Slip rings are sophisticated electromechanical devices designed to enable the transmission of electricity or electrical signals from stationary to rotating structures. Central to a multitude of modern machines, slip rings pave the way for streamlined operation in rotary applications. They sit comfortably in our daily lives, from wind turbines generating green energy to surveillance cameras sweeping across our surroundings, even in medical equipment like CT scanners for advanced diagnostics. The principle is straightforward – slip rings efficiently combat confinement caused by traditional wires, providing electrical continuity in motion-based systems and overcoming rotational limitations.

Treading deeper into the category of slip rings, the 120v variant deserves special attention. Indispensable within industries such as robotics, defense, manufacturing, and telecommunications, the 120v slip ring is prominent in applications demanding stable, intermediate-voltage transmission. Through its core function of directing the 120v power or signal input across a rotary interface, the 120v slip ring ensures efficient and uninterrupted transmission.

The importance of the 120v slip ring shouldn’t be underestimated. Its role has proved crucial in maintaining the smooth operation of numerous rotating systems, powering functionality, ensuring safety, and promoting efficacy. These regions take advantage of the 120v slip ring’s sturdy construction and design, developed to match the operational demands and efficiently carry the electrical load. An understanding of this slip ring variant proves helpful for industries looking to capitalize on the benefits provided by engineered rotary solutions. Harnessing the potential of the 120v slip ring can result in substantial operational improvements, powering advancements in the technological arena. Fundamentally, these rings facilitate free, easy movement, providing the foundation for applications reliant on rotation, which ultimately drive modern technology forward.

120v Slip Rings Basic Working Principle

The core functionality of a 120v slip ring is defined by its ability to transfer electrical power or signals through a rotating assembly. The creativity in this process lies in overcoming the traditionally limiting aspect of employing direct wiring, which tends to tangle or twist when an application requires continuous or multiple rotations.

To sketch the working principle, let’s first envision two portions within a typical device needing electrical transfer – a stationary part and a rotating part. Now here, the role of a 120v slip ring comes into play. It makes a reliable bridge between the stationary and rotating parts, providing a 120v electrical pathway that moves freely along the rotation.

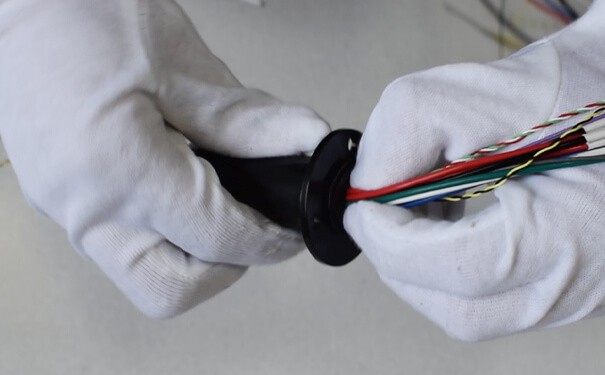

The functionality of this electromechanical device can be further dissected by looking at its core components, namely, the brushes and the rings. The word ‘slip’ in a slip ring refers to the sliding action of brushes over the rings. Rings are connected to the rotating part of the device, whereas brushes are kept stationary, usually in contact with the rings. Here’s where the magic happens the power or signal originating from the stationary interface is transferred through the brushes to the ring, then onto the rotating part of the application. Despite the constant motion, the transmission remains continuous and uninterrupted, thanks to the sliding contact between brushes and rings.

However, the mechanism is not as simple as it may seem. The transmission process must happen without substantial wear and tear, without causing too much friction, and with high efficiency. This aspect brings particular focus onto the brushes and the rings – the heart and soul of a slip ring. These components have to be made with suitable materials to ensure low electric resistance, and minimum noise, and to tolerate the wear from continuous rotations. They must provide secure contact, with brushes pressing steadily against the rings, and finally, they must overcome temperature changes, vibration, and other operational challenges.

Understanding the workings and requirements of these internal components could be key to understanding the overall functionality, effectiveness, and longevity of a 120v slip ring. The coherent interplay of its components, optimized to cope with requirements, ensures the 120v slip ring delivers its essential role—seamless and efficient transfer of electrical power or signals across a rotation interface.

Specification of 120v Slip Rings

When specifying a 120V slip ring, several important factors need to be considered to ensure it meets your application requirements. Below is a detailed specification guide for a 120V slip ring:

1. Voltage Rating

- Rated Voltage: 120V AC (This specifies the maximum voltage the slip ring can handle.)

2. current Rating

- Current Capacity: Typically ranges from 2A to 30A per circuit, depending on the design. Ensure the current rating meets your application’s requirements.

- Circuit Count: The number of electrical circuits or channels that can pass through the slip ring. This can range from 1 circuit to over 100 circuits. Choose based on how many separate electrical connections are needed.

4. Size and Dimensions

- Outer Diameter: Ranges from 10mm to over 100mm, depending on the application and space constraints.

- Length: Also varies widely but typically ranges from 30mm to 200mm.

- Maximum RPM: The maximum rotation speed the slip ring can handle without degradation, usually specified in Revolutions Per Minute (RPM). Common ranges are from 100 RPM to 5000 RPM.

6. Material

- Housing Material: Often made from materials like aluminum, stainless steel, or plastic, depending on environmental conditions and weight considerations.

- Contact Material: Gold-to-gold or silver-to-silver contacts are common for reliable low-resistance connections.

7. Insulation Resistance

- Insulation Resistance: Typically above 500 MΩ at 500 VDC, ensuring the slip ring can isolate the circuits effectively.

8. Dielectric Strength

- Dielectric Strength: Ability to withstand high voltage without breakdown, often around 1000V AC for one minute.

9. Operating Temperature

- Temperature Range: Generally -40°C to +80°C, depending on materials used and environmental conditions.

10. IP Rating

- Ingress Protection: For outdoor or harsh environment use, an IP rating (e.g., IP65, IP67) is crucial to ensure dust and water resistance.

11. Noise

- Electrical Noise: Should be minimal, typically below 10 milliohms, for stable signal transmission.

12. Mounting Options

- Mounting Type: Flange mount, through-bore, or end-of-shaft mount depending on the application setup.

13. Special Features

- Integrated Signal Transmission: Some slip rings also allow the transmission of signals (e.g., Ethernet, HDMI) alongside power.

- Maintenance: Consider whether the slip ring is maintenance-free or requires periodic servicing.

14. Compliance and Certifications

- Certifications: Check for industry-standard certifications (e.g., RoHS, CE) based on the application’s requirements.

15. Application Considerations

- Intended Use: Specific applications may require custom slip rings, such as those used in robotics, wind turbines, medical devices, or military equipment.

These specifications will vary depending on the manufacturer and the specific needs of the application. Ensure to select a slip ring that aligns with the electrical, mechanical, and environmental demands of your project.

120v Slip Rings: Electrical Slip Rings

When discussing 120V Slip Rings in the context of Electrical Slip Rings, it’s important to focus on the specific requirements and applications of slip rings designed to handle 120V AC power. Below is an overview of what to consider when specifying or selecting a 120V electrical slip ring:

1. Voltage and Current Specifications

- Rated Voltage: 120V AC, which is a common voltage level for many industrial and commercial applications.

- Current Capacity: The current rating varies depending on the application, typically ranging from 2A to 30A per circuit.

2. Circuit Configuration

- Number of Circuits: The number of circuits or channels available for transmitting power or signals. This can range from a single circuit to multiple circuits, depending on the complexity of the system. For instance, a simple system might require just one circuit for power, while a more complex system might need multiple circuits for power and signal transmission.

3. Types of 120V Electrical Slip Rings

- Standard Slip Rings: Designed for general use in applications requiring the transmission of 120V power and potentially low-frequency signals.

- Through-Bore Slip Rings: These have a hollow center, allowing for the passage of additional mechanical components or wiring, making them ideal for rotating machinery or equipment that requires central cabling.

- Capsule Slip Rings: Compact designs that are ideal for space-constrained environments like robotics or medical devices.

- Pancake Slip Rings: These are used where axial space is limited, offering a flat, disc-shaped design that is beneficial in certain industrial applications.

4. Material Considerations

- Housing Material: Often constructed from durable materials like aluminum or stainless steel to protect against environmental factors.

- Contact Material: Gold-to-gold or silver-to-silver contacts are commonly used for their low resistance and durability, ensuring reliable transmission of 120V power.

5. Rotational Speed

- RPM (Revolutions Per Minute): The slip ring must support the operational speed of the rotating component, typically ranging from 100 RPM to 5000 RPM depending on the application.

6. Environmental Resistance

- Ingress Protection (IP Rating): Depending on where the slip ring is used, it might need to be protected against dust, moisture, and other environmental factors. Common IP ratings include IP65 for dust and water resistance.

- Operating Temperature: Ensure the slip ring can operate reliably within the temperature range of your application, typically from -40°C to +80°C.

7. Signal Transmission

- Power and Signal Combination: Many 120V slip rings are designed to transmit both power and signals, including analog or digital signals. If signals are to be transmitted, ensure the slip ring is capable of handling the required signal type without interference.

8. Applications of 120V Electrical Slip Rings

- Industrial Machinery: Used in rotating equipment like packaging machines, rotary tables, and conveyors.

- Wind Turbines: Facilitates the transfer of power and signals between the rotating blades and the control system.

- Robotics: Powers robotic arms and other automated systems that require continuous rotation.

- Medical Devices: Allows for the continuous rotation of imaging devices like CT scanners.

- Cranes and Lifts: Transfers power to the rotating components of cranes and lifts, ensuring uninterrupted operation.

9. Maintenance and Longevity

- Maintenance-Free Designs: Some slip rings are designed to be maintenance-free, utilizing advanced materials that reduce wear and prolong operational life.

- Serviceable Designs: In some applications, slip rings might require periodic maintenance, such as cleaning and lubrication, to ensure continued performance.

10. Compliance and Standards

- Safety Certifications: Ensure that the slip ring complies with relevant electrical standards and certifications such as CE, RoHS, and UL to meet safety and performance requirements.

When selecting a 120V electrical slip ring, it is essential to consider the specific requirements of your application, including voltage, current, environmental conditions, and the type of signals being transmitted. By carefully matching the slip ring’s specifications to your needs, you can ensure reliable performance and longevity in your electrical systems.

Different Types of 120v Slip Rings

Within the vast diversity of electromechanical 120v slip rings, unique subclasses strike the right balance between application requirements and design adaptabilities. These subclasses can be broadly categorized based on several factors, such as size, current-carrying capacity, the number of channels (circuits), and the slip ring’s intended operational environment. This section will take you through an overview of some common 120v slip ring types and discuss how each variant caters to specific applications and industries.

Capsule Slip Rings

Compact in size and suitable for low to moderate power transmission, capsule slip rings are designed for use in applications requiring a limited number of circuits and lower current ratings. These slip rings typically feature a cylindrical form factor, granting versatility in limited spaces. With their compact dimensions and lightweight construction, they are perfect for small-scale rotary devices, like CCTV cameras, robotics, and medical equipment.

Through Hole Slip Rings

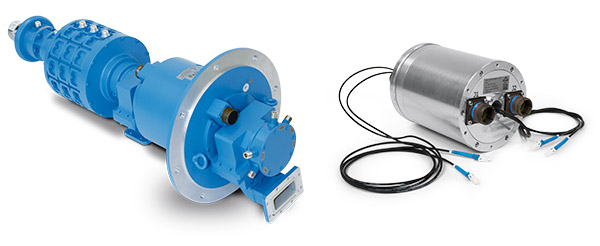

Also known as hollow shaft slip rings, these 120v slip rings feature a central hole that can accommodate the rotation of a shaft or allow wire bundles and hydraulic lines to pass through the cavity. Often used in applications involving large-scale structures and higher current ratings, their design allows the transmission of electrical power and signals from both stationary and rotating parts, while the central hole grants additional flexibility. Examples of applications include radar systems, wind turbines, and packaging machines.

Pancake Slip Rings

Distinct in their flat, disc-like shape, pancake slip rings are perfect for spaces restricted in the axial direction rather than those constrained radially. These slip rings are ideal for applications that prioritize low axial length, where the overall height of the slip ring is crucial. Instances of applications include cable reels, indexing tables, and turntables.

High-Current Slip Rings

Engineered for applications involving high power transmission, high-current 120v slip rings employ robust materials and construction to support the transfer of increased current loads. Industries like renewable energy, electric vehicles, and heavy-duty manufacturing may turn to high-current slip rings for their demands.

Hybrid Slip Rings

Integrating electrical power, signal transmission, and other functions such as fiber-optic communication or pneumatic and hydraulic transmission, the hybrid slip ring’s versatility meets complex requirements. Defense, offshore drilling, and aerospace industries often rely on hybrid slip rings in radar systems and robotic arms.

Each of the various 120v slip ring types is designed to address different needs, offering application-specific solutions for a wide range of industries. Gaining an understanding of individual variants and their suitability for different uses is key to unlocking the potential of 120v slip rings. From compact capsules to multifunctional hybrids, it’s essential to invest in the correct type to suit your application, ensuring optimal performance and longevity.

120v Slip Rings Key Applications and Industries

120v slip rings are the silent facilitators of countless applications across a multitude of sectors. Their primary function, to convey power or signals from a stationary source to a rotating assembly, is a requirement in a vast array of environments. Let’s delve into some specific applications and industries where 120v slip rings are fundamental, illustrating how they help drive progress and advancement in diverse sectors.

Renewable Energy

The green energy sector, notably wind turbines, relies heavily on 120v slip rings. Wind turbines are pinnacles of rotational machinery. The wind powers the blades, which rotate the shaft that, in turn, spins a generator to produce electricity. As the blades spin, they move the attached generator assembly in an unrestricted, rotational manner. Here, 120v slip rings come into play, transmitting generated power and critical sensor data from the rotating generator assembly to the stationary grid infrastructure. Without this essential component, power could not efficiently be transferred, and the effectiveness of the entire wind turbine system would be compromised.

Defense

In the defense industry, radar systems utilize slip rings significantly. Radar systems must rotate unimpeded to provide 360-degree coverage. This continuous rotation calls for power and signal transmission across the rotary boundary – a task assigned to the 120v slip ring. It ensures consistent and reliable data transmission from the rotating antennas to stationary processing units, thus enabling constant monitoring and robust defense capabilities.

Telecommunications

In this sector, slip rings have found their place in satellite dish systems. These systems require an unrestricted rotational pan and tilt function to track moving satellites. The slip rings provide steady power and communication signals between stationary and rotating parts of satellite dish assemblies, ensuring seamless communication links.

Medical Equipment Imaging

Medical imaging systems, such as computed tomography (CT) scanners, are another universe where 120v slip rings are omnipresent. As the scanner rotates around the patient, slip rings deliver the power and transfer data between the rotating gantry and the stationary part of the machine, thereby enabling continuous and high-speed data transmission crucial for generating accurate medical images.

CCTV Systems

Slip rings also have a vital role in closed-circuit television (CCTV) camera systems. Pan-tilt-zoom (PTZ) cameras need to rotate freely and continuously to cover broader surveillance areas. Slip rings in these systems ensure unhindered 360-degree rotation without tangling any wires, thereby providing power and transmitting video signals and control data between the static and rotating parts of the device.

Indeed, 120v slip rings have endless possibilities when it comes to their applications. Whether it’s powering a wind turbine, enabling 360-degree surveillance, or ensuring seamless telecommunications, the significance of 120v slip rings transcends industries. Understanding the practicality and adaptability of these slip rings across varied applications allows for their optimal use and reveals their true value within the broader technological landscape.

Key Factors to Consider When Purchasing a 120v Slip Ring

Selecting a 120v slip ring isn’t about simply choosing the first product one comes across. To ensure an optimal operation that suits individual requirements, prospective buyers must consider several key factors before making a purchase. These factors range from durability and ampacity to signal integrity, speed, temperature range, and price, among others. This section aims to act as a guide for end-users, emphasizing why these fundamental considerations are crucial when choosing a 120v slip ring.

Voltage and Current Rating

- Voltage Rating: Ensure the slip ring is rated for 120V AC. This is crucial to prevent electrical failure or hazards.

- Current Rating: Verify that the slip ring can handle the required current per circuit. Common ratings range from 2A to 30A, depending on the application.

Number of Circuits

- Power Circuits: Determine how many separate power circuits are required for your application.

- Signal Circuits: If your application requires the transmission of signals (e.g., data, control signals), ensure the slip ring has adequate circuits for both power and signal transmission.

Rotational Speed (RPM)

- Maximum RPM: Check the slip ring’s maximum rotational speed to ensure it can operate effectively at the required speed of your rotating assembly. Exceeding this limit can lead to increased wear or failure.

Physical Dimensions

- Size and Space Constraints: Ensure the slip ring fits within the available space in your equipment. Consider both the outer diameter and length, especially if your application has strict space limitations.

- Through-Bore Diameter: If using a through-bore slip ring, ensure the bore size accommodates any shafts or cables that need to pass through.

Material and Contact Quality

- Housing Material: The slip ring housing should be durable and suitable for the operating environment, often made from aluminum, stainless steel, or plastic.

- Contact Material: High-quality contact materials like gold or silver are preferred for low-resistance, reliable connections and long life.

Environmental Conditions

- Ingress Protection (IP Rating): For outdoor or harsh environments, select a slip ring with an appropriate IP rating (e.g., IP65 or higher) to protect against dust and moisture.

- Operating Temperature: Ensure the slip ring operates within the temperature range of your environment, typically from -40°C to +80°C.

Durability: The longevity of a slip ring is tied directly to its durability. Understanding the expected lifespan under specific operational conditions is a must. This factor depends largely on the materials used and the quality of the build. Robust materials and meticulous design warrant durability, thus demanding less frequent replacement or maintenance.

Ampacity: Ampacity refers to how much current a slip ring can handle. It’s essential to match the slip ring’s current-carrying ability to the expected load in the application. Exceeding the stated current ratings can lead to overheating and possible failure, thus adversely impacting the operation.

Signal Integrity: In applications where slip rings not only transmit power but also signals (data, video, etc.), maintaining signal integrity is critical. The slip ring should offer minimal noise and interference to ensure that the transmitted signals are clean and sharp, to maintain the effectiveness of the system.

Speed: The rotational speed of the slip ring should align with the speed requirement of the application. Slip rings designed for high-speed applications may use different materials and designs compared to those for low-speed uses. Selecting the correct slip ring based on speed ensures that performance isn’t compromised and longevity isn’t shortened due to excessive wear and tear.

Temperature Range: Slip rings must endure a vast range of operating temperatures, especially in harsh environments. Understanding the expected operational temperature range, from the coldest to the hottest, will guide you in selecting a slip ring designed to withstand these extremes without any performance falter.

Price: While it might be tempting to choose the least costly option, one must not overlook the operational efficiency and durability of the device. Balancing between the cost and the quality is thus paramount. It’s important to consider the total cost of ownership, which includes maintenance and replacement costs over the product’s lifespan and not just the initial purchase price.

These factors not only contribute to the proper functioning and longevity of a 120v slip ring but also ascertain its compatibility with the rest of the system. By carefully evaluating these features, prospective buyers can ensure a tailored fit between applications and the chosen slip ring, optimize performance, and minimize potential operational issues. Essentially, these considerations ensure the end-users get the most out of their slip ring investment, maximizing the value and efficacy of the device within the intended application.

Looking for a specific slip ring solution? Let us know your requirements through this form.

Care and Maintenance of 120v Slip Rings

The longevity and optimal operation of your 120v slip ring are largely dependent on appropriate and well-timed care and maintenance. This section outlines how routine inspections and common troubleshooting help maintain consistent slip ring performance and discusses the importance of regular maintenance in ensuring durability, thereby extending the device’s service life.

Routine Inspections: Conducting regular inspections is a proactive approach to maintaining the health of a slip ring. Observations should cover physical aspects such as the robustness of the casing, wear and tear on the rotating parts, and the presence of excess grease or debris, which could lead to degraded performance. Checking for signs of overheating, like discoloration or odor, can help detect issues with overload or inadequate cooling.

Electrical Testing: Regular electrical tests can provide a comprehensive health report of your slip ring. Checking for resistance changes in the circuits can help identify any poor connections or fractures. Monitoring noise and signal strength in circuits transmitting data or other signals will also ensure their consistent quality.

Common Troubleshooting: Common issues such as reduced performance, increased noise, or intermittent connections might surface during the usage of a slip ring. Understanding how to troubleshoot these issues effectively by checking the alignment, cleaning the contact surfaces, or tightening any loosened parts can quickly resolve most of these concerns.

Cleaning: Cleaning mating surfaces plays a pivotal role in the upkeep of a slip ring. Regular removal of contaminants and debris, followed by re-lubrication (if suggested by the manufacturer), is necessary to maintain efficient operation and prevent premature wear.

Scheduled Servicing: Depending on their environment and usage, some slip rings might benefit from scheduled servicing. Such servicing can involve in-depth cleaning, component checking/updating, or re-lubrication.

Regularly performed, these care and maintenance practices can significantly prolong the functional life of a 120v slip ring, ensuring a seamless transfer of power and signals. Proper maintenance impacts not only its operational efficiency but also avoids unexpected downtime, costly repair bills, or complete replacement needs.

In a nutshell, good maintenance practices ensure the durability and longevity of a slip ring, which, in turn, leads to increased reliability and productivity of the entire system. By staying disciplined with the care and maintenance of a slip ring, users can secure a solid return on their investment, enhancing their operational efficiency and safety.

Future Trends in 120v Slip Rings

In the evolving landscape of technology, even fundamental components like 120v slip rings are subject to considerable transformation. This section will explore the emerging technological trends impacting the evolution of 120v slip rings and examine how the relentless pursuit of miniaturization, efficiency, and performance is setting the stage for future advancements in this field.

Technological Advancements Affecting 120v Slip Rings:

Technological advancements are playing a crucial role in the evolution of 120v slip rings. Developments include fleeting trends to technologies that promise to reshape the way these devices are designed and used.

- Materials Science: New lead-free materials and alloys, exhibiting disruptive conductive and anti-corrosion properties, have the potential to improve the endurance and efficiency of slip rings significantly. Additionally, the emergence of new composites for the brush and track materials could alter slip ring performance for specific applications.

- Wireless Technology: Novel wireless power transmission technologies are influencing the design of 120v slip rings. While wired connections still hold the majority share, wireless power transmission might soon find its niche in specific applications, allowing for even more freedom in motion.

- Signal Transmission: Advances in data transmission technologies are pushing the limits of signal transfer speed, quality, and density in slip rings, catering to the demanding requirements of sectors such as telecommunications and medical imaging.

The Pursuit of Miniaturization, Efficiency, and Performance:

The continued drive towards miniaturization, optimization of efficiency, and enhanced performance is pushing remarkable evolution in the design and function of 120v slip rings.

- Miniaturization: As devices and systems become smaller and more compact, so too must the slip rings that support them. Slip ring manufacturers are developing tiny, yet highly-efficient slip rings compatible with miniature devices without compromising their performance.

- Efficiency: Maximizing operational efficiency while minimizing loss is a top priority in slip ring technology. This focus on efficiency will likely lead to advancement in design and material science, resulting in slip rings that reduce power loss, heat generation, and wear, extending rise to longer product lifespans.

- Performance: The drive for superior performance, in terms of powerful transmission and high-quality signal transfer, is also guiding trends in slip ring technology. The quest is to engineer slip rings that can handle heavy-duty tasks while retaining their integrity and delivering flawless performance, ensuring that mission-critical applications function uninterrupted and accurately.

As the years progress, these trends in technology will propel the continuous advancement of 120v slip rings, promising to meet the increasing demands and challenges faced across various sectors. Looking forward, we can expect to see more sophisticated, efficient, and durable slip rings that can support the complex and high-performance machinery of tomorrow.

Conclusion

The 120v slip ring is not just a humble component but a crucial player in many technological settings. As they continue to evolve in line with technological advancements, their range and applications will likely widen. Consequently, understanding and selecting the right 120v slip ring become more important than ever. We hope this comprehensive look into 120v slip rings equips you to make an informed investment in your next engineering project.

FAQs about 120v Slip Rings

This section covers frequently asked questions (FAQs) about 120v slip rings that users might inquire about before purchasing or while using these devices. This resource aims to provide clarity, address common concerns, and assist in the decision-making process when choosing the appropriate slip ring.

Q: What is the primary function of a 120v slip ring?

A: A 120v slip ring enables the transfer of electrical power, data, or signals from a stationary source to a continuously rotating assembly. It helps maintain electrical connections between a rotating device and its stationary counterpart without restricting motion or tangling wires, providing uninterrupted performance.

Q: Do slip rings only transmit power? Can they transmit data as well?

A: Slip rings are versatile and can transmit not only power but also data, video, or other signals. Some advanced slip rings maintain exceptional signal integrity for high-speed data transfer or video signals in applications such as radars, medical devices, and telecommunications.

Q: How do I know if I need a 120v slip ring?

A: If your application requires transferring power or signals between a stationary part and a rotating or swiveling component, you may require a 120v slip ring. Key applications include wind turbines, radar systems, satellite dishes, medical imaging equipment, and CCTV systems, among others.

Q: What are the essential factors to consider when choosing a 120v slip ring?

A: Important factors to consider when selecting a 120v slip ring include durability, ampacity, signal integrity, rotational speed, temperature range, and price. Each factor helps ensure compatibility with your application and contributes to the longevity and performance of the slip ring.

Q: Is maintenance necessary for 120v slip rings?

A: Yes, proper maintenance is crucial for both the longevity and optimal performance of a 120v slip ring. Performing routine inspections, troubleshooting common issues, and scheduled servicing can minimize potential problems and maximize the service life of the device.

Q: How long does a 120v slip ring typically last?

A: The lifespan of a 120v slip ring depends on several factors, including the quality of the materials and construction, operating environment, maintenance, and usage. High-quality slip rings can last for millions of rotations, whereas low-quality or improperly maintained ones may require more frequent replacement or repair.

Q: Can slip rings be customized for specific applications?

A: Yes, slip rings can be tailored to the unique requirements of specific applications by altering aspects such as size, materials used, signal types, and rotating speeds. Customization ensures greater compatibility with typical operational environments, as well as optimal performance and longevity.

See What We Can Do