Slip rings, often overlooked in the grand narrative of technological advancements, play a crucial role in modern engineering and industrial applications by facilitating continuous electrical connections in systems in motion. This article delves into the essence of what are slip rings , unraveling their definition, mechanics, history, and the diversity of their designs. Through a comprehensive exploration from basic principles to real-world applications, and an insightful glance into future innovations and maintenance practices, the reader will gain a holistic understanding of slip rings’ indispensable role in motion systems. Each section, from the elementary to the complex, is crafted to enlighten both novices and professionals about the ubiquity and importance of slip rings, ultimately showcasing their enduring relevance in a world that is moving towards, yet cannot entirely rely on, wireless connections.

Introduction: Unveiling the Mystery of What Are Slip Rings

Imagine the giant arms of a wind turbine, relentlessly spinning day after day. How does it continuously receive the power it needs, or send the generated electricity, without getting wires tangled? This modern marvel—like so many rotating machines—relies on an ingenious yet often-overlooked component: the slip ring.

At its heart, our technologically driven world depends on uninterrupted electrical power and signal transmission—be it for something as monumental as a space station’s solar panels turning to face the sun or as routine as a kitchen appliance where parts need to spin freely. The common thread among them is the need for constant power and data exchange within a moving joint, a task that is anything but trivial.

Enter slip rings, the unsung heroes that stand at the core of these endless rotations. They facilitate an electrical connection that is as constant as it is silent, ensuring a ceaseless flow of electrons exactly where and when they are needed. Though they might not capture the limelight like lightning-fast processors or vast solar arrays, their role is every bit as critical.

In this article, we embark on a journey to uncover precisely what slip rings are, peeling back the layers of their discrete presence in the machines all around us. We will tread the path that power takes in a world in motion, illuminating the elegance and necessity of slip rings. Through real-world examples—from the emergency lights of an ambulance to the spinning canvases of amusement park rides—the indispensability of these devices becomes vividly clear.

So, as we zoom in from the grand picture of our powered, moving world to the miniature marvel that is the slip ring, prepare to gain an appreciation for a device that smoothly sails beneath the radar, yet is foundational to the gadgets, vehicles, and industrial machines we rely on. This is your invitation to understand the essence of slip rings—their design, function, and undeniable value in a world that never stops turning.

The Basics of What Are Slip Rings

Unraveling Slip Rings: Definition and Purpose

At their simplest, slip rings are compact devices designed to transmit power and electrical signals from a stationary structure to a rotating one. Imagine a revolving door; as it turns, its positioning changes, but it must remain connected to the building and ground it serves. Similarly, slip rings provide a continuous electrical connection between stationary and rotating systems, ensuring smooth and uninterrupted transfer of currents or data despite movement.

The beauty and functionality of slip rings lie in their ability to enable complex movements and rotations in machinery while maintaining a stable power or data flow. They are pivotal in applications where wires cannot be simply twisted or draped over moving parts without eventual tangling, wear, or operational hazard.

Exploring the Mechanics

Understanding how slip rings work can be likened to understanding a relay race where the baton must be passed smoothly and consistently. A slip ring system generally consists of:

- The Rotor: This is the part that rotates, carrying the “baton” of electrical current or data from its source.

- The Brushes: Static conductive components that maintain contact with the rotor, picking up or transferring the signals.

- The Housing: A protective enclosure that supports the entire assembly, ensuring stability and safety from environmental elements.

Visual Insight: A Dash of Clarity

Figure 1: Basic components of a slip ring. Note how the brushes contact the rotor, allowing for continuous data and power transfer.

Real-World Example: The Amusement Park Carousel

To see slip rings in action, consider a carousel at an amusement park. As the platform spins, lights and music create a magical atmosphere. The continuous and reliable delivery of electricity to the rotating platform is managed by slip rings. Without them, the wires would twist, eventually leading to electrical failure and stopping the ride—much to the disappointment of its riders.

By integrating slip rings into the system, park engineers ensure that the ride can turn endlessly while music blares and lights dazzle, all without a hitch in power supply. This everyday example encapsulates the core utility of slip rings—providing an unseen but essential service that keeps our world, quite literally, turning.

In this chapter, we have peeled back the first layer of complexity surrounding slip rings, framing their definition and operation in both schematic and practical perspectives. As we delve deeper into their types, design variations, and applications in the following sections, the versatile and indispensable nature of slip rings will become increasingly apparent.

Historical Insight: The Evolution of What Are Slip Rings

Tracing the Ancestry of Slip Rings

The journey of slip rings from inception to integration into the bedrock of modern machinery is nothing short of remarkable. Their story begins in the early days of electrical experimentation, not long after the pioneering discoveries of Faraday and Edison. The initial concept came out of the need for a solution to a basic problem: how to maintain an electrical contact with a moving component without hindering its movement.

From the primitive designs in the early 1900s, which were little more than metal brushes rubbing against the outer surface of a rotating metal ring, the evolution of slip rings has been driven by ingenuity and necessity. Each iteration brought increased efficiency, utility, and application. The advent of new materials, precise fabrication techniques, and a deeper understanding of electrical science all played a part in transforming these devices into the precise and reliable components we rely on today.

Innovations That Paved the Way

Over time, the development of slip rings saw several transformative innovations. One of the most critical was the introduction of advanced materials like silver-graphite for brushes, which offered reduced friction, longer wear life, and better conductivity. Another was the precision engineering of the slip ring contacts themselves, allowing for more refined and stable electrical transmission even at high speeds or in harsh conditions.

Modern Designs: A Legacy of Innovation

Modern slip ring designs have benefited enormously from these advancements. They can now manage more complex data signals, from high-bandwidth digital communication to sensitive analog signals, all while operating in extreme environments—from the vacuum of space to the depths of the ocean. The integration of new technologies like fiber optics and wireless power transfer into slip ring assemblies exemplifies the innovative spirit that has driven their evolution.

The Engineering Iteration Continuum

With each leap forward, slip rings have become less obtrusive and more integral. For instance, the development of modular slip rings allowed for customization to specific tasks without redesigning the entire system. This agility has led to rapid adoption across industries, allowing designers to consider rotational power and data transfer as givens rather than obstacles.

Aligning with the Present

Now, with contemporary tech such as drones and satellites relying on seamless 360-degree maneuvers, the sophistication achieved in the design of slip rings underpins many systems crucial to our daily life and future advancements.

By chronicling the historic progression of slip rings, this chapter illuminates their status not just as artifacts but as living examples of continuous improvement. The legacy of slip rings is interwoven with the fabric of both past and present technology, standing as a testament to human creativity and its relentless push towards better solutions to complex problems. As we explore further, maintaining an awareness of their storied past will enhance our appreciation for the meticulous engineering and crucial applications of slip rings in our modern world.

Technical Dive: Understanding How Slip Rings Work

The operation of slip rings, while seemingly straightforward, rests on a complex interplay of physical and electrical principles. At their core, slip rings function as a bridge, ensuring the seamless transfer of power and data across rotating interfaces. This section delves into the nitty-gritty of how slip rings facilitate this critical functionality and explores the diverse types of signals they manage.

The Fundamentals of Transmission

At the heart of slip ring technology lies the principle of conductive contact. When the rotating part of the slip ring (rotor) turns, it maintains a constant physical connection with the stationary part (brushes). This connection is made possible through materials engineered for optimal conductivity and minimal wear. The brushes gently press against the rotor, allowing electricity to flow between the moving and stationary components without interruption. This method of transmission utilizes the principle of electrical conductivity, with the materials chosen to ensure a balance between durability and efficient current transfer.

Beyond Electricity: Diverse Signal Transmission

While power transmission is a primary function, slip rings can carry a variety of signal types:

- Electrical Signals: This includes direct current (DC) or alternating current (AC) for power. The electrical signal’s uninterrupted flow is crucial for machinery that requires continuous operation, like wind turbines or medical equipment.

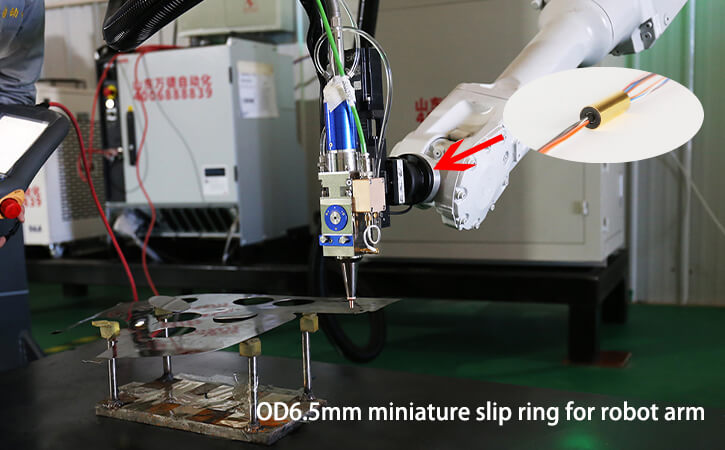

- Data Signals: High-speed data transmission through slip rings supports critical communications in many applications, from robotic arms needing real-time control data to cameras mounted on rotating platforms streaming live video.

- Fluid and Gas Couplings: Some advanced slip rings include channels for transferring fluids or gases in addition to electrical and data signals. This capability is essential in applications requiring hydraulic pressure, coolant flows, or air supply to rotating parts, such as in certain industrial processes or aerospace systems.

Practical Insight: The Wind Turbine Example

A wind turbine exemplifies the multifaceted role of slip rings. The turbine’s nacelle (the housing that contains the generator) rotates to face the wind, while its blades spin to generate power. A slip ring in the nacelle transfers electrical power and data (such as operational status and wind speed) to and from the stationary part of the turbine. Additionally, if the turbine uses a hydraulic pitch control system for its blades, slip rings may also transfer hydraulic fluid, allowing for blade angle adjustments based on wind conditions.

Addressing Misconceptions

A common misunderstanding is that slip rings are a one-size-fits-all solution. In reality, the design and materials of a slip ring must be carefully matched to its application. Parameters like the required data bandwidth, electrical load, speed of rotation, and environmental conditions influence the choice of slip ring. For instance, a slip ring used in an underwater remotely operated vehicle (ROV) would have significantly different specifications from one utilized in a wind turbine, especially concerning material choices, sealing against environmental factors, and capacity to handle specific signal types.

Tailoring Solutions

Recognizing the specific requirements of each application allows engineers to customize slip ring solutions effectively. Material science advancements have led to the development of brushes and contact surfaces that minimize wear and electrical noise, enhancing the reliability of signal and power transmission. Meanwhile, the integration of digital communication protocols with traditional slip ring designs enables the support of complex, high-speed data transmission alongside power, expanding the capabilities and applications of slip rings in modern technology.

Understanding the physical principles, design considerations, and signal types associated with slip rings provides a solid foundation for appreciating their critical role in various technologies. As we move forward, it’s clear that slip rings stand as silent yet indispensable enablers of the dynamic, interconnected systems that power our world.

Major Types and Designs: The Diversity of What Are Slip Rings

Slip ring technology is rich and varied, with a spectrum of designs that cater to an array of industrial challenges. Understanding the different types of slip rings and their unique applications is pivotal for selecting the right slip ring for the right job. This chapter illuminates the diversity within slip ring technology and illustrates how each design is a response to specific functional needs.

Pancake Slip Rings: When Space is at a Premium

Design: The pancake slip ring is characterized by its flat, disc-like shape. This form factor is not just aesthetic but functional, designed for equipment where length is more restricted than diameter.

Applications: They are commonly used in CCTV camera systems, robotics, and medical equipment where a slim profile is required to fit into tight axial spaces. Think of the delicate internals of CT scanners — compactness is key, and pancake slip rings meet that spatial constraint without compromising performance.

Through-Bore Slip Rings: Central to Rotation

Design: Through-bore slip rings come with a hollow shaft at the center, providing a clear passage for shaft mounting or for routing other media, such as fluid or pneumatic lines.

Applications: This design is perfectly suited to tasks that require a central rotational axis, such as wind turbines for routing cabling down the mast or turntables used in manufacturing processes.

Wireless Slip Rings: A Leap Into Contactless Transmission

Design: Wireless slip rings, also known as “inductive couplers,” are a bit of a misnomer as they’re not slip rings in the traditional sense. They use electromagnetic fields to transfer power and data across a small air gap.

Applications: Their primary utility shines in environments where maintenance is challenging or where contact wear must be eliminated, such as in underwater equipment or in automated machinery where cleanliness and minimal maintenance are paramount.

Capsule Slip Rings: The All-Rounder

Design: Capsule slip rings are compact, cylindrical units that house the contact brushes and rings in a sealed enclosure. They are built to be small and versatile.

Applications: Their adaptability makes them a staple across various industries, from packaging machines that need to rotate continuously to video surveillance systems where reliable signal transmission is crucial.

Innovations: Addressing Real-World Needs

Each design speaks to the diverse industrial landscape’s requirements, from the marine explorer using remotely operated vehicles that rely on the corrosion-resistant properties of certain slip rings, to the theme park engineer looking for a durable slip ring solution that can handle the high-cycle rotations of a Ferris wheel.

Understanding Misconceptions

A prevalent misconception is that one type of slip ring can be a universal solution for any rotating equipment challenge. However, each design comes with trade-offs, and it’s up to the engineer to discern which slip ring type aligns with the mechanical and electrical demands of their specific application.

Choosing Wisely: A Case Study Approach

Real-world case studies can be incredibly helpful to understand the context-specific application of slip rings. Take, for example, a rotating stage used in a theatrical production. Here, a through-bore slip ring can facilitate the integration of dynamic lighting and sound equipment without the hindrance of tangled cables, creating a seamless and magical audience experience.

Final Thoughts: Tailoring to Task

From the compact capsule to the robust through-bore, slip rings are as varied as the solutions they provide. With the continuous march of technological advancement, we can expect to see even more specialized slip ring types and designs, each tailored to an ever-growing list of applications. Understanding the fundamental principles and diverse types of slip rings allows us to appreciate the detailed engineering behind the seamless operations of rotating equipment that we often take for granted.

In sum, the innovation behind slip rings is not just about creating a connection but about designing the right connection for the right motion—fostering a harmonious interface between the static and the dynamic, the fixed and the rotating.

Common Applications: Where and What Are Slip Rings Used

Slip rings occupy a critical yet often unseen role across a myriad of industries. By facilitating the transfer of power and data between stationary and rotating components, they enable the seamless operation of many devices and systems we encounter in daily life. This chapter takes a closer look at real-world applications of slip rings, illustrating their indispensable value.

The Power of Wind: Wind Turbines

Context: One of the most impactful applications of slip rings is found within the towering forms of wind turbines. As these structures harness the power of the wind, their blades rotate, necessitating a solution for transmitting generated electricity and data from the moving nacelle to the stationary base.

Importance: Slip rings provide that solution. They allow for continuous energy transfer from the rotating part of the turbine to the grid, despite the varying directions of the wind. Moreover, they facilitate the flow of critical operational data, including speed, temperature, and torque measurements, ensuring efficient and safe turbine function.

In the Heart of Healing: Medical Equipment

Context: In the medical field, slip rings play a pivotal role, especially in advanced diagnostic imaging machines like CT scanners. These machines rely on the rapid rotation of the X-ray source and detectors around the patient to create detailed cross-sectional images.

Importance: Here, slip rings are used to transmit power to the rotating parts and to relay the gathered image data to the stationary computer for processing. The reliability and precision of slip rings in these applications are paramount, as they directly impact the quality of care a patient receives through accurate diagnostics.

Capturing Moments: Rotating Cameras

Context: From broadcasting live sports events to ensuring public safety via surveillance systems, rotating cameras are ubiquitous. These cameras must rotate smoothly to follow action or monitor spaces without restricting the wiring.

Importance: Slip rings enable these cameras to pan and tilt freely, transmitting electrical power and high-definition video signals without tangling or interrupting the feed. They exemplify the seamless blend of mechanical mobility and data integrity, crucial for real-time broadcasting and security monitoring.

Addressing Misconceptions and Questions

A common question revolves around how slip rings maintain reliable connections despite continuous rotation. The answer lies in their design, which optimally balances contact force and material choice to ensure consistent performance and minimize wear over time.

The Unseen Enabler: Other Noteworthy Applications

Beyond these examples, slip rings serve in countless other applications, further cementing their role as unseen enablers of technology:

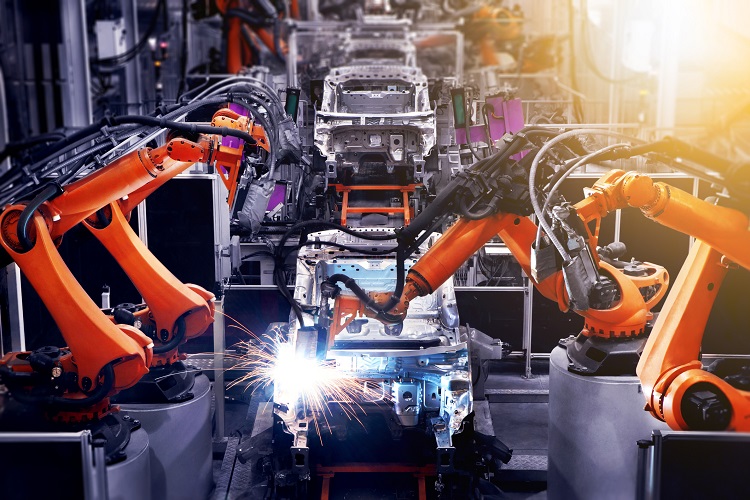

- Industrial Automation: In automated manufacturing lines, slip rings facilitate the smooth integration of robotics, enabling continuous movement and operation.

- Amusement Rides: They ensure the electrification and control of rides, delivering power and signals for lighting, sound, and safety systems in motion.

- Aerospace: In satellites and space stations, slip rings transfer power and data between stationary and moving parts, crucial for operations in the harsh environment of space.

Choosing the Right Slip Ring

Selecting the appropriate slip ring requires a deep understanding of the application’s specific needs, including the type of signals transmitted, the environment, and the space available for the slip ring. Consulting with experts and manufacturers can provide guidance and insights tailored to each unique challenge.

Final Thoughts: The Critical Link

The applications of slip rings are as diverse as the industries they serve. From generating green energy to saving lives in medical diagnostics, their role remains crucial yet often hidden. By understanding where and why slip rings are used, we gain a greater appreciation for these essential components and the smooth operation they ensure in devices and systems integral to our modern world. As technology evolves, so too will slip rings, continuing to bridge the gap between the stationary and the rotating, the static and the dynamic.

What Are Slip Rings: Key Considerations When Choosing Slip Rings

When it comes to incorporating a slip ring into your project or industrial application, the selection process extends far beyond merely picking a standard model off the shelf. These devices, crucial for the seamless transfer of power and signals across rotating interfaces, come with an array of variables that require careful consideration. Let’s delve into the primary factors influencing slip ring selection and navigate through the common challenges and trade-offs that professionals encounter in the field.

Sizing Up the Situation: Physical Dimensions

Size Considerations: The physical constraints of your application drive the initial considerations for slip ring size. The design must align with the available space while meeting operational requirements.

- Example: In the confined space of a CCTV camera dome, a pancake slip ring’s slim profile is optimal, whereas in the broader confines of a wind turbine nacelle, a larger through-bore design is appropriate.

The Need for Speed: Operating Velocity

Speed Requirements: The rotation speed of the application dictates the type of slip ring you’ll need. High-speed applications demand slip rings with low friction and durable contacts to withstand the centrifugal forces.

- Example: On a high-speed bottling line, slip rings must cope with quick rotations without overheating or excessive wear.

Battling the Elements: Environmental Adaptability

Environmental Factors: Slip rings operate in diverse environments – from the pristine conditions of a cleanroom to the harsh, abrasive expanse of a desert.

- Example: In marine applications, slip rings must resist corrosion due to saltwater exposure, whereas in an industrial plant, they may need additional protection from dust and debris.

Powering Up: Electrical and Signal Requirements

Electrical Specifications: Understanding the electrical load, including power requirements and signal types (data, video, etc.), is crucial. This impacts choices around the contact material and insulation.

- Example: A slip ring in a medical imaging device must not only provide power but also ensure high-fidelity signal transmission for detailed images.

The Balancing Act: Challenges and Trade-offs

Selecting the right slip ring is often a delicate balancing act between competing factors. A slip ring that’s perfect for a high-speed application may not be the best for one requiring high power or complex data transmissions.

- Example of a Trade-off: In a robotic arm, using a slip ring that supports a high number of circuits for signal transmission may mean compromising on the speed or size of the unit.

Frequently Asked Questions and Misconceptions

Common Questions: Professionals often inquire about the longevity of slip rings and how maintenance can be minimized. The answer generally lies in the quality of materials and the design specificity for the application.

Misconceptions: A widespread misconception is that a higher price tag always equates to superior performance. Instead, the focus should be on compatibility with the specific requirements of the application.

Real-World Scenario: A Case Study Approach

Case Study: Consider an automated warehouse where slip rings are used within the conveyor system. Here, the choice will pivot on a medium capable of withstanding continuous operation and varying loads, underlining the importance of robust design and reliable power transmission.

Expert Tip: Always engage with manufacturers early in the selection process. Their expertise can provide invaluable insights into the nuances of slip ring technology and how it can be tailored to fit your specific needs.

The Informed Choice

The quest for the ideal slip ring is complex, but a structured approach to its selection rooted in an understanding of the pivotal factors and practical trade-offs elevates the likelihood of project success. Recognizing that every application brings unique challenges, the selection process becomes not just about the technical specifications, but about the narrative of the application itself—its story, demands, and expectations. This underscores the inherent value in this selection process as not just a purchasing decision, but as a strategic and critical component of design and engineering.

Future Innovations: What Are Slip Rings

The realm of slip ring technology, pivotal for its role in enabling seamless connections between stationary and rotating systems, stands on the cusp of transformative advancements. As we propel into the future, the continuous evolution of materials, design innovations, and the emergence of novel applications herald a new era of possibilities. This chapter delves into speculative yet plausible future trends in slip ring technology, painting a picture of what could lie ahead and encouraging stakeholders to envision the expanding role of slip rings in driving technological progress.

Material Innovations: Beyond the Conventional

The Evolution of Contacts: Traditional metal contacts are being reconsidered, with research delving into composite materials that offer superior performance characteristics such as reduced wear, enhanced electrical conductivity, and minimal maintenance requirements.

- Example: The exploration into carbon nanotube-infused composites for contact brushes could revolutionize slip ring efficiency, significantly extending their operational life and reducing electrical noise.

Rethinking Design for Enhanced Efficiency

Modular and Scalable Solutions: Future slip rings might adopt highly modular designs, allowing for scalable solutions that can be tailored to specific application requirements without the need for entirely bespoke systems.

- Example: In the rapidly evolving drone industry, slip rings could be designed to easily integrate additional power or data transmission capabilities as the technology progresses.

The Dawn of Smart Slip Rings

Integration with IoT and Smart Technologies: The incorporation of sensors and IoT connectivity into slip rings could enable real-time monitoring of wear and performance, predictive maintenance, and dynamic optimization based on operational data.

- Example: In wind turbines, smart slip rings could actively adjust to environmental conditions, optimizing power transmission efficiency and predicting maintenance needs to avoid downtimes.

Broadening the Application Spectrum

Emerging Applications: As industries converge and new realms of technology emerge, slip rings will find applications in areas previously unimagined. This includes robotics, renewable energy storage solutions, and even space exploration.

- Case Study: Consider the potential for slip rings in the burgeoning field of space-based solar power collection, where they could play a crucial role in the transmission of power from space-based collectors to Earth.

Addressing Common Questions and Future Misconceptions

Future-Proofing Concerns: A question that surfaces often is how future-ready today’s slip ring technologies are. Adapting to the rapid pace of innovation requires not only forward-thinking design but also an openness to interdisciplinary collaboration.

Misconceptions: There may be a belief that slip ring technology has reached its zenith. However, with the advent of new materials and digital integration, we’re merely at the beginning of what’s possible.

Pioneering Slip Ring Technology: A Glance Forward

Visionary Outlook: Imagine a world where slip rings enable the seamless transfer of high-bandwidth data across dynamic, globally distributed networks, or where energy harvested in space is transmitted to Earth with minimal loss, all thanks to the advances in slip ring technology.

Encouragement for Innovation

Call to Action: For aspiring engineers, researchers, and technologists, the message is clear – the field of slip ring technology is ripe for innovation. Leveraging advances in materials science, digital technology, and creative engineering can lead to breakthroughs that redefine the capabilities of these essential components.

The Unfolding Future of Slip Rings

As we look towards the horizon of what slip rings are and could be, it’s evident that their journey is far from complete. The future promises not just incremental improvements, but leaps in efficiency, application, and integration that will further cement slip rings as a foundational technology in the push towards an interconnected, efficient, and innovative technological landscape. It’s an exciting time for stakeholders in this field to contribute to the narrative of slip rings, shaping their evolution and ensuring their place in the future of technology.

Maintenance and Troubleshooting: What Are Slip Rings

In the mechanical ballet of industrial machinery and high-precision devices, slip rings perform quietly yet critically, maintaining the flow of power and data between stationary and rotating structures. Their importance is often realized only when failure occurs, bringing operations to a halt. This chapter is dedicated to the essential practices of maintaining slip rings and troubleshooting common problems, thereby ensuring their longevity and reliability in diverse applications.

Regular Maintenance: The Lifeline of Slip Rings

Routine Inspections and Cleaning: Emphasize the significance of regular visual inspections and cleaning, which are pivotal in preventing buildup and wear. Equipping readers with specific maintenance schedules and cleaning methods tailored to various environments can form the core of this section.

- Example: In an industrial setting, a monthly inspection and cleaning session could prevent the accumulation of dust and grime that would otherwise cause signal interference or electrical shorts within the slip ring assembly.

Tackling Typical Troubles

Addressing wear and tear: Educate readers about recognizing signs of wear, such as fluctuating voltage or intermittent signal loss, and suggest methods for assessing and replacing worn components before they fail.

- Example: A wind turbine technician may notice inconsistent power output from the blades. A check might reveal worn contact brushes in the slip ring that require replacement.

Troubleshooting Techniques: Small Steps, Big Impact

Systematic Problem-Solving: A breakdown of step-by-step troubleshooting protocols can guide the reader through the logical progression of identifying and resolving common slip ring issues.

- Example: If a rotating surveillance camera experiences erratic operation, a step-by-step guide could help isolate the problem to a faulty slip ring, which can then be cleaned, repaired, or replaced.

Common Questions and Clearing Confusions

Myth-Busting and Clarifications: Dispel myths such as the infallibility of seal-for-life units and clarify why even the most robust slip rings require attention. Address frequent queries regarding the lifespan of a slip ring and variables that might affect it, providing enlightening insights.

Misconceptions: A prevailing misconception is that slip ring failures always require expert intervention. While true in complex systems, many simpler issues can be addressed with basic maintenance knowledge.

Practical Case Study: A Real-World Lesson

Bringing Maintenance to Life: An illustrative case study — perhaps detailing the discovery and rectification of a fault within an amusement park ride’s lighting system — can help readers appreciate the value of proactive maintenance.

- Actionable Steps: The case study could show how regular maintenance could prevent a flicker in the lights from escalating into a complete power loss during peak operation hours.

Actionable Advice: Empowering Users

Empowering with Knowledge: Concluding the chapter with key takeaways, such as a checklist of maintenance tasks or a table of troubleshooting symptoms and solutions, provides readers with powerful tools.

- Expert Tips: Offer insider knowledge, like the importance of using the right cleaning solvents that won’t degrade electrical contacts or the benefits of keeping a logbook of maintenance activities.

Sustaining the Spin

Effortlessly rotating around their axis, slip rings are silent sentinels bridging the divide between motion and stasis. Their unassuming presence is fundamental to the modalities of countless systems, and yet, they too are susceptible to the rigors of their environment. By investing in their care through maintenance and being adept in troubleshooting, we can ensure the dance goes on, unhindered. This chapter aims not just to inform but to equip practitioners and enthusiasts with the knowledge to act swiftly and effectively, keeping their systems in perpetual motion.

The Continuing Relevance of What Are Slip Rings

As we draw this exploration to a close, it’s imperative to underscore the indelible mark slip rings have imprinted on the canvas of modern technology. From the whisper-quiet rotations of CCTV cameras to the robust gyrations of wind turbines generating sustainable energy, slip rings serve as the unsung heroes, ensuring seamless power and data transmission across rotating interfaces. This concluding chapter encapsulates the importance of slip rings in the grand tapestry of motion systems and reflects on the perpetual need for physical connectivity in a world that’s rapidly leaning towards wireless realms.

The Unsung Pioneers of Continuous Motion

Core to Innovation: Slip rings have not only supported but also propelled advancements across various sectors. Their adaptability and efficiency in transferring current and signals have opened doors to innovations in robotics, medical equipment, and renewable energy systems, to name a few.

- Example: Consider the evolution of MRI machines, where slip rings have played a pivotal role in enabling the high-speed rotation of the gantry, leading to advancements in diagnostic imaging.

Slip Rings: Bridging the Gap Between Past and Future

A Testament to Durability and Reliability: Despite the swift currents of technological change, slip rings have remained irreplaceable components in many applications. Their continuous evolution in materials and design underscores a commitment to meeting the demands of the future.

- Case Study: The transition from traditional metal-based contacts to advanced materials like graphene exemplifies the innovation within slip rings, ensuring they remain at the forefront of efficiency and reliability.

In Defense of the Physical Connection

The Enduring Need for Tangible Links: In an age where wireless communication is celebrated for its convenience and breadth, it’s critical to acknowledge the undiminished importance of physical connections. Slip rings embody the reliability, continuous power supply, and secure data transmission that wireless technologies cannot always guarantee, especially in high-demand, industrial, or critical safety environments.

The Symphony of Wireless and Wired

Complementary, Not Competing: As we envisage the future, slip rings stand not in opposition but in concert with wireless technologies. They represent the crucial balance between the allure of wireless freedom and the steadfastness of wired connections.

- Reflective Insight: Imagine a world where drones, enabled by slip rings, wirelessly transmit real-time data to disaster relief teams, showcasing the harmonious potential of integrating both forms of connectivity.

The journey of understanding slip rings, from their basic function to their complex applications and the challenges of maintenance, brings us full circle to appreciate their intrinsic value in our technological landscape. As we advance, pushing the boundaries of what is possible, slip rings will undoubtedly continue to evolve, adapting to new challenges and enabling future innovations.

In closing, let this reflection serve not only as a testament to the enduring relevance of slip rings but also as an invitation to readers—engineers, designers, and technologists—to embrace and innovate on the foundations that slip rings provide. For in the dance of innovation and technology, slip rings maintain the rhythm, ensuring the motion never stops, and the music plays on, connecting the past, present, and future in an unbroken circle of progress.