In this article, we explore the intricacies of the 30 Amp slip rings – the critical components that seamlessly enable power transmission between static and rotating parts.

Introduction to 30 Amp Slip Rings

In the vast landscape of electrical and mechanical engineering, the invention of slip rings has proven to be an inventive game-changer. These remarkable components allow for the transmission of power and electrical signals from a stationary structure to a rotating one, thereby opening up a plethora of opportunities for technological innovation.

Slip rings come in various types and sizes, tailored to suit the varying needs of numerous applications in different industries. However, among this broad array, the 30 Amp slip rings distinctly stand out. They play an essential role in applications demanding high-power transmission coupled with a robust and reliable structure to withstand challenging operating conditions.

These devices are a culmination of intricate design and precise engineering, interfacing stationary and rotating parts seamlessly to allow uninterrupted power and signal transmission. If we take a closer look, we realize that their seemingly simple role of establishing connections is what enables a variety of applications, from wind turbines and heavy machinery to automotive systems and communication devices, to function.

The importance of these 30 Amp slip rings extends across various industries and applications. Their high current carrying capacity, combined with reliable performance, makes them the preferred choice for heavy machinery and industries like renewable energy, aerospace, and marine settings, where power transmission remains crucial.

In essence, the journey of understanding slip rings transcends from just knowing them as power transmission facilitators to marveling at their underlying complexity and the pivotal role they play in today’s technological advancements. Their precise function, high power transmission capacity, and utilization in critical industrial applications not only underline the importance of 30 Amp slip rings but also pave the way for us to explore more about their design, features, applications, and future developments.

Design and Construction of 30 Amp Slip Rings

The design and construction of 30 Amp slip rings are a perfect blend of meticulous detail, a deep understanding of electrical and mechanical dynamics, and a careful selection of materials.

At first glance, a slip ring might appear as a simple device. Yet, it is the product of thoughtful design nuances. The construction begins by determining the critical parameters, such as the number of circuits required, the operating speed, signal types (analogous or digital), and the environment in which the slip ring will operate. These factors significantly influence the design and materials used in the slip ring construction.

The core materials often used in the construction of 30 Amp slip rings are chosen for their durability, resistance to wear and tear, and excellent electrical conductivity. These could range from different types of metals for contacts (like gold or silver alloys), specialized plastics or ceramics for insulation, and housing materials that can range from stainless steel to high-grade plastics, each chosen keeping in view the operational demands.

The mechanical characteristics of a 30 Amp slip ring are equally important. The rotational speed is a crucial consideration during design, as it significantly impacts the performance and durability of the slip ring. The design ensures minimal friction between rotating parts to uphold efficiency while also maintaining the integrity of transmitted signals.

Moreover, the internal configuration – the number of circuits and type of contacts – is also a key aspect of the construction phase. For instance, a 30 Amp slip ring designed for high current applications would house multiple circuits with robust contacts. This intricacy allows the delivery of high power without risking overheating issues or signal disruption.

The electrical characteristics center around the effective transmission of power without loss or distortion. Here, the correct choice of conductive materials, insulation, and contact technology plays a pivotal role. The design and construction ensure proper insulation between circuits to prevent cross-talk and also to shield the signals from external electromagnetic fields if needed.

In conclusion, the design and construction of 30 Amp slip rings isn’t a one-size-fits-all approach. It is an intricate process of balancing performance capability, reliability, and longevity fueled by detailed engineering knowledge and precise materials selection, showcasing a remarkable blend of electrical and mechanical engineering disciplines.

Core Features of 30 Amp Slip Rings

One of the key characteristics that have led the 30 Amp slip rings to become an essential component of various industries is their unique combination of features and performance capabilities. These distinct attributes define their practicality, efficiency, and durability, making them irreplaceable in many applications.

One of the primary features that make 30 Amp slip rings stand out is their high load capacity. Designed for high-current applications, these slip rings can endure and efficiently handle heavy power loads without overheating or showing signs of performance degradation. This high-endurance level towards electric current load is a crucial aspect for heavy machinery, renewable energy systems, military hardware, and any setting that needs powerful and continuous power transmission.

Temperature resistance is another notable feature of these slip rings. The materials and design incorporated into these devices ensure they maintain their performance even under high temperatures or drastic temperature fluctuations. This makes them an excellent choice for applications facing challenging and harsh environmental conditions.

The encapsulation is another key feature of 30 Amp slip rings. This technique seals the slip ring, protecting it from contaminants and preventing potential intrusion of particles that could disrupt functionality. Protective housings or seals are specially designed to resist dust, foreign particles, or in some cases, even water, thus ensuring operation in various environments.

An often overlooked but critical feature is the Ingress Protection (IP) rating of a slip ring. This rating signifies the level of resistance towards the intrusion of solid or liquid particles. 30 Amp slip rings come with an impressive IP rating, implying high resistance to dust and water, allowing them to operate even in challenging environments.

Overall, the unique blend of these features and performance capabilities results in a reliable, effective, and durable power transmission solution and makes 30 Amp slip rings suitable for a comprehensive range of applications. The coherence and synergy between these various aspects such as high load capacity, temperature endurance, effective encapsulation, and impressive IP rating give these slip rings the edge and contribute greatly to their success and wide acceptance.

Advantages of Using 30 Amp Slip Rings

The diverse applications and widespread use of 30 Amp slip rings are a testament to the numerous advantages they offer. Listed below are some essential benefits that make these slip rings a preferred choice across various sectors:

- Durability: With their robust design, high-quality material selection, and precise engineering, 30 Amp slip rings offer longevity, making them a cost-effective solution in the long run. High durability translates to less maintenance and longer intervals between replacements, offering valuable benefits in critical and high-stakes environments.

- High current transmission: As the name suggests, the 30 Amp slip rings are designed to handle high current loads, up to 30 Amps. This is crucial in heavy industries and complex machinery which require high-power input, thus ensuring that the stringent power demands are met efficiently.

- Temperature resistance: The 30 Amp slip rings are engineered to perform under a wide range of temperature environments. This feature is particularly beneficial in industries such as aerospace, marine, or energy, where the devices face diverse and often adverse temperature scenarios.

- Environmental Resistance: The encapsulation design and impressive IP ratings mean that these slip rings can withstand harsh environmental conditions – from dust and water ingress to corrosive atmospheres – thereby expanding their application spectrum to virtually any environment.

There’s a coherence between these mentioned advantages that heavily influences their industry-specific roles. For instance, for a wind turbine application, the high current transmission capability of a 30 Amp slip ring ensures the generated power is efficiently transmitted. Meanwhile, its temperature resistance feature enables it to cope with the varying temperature conditions in an outdoor setting.

Likewise, in a marine application, the encapsulation and high IP rating safeguard the slip ring against corrosive seawater and humidity, guaranteeing consistent performance.

To summarize, these benefits not only justify the selection of 30 Amp slip rings for different applications but also underscore their critical role in the smooth operation of various industry equipment. Their durability, high current handling capacity, temperature resistance, and environmental resilience collectively ensure that they’re equally effective in every setting, from the calm confines of a lab to the rigors of an industrial field site.

30 Amp Slip Ring Electrical Specs

30 Amp Slip Ring Technical Specifications

Potential Drawbacks and Limitations of 30 Amp Slip Rings

Despite the numerous advantages associated with 30 Amp slip rings, like any other device, they have certain limitations and potential disadvantages to consider:

- Size Constraints: Due to the high power handling capacity of 30 Amp slip rings, they tend to be larger compared to lower current handling slip rings. Therefore, incorporating such a slip ring into a design could be a challenge where space is a constraint or compact design is essential.

- Cost Considerations: The high durability, comprehensive features, superior materials, and meticulous design of these slip rings can result in a higher cost, making them more expensive than their low-power counterparts. For companies constrained by budget or working on cost-sensitive projects, this factor may be a limitation.

- Unconventional Usages: While the 30 Amp slip rings are designed keeping in mind a broad range of generic applications, they may not perfectly fit all unconventional or niche applications. Customization may be required, which could increase the complexity and cost.

Despite these potential drawbacks, there are ways to mitigate these factors, and careful planning and design considerations can help address these challenges:

Size Constraints: By working closely with the slip ring manufacturer, the size requirements can be conveyed right at the design phase to ensure the slip ring fits within the required operational space. Also, with advancements in technology, compact high-capacity slip rings are becoming more common.

Cost Considerations: While the initial investment might appear high, the longevity, efficiency, reliability, and reduced maintenance costs associated with 30 Amp slip rings result in a good return on investment over the long term. However, a thorough cost-benefit analysis should be undertaken to make an informed decision.

Unconventional Usages: For atypical applications, custom-made slip rings could be the best bet. Customization allows you to have a slip ring designed to perfectly match the application requirements. While this might be expensive, it’s likely to prove beneficial in the long run, owing to optimal performance and enhanced durability.

To conclude, while it’s important to understand these potential limitations of 30 Amp slip rings, it’s equally crucial to consider the holistic view and the mitigating factors. In most cases, these limitations can be addressed or worked around to deliver durable, reliable, and efficient performance, thereby ensuring these slip rings maintain their relevancy across a plethora of applications.

Wind Generator 30 Amp Slip Ring

A Wind Generator 30 Amp Slip Ring is a specialized electrical component used in wind turbines to allow for the continuous transfer of power and signals between the stationary base and the rotating parts of the turbine. It plays a crucial role in wind energy systems, ensuring the smooth transmission of electricity from the rotating blades and nacelle to the stationary components without causing tangling or wear on the cables.

Here’s a detailed breakdown of its key features and functions:

Purpose and Function

The main function of a 30 Amp slip ring in a wind generator is to enable continuous electrical contact as the turbine blades rotate. Wind turbines often rotate to align with the wind direction, and a slip ring ensures that electrical connections are maintained during this rotation. This prevents cables from twisting or getting damaged due to the constant motion.

Electrical Capacity (30 Amp Rating)

- The “30 Amp” specification refers to the slip ring’s current-carrying capacity. It is capable of handling electrical currents up to 30 amperes without overheating or degrading.

- This rating indicates that the slip ring can be used in systems where the generated power is substantial, typically in small to medium-sized wind turbines. The slip ring must match the turbine’s output to handle the power effectively.

Structure and Design

- Rotating Mechanism: The slip ring is designed to allow for continuous 360-degree rotation. It connects to the rotating part of the wind turbine (often the rotor or nacelle).

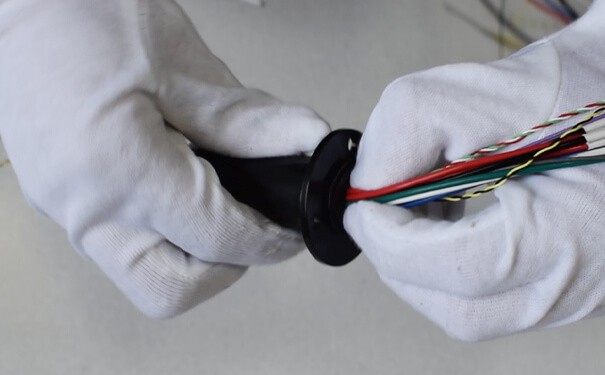

- Conductive Rings and Brushes: Inside the slip ring, conductive rings are mounted on the rotating part. Brushes (usually made of graphite or metal alloys) make contact with these rings to maintain the electrical connection while allowing for rotation.

- Sealed Enclosure: Many slip rings are housed in a sealed enclosure to protect the internal components from environmental factors like dust, moisture, and debris, which are common in outdoor wind turbines.

- Multiple Channels: Slip rings can have multiple channels, meaning they can transmit more than one circuit of power or signals simultaneously. For instance, it might handle both power transmission (e.g., 30A for the generator output) and data transmission (e.g., sensor signals from the turbine’s control system).

Durability and Material

- Corrosion Resistance: Since wind turbines are often located in harsh environments, like coastal areas or high-altitude locations, slip rings are usually made from corrosion-resistant materials, such as stainless steel or other alloys, to ensure long-term durability.

- Wear Resistance: The brushes and rings are designed to minimize wear due to constant contact and movement. High-quality slip rings often use self-lubricating materials or maintenance-free designs to increase their lifespan.

Alternative Technologies

- Some wind turbine designs use wireless or contactless rotary joints to eliminate physical wear associated with traditional slip rings. However, these are often more expensive and less common in small to medium-sized installations.

In summary, a Wind Generator 30 Amp Slip Ring is an essential component in wind energy systems that ensures the efficient transmission of power and signals from the rotating parts of a turbine to its stationary base. Its 30-amp capacity makes it suitable for small to medium wind turbines, and its durable design helps to extend the operational life of the wind generator by preventing damage to the power cables during rotation.

30 Amp Slip Rings Troubleshooting and Common Issues

Despite their robust design and operation, 30 Amp slip rings are not devoid of potential issues. It’s crucial to understand the common problems that may arise with these devices to implement corrective measures or preventive actions promptly.

- Overheating: Given the high power transmission, 30 Amp slip rings are occasionally prone to overheating – especially in cases of extended usage, unsuitable environments, poor ventilation, or design mismatch.

Solution: Incorporating a cooling system or a heat sink is one solution to excessive heating. Furthermore, regular checkups for any noticeable increase in temperature and performance should be conducted. However, it’s crucial to ensure that the slip ring design aligns well with the application’s power requirements in the preliminary stages.

- Connectivity Issues: Certain applications might witness connectivity issues manifesting as intermittent signal loss, noise, or complete disconnection. These could be due to damaged or worn-out brushes or rings, improper alignment, or dust and debris accumulation.

Solution: Regular inspection and maintenance can help identify and correct these issues early. Depending on the problem’s severity, solutions could range from cleaning dust and debris to replacing worn-out components. In cases of repeated connectivity issues, reevaluating the slip ring specification concerning the application requirements is recommended.

- Electrical Noise: Intrusion of electromagnetic noises or interference can lead to transmission disruptions and performance degradation.

Solution: Shielding is a potent way to prevent this issue. Ensuring that the slip ring design incorporates proper shielding and ground connection can help maintain signal integrity despite external interferences.

All issues considered, proactive maintenance plays a significant role in preventing common issues from escalating into serious problems. Regular inspections and quick responses to any change in performance parameters can ensure that the 30 Amp slip ring maintains its efficiency, longevity, and effectiveness.

It’s important to remember that these solutions are holistic, meaning that addressing one issue may help mitigate others. For example, conducting regular maintenance checks helps prevent overheating and connectivity issues, highlighting the coherence in troubleshooting processes. This coherent approach to troubleshooting ensures optimal performance and extends the slip ring’s lifespan.

Applications of 30 Amp Slip Rings

30 Amp slip rings are integral tools used across a broad range of sectors due to their high-power transmission capacity and impressive resilience. Let’s explore some substantial applications across various industries, speaking volumes about their versatility:

- Renewable Energy: With the push toward greener sources of energy, the renewable energy industry, particularly wind turbines, relies heavily on 30 Amp slip rings. The high current transmission capability ensures the generated energy is efficiently transferred. In addition, their durability, temperature resistance, and environmental resilience make them suitable for outdoor settings where wind turbines are typically located.

- Heavy Machinery: In various sectors like construction, manufacturing, and mining, heavy machinery necessitates a robust power supply. This power requirement is aptly met by the 30 Amp slip rings, capable of enduring high power loads and operating under the challenging environments common in such industries.

- Defense and Aerospace: The robustness, reliability, and performance consistency of 30 Amp slip rings make them an excellent choice for military and aerospace applications. Their high-temperature resistance is particularly advantageous enabling these slip rings to operate in diverse temperature conditions that are typical in such applications.

- Marine Settings: In marine applications, the 30 Amp slip rings are trusted for their high current transmission capabilities coupled with an impressive IP rating, protecting against corrosive seawater. Right from shipboard systems to underwater remotely operated vehicles (ROVs), these slip rings deliver reliable performance.

The coherence and context in these applications can be better understood by evaluating the presence of a common thread— environments with high power requirements and potential exposure to challenging conditions. The 30 Amp slip rings, with their high endurance, superior temperature resistance, impressive IP rating, and high current handling ability, have consistently proven their worth across these diverse industries.

In essence, the various features of 30 Amp slip rings offer a tailored-fit solution for these applications, thereby demonstrating their robust applicability, marked by versatility and adaptability.

30 Amp Slip Rings Selection and Purchasing Considerations

Choosing the right 30 Amp slip ring involves several key factors that directly impact your application’s performance and efficiency. Here is a comprehensive guide on essential factors to consider:

- Quality: The slip ring quality directly influences durability, performance, and longevity. Ensure the slip ring is made of high-quality materials, built to handle the specified load, and has undergone rigorous quality checks and tests.

- Performance: Always consider the slip ring’s performance metrics such as current capacity, rotational speed, temperature range, IP rating, noise level, and overall reliability.

- Manufacturer Credentials: A manufacturer with a proven track record and established reputation is fairly important. Delve into their experience in the field, client testimonials, after-sales services, and technical expertise.

- Customization Options: The ability to customize designs as per specific needs can be a considerable advantage, particularly for non-standard applications. Check if the manufacturer offers customization options that match your application’s unique requirements.

While there are many manufacturers in the market, only a handful stand out as reliable and trustworthy. These manufacturers distinguish themselves through their consistency in product quality, commitment to innovation, vast industry experience, and a track record of providing excellent service.

The reliability of these manufacturers is dictated by their adherence to quality standards, use of advanced technology, systematic testing procedures, and a genuine commitment to customer satisfaction (be it through robust after-sales services or customization options).

The coherence in these considerations alludes to the significant interplay between a product’s quality and the manufacturer’s credibility. A top-tier manufacturer is expected to deliver superior quality products, while a high-quality 30 Amp slip ring is likely to originate from a well-known and respected manufacturer.

To summarize, investment in a 30 Amp slip ring should be guided by these crucial considerations, each influencing the other, and a cumulative assessment deciding the final choice. By striking a balance between quality, performance, manufacturer reputation, and customization options, an optimal selection can be made that perfectly aligns with the intended application’s demands.

Installation of 30 Amp Slip Ring

Installing a 30 Amp Slip Ring in a wind generator requires careful attention to detail to ensure safe and efficient operation. The installation process involves mounting the slip ring between the rotating and stationary components of the wind turbine, connecting the electrical wiring, and securing the device to prevent movement. Here’s a step-by-step guide to properly installing a 30 Amp slip ring:

Step 1: Safety Precautions

Before starting the installation, take the following safety precautions:

- Power Off: Ensure the wind turbine is completely shut down and isolated from the power source. Lockout and tagout procedures should be followed to prevent accidental startup.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including insulated gloves, safety goggles, and protective clothing, especially when handling electrical components.

- Ensure Stability: Confirm that the wind turbine’s rotor is immobilized and secure to avoid accidental movement during installation.

Step 2: Gather Required Tools and Materials

You will need the following items for the installation:

- 30 Amp slip ring

- Appropriate wiring (sized for 30A current)

- Mounting hardware (bolts, screws, brackets)

- Insulated tools (screwdrivers, wrenches)

- Wire strippers, crimpers, and connectors

- Multimeter (for testing electrical continuity)

- Lubricant (if required for specific parts)

- Sealing compounds (if necessary to ensure weatherproofing)

Step 3: Verify Slip Ring Specifications

Before installation, verify that the slip ring is suitable for your wind generator. Confirm the following:

- Current Rating: Ensure that the slip ring can handle 30 amps.

- Voltage Rating: Make sure the voltage rating of the slip ring matches or exceeds the turbine’s output.

- Channel Count: Ensure the slip ring has enough channels (conductive paths) for both power and any signal transmission required by your system.

Step 4: Prepare the Installation Area

- Location: The slip ring is typically installed between the nacelle (the housing that contains the generator and mechanical components) and the tower of the wind turbine.

- Clean the Mounting Area: Ensure the mounting surfaces on both the stationary and rotating parts are clean, dry, and free of debris or rust. This will help the slip ring mount securely and perform optimally.

- Check Alignment: The mounting area must allow for precise alignment between the rotating part of the slip ring and the stationary part to avoid undue wear or misalignment during operation.

Step 5: Mount the Slip Ring

- Attach the Rotating Part:

- Install the rotating part of the slip ring onto the shaft or the rotor (the part of the wind turbine that turns with the blades).

- Secure it using the provided mounting hardware (such as bolts or clamps). Make sure the rotating component is snug and aligned properly with the stationary part of the system.

- Some designs may require spacers or adaptors, depending on the specific turbine.

- Mount the Stationary Part:

- Attach the stationary part of the slip ring to the fixed structure of the wind turbine, often within the tower or at the base of the nacelle.

- Use appropriate mounting brackets or flanges to ensure it remains immobile while the rotor turns.

- Ensure Proper Clearance:

- There should be sufficient clearance between the rotating and stationary parts, allowing for smooth, friction-free operation. Refer to the manufacturer’s manual for the recommended clearance specifications.

Step 6: Connect the Electrical Wiring

- Strip the Wires: Use a wire stripper to expose the correct length of wire ends for connections, according to the slip ring’s input/output terminals.

- Attach the Wires to the Slip Ring:

- Power Conductors: Connect the power conductors (usually large gauge wires) to the appropriate terminals on the slip ring, following the color coding or labeling provided by the manufacturer.

- Signal Wires (if applicable): If the slip ring is transmitting sensor data or control signals in addition to power, connect the signal wires to the appropriate channels.

- Secure Connections: Use crimp connectors or soldered joints to ensure strong, vibration-resistant connections. For screw terminals, tighten the screws securely but avoid over-tightening, which could damage the wires.

- Check Grounding: Ensure that all components, including the slip ring, are properly grounded to prevent electrical faults or surges.

Step 7: Perform Continuity and Resistance Testing

- Test Continuity: Use a multimeter to test the continuity of each channel (power and signal) to ensure there is no break in the circuit between the stationary and rotating parts.

- Check Resistance: Measure the resistance across the slip ring connections. Any unusually high resistance might indicate poor contact between the brushes and rings, which could lead to inefficient power transfer.

Step 8: Seal and Protect the Slip Ring

- Apply Sealing Compound: If the slip ring is not pre-sealed, apply a weatherproof sealing compound or gasket to protect it from environmental factors such as moisture, dust, and corrosion. This is especially important for outdoor wind turbines exposed to the elements.

- Install a Protective Enclosure: In some installations, an additional protective housing or enclosure may be needed to shield the slip ring from harsh conditions. Ensure that this housing does not interfere with the rotation or functionality of the slip ring.

Step 9: Final Checks and Testing

- Manually Rotate the Rotor: After installing the slip ring, manually rotate the rotor to ensure that the slip ring rotates smoothly without any obstruction or friction.

- Re-check Alignment: Verify that the rotating and stationary parts of the slip ring are still properly aligned after installation.

- Power On the System: Gradually restore power to the wind turbine and monitor the slip ring’s operation under load. Check for stable power transfer and proper signal transmission, if applicable.

Step 10: Maintenance and Monitoring

- Periodic Inspection: Regularly inspect the slip ring for signs of wear, debris, or damage. Pay attention to the brushes, which may require replacement over time.

- Lubrication (if applicable): Some slip rings may require periodic lubrication to maintain smooth operation.

- Monitor for Noise or Excessive Heat: If the slip ring makes unusual noises or becomes excessively hot, it could indicate a problem such as misalignment or electrical issues that should be addressed immediately.

By following these steps, you can ensure the proper installation of a 30 Amp slip ring in a wind generator, allowing for continuous and reliable power transfer even as the turbine rotates to capture wind from different directions.

30 Amp Slip Rings Maintenance Practices and Enhancing Lifespan

Proper maintenance practices play a pivotal role in ensuring the longevity and optimal performance of 30 Amp slip rings. A well-maintained slip ring can offer reliable service for years, reducing overall operational costs. Here’s a guide to best maintenance practices to enhance your slip ring’s lifespan:

- Regular Inspections: This involves routinely checking the slip ring for signs of wear, damage, overheating, or any other operational irregularities. For example, a sudden increase in temperature or noise could signal potential issues that need attention.

- Cleaning: Dust and debris can reduce a slip ring’s performance over time. Regular cleaning of contact surfaces ensures maximum contact and prevents connectivity issues related to dust accumulation. Cleaning should be done gently to prevent damage to delicate components.

- Lubrication: Certain types of slip rings require periodic lubrication to ensure smooth rotation, reduce friction, and prevent premature wear and tear. Using the right kind of lubricant and following the manufacturer’s guidelines can significantly enhance a slip ring’s operational life.

- Preventive Maintenance: Don’t wait for a problem to appear before taking action. Routine preventive maintenance, involving all of the above, can help spot potential issues early and rectify them before they escalate into more severe problems.

The context here revolves around maintaining the smooth operation and longevity of the 30 Amp slip ring. The coherence lies in the preventive nature of each practice— regular inspections help detect issues, cleaning reduces debris-induced problems, lubrication mitigates wear and tear, and overall preventive maintenance ensures potential issues are nipped in the bud.

Each of these practices is interlinked, contributing to the overall health and functionality of the slip ring. They show how investing a little effort into routine maintenance can go a long way in preventing operational disruptions, thereby extending the lifespan of the 30 Amp slip ring.

Future Trends and Innovations Surrounding 30 Amp Slip Rings

The ever-evolving technological landscapes steer continuous innovation in the design, performance, and application of 30 Amp slip rings. Let’s delve deeper into some future trends and potential advancements in this sphere:

- Miniaturization: As space becomes an increasingly precious commodity in various technologies, the drive towards miniaturization of slip rings is expected. Future 30 Amp slip rings might come in much smaller sizes without compromising their power handling capabilities, allowing them to be integrated into more compact systems.

- Internet of Things (IoT): IoT technology has a promising role in advancing the monitoring and maintenance of slip rings. IoT-enabled 30 Amp slip rings could offer real-time status updates, predictive maintenance alerts, and even remote troubleshooting, significantly improving efficiency and system uptime.

- Smart Materials: The use of advanced materials with superior attributes such as high-temperature resistance, wear resistance, and self-lubricating properties will likely form the future of slip ring manufacture. This not only enhances performance but also extends the life span of the slip rings.

- Improved Integration: Future trends may focus on enhancing the ease of integration of these slip rings into various systems. Innovations may allow slip rings to better interface with different components, enabling seamless integration into a wide array of applications, from renewable energy systems to sophisticated defense machinery.

Get detailed information about our 30 Amp Slip Rings by contacting us.

The context here pertains to the future advancements and trends in the 30 Amp slip ring space. All these trends show coherence in aiming to increase efficiency, reduce maintenance needs, and adapt to the changing demands of various industries.

Each of these trends—miniaturization, IoT technology, smart materials, and improved integration—has a singular goal: to make 30 Amp slip rings more robust, reliable, and versatile for future applications. By staying abreast of these trends, users can better understand how these slip rings will continue evolving and where to invest their resources for the most beneficial returns.

Conclusion

In the realm of rotating systems, 30-amp slip rings hold significant importance. From their design to their potential applications, everything about these components is intriguing. Proper selection, maintenance, and staying in touch with future developments can ensure we harness their full potential in the coming times. It is a fascinating world, indeed!

See What We Can Do