This comprehensive article dives into unraveling the mystery around slip rings, essential components in the realm of engineering. “What is a slip ring?” is more than a question—it’s an invitation to explore the intricate world of electrical engineering and understand the pivotal role slip rings play in modern technology. From their basic definitions, mechanical workings, and types to their applications across various industries, this article covers it all. It also provides a detailed guide on selecting the right slip ring, tackling common issues, integrating slip rings into systems, and peering into the future of slip ring technology. Whether you’re an engineer, a technology enthusiast, or simply curious, this article promises a thorough understanding of slip rings and their significance in our technologically advanced world.

Unraveling the Mystery – What Is a Slip Ring?

Brief Overview of the Article

Welcome to a journey into the enigmatic world of slip rings, components pivotal to the seamless operation of countless modern machines yet remain shrouded in mystery for many. This article is designed as a comprehensive guide to not only introduce you to the basic concept of slip rings but also to take you through their operational principles, types, applications, and much more. From the challenges in selecting the right slip ring to the intricacies of their maintenance, we aim to cover a broad spectrum of topics that will illuminate every facet of slip rings. Along the way, we’ll employ real-world examples, engaging visuals, and practical advice to ensure a thorough understanding of slip rings and their critical role in modern engineering.

Importance of Understanding Slip Rings in Modern Engineering

In the intricate dance of engineering and technology, slip rings play a fundamental yet often understated role. They are the unsung heroes enabling the continuous transmission of power and data between stationary and rotating parts — a crucial function in anything from the colossal turbines harnessing wind energy to the surgical robots making precision cuts. Understanding slip rings is not just an academic exercise; it’s a necessity for innovators, engineers, and technicians working to push the boundaries of what’s possible in fields such as renewable energy, robotics, space exploration, and beyond. Insights into how slip rings work, their applications, and troubleshooting can be the difference between a smoothly operating system and one plagued with problems. Moreover, with the advent of new technologies and the ever-increasing demand for efficient and reliable rotational systems, the importance of slip rings and the expertise around them is only set to grow.

The Basics – What Is a Slip Ring, and How Does It Work?

In this chapter, we unravel the fundamental aspects of slip rings, providing essential groundwork for understanding their role in modern engineering. By explaining the core principles behind their operation, the various types available, and incorporating visual aids, this section aims to demystify slip rings for enthusiasts and professionals alike.

Definition of a Slip Ring

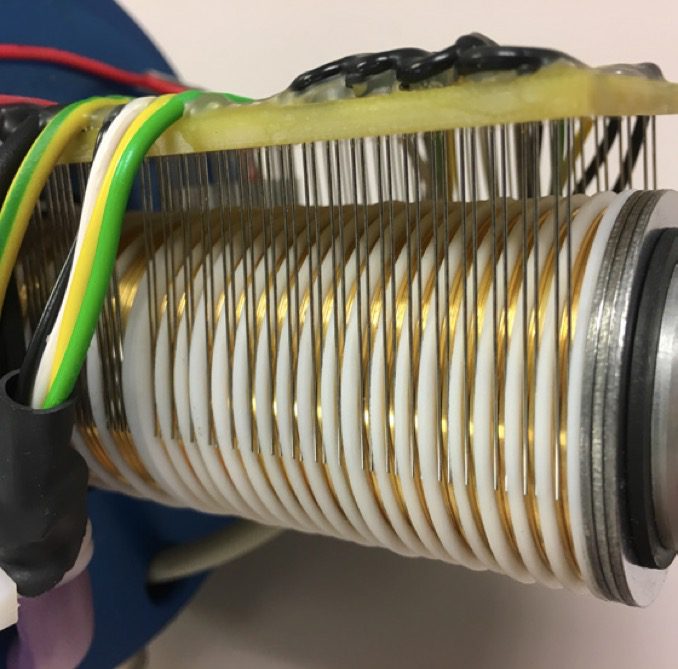

A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary part to a rotating part. It consists of a rotating metal ring and stationary brushes or contacts. As the ring turns, electrical current or data is conducted through the brushes that remain in contact with the rotating ring, thus maintaining a continuous connection without tangling wires.

Mechanical and Electrical Principles Behind Slip Rings

The operation of slip rings is grounded in basic mechanical and electrical principles. Mechanically, slip rings are designed to provide a smooth and continuous rotation, bearing in mind the need to minimize wear and tear on both the ring and brushes. Electrically, they must ensure minimal electrical resistance and interference to maintain integrity in power and signal transmission. This balancing act requires a sophisticated design that often incorporates materials optimized for conductivity and durability, such as gold or silver alloys for the brushes.

Types of Slip Rings

Several types of slip rings have been developed to cater to a diverse range of applications, each with its unique set of advantages:

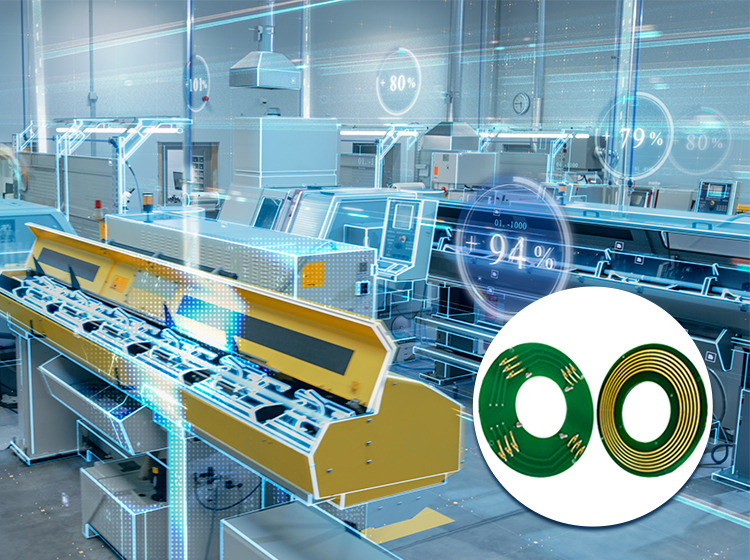

- Capsule Slip Rings: Compact and designed for use in small devices, where space is limited. They’re often used in cameras and medical equipment.

- Through-bore slip rings: Characterized by their hollow shaft, these slip rings are suitable for applications requiring the routing of hydraulics or pneumatics through the center of the slip ring, such as in wind turbines.

- Wireless Slip Rings: Utilize magnetic fields to transfer power and data wirelessly between the stationary and rotating parts. Though not “slip rings” in the traditional sense, they provide a similar function without physical contact, reducing wear and extending lifespan.

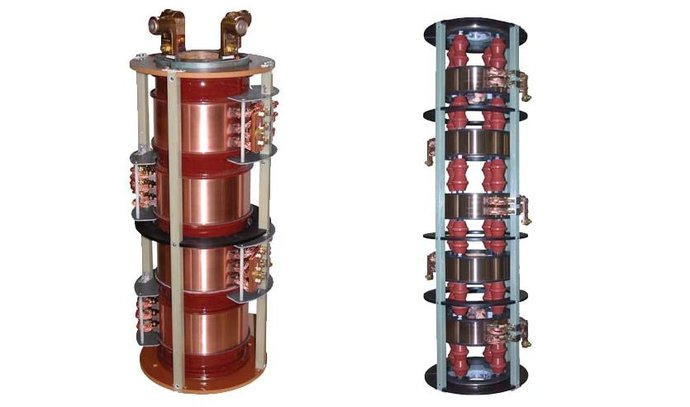

Visuals and Diagrams for Better Understanding

To aid comprehension, this section includes detailed diagrams and visuals showcasing:

- A cross-sectional view of a typical slip ring, illustrating the interaction between the ring and brushes.

- Schematic diagrams highlighting the electrical paths through a slip ring, making the concept clearer.

- Comparative visuals of different types of slip rings, helping readers understand each type’s specific structure and suited applications.

Through clear, engaging explanations and the strategic use of visuals, this chapter sets the foundation for not only understanding what slip rings are and how they operate but also appreciating their diversity and significance in various technological applications. Real-world examples, such as the use of through-bore slip rings in wind turbines for transferring power and data from the nacelle to the blades, further exemplify the critical role slip rings play in modern engineering solutions.

The Significance – What Is a Slip Ring in Technology

The vitality of slip rings in modern technology spans across multiple industries, showcasing their indispensable role in enabling dynamic innovations and facilitating the seamless operation of complex machinery. This chapter delves into the widespread applications of slip rings, supported by illustrative examples and case studies, and looks forward to the impact they may continue to have as technology evolves.

Applications of Slip Rings in Various Industries

Slip rings find their application in an array of fields, each benefiting from their unique ability to transmit power and data across rotating interfaces. Here are some notable examples:

- Wind Turbines: Within these renewable energy giants, slip rings transfer electrical signals and power from the nacelle to the rotating blades, ensuring the wind turbine can adjust to wind directions efficiently and perform optimally.

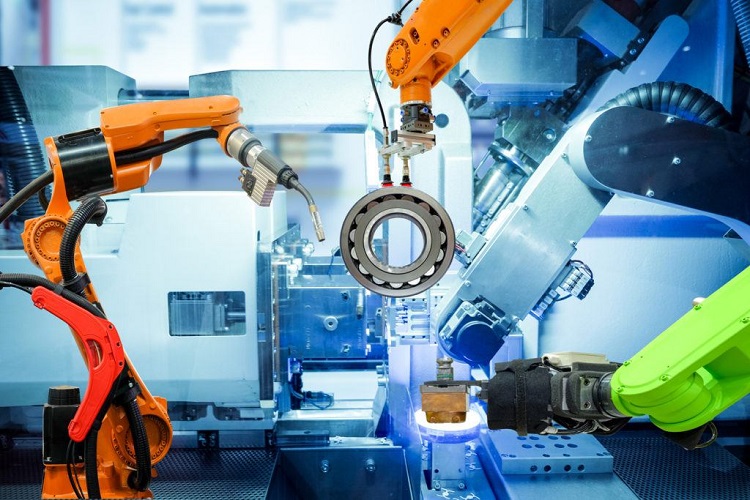

- Robotics: Robotic arms extensively employ slip rings, allowing for the transmission of control signals and power to parts of the robot that perform continuous or repeated rotations.

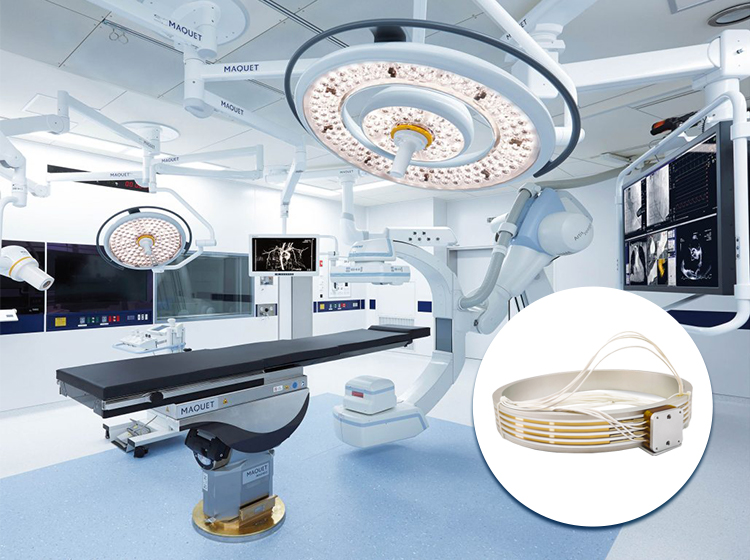

- Medical Equipment: Devices such as CT scanners utilize slip rings to provide uninterrupted power and data flow between the rotating scanner and the stationary data processing unit, enabling the acquisition of high-resolution images.

Case Studies or Examples of Slip Ring Implementation

To bridge the gap between theory and practice, let’s explore a case study highlighting the role of slip rings in technology:

- Case Study: Slip Rings in Space Robotics

- Context: Space robots, such as those used on the International Space Station (ISS) for maintenance and construction tasks, require robust systems for power and data transfer.

- Challenge: The harsh conditions of outer space, coupled with the need for precise operation and longevity of the robots.

- Solution: Specially designed high-performance slip rings were implemented, capable of withstanding the extreme temperatures and vacuum of space, ensuring that the robotic arms could maneuver without restriction, providing continuous power and data transmission.

- Outcome: These slip rings have significantly contributed to the success of numerous missions, demonstrating their reliability and critical role in advancing space technology.

Future Prospects of Slip Rings in Emerging Technologies

The future of slip rings appears promising, especially as emerging technologies demand more sophisticated and efficient power and data transmission solutions. Innovations such as electric vehicles (EVs), renewable energy, and advanced automation systems are areas where slip rings are expected to play a pivotal role. For instance, in EVs, slip rings could be used in steering systems or in the transmission of power and signals in complex battery management systems. Moreover, as the world leans more towards sustainable energy solutions, the implementation of slip rings in devices harnessing wind, solar, and kinetic energy is bound to increase, making them an even more critical component of our technological infrastructure.

By showcasing the broad applicability and significant contributions of slip rings across various industries, this chapter not only highlights their importance but also opens the door to future possibilities. As we delve deeper into exploring and understanding these versatile devices, their continuous evolution is set to propel numerous technological advancements, making them an exciting area of study and investment for researchers, engineers, and technology enthusiasts alike.

The Selection Process – What Is a Slip Ring

In any electrical system, few components are as important as the humble slip ring. These seemingly small parts facilitate an essential function: safely transferring power and signals from a stationary to a rotating structure. However, not all slip rings are created equal, and it is crucial to select the right one for your specific application. Understanding the different factors impacting the choice is critical and can make a notable difference in the efficiency and longevity of your equipment. This chapter aims to shed some light on the process.

Key Factors to Consider

There is a myriad of slip rings available in the market today, each with its’ unique specifications and application areas. When evaluating your options, you should take the following into account:

- Size: The dimension of a slip ring will determine whether it can comfortably fit into your system. Depending on your system space, a compact design may be more suitable as opposed to a larger one.

- Speed: Slip rings are designed to handle varying rotating speeds, measured in RPM (Revolutions Per Minute). It’s essential to choose a slip ring capable of withstanding the system’s desired speed, given the rate of rotation directly influences the slip ring’s wear and tear.

- Current and Voltage Ratings: Every slip ring is designed to carry a certain level of current and voltage. Exceeding these ratings could lead to equipment damage or even system failure. Always consider the power requirements of your application before making a choice.

- Environment: The slip ring’s environment can affect its function and durability. Factors such as moisture, dust, temperature, and exposure to corrosive substances should be considered. Some slip rings come with special protection features to withstand harsh conditions.

Guide to Selecting the Right Type of Slip Ring

Different applications require different types of slip rings:

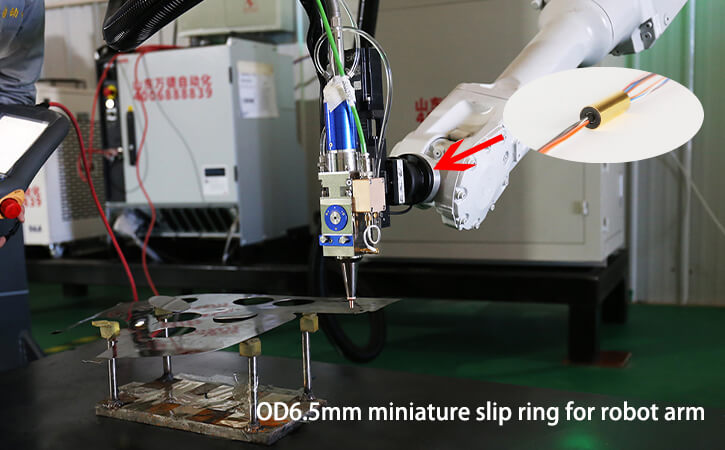

- For automated equipment and robotic systems, Miniature Slip Rings are typically employed due to their compact size and efficient data transmission.

- Through Bore Slip Rings are excellent choices for systems requiring the transfer of high-power signals and have a hollow space for shaft mounting.

- In wind turbines, high-performance Wind Turbine Slip Rings are utilized since they’re designed to handle high rotation speeds and challenging environmental conditions.

A deep understanding of the precise requirements of your application is key to choosing correctly.

Common Pitfalls in Slip Ring Selection and Avoidance Strategies

Selecting the right slip ring can sometimes be a challenging process, and mistakes are made. Here are some of the most common pitfalls and strategies to avoid them:

- Overlooking Operating Conditions: Often, one might ignore the working conditions which can lead to premature failure of the slip ring. Always consider the operating environment of your system before selecting a slip ring.

- Neglecting Future Needs: Sometimes, only the current need is considered when choosing a slip ring. However, future expansion or system upgrade possibilities should be factored in.

- Selecting on Price, not Value: Going for the cheapest option might seem economical, but may not serve your need effectively. Always consider the value offered by the slip ring, not just the cost.

By acknowledging these pitfalls and staying vigilant, you can make more-optimal selection decisions. Always remember, a well-chosen slip ring will ensure improved system performance, reliability, and lifespan, thereby providing a solid return on investment in the long run.

The Challenges and Solutions – What Is a Slip Ring

Slip rings play a crucial role in numerous applications by providing a continuous electrical connection between stationary and rotating systems. However, they are not without their challenges. This chapter explores common issues with slip rings, offering troubleshooting advice and maintenance tips to ensure their long-term reliability and efficiency. Additionally, we delve into recent innovations and advancements in slip ring technology that aim to overcome traditional obstacles.

Common Issues Encountered with Slip Rings

Slip rings can encounter several problems during their operation, impacting their performance and the overall system’s effectiveness. The most prevalent issues include:

- Wear and Tear: Given their mechanical nature, wear and tear on slip rings and brushes are inevitable, leading to decreased performance and, eventually, failure.

- Interference: Electrical noise and signal interference can degrade the data transmitted through slip rings, affecting the quality of communication in sensitive applications.

- Maintenance: Regular maintenance is crucial for optimal slip ring performance, yet accessing and servicing them can be challenging in complex machinery.

Tips and Techniques for Troubleshooting and Maintaining Slip Rings

To mitigate these issues, several strategies can be employed:

- Regular Inspection and Cleaning: Keeping slip rings and brushes clean from dirt and debris can significantly reduce wear and tear. Regular inspection helps identify potential problems before they escalate.

- Proper Lubrication: Appropriate lubrication reduces friction between contacts, extending their lifespan. However, it’s important to use the correct type of lubricant as per the manufacturer’s recommendation to avoid contamination and build-up.

- Noise Mitigation Strategies: Employing shielding, grounding, and using filters can help reduce electrical noise and improve signal integrity in slip rings.

- Scheduled Maintenance: Establish a scheduled maintenance plan based on the manufacturer’s recommendations and the application’s specific needs. This proactive approach can prevent unexpected downtime and extend the life of the slip ring.

Innovations and Advancements in Slip Ring Technology

Recent advancements aim to address the inherent challenges associated with slip rings:

- Fiber Optic Slip Rings: For applications requiring the transfer of large amounts of data with minimal interference, fiber optic slip rings offer a solution by using light instead of electrical currents, substantially reducing signal loss and noise.

- Wireless Power Transmission: Emerging technologies in wireless power transfer offer an alternative to traditional slip rings by eliminating physical contact, thus reducing wear and maintenance requirements.

- Contact Materials and Design: Improved materials for contacts and brushes, such as gold-gold contacts, offer better conductivity, lower resistance, and reduced wear. Concurrently, the evolution in design, such as the integration of microelectronics for signal processing, improves signal integrity and system reliability.

Real-World Application: Wind Turbines

Wind turbines present a perfect case study for applying these strategies and innovations. The demanding environment and the need for reliable power and data transmission in continuously rotating parts make slip ring maintenance a significant challenge. By employing advanced slip rings with superior materials and integrating monitoring systems for proactive maintenance, operators can enhance performance and reduce downtime, exemplifying how technology advancements directly benefit real-world applications.

Overall, while slip rings are fundamental components, they require careful consideration regarding maintenance and design to ensure they meet the needs of today’s sophisticated electrical systems. By understanding common issues, employing effective maintenance strategies, and staying informed about technological advancements, one can significantly improve the performance and reliability of slip rings in any application.

The Consumer’s Guide – What Is a Slip Ring

Choosing the optimal slip ring is only part of the journey. The next step is knowing where to source it and understanding how to integrate it into your system. This chapter will provide advice on the best places to purchase slip rings and share a step-by-step guide on integrating them into your systems, considering regulatory and safety aspects.

Advice on Where to Buy Slip Rings

The market offers a variety of sourcing avenues, each with its advantages:

- Original Equipment Manufacturers (OEMs): Buying directly from the manufacturer can ensure you receive genuine, high-quality products with warranties. OEMs also generally offer technical support and comprehensive documentation.

- Aftermarket Providers: Aftermarket providers often offer multiple brands and types of slip rings, which can be useful when looking for a specific type or when the original manufacturer no longer provides a particular model.

- Custom Manufacturers: If your application demands a unique slip ring not typically available, custom manufacturers can design and produce a slip ring that meets your specific requirements.

Choose a supplier who demonstrates industry expertise, offers quality customer service, and provides complete product support.

Step-by-step Guide on Integrating Slip Rings into a System

Incorporating a slip ring into your system involves careful planning and execution. Here’s a step-by-step guide:

- Identify Application Needs: Determine the operational requirements of your application. Consider the type of signals to be passed, the system’s speed, the working environment, and potential future modifications.

- Choose the Right Slip Ring: Based on your needs, choose an appropriate slip ring that fits both your operational and physical criteria.

- Plan the Installation: Consider the physical layout and how the slip ring will be interfaced with the existing system.

- Install the Slip Ring: Follow the manufacturer’s instructions. Ensure proper alignment, maintain appropriate torque for all fasteners, and ensure secure wire connections.

- Test the System: After installation, thoroughly test the system under different operating conditions to ensure successful integration.

Regulatory and Safety Considerations

Bearing in mind regulatory and safety considerations is crucial when choosing and integrating slip rings:

- Compliance with Standards: Ensure that your chosen slip ring complies with all applicable domestic and international standards. These can include electrical safety standards, environmental standards, and industry-specific regulations.

- Safety during Installation and Maintenance: Adhere to all safety protocols during installation and maintenance to prevent electrical shocks and mechanical injuries. Always disconnect power before performing any work on the slip ring.

- Environmental Considerations: Consider the slip ring’s resistance to environmental factors such as dust, moisture, and extreme temperatures.

Real-World Example: Integrating Slip Rings in Medical Imaging Equipment

An excellent example of successful slip ring integration is in medical imaging equipment such as CT scanners. These high-tech devices require specialized slip rings to provide continuous power and transmit high-resolution image data during a full 360-degree rotation. Sourcing from reputable OEMs and following rigorously planned integration steps ensures reliable performance and meets stringent medical industry regulations.

Selecting the right slip ring, sourcing from a reputable supplier, and ensuring proper integration within the boundaries of necessary regulations can significantly impact your system’s performance and safety. Keep these tips in mind to make an informed decision that best suits your unique application needs.

The Future of Slip Rings – What Is a Slip Ring

As we draw to a close on our exploration of slip rings, it’s clear that these components are more than just physical links in various systems; they are dynamic solutions pivotal for the advancement of numerous industries. This chapter recapitulates the essential points covered and offers a glimpse into the future of slip ring technology, emphasizing the potential impacts on diverse sectors and encouraging ongoing innovation and exploration.

Key Points Recap

Throughout this exploration, we covered the intrinsic challenges associated with slip rings, from wear and tear to maintenance and signal interference. We navigated through troubleshooting techniques, maintenance best practices, and innovative solutions developed to address these issues, including fiber optic slip rings and advances in contact materials.

We also provided guidance on sourcing slip rings, integrating them into systems safely and efficiently, and underscored the importance of adhering to regulatory standards for ensuring safety and compatibility within specific applications.

The Future of Slip Ring Technology

The evolution of slip ring technology promises exciting advancements:

- Smart Slip Rings: The integration of sensors and IoT capabilities in slip rings for real-time monitoring and predictive maintenance analysis. This advancement allows for meticulous control and management, substantially increasing reliability and efficiency in a myriad of applications.

- Material Science Breakthroughs: New materials and coatings are on the horizon, offering enhanced durability, reduced friction, and improved electrical conductance. These innovations could significantly extend the lifespan of slip rings and reduce maintenance requirements.

- Enhanced Signal Integrity: Sophisticated designs and technology, such as shielded cables and advanced noise cancellation techniques, will improve signal transmission quality, crucial for the increasing demands in data and power transmission in complex systems.

- Wireless Slip Rings: Though still in its nascent stages, the possibility of replacing mechanical contacts with magnetic induction or other wireless technologies could revolutionize slip ring applications, potentially eliminating mechanical wear and significantly reducing maintenance needs.

Industries Impacted

From renewable energy to aerospace and from automotive to medical devices, the implications of these advancements are profound. For example, smart slip rings in wind turbines could predict maintenance needs and adjust to optimize power transmission efficiency, significantly enhancing renewable energy production. Similarly, in the aerospace industry, the demand for reliable, high-performance slip rings will continue to grow, driven by the increasing complexity of spacecraft and satellites.

Encouragement for Further Exploration

The potential of slip ring technology is vast, and its evolution is continuous. As such, there remains a wide landscape for innovation and exploration. We encourage engineers, scientists, and industry professionals to delve deeper into the challenges and opportunities presented by slip ring technology. Collaboration across disciplines and industries will be key to unlocking new applications and pushing the boundaries of what is possible.

A Call to Innovation

The journey of slip ring technology is far from complete. As market demands evolve and new challenges arise, the call to innovate becomes louder. By embracing emerging technologies and trends, fostering collaboration, and prioritizing sustainability, the future of slip rings is poised to make a significant impact across a spectrum of industries. Let us move forward with curiosity and commitment, championing the advancements that slip rings can bring to our technologically driven world.

FAQs about What Is A Slip Ring

Q: How do slip rings work?

A: Slip rings work by making continuous electrical connections between a stationary system and a rotating part. The ring rotates with the device, while brushes remain stationary, allowing for continuous power or data transfer.

Q: What are the types of slip rings?

A: There are several types, including capsule slip rings, through-bore slip rings, pancake slip rings, and wireless slip rings, each designed for specific applications and space constraints.

Q: Why are slip rings important in technology?

A: Slip rings are crucial for devices that require rotation while transmitting power or signals. They’re used in wind turbines, rotary tables, medical equipment, robotics, and many other applications, making them indispensable in modern engineering and technology.

Q: What factors should I consider when choosing a slip ring?

A: When selecting a slip ring, consider factors such as the operational environment, speed of rotation, type and amount of data or power to be transmitted, size constraints, and the necessary durability.

Q: What are common problems with slip rings, and how can they be solved?

A: Common issues include wear and tear, electrical noise, and signal interference. Solutions involve selecting the right materials, ensuring proper installation and maintenance, and opting for advancements like fiber optic slip rings for high data transfer needs.

Q: How can I integrate a slip ring into my system?

A: Integration involves planning the installation based on the system layout, carefully installing the slip ring according to the manufacturer’s instructions, and testing the setup under different operating conditions to ensure proper function.