In this article, we aim to provide readers with an in-depth understanding of the 6 wire capsule slip ring, covering its design, application, and other crucial aspects. Our goal is to help professionals, students, and anyone else interested in this field gain valuable insight into the workings of this vital component.

Introduction to 6 Wire Capsule Slip Ring

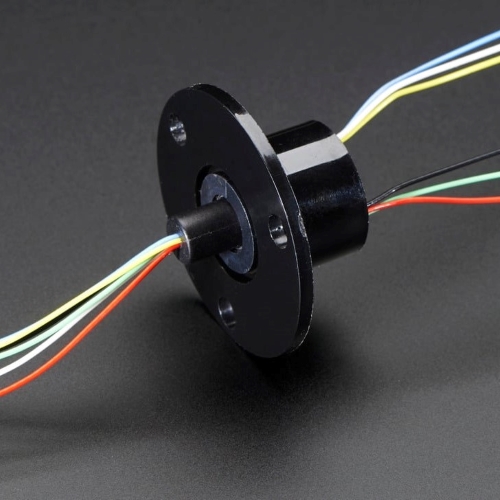

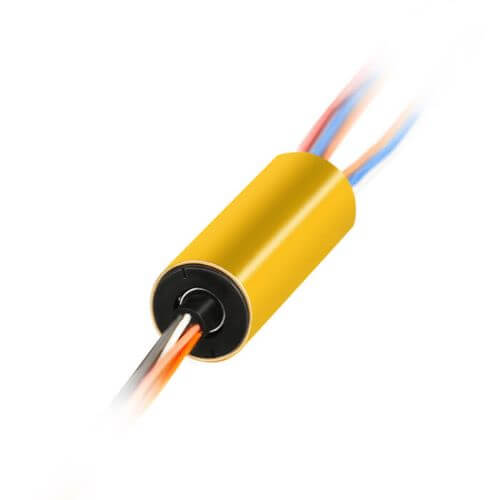

The 6 wire capsule slip ring is an intricate yet highly efficient electromechanical device with a mission to connect stationary and rotating parts of a mechanical assembly. Its primary function is to enable the transfer of energy – electrical power and signals – from a static source to a part that rotates, thus supporting the continuous functionality of various machines and appliances.

The term “6 wire” in its name refers to the number of electrically conductive circuits it carries. Each one of these circuits is capable of functioning independently, meaning each can transmit a unique electrical signal or a different power source. This multiplicity feature greatly extends the scope of its use.

In terms of structure, a 6 wire capsule slip ring is compact and typically enclosed in a protective shell, hence the term “capsule”. This shell not only serves as a protective layer for the internal conductive circuits but is also specifically designed to help the device withstand harsh environmental conditions, vibrations, and other external forces.

Significantly, the 6 wire capsule slip ring holds immense importance due to its multipurpose functionality. Its versatility makes it suitable for numerous applications, providing a vital interface solution in a wide range of fields – from communication technologies, industrial equipment, and security systems, to medical machinery and even in the soaring domain of renewable energies such as wind power systems.

In essence, understanding the 6 wire capsule slip ring opens up a world of progress in mechanical and electrical engineering. To license a device to rotate unhindered while maintaining a steady and reliable supply of power and signal communication is undoubtedly a remarkable innovation. It’s an embodiment of technological advancement, solving complexities in electromechanical systems with brilliant simplicity.

6 Wire Capsule Slip Ring Design and Working Principle

One of the key aspects that make a 6 wire capsule slip ring quite fascinating is its intricate design and working principle. This compact yet versatile device showcases a perfect blend of simplicity and sophistication, solving one of the most pressing challenges in the field of electrical and mechanical engineering – transmitting power and signals to a rotating assembly.

A basic 6 wire capsule slip ring comprises several key components, including a capsule housing, metal rings, brushes, and wires. The capsule design incorporates 6 conductive circuits encapsulated in a small housing. This feature ensures its compact size, which comes in handy in applications where space is a major constraint.

Structurally, inside the capsule, we have the rotating parts and the stationary parts. The main rotating component is the conductive metal ring, often made from precious metals or alloys due to their excellent conductivity. Additionally, these materials are also resistant to wear, ensuring the slip ring’s longevity. On the other hand, the stationary elements are mainly the brushes that maintain continuous electrical contact with the rotating ring as the system rotates.

Each conductive circuit in the 6 wire capsule slip ring has a corresponding set of brushes and metal rings. They are configured so that each set of these components forms an independent circuit, providing six separate paths for power and signal transmission.

Notably, the functionality of the 6 wires in the capsule slip ring cannot be overstated. These wires are connected to the brushes, and they carry electrical currents or signals between the stationary and rotating machine parts. The wires’ insulation is critical to prevent short circuits, ensuring no signal gets mixed up with unintended circuits.

As for the working principle, the 6 wire capsule slip ring uses a simple yet efficient method. As the rotating part of the machine turns, so do the metal rings in the slip ring. The brushes maintain a continuous, sliding contact with these rings, facilitating the transmission of electrical power or signals through the wires to the rotating end.

Ultimately, the importance of slip rings in powering rotating machines is monumental. Be it in the field of renewable energy, where wind turbines are rotated to generate electricity, or in the security sector, where closed-circuit television (CCTV) cameras require continuous 360-degree rotations – capsule slip rings form the backbone of these systems. By creating an uninterrupted circuit between rotating and stationary parts, the 6 wire capsule slip ring has successfully empowered a wide range of industries, paving the way toward a more innovative and efficient future.

6 Wire Capsule Slip Ring Key Specifications and Parameters

Understanding a 6 wire capsule slip ring requires an appreciation of its key specifications and operating parameters. These technical aspects define the capabilities and constraints of the device, underlining its suitability for particular applications. Here, we delve into the crucial, defining parameters of a 6 wire capsule slip ring.

Voltage: The rated voltage or maximum voltage refers to the highest amount of electrical potential difference that the slip ring can safely handle. It is crucial to adhere to this specification to avoid sparking or short-circuiting during operation. For instance, if a slip ring is rated at a maximum voltage of 250V, any attempt to apply a voltage higher than this could lead to electrical faults or catastrophic consequences like a fire.

Current Capacity: This parameter denotes the maximum electrical current that can flow through each channel of the slip ring without causing damage, typically measured in amperes (A). Overloading the current capacity could lead to overheating and even meltdown of the conductive material, leading to device failure.

Rotational Speed: Another key specification is the maximum rotational speed, typically given in revolutions per minute (RPM). This is the top speed at which the slip ring can rotate while maintaining optimal performance without risking premature wear or damage. Maintenance of this parameter is critical, especially in heavy-duty operations like wind turbines or industrial rotating platforms, where the continuous rotation can be fast and prolonged.

Wire Insulation: Given that the six wires within the slip ring are designed to carry power and signals, they must be adequately insulated. Wire insulation prevents the circuits from unintentional connections that can result in short circuits or signal interference. The quality of insulation material also dictates the longevity and reliability of the entire device.

Operating Temperature: This parameter captures the temperature range under which the slip ring can function effectively. Exposing the slip ring to temperatures exceeding this range might affect its structural integrity, interfere with its performance, or adversely shorten its lifespan.

Each of these parameters is crucial for ensuring that a 6 wire capsule slip ring operates optimally and within safe limits. When selecting a slip ring, users should carefully review these specifications and align them with their application’s requirements, as adherence to the slip ring’s specs guarantees safe operation and prolongs its service life.

Price of 6 Wire Capsule Slip Ring

The 6-wire slip ring price can vary significantly based on factors like quality, brand, size, and the specific requirements of your application. Typically, the price range for a 6-wire capsule slip ring starts from around $50 to $200 or more. High-quality or custom-made versions can be priced higher, depending on their durability, performance, and features. When evaluating the price, it’s important to consider both the initial cost and the potential long-term value in terms of maintenance and reliability.

Applications of the 6 Wire Capsule Slip Ring

The versatility and robustness of the 6 wire capsule slip ring make it apt for various applications across multiple industries. This section dives into some noteworthy applications where these slip rings are frequently utilized and discusses the distinct advantages they provide in each context.

CCTV Surveillance Systems: 6 wire capsule slip rings are indispensable in CCTV systems, particularly those cameras designed for a full, continuous 360-degree rotation. The slip rings enable the camera to rotate without hindrance while maintaining a stable power supply and signal transmission. With a 6-wire configuration, the slip ring can manage both power and multiple video feeds simultaneously.

Robotics: The field of robotics widely uses 6 wire capsule slip rings, especially in robotic joints or manipulator arms. These rotating parts require constant power and data transmission while they continuously move without tangling or damaging the wires. Furthermore, the 6 independent circuits could aid in separately controlling different parts of the robotic arms, providing refined functionality.

Wind Turbines: In wind turbines, the blades’ rotation generates electricity while the stationary component remains fixed. Using a 6 wire capsule slip ring, power and data collected from instrumentations in the rotating blades can be transmitted efficiently to the control systems in the stationary part. It significantly reduces the probability of cable damage from twisting or coiling when rotating.

Medical Equipment: Healthcare technology, such as imaging systems in CT scanners or dental X-ray machines, leverages the advancements in slip ring technology, including 6 wire capsule slip rings. They allow the rotating parts of these machines to receive continuous power, ensuring seamless operation and high-definition imaging.

In each of these applications, the 6-wire capsule slip ring brings distinct advantages such as enabling free rotation without worrying about tangled or twisted wires, providing stable power and signal transmission, and lasting durability due to high-quality construction.

Moreover, these advantages of 6 wire capsule slip rings extend far beyond these applications, opening up numerous possibilities across varying industries. So whether it’s for a complex industrial machine or a sophisticated medical device, a 6 wire capsule slip ring ensures efficient, reliable, and continuous performance.

6 Wire Capsule Slip Ring Installation and Maintenance

Achieving the best performance and longest possible lifespan from a 6 wire capsule slip ring relies heavily on proper installation and diligent maintenance. Below, we guide how to install a 6 wire capsule slip ring as well as share preventive measures to ensure it remains in good working condition.

Installation

- Read the Manual: Begin with a thorough read of the manufacturer’s manual specific to the model of the slip ring you have. This document contains vital information regarding the specifications, constraints, and any special installation instructions.

- Prepare the Workspace: Ensure you have enough space to carry out the installation process. Make sure the area is clean, well-lit, and free from dust or debris that might contaminate the slip ring components.

- Turn Off the Power: Before proceeding, ensure all sources of power to the machinery have been switched off and disconnected.

- Mount the Capsule Slip Ring: Secure the slip ring to the stationary part of the system by attaching it to the designated mounting platform using the recommended method, usually with screws or brackets.

- Connect Wires: Establish connections between the 6 wires from the slip ring and the respective components on the stationary part of the machine. It is essential to adhere to the manufacturer’s wiring diagram to prevent short circuits or other electrical issues.

- Secure the Rotating Part: Attach the rotating component of the slip ring, which includes the metal rings and wire connectors, to the rotating part of the system.

- Inspect Connections: Before restoring power, double-check all connections to ensure proper contact, secure attachments, and no loose parts.

- Test: Once the installation is complete, turn on the system to test the connectivity and effectiveness of the 6 wire capsule slip ring.

Maintenance

- Regular Inspection: It is crucial to perform periodic visual inspections of the slip ring to detect signs of wear, corrosion, or damage in the brushes, metal rings, or wires.

- Clean Contacts: Using non-abrasive materials, such as lint-free wipes and appropriate contact cleaning solution, remove dust and debris from the brushes and metal rings. This helps prevent excessive wear and maintain smooth electrical contact.

- Apply Lubrication: If recommended by the manufacturer, occasional lubrication of the brushes and rotating components might be necessary to reduce friction and maintain smooth rotations.

- Check Wire Insulation: Inspect the wire insulation regularly. In case of any damage, address it immediately to prevent short circuits or signal interference.

- Monitor Operating Conditions: Ensure the slip ring operates within the specified temperature range and does not exceed the specified voltage, current, or rotational speed limits.

By adhering to the installation guidelines and maintenance tips discussed above, one can extend the service life of the 6 wire capsule slip ring, ultimately benefiting from its full potential and advantages in various applications.

Selection Guide for a 6 Wire Capsule Slip Ring

Selecting the most suitable 6 wire capsule slip ring is vital for optimal system performance and reliability. This section provides a guide on the key factors to consider while choosing the perfect 6 wire capsule slip ring for your application, ensuring a seamless fit and effective operation.

- Operating Parameters: Evaluate the operating parameters, such as voltage, current capacity, rotational speed, and temperature range, as per your specific application requirements. Choose a slip ring that meets or exceeds these parameters to ensure reliable performance and prevent issues caused by inadequate specifications.

- Quality: Seek out high-quality components that promise durability and longevity. Factors like housing material, brush composition, and metal ring quality all contribute to the overall sturdiness of the slip ring. It is crucial to prioritize quality over lower costs because a slip ring failure could lead to expensive repairs and possible system downtime.

- Brand Reputation: Opt for a reputable brand that specializes in manufacturing slip rings or related components. Brands with a known history of producing reliable and high-quality products offer higher confidence in performance and support. Additionally, a well-regarded brand often provides better after-sales services, including product support and assistance.

- System Compatibility: Ensure the dimensions and design of the 6 wire capsule slip ring are compatible with your target system. Take into consideration aspects such as mounting method, available space, and the routing of wires. Incompatibility issues could lead to installation difficulties, ineffective operation, or the need to modify your existing system.

- Requirements for Signal Transmission: Consider the signal types that the slip ring will transmit. This could include signals for instrumentation, control systems, or multiple data lines. The 6 wire configuration should provide enough channels for all required signals without impacting performance or other transmission objectives.

- Environmental Factors: Assess the environmental conditions under which your capsule slip ring will operate, such as corrosive or high-moisture conditions. In such cases, opt for a slip ring designed with appropriate material and measures to protect it from the detrimental effects of its environment.

- Maintenance and Serviceability: Choose a slip ring with readily available replacement parts or those that adhere to the industry’s standard components. This ensures that when maintenance or repairs are required, accessibility to compatible parts or services will not be an issue.

- Budget: While it is vital to prioritize quality and compatibility, it is also essential to strike a balance between your budget and the slip ring’s specifications. Find a slip ring that offers the best value without compromising essential features, performance expectations, or financial constraints.

Taking into account these factors while selecting a 6 wire capsule slip ring will enable you to integrate the best-fit component into your system, optimizing performance, durability, and efficiency. By giving due consideration to the quality, brand, operating parameters, compatibility, and other influential factors, your choice of a 6 wire capsule slip ring will offer a robust solution for the application at hand.

6 Wire Capsule Slip Ring Market Trends and Future Advancements

With the evolution of technology and the ever-increasing complexity of applications, the 6 wire capsule slip ring devices have seen notable trends and are poised for more advancements in the future. This section will shed light on these market dynamics and give you a glimpse into what the future holds for these versatile components.

Current Market Trends

- Increased Demand in Surveillance and Security Systems: With the heightened emphasis on surveillance and security, there has been significant growth in demand for highly reliable and efficient slip rings. The 6 wire capsule slip ring’s ability to offer constant, uninterrupted signal and power transmission for 360-degree rotating cameras has underpinned this demand.

- Rapid Adoption in Wind Energy Systems: As renewable energy generation becomes the priority, wind turbines have been witnessing rapid growth. The 6 wire capsule slip rings play a pivotal role in these systems, ensuring efficient power generation and condition monitoring, leading to increased demand in this sector.

- Integration in Modern Robotic Systems: With advancements in automation and robotics, the need for slip rings able to operate under continuous motion, like in robot arms or manipulators, has surged. The 6 wire capsule slip ring is a popular choice due to its reliability and functionality.

- Growth in the Medical Industry: Medical imaging systems, such as CT and MRI machines, require slip rings for uninterrupted power and signal transmission. As the healthcare industry embraces newer technology, the market for 6 wire capsule slip rings grows.

Future Advancements and Predicted Trends

- Miniaturization: As the trend towards compact devices and systems continues, we can expect more miniature versions of the 6 wire capsule slip rings that can handle the same load and offer similar performance to their larger counterparts.

- Intelligent Slip Rings: The integration of smart technologies into slip rings is a significant area of focus for R&D. Future 6 wire capsule slip rings might be equipped with sensors for monitoring wear and operational components conditioning, ensuring predictive maintenance and prolonging lifespan.

- Improved Material Technologies: With continuous advancements in materials science, the future may introduce slip rings with even better-performing contacts, using novel alloys or coatings that decrease friction, resist corrosion, and improve signal integrity.

- High-Speed Data Transmission: As the need for high-speed data transmission continues to increase, especially with the rise of 5G and IoT technology, future innovations might focus on enhancing the data transmission capability of the slip rings.

By understanding the current market trends and future advancements, businesses and end-users can make informed decisions regarding the selection and usage of 6 wire capsule slip rings. Innovations and advancements in this field will continue to drive the relevance and versatility of these components in a broad range of industries and applications.

Conclusion

The 6 wire capsule slip ring is a vital component in numerous rotating applications, ensuring efficient power and data transmission even during continuous rotation. By understanding its design, usage, and maintenance, users can optimize the performance and longevity of this critical electromechanical device. As technology advances, the 6 wire capsule slip ring will continue to evolve, meeting the ever-growing demands of the industries that rely heavily on it.

FAQs about 6 Wire Capsule Slip Rings

Selecting, installing, and maintaining a 6 wire capsule slip ring might raise some questions, especially due to its technical nature. This section will address some of the most popular queries concerning this topic, providing quick answers and valuable insight to end users.

Fill Out the Form to Receive a 6 Wire Capsule Slip Ring Solution Tailored to Your Needs.

Q: What is a 6 wire capsule slip ring?

A: A 6 wire capsule slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary component to a rotating component within a system. The “6 wire” refers to the number of circuits available for this transmission.

Q: What industries typically use 6 wire capsule slip rings?

A: These slip rings have broad applications across various industries, including wind energy, security systems, medical imaging, automation & robotics, amusement rides, and military equipment among others.

Q: How do I install a 6 wire capsule slip ring?

A: Proper installation requires attention to specific details: start by switching off the power, then mount the slip ring, connect the wires, attach the rotating part, perform a thorough check of all the connections, and finally, run a test to ensure successful connectivity.

Q: How much does a 6 wire capsule slip ring cost?

A: The price can vary widely based on factors like the specific model, manufacturer, component quality, and distributor. Generally, prices can range from around $50 for basic models to several hundred dollars or more for those with advanced capabilities or designed for specialized applications.

Q: Where can I buy a 6 wire capsule slip ring?

A: These devices can be purchased from various sources, including directly from manufacturers, via electrical component distributors, or through online platforms. Ensure to verify the reliability of the source to guarantee you receive a genuine, high-quality product.

Q: What maintenance does a 6 wire capsule slip ring require?

A: Regular inspection of the brushes, rings, and wires is essential, as is cleaning to remove dust and debris. Some slip rings may require occasional lubrication, and checking the wire insulation for any damage is recommended. Do monitor the operating conditions, ensuring the slip ring does not exceed its specified limits.

Q: What should I do if my 6 wire capsule slip ring stops functioning?

A: Many issues can be resolved through simple troubleshooting, like checking the connections or cleaning the contacts. If these steps don’t solve the issue, consider consulting with a professional service technician or contacting the manufacturer’s support service.

See What We Can Do