. The intervention led to reliable data transmission, showcasing the importance of understanding and addressing the root causes of slip ring issues.

When to Seek Professional Help

While many slip ring issues can be resolved with routine maintenance and simple repairs, there are circumstances when calling in professionals is the best course of action.

Complex Electrical Failures

When slip ring problems stem from complex electrical issues that go beyond simple wear or loose connections, professional expertise is needed. This includes failure of integrated circuits or complex signal interference issues that require specialized diagnostic equipment.

Repeated Failures

If the same problem recurs despite attempted repairs, it’s likely that a deeper, possibly systemic issue exists. Professional technicians can conduct a comprehensive analysis to identify and rectify the underlying causes.

Significant Physical Damage

Severe physical damage to the slip ring, such as that resulting from accidents or major operational failures, often necessitates professional intervention. This ensures that the repair or replacement is done correctly, securing the reliability and safety of the equipment.

Addressing Common Questions

One prevalent concern is the fear of exacerbating the problem by attempting DIY repairs. It’s essential to assess the complexity of the issue and one’s technical capability realistically. For basic maintenance or clear-cut issues, following manufacturer guidelines can lead to successful resolutions. However, for more intricate problems, seeking professional help is advisable to avoid causing further damage.

Troubleshooting common issues with laboratory slip rings requires a balanced approach of preventive maintenance, timely intervention for simple repairs, and the prudence to seek professional help when needed. Understanding the typical problems and their resolutions empowers laboratory personnel to maintain the seamless operation of their equipment, while knowing when to call in experts ensures that complex issues are resolved efficiently and effectively. Adopting a proactive stance towards slip ring maintenance and issue resolution underpins the laboratory’s operational integrity, ensuring that scientific inquiry proceeds without unnecessary hurdles.

Laboratory Slip Rings Manufacturers and Suppliers

The functionality and longevity of laboratory slip rings hinge not only on proper installation and maintenance but also significantly on the choice of manufacturers and suppliers. Navigating the landscape of countless vendors to find reputable sources can be daunting. This chapter aims to demystify the process, providing a structured guide to finding credible manufacturers and offering tips to assess the quality of their products and customer service. Understanding these aspects ensures laboratories invest in reliable, high-performing slip rings that contribute to the integrity of research endeavors.

Guide to Finding Reputable Manufacturers

Identifying reputable manufacturers of laboratory slip rings involves a thorough vetting process. Ensuring the credibility of your supplier guarantees that the equipment meets stringent research demands.

Industry Reputation and Experience

- Research: Start by conducting thorough online research. Look for manufacturers with a robust presence in the scientific community, demonstrated through industry papers, partnerships, or contributions to leading research projects.

- Experience: Consider the duration the manufacturer has been in business. Long-standing companies often have a proven track record of reliability and innovation.

Certifications and Standards Compliance

- Quality Certifications: Look for manufacturers who adhere to international quality standards such as ISO 9001. Such certifications are a testament to the manufacturer’s commitment to maintaining high-quality production processes.

- Compliance: Ensure the products meet relevant industry standards, which could include electrical safety and environmental regulations. Compliance signifies that the slip rings are designed for rigorous use in laboratory settings.

Case Study: Partnering with a Reputable Slip Ring Manufacturer for a Space Simulation Laboratory

A renowned space simulation laboratory required high-grade slip rings capable of operating under extreme conditions for a pivotal experiment. They selected a supplier with extensive experience in aerospace applications, evidenced by their ISO certifications and adherence to international aerospace standards. This collaboration ensured the reliability of their experimental setup in a highly demanding environment, illustrating the significance of choosing a reputable manufacturer.

Tips for Assessing Quality and Customer Service

Beyond the technical specifications and certifications, assessing a manufacturer’s commitment to quality and customer service is crucial. These factors play a pivotal role in ensuring that the supplied slip rings meet the laboratory’s unique needs and that support is readily available when needed.

Product Quality and Durability

- References and Reviews: Look for testimonials and case studies from other laboratories or research institutions. Peer feedback can provide invaluable insights into the real-world performance and durability of the products.

- Material and Design: Inquire about the materials used and the design process. High-quality materials and thoughtful design indicate a manufacturer’s dedication to producing superior products.

Exceptional Customer Service

- Pre-sales Consultation: A manufacturer’s readiness to engage in detailed pre-sales consultations, offering customized solutions, is a sign of excellent customer service.

- After-sales Support: Assess the after-sales support structure, including warranty terms, technical assistance, and availability of spare parts. Responsive after-sales support is critical for resolving any operational issues swiftly.

Addressing Common Questions

A common question is whether to prioritize cost over quality. While budget constraints are an understandable consideration, investing in high-quality slip rings from reputable manufacturers ensures long-term savings by minimizing operational disruptions and unnecessary replacements. Another frequent inquiry concerns the difficulty of switching suppliers. Establishing a clear understanding of your laboratory’s requirements and conducting thorough due diligence can make transitioning to a new supplier a strategic move toward enhanced productivity and reliability in lab operations.

Choosing the right laboratory slip ring manufacturer is a critical decision that affects the functionality and reliability of laboratory equipment. By focusing on industry reputation, quality standards, product durability, and customer service, laboratories can establish partnerships with manufacturers that contribute positively to their research outcomes. Encouraging a strategic approach to finding and assessing manufacturers, supported by real-world examples and actionable advice, is key to navigating the complex market of laboratory slip rings. Making informed decisions backed by thorough research ensures that laboratories can count on their slip ring solutions to support their scientific quests without falter.

The Future of Laboratory Slip Rings

As laboratories around the globe continue to push the boundaries of science and technology, the equipment facilitating these advancements, including slip rings, must evolve in tandem. The future of laboratory slip rings promises transformative developments, driven by innovation and the integration of emerging technologies. This chapter ventures into a speculative yet informed discourse on the potential advancements in the field of slip rings, exploring how they may change the landscape of research and affect the efficiency and capabilities of lab apparatus.

Speculating on Future Developments in the Field

The continuous march of technological progression points toward a future where laboratory slip rings are not mere passive conduits for power and data but active components of advanced research equipment.

Material Innovations

- Nano-materials: The integration of nano-materials into slip ring contacts could drastically enhance their durability and reduce maintenance needs. These materials combat wear and offer self-repairing capabilities.

- Superconductors: The emergence of room-temperature superconductors would revolutionize slip ring efficiency, virtually eliminating electrical resistance and heat generation, thus allowing for the transmission of power and signals with unprecedented efficiency.

Digital and Communication Advancements

- Integrated Sensors: Future slip rings could possess sensors that continuously monitor their own health and operational status, enabling predictive maintenance and preemptive issue resolution.

- Wireless Communication: Advances in wireless technology may lead to hybrid systems where slip rings transfer power traditionally but use secure, high-speed wireless methods for data transmission, reducing mechanical complexity.

Case Study: Implementing Fiber Optic Technology in Biomedical Research

A biomedical research laboratory specializing in live cell imaging implemented slip ring systems leveraging advanced fiber optic technology. It enabled high-speed data communication between rotating and stationary platforms without compromising the fragile cellular samples with electromagnetic interference. This foresight not only enhanced the quality of their research but positioned them to seamlessly upgrade to future technologies.

Potential Impact of Emerging Technologies

Emerging technologies hold the promise to not only refine existing slip ring capabilities but also to pave the way for entirely new applications within laboratory settings.

Internet of Things (IoT) Integration

- Smart Laboratory Ecosystems: Slip rings could become nodes within IoT-enabled laboratory environments, contributing to a networked ecosystem that facilitates real-time data sharing and collaborative research across the globe.

Automation and Robotics

- Robotic Integration: As robotics become more ingrained in laboratory workflows, slip rings will need to accommodate the dynamic and precise movements required, likely evolving into more compact and modular designs that support a wide range of robotic functions.

Addressing Common Questions

A question that often arises is whether advancements in slip ring technology will render existing laboratory setups obsolete. While new technologies inevitably outpace older ones, many slip ring innovations are likely to focus on compatibility and retrofitting capabilities, allowing labs to gradually transition rather than undertake complete overhauls. Moreover, manufacturers will likely strive to maintain a degree of standardization, ensuring fundamental interchangeability and functionality with past and future designs.

Another concern is the affordability of advanced slip ring technologies. As with most technology lifecycles, initial costs will likely be higher, but as adoption widens and production becomes more efficient, prices should decrease, making these innovations accessible to a broad range of laboratories.

The evolution of laboratory slip rings is poised to impact the scientific world profoundly, enhancing the precision, efficiency, and scope of research. By embracing emerging materials, digital sensing, communication technologies, and integrating with global networks, future slip ring advancements will empower researchers to achieve more with their equipment. Laboratories that stay attuned to these technological trends and thoughtfully integrate new slip ring developments will find themselves at the forefront of scientific discovery, armed with tools that are not just fit for purpose but actively contribute to novel investigations and breakthroughs.

Conclusion

The exploration of laboratory slip rings through this guide has woven a comprehensive tapestry of knowledge that spans their fundamental principles, practical applications, management, and the exciting possibilities posed by future technological advancements. In this final chapter, we’ll encapsulize the essential points covered and encourage the reader to continue engaging with the subject matter, reinforcing the importance of remaining informed and proactive about their laboratory’s slip ring systems.

Recapitulation of Core Elements

Understanding Slip Rings

- Basics and Types: We delved into understanding what slip rings are, their primary use in facilitating rotation and transmission of electrical signals and power, and the various types available tailored to lab environments.

- Selection Criteria: Selecting the right slip ring for your application was guided by factors such as size, speed, material, and electrical requirements, ensuring compatibility with the demands of high-precision research apparatus.

Practical Applications in Laboratories

- Diverse Use Cases: Real-world examples highlighted slip rings’ roles in centrifuges, rotating microscopes, and medical systems, illustrating their ubiquity and functional versatility within research environments.

- Enhancing Functionality: We’ve seen that they extend beyond mere connection points, improving equipment functionality and paving the way for experiments that were once impossible.

Maintenance and Troubleshooting

- Preserving Performance: The importance of routine maintenance, the nuances of troubleshooting common issues, and effective methods to keep slip rings running optimally were addressed, extending equipment life and maintaining data integrity.

- A Proactive Approach: Preventive tips were shared to help avert common pitfalls and instill a culture of proactive equipment care in the laboratory.

Looking Toward the Horizon

- Technological Evolution: The potential future of slip rings was contemplated, suggesting groundbreaking developments like material innovations, integrated sensors, and IoT integration that could redefine laboratory equipment operation.

- Impactful Integration: Emerging technologies are anticipated to significantly enhance the interactivity, data management, and communication efficiency of slip ring involved equipment.

Charting a Path Forward

For readers, the journey doesn’t end here. With the knowledge acquired, you are now equipped to make informed decisions about selecting, using, and maintaining slip rings. More so, you’re poised to embrace future advances in slip ring technology that can amplify your laboratory’s research capabilities.

Engaging with Manufacturers

- Taking a proactive stance, consider reaching out to slip ring manufacturers and suppliers to discuss your specific laboratory needs and evaluate the latest products.

- Request demonstrations or trial units to assess how newer slip ring models might fit into your existing or planned equipment setups.

Pursuing Further Knowledge

- Regularly consult academic papers, technical journals, and trade publications that focus on laboratory technologies to stay abreast of the latest trends and innovations in slip ring design and application.

- Consider attending industry conferences or webinars where slip ring advancements are showcased and discussed, allowing for networking opportunities with peers and industry experts.

Addressing Lingering Questions

Before we conclude, it’s important to dispel any remaining doubts. If you’re wondering whether the investment in high-quality slip rings is justified, consider the long-term benefits of minimized downtime, less frequent replacements, and safeguarded experiment data. The pursuit of knowledge, after all, is often intertwined with the tools that enable discovery.

The importance of laboratory slip rings cannot be overstated—they are vital to the successful operation of many types of lab equipment and, by extension, to the entire scientific endeavor. As you advance in your research and continually improve your laboratory’s capabilities, remember to reflect on the roles these intricate devices play. Engage with the subject, consult with professionals, and always be prepared for the innovations that lie ahead. Let the curiosity that drives your research extend to the tools you employ, and continue to seek out the best solutions that science and technology can offer.