Slip rings are essential components in many rotating systems, playing a vital role in transmitting power and signals between stationary and rotating parts of a machine or system. These components allow for continuous, uninterrupted power and signal transmission without the need for physical connectors that would limit the movement or rotation of the system. Whether it’s in industrial machinery, wind turbines, robotics, or military applications, slip rings ensure seamless electrical and data flow, contributing to system efficiency, reliability, and longevity. Their importance spans across various industries, making them an indispensable part of modern engineering.

At Grand Slip Rings, we position ourselves as a trusted and experienced manufacturer of high-quality slip rings and rotary joints. With years of expertise in the industry, we specialize in providing tailored solutions for a diverse range of applications. We understand that no two systems are alike, which is why we focus on customization, ensuring that each slip ring we produce is engineered to meet the specific requirements of our customers’ unique systems.

Our commitment to quality and innovation is reflected in every slip ring and rotary joint we manufacture. By offering solutions that are both reliable and efficient, we’ve built a reputation for delivering performance and durability in the most demanding environments. Whether it’s a small, compact system or a large, complex setup, we work closely with our clients to create the perfect solution. From standard designs to highly specialized, custom-made products, Grand Slip Rings provides unrivaled expertise and flexibility in meeting the power and signal transmission needs of modern rotating systems.

Key Factors Affecting 6-Wire Slip Ring Prices

The price of 6-wire slip rings can vary significantly based on several key factors, each impacting the design, materials, and performance characteristics. Below are the main factors that contribute to the price variation:

Current/Voltage Ratings

One of the most important factors affecting the price of slip rings is their current and voltage rating. Slip rings are designed to handle different power loads, and as the current and voltage capacity increases, so does the price.

Low-current models (e.g., 2A): These slip rings are generally used in applications that require minimal power transmission, such as small electronics or data signal transmission. These slip rings are often less expensive due to their simpler construction and smaller scale.

High-current models (e.g., 30A–180A): Slip rings designed to handle higher current ratings are significantly more expensive. High-current slip rings are crucial for industrial applications, power generation, or renewable energy systems such as wind turbines, where large amounts of power need to be transmitted through rotating systems.

Design Type

The design of a slip ring also plays a crucial role in determining its price. Different designs are suited to different applications, and each has its own cost structure.

Through Hole Slip Ring: These slip rings have a hollow center, allowing the shaft of the system to pass through. The price of through bore slip rings can vary depending on the size of the bore, as larger bores require more complex manufacturing and precise tolerances. They are commonly used in applications like robotics or industrial machinery, where components need to pass through the center of the slip ring. Their cost typically increases with the size of the bore and the materials used for the shaft and housing.

Pancake Slip Ring: Pancake slip rings have a flat, compact design, making them ideal for space-constrained applications. While their compact nature provides significant advantages in terms of space efficiency, they are generally more expensive than other designs due to the specialized manufacturing processes and precision required to maintain high performance in a small package. These are commonly used in applications like aerial systems or compact machines, where size is a critical factor.

Hollow Shaft Slip Ring: These are versatile and durable slip rings designed to provide a robust solution for systems with rotating shafts. They are typically priced in the mid to high range because they combine durability with flexibility in application. The hollow shaft design allows for the integration of other components or systems through the center of the slip ring, making them suitable for both small and large machinery, from medical equipment to industrial robots.

Material Quality

The materials used in the construction of the slip ring can have a significant impact on its price. The choice of contact materials, housing, and insulation materials all affect both the performance and cost of the slip ring.

Gold Contacts: Slip rings with gold contacts are typically more expensive because gold offers superior conductivity, durability, and resistance to corrosion. Gold contacts are often used in high-precision applications, such as aerospace or medical devices, where reliability and performance are paramount.

Silver Contacts: Silver is another common contact material, and while it is less expensive than gold, it still offers excellent conductivity. However, silver is more prone to oxidation and requires additional protection or coatings. Silver-based slip rings tend to be more affordable than gold-based ones, but they may not be as durable in harsher environments.

Corrosion-resistant Housing: The housing material used for slip rings is critical for ensuring their longevity, especially in industrial and outdoor environments. Materials like stainless steel or aluminum are commonly used for their corrosion resistance. Slip rings with these durable materials typically cost more because they provide long-term protection against wear and environmental factors.

Customization

Slip rings are often customized to meet specific application needs, and custom solutions generally come with a premium price. Customization may involve tailoring the number of circuits, the type of materials used, the overall design, or even adding features such as integrated sensors or temperature controls.

- Grand Slip Rings‘ Tailored Solutions: At Grand Slip Rings, we specialize in providing highly customized solutions to meet the unique needs of our clients. This could include adjusting the size, power rating, number of wires, or specific environmental protections. Such customizations require additional engineering work and testing, which increases the cost. For applications requiring specialized materials or configurations, such as high-speed rotating systems or systems with stringent environmental conditions, the price of the slip ring will reflect the complexity and premium nature of the solution.

The price of 6-wire slip rings is influenced by the current/voltage ratings, design type, material quality, and customization requirements. Understanding these factors helps businesses choose the right slip ring for their specific needs while balancing performance and cost.

6-Wire Slip Rings Price

The price of 6-wire slip rings can vary depending on the specifications, features, and benefits provided. However, at Grand Slip Rings, we offer competitive pricing for slip rings with similar specifications, such as the 30A models, while ensuring that additional benefits are included, making our products an attractive choice for businesses seeking both performance and value.

Competitive Pricing for Similar Specs (e.g., 30A Models)

Slip rings with 30A current ratings are commonly used in various industrial and commercial applications, such as wind turbines, heavy machinery, and robotics. These slip rings typically fall within a mid-to-high price range due to the need for durable materials and high power-handling capabilities.

At Grand Slip Rings, we understand the importance of cost-effectiveness, especially in industries that require consistent and reliable performance from their rotating systems. Our 30A slip rings are priced competitively within the market, ensuring that our clients receive high-quality products at affordable rates. We achieve this by optimizing our production processes, sourcing materials efficiently, and reducing unnecessary overhead costs, allowing us to pass on the savings to our customers.

In comparison to similar 30A models available from other manufacturers, Grand Slip Rings strives to offer equivalent or superior quality while maintaining a pricing structure that remains cost-effective. Our customers can expect to receive great value for their investment, without compromising on the performance and longevity of the slip rings.

Added Benefits:

While the competitive pricing of our 30A slip rings is a key factor, there are several additional benefits that make our offerings stand out in the market:

Warranty: At Grand Slip Rings, we provide an industry-leading warranty for our 6-wire slip rings. This warranty not only guarantees the performance of the product but also assures our clients that they are protected against any defects or failures that may occur during normal operation. A solid warranty demonstrates our confidence in the durability and reliability of our products, offering peace of mind for businesses that rely on consistent power and signal transmission.

Customization: We offer extensive customization options for our 6-wire slip rings to cater to specific application requirements. This customization can include adjustments to current ratings, size, housing materials, connection types, and more. Whether you need a slip ring with a unique design or specific features like enhanced corrosion resistance or specialized wiring configurations, we can tailor the slip ring to fit your needs.

This level of customization ensures that businesses can integrate Grand Slip Rings products seamlessly into their systems, even for highly specialized applications. This added flexibility gives customers more control over the final product, ensuring it performs optimally in their specific environment.

Enhanced Performance: Beyond just meeting basic requirements, our 30A slip rings are designed for enhanced performance, offering superior conductivity, heat resistance, and minimal wear over time. We use high-quality materials, such as gold or silver contacts, and corrosion-resistant housing to ensure that our slip rings last longer and perform reliably, even in challenging conditions. This commitment to excellence adds extra value to our products, making them more durable and cost-effective in the long run.

Technical Support and Consultation: We also provide ongoing technical support and consultation services for our clients. If you’re unsure about which slip ring best suits your needs or if you require assistance during installation or maintenance, our experienced engineers are available to help. We offer guidance on optimal installation practices, potential upgrades, and maintenance schedules to ensure that your slip rings continue to function at peak performance.

Fast Turnaround and Delivery: We understand that time is a crucial factor in many industrial and commercial applications. That’s why we focus on providing fast turnaround times and reliable delivery services. With Grand Slip Rings, you can rest assured that your customized or standard 30A slip rings will arrive on schedule, ensuring that your operations are not delayed due to extended lead times. This fast service enhances overall project efficiency and reduces downtime for our customers.

Cost-Efficiency in Bulk Orders: For customers looking to purchase multiple slip rings, we offer additional pricing discounts on bulk orders. This makes Grand Slip Rings an even more attractive option for large-scale industrial projects or businesses with multiple machines requiring slip rings. By offering cost-effective pricing for bulk purchases, we help our customers lower their overall operational expenses while maintaining high-quality standards.

At Grand Slip Rings, we not only focus on offering competitive pricing for our 6-wire slip rings, such as the 30A models, but also prioritize providing added benefits such as extended warranties, customization options, superior performance, technical support, fast delivery, and cost-efficient bulk pricing. By combining excellent pricing with these extra advantages, we ensure that our clients receive exceptional value in their slip ring investments. Whether for small-scale applications or large industrial systems, our slip rings are built to meet the highest standards of quality and reliability.

Types of 6-Wire Slip Rings & Price Ranges

6-wire slip rings come in various designs, each suited for different types of applications, depending on the requirements for size, power transmission, and durability. Below is a detailed breakdown of the different types of 6-wire slip rings, along with their price ranges and key features.

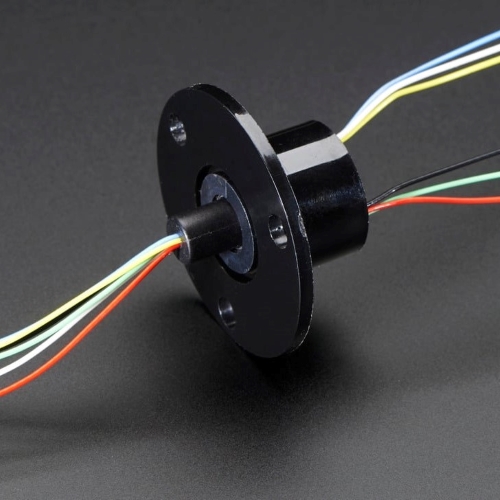

1. Standard 6-Wire Slip Ring

Standard 6-wire slip rings are the most commonly used type of slip ring in various industries. They are designed to transmit power and signals between stationary and rotating parts in a wide range of applications, such as industrial machinery, robotic arms, and commercial systems. These slip rings are often compact, easy to install, and versatile, making them suitable for applications that don’t require specialized designs or large current ratings.

Price Range:

The price of standard 6-wire slip rings generally falls between $30 and $300, depending on factors such as the material quality, current rating (e.g., 2A, 5A), and environmental protection features. The more standard the design and materials, the more affordable the slip ring tends to be. Entry-level models are more budget-friendly, while higher-end options with gold contacts or additional features (such as IP-rated housings) may cost more.Key Features:

- Simple design for basic applications.

- Wide range of current ratings (typically 2A to 10A).

- Often used in electronics, communications, and light industrial systems.

- Can be customized for various mounting configurations and wiring options.

- Basic housing materials such as aluminum or plastic.

2. Through Bore Slip Ring

Through bore slip rings feature a hollow shaft design that allows the passage of cables, hoses, or other components through the center of the slip ring. This design is particularly beneficial in applications where space inside the system is constrained or where additional components need to be integrated through the center of the rotating assembly. Through bore slip rings are widely used in industrial equipment, robotics, and machinery where the center of the slip ring must be accessible for other components.

Price Range:

Through bore slip rings typically range from $100 to $500 or more, depending on factors like the bore size, current rating, and materials used. Larger bore diameters or higher current capacities (e.g., 10A to 30A) will increase the cost. The price also varies based on the number of circuits and customization options.Key Features:

- Hollow center allows for the integration of additional components.

- Used in industrial robots, crane systems, and wind turbines.

- Flexible mounting and installation options.

- Suitable for applications requiring continuous rotation with additional cable or hose routing.

- Available in various sizes, from small bores (e.g., 20mm) to large bores (e.g., 150mm or more).

- Can be designed for higher current and voltage transmission.

3. Pancake Slip Ring

Pancake slip rings are characterized by their flat, compact design, making them ideal for applications where space is limited. These slip rings have a low profile, often resembling a “pancake,” and are typically used in applications that require a smaller form factor, such as aerial systems, compact robotics, and small machinery. Their design allows them to transmit power and signals while maintaining a low height, making them perfect for space-constrained environments.

Price Range:

Pancake slip rings are generally more expensive than standard models due to their compact size and specialized design. Prices typically range from $150 to $800, depending on factors such as the number of circuits, current rating (e.g., 2A to 10A), and the specific customization required for the application.Key Features:

- Ultra-compact design ideal for small or confined spaces.

- Low profile allows integration into tight installations where space is limited.

- Typically used in small, high-performance systems, including camera platforms, small machines, and robotics.

- Can transmit both power and data signals.

- Higher manufacturing precision is required, leading to higher prices.

- Generally available in sizes ranging from 2 to 6 inches in diameter, depending on the application.

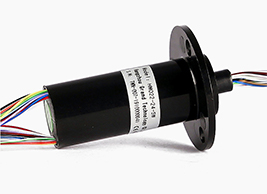

4. Hollow Shaft Slip Ring

Hollow shaft slip rings feature a design with a central hollow shaft, similar to through bore slip rings, but with added versatility and durability. These slip rings are made for industrial applications that demand high power transmission, durability, and flexibility. The hollow shaft design allows for the integration of other components through the center, making them particularly useful in systems with complex configurations, such as automated machinery, large-scale robotics, and wind turbines.

Price Range:

Hollow shaft slip rings typically fall within a price range of $200 to $1,500, depending on the specifications. Larger diameters and higher current ratings (e.g., 30A to 180A) push the price higher. Customizations, such as special materials (e.g., gold or silver contacts), can also affect the price.Key Features:

- High durability and versatility for demanding industrial applications.

- Suitable for high current and voltage transmission (e.g., 30A to 180A).

- Often used in heavy machinery, renewable energy applications, and automated systems.

- Provides additional integration space through the hollow shaft for cables or other components.

- Can be customized for environmental protection (e.g., IP-rated housings).

- Available in various sizes, typically ranging from 20mm to 100mm or more for larger applications.

Each type of 6-wire slip ring—whether it’s the standard, through bore, pancake, or hollow shaft design—comes with its unique features and price range, catering to different applications. The selection of the appropriate slip ring depends on the specific requirements of the application, including size, power capacity, design constraints, and durability needs. At Grand Slip Rings, we offer these various designs to meet the diverse needs of our customers, ensuring that they receive high-quality, reliable products at competitive prices.

Why 6-Wire Slip Rings Are Essential for Specific Applications

6-wire slip rings are crucial components in a variety of specialized applications where reliable power and signal transmission is required between stationary and rotating parts. Their versatility and performance make them indispensable in industries like wind energy, robotics, and automation. Below is a detailed breakdown of how 6-wire slip rings serve specific applications:

Wind Turbines: High-Current Models (e.g., 180A Kits) for Power Transmission

Wind turbines are complex systems that generate power by converting wind energy into electrical energy. They have rotating components like blades and a rotor that need to transmit large amounts of power back to the stationary electrical systems. Slip rings play a crucial role in transmitting the electrical power generated by the rotating blades to the fixed system, ensuring that power flows uninterrupted from the turbine to the grid or energy storage systems.

High Voltage Current Slip Ring:

Wind turbines require slip rings that can handle high currents due to the significant amount of electrical power involved. For example, 180A kits are designed to transmit large amounts of power generated by the turbine. These high-current slip rings are essential to avoid overheating, power loss, or signal degradation, which could compromise the efficiency and reliability of the system.Key Features:

- High Power Handling: 180A slip rings are capable of transmitting high current without excessive wear or loss of performance, ensuring that the turbine continues to operate smoothly.

- Durability: Wind turbines operate in challenging environments, often exposed to harsh weather conditions. High-current slip rings designed for these applications are built to withstand these elements, using corrosion-resistant materials and robust designs to ensure long-lasting performance.

- Continuous Rotation: Slip rings ensure continuous power transmission as the turbine blades rotate, offering seamless functionality without the need for complex wiring systems that would otherwise limit the range of movement.

Price Range:

The price of high-current models, such as 180A slip rings, typically ranges from $500 to $2,000 or more, depending on the design complexity and required specifications. These models often feature advanced materials, like gold or silver contacts, to maintain high performance in harsh conditions.

Robotics: Compact Pancake Slip Rings for Rotational Joints

Robotics is a field that relies heavily on precise motion control, especially when robots are required to perform tasks involving continuous or multi-directional movement. In robotics, slip rings are used to transfer electrical signals and power to and from the rotating parts of robotic arms, joints, or other actuators. Pancake slip rings are particularly suited for these types of applications due to their compact, flat design.

Compact Pancake Slip Rings:

Pancake slip rings are designed to take up minimal space while still offering reliable signal and power transmission. Their flat, low-profile design makes them perfect for robotic applications where there is a need to minimize the size of the components involved, especially in compact robotic joints or mobile platforms.Key Features:

- Space Efficiency: The slim, compact profile of pancake slip rings allows them to be integrated into small, confined spaces where conventional slip rings would not fit. This is especially crucial for robotic joints and platforms where size is a key consideration.

- Lightweight: Pancake slip rings are often lighter than other types of slip rings, which is important for applications like robotic arms or mobile robots, where weight reduction can improve performance and energy efficiency.

- High-Precision: Robotic applications often require high-precision and reliability in signal transmission. Pancake slip rings offer excellent performance for transferring power and data to sensitive robotic components, ensuring accurate control during operation.

Price Range:

Pancake slip rings are typically priced between $150 and $800, depending on their specifications such as the number of circuits, the current rating (e.g., 2A to 5A), and customization options. The compact design and precision required for robotics applications contribute to their higher cost compared to standard slip rings.

Automation: Through Bore Designs for Integrated Cabling

Automation systems often involve complex machinery with rotating parts, such as conveyor belts, robotic arms, or automated assembly lines. These systems require the seamless transmission of power, signals, and data between stationary and rotating components. Through bore slip rings are particularly well-suited for these applications because they allow for the integration of additional cables, hoses, or components through the center of the slip ring, making them ideal for systems with intricate wiring or multiple integrated components.

Through Bore Designs:

Through bore slip rings feature a hollow shaft, allowing cables or hoses to pass through the center of the slip ring while maintaining uninterrupted power and signal transmission. This is particularly useful in automation systems, where multiple components (such as power lines, control wires, or pneumatic tubes) may need to be routed through rotating parts.Key Features:

- Integration of Additional Components: The hollow design enables the passage of multiple cables, hoses, or other mechanical parts through the center, which is essential for automation systems that involve intricate setups with rotating elements.

- Versatility: Through bore slip rings can be customized to handle a variety of cables and components, making them extremely versatile for different automation needs. They can be tailored for applications requiring different voltages, signal types, or high-speed data transfer.

- Enhanced Space Utilization: By utilizing the central bore for additional components, these slip rings optimize space, allowing for cleaner and more organized systems in automation applications. This can lead to easier maintenance and less risk of damage to cables and connectors.

Price Range:

Through bore slip rings typically range from $100 to $500 or more, depending on the bore size, current rating, and additional customization. Larger bores or more advanced designs for heavy-duty automation systems can push the price upwards.

6-wire slip rings are essential components in applications such as wind turbines, robotics, and automation, where reliable, continuous power and signal transmission are required for rotating systems. The specific design of each slip ring, whether it’s a high-current model for power transmission, a compact pancake slip ring for rotational joints, or a through bore slip ring for integrated cabling, ensures that these systems function efficiently and effectively in their respective industries. By selecting the right type of slip ring for each application, businesses can improve the reliability, performance, and longevity of their systems.

Grand Slip Rings’Competitive Edge

At Grand Slip Rings, we take pride in providing high-quality, tailored solutions for every application, setting ourselves apart from the competition. Our comprehensive approach combines customization, superior materials, cost-effectiveness, and exceptional customer support, making us a trusted partner for all slip ring needs. Below, we outline the key aspects of Grand Slip Rings’ competitive edge.

Custom Solutions: Tailored 6-Wire Slip Rings for Unique Voltage/Current Needs

One of the key differentiators for Grand Slip Rings is our ability to provide customized slip rings that meet the specific voltage, current, and other technical requirements of our customers. We understand that each system has unique needs, whether it’s handling higher current loads, managing specific voltages, or integrating additional components. This flexibility allows us to deliver solutions that fit seamlessly into a wide variety of industrial, commercial, and specialized applications.

Tailored Design:

We work closely with our clients to understand the exact requirements of their systems, whether they need a slip ring to handle 2A or 180A or require specific configurations for optimal power and signal transmission. Our team of engineers ensures that every slip ring is designed to meet the precise technical specifications, including factors such as current, voltage, number of circuits, and even environmental protection.Benefits:

- Increased reliability and efficiency through exact specifications.

- Enhanced performance for specialized applications.

- More flexible integration for systems with complex wiring or unique constraints.

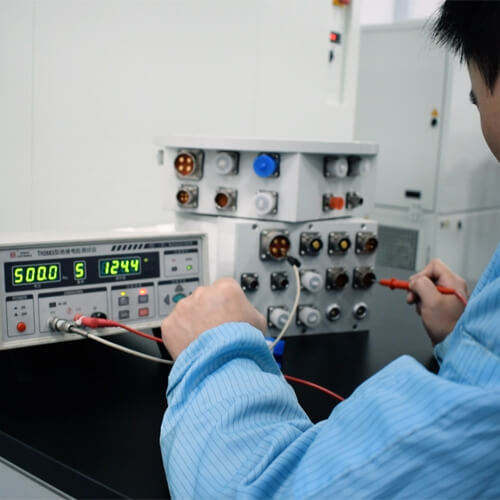

Quality Assurance: Durable Materials (Gold Contacts, IP-Rated Waterproofing)

At Grand Slip Rings, we prioritize quality and longevity. We use only the best materials to ensure that our slip rings deliver reliable performance in even the most challenging environments. Whether it’s high-current transmission or environments with high humidity or harsh conditions, our slip rings are built to last.

Gold Contacts:

Gold is known for its exceptional conductivity, resistance to corrosion, and long lifespan. We use gold contacts in our slip rings to ensure superior signal and power transmission without the issues of oxidation or degradation. This makes them ideal for precision-driven industries such as robotics, aerospace, and medical equipment, where high reliability is essential.IP-Rated Waterproofing:

For systems operating in wet or exposed environments, we offer slip rings with IP-rated waterproofing. This feature ensures that the slip rings can withstand exposure to moisture, dust, and other environmental factors without compromising their functionality or longevity.Benefits:

- Enhanced durability and longevity in harsh environments.

- Superior conductivity and consistent performance over time.

- Protection against environmental factors, increasing operational reliability.

Cost-Effectiveness: Price Matching or Bulk Discounts

While quality is a major factor in the value of our slip rings, we also strive to provide our customers with competitive pricing. We understand that cost is a key consideration, especially for businesses with tight budgets or large-scale orders. Grand Slip Rings offers price matching or bulk discounts to ensure that our customers get the best possible value for their investment.

Price Matching:

If you find a comparable product from another manufacturer at a lower price, we will match or beat that price, ensuring that you don’t have to compromise on quality for affordability. We believe that cost-effective pricing should not come at the expense of product reliability or performance.Bulk Discounts:

For larger orders, such as for industrial applications or ongoing projects, we offer substantial discounts. Ordering in bulk allows our customers to save on overall costs, making our slip rings an even more affordable option for large-scale businesses or projects.Benefits:

- Cost-effective solutions that don’t sacrifice quality.

- Flexibility in pricing based on volume or competitive offerings.

- Long-term savings on large orders, reducing overall project costs.

Warranty & Support: Compare with Generic Retailers Lacking After-Sales Service

At Grand Slip Rings, we believe in building lasting relationships with our customers through exceptional after-sales support and strong warranty policies. Unlike generic retailers who may offer limited or no support, we provide comprehensive warranty coverage and personalized customer service to ensure that your systems continue to perform optimally.

Warranty:

Our slip rings come with an industry-leading warranty that covers defects in materials and workmanship. This warranty gives our customers peace of mind knowing that if any issues arise, we will address them promptly. Whether it’s a standard or customized slip ring, our warranty ensures that we stand behind our products.Technical Support:

We provide ongoing technical support to help our clients with any issues they might face during installation, operation, or maintenance. Our dedicated support team is available to answer questions, troubleshoot problems, and guide customers through optimal installation practices.Benefits:

- Peace of mind with a strong warranty backing.

- Personalized, ongoing support from our experienced team.

- Fast response times to address any issues quickly, minimizing downtime.

Grand Slip Rings offers a competitive edge in the market by providing custom solutions tailored to the specific needs of each customer, using high-quality materials to ensure durability and performance, and offering cost-effective pricing through price matching and bulk discounts. Our commitment to exceptional after-sales service, including industry-leading warranties and technical support, sets us apart from generic retailers who may lack such comprehensive services. By choosing Grand Slip Rings, businesses gain a reliable partner that prioritizes quality, performance, and customer satisfaction, ensuring that systems continue to operate seamlessly in the long term.

Tips for Choosing the Right 6-Wire Slip Ring

Choosing the right 6-wire slip ring is essential for ensuring the efficiency, reliability, and longevity of your system. Slip rings are critical components in rotating systems, and selecting the right one involves understanding the specific needs of your application. Here are some important tips to guide you through the selection process:

Match Specs (Current, Voltage, RPM) to Your Application

One of the most crucial factors in selecting a 6-wire slip ring is ensuring that its specifications—such as current rating, voltage, and rotational speed (RPM)—align with the demands of your system. A slip ring that cannot handle the required current or voltage could lead to inefficiency, overheating, or failure, while one with a higher rating than necessary may be over-engineered and result in unnecessary costs.

Current Rating:

Ensure the slip ring can handle the specific current load your system requires. For instance, a system with a low-power motor might only need a slip ring rated for 2A to 10A, while high-power applications such as wind turbines or industrial machinery may need slip rings rated for 30A or higher.Voltage:

Confirm that the voltage rating of the slip ring matches or exceeds the voltage required by your system. Using a slip ring rated for lower voltage than your system needs can result in short circuits or component damage.RPM:

The rotational speed of your system is another critical factor. Slip rings are designed to handle different levels of RPM. If the slip ring is used in high-speed applications, it must be able to function properly at the required rotational speed without degrading signal or power transmission.Benefit:

Matching these specifications ensures that the slip ring will function efficiently, avoid system failures, and contribute to the longevity of the system.

Prioritize Durability for Harsh Environments (e.g., Wind Turbines)

Certain applications, such as wind turbines, industrial equipment, or outdoor systems, operate in harsh or extreme environments. For these applications, durability is essential. Slip rings used in these environments must be able to withstand factors like extreme temperatures, humidity, dust, moisture, and mechanical wear.

Materials:

Select slip rings made from durable materials like corrosion-resistant stainless steel or IP-rated waterproofing for protection against dust, water, and other environmental contaminants. Slip rings with gold contacts offer superior resistance to corrosion and degradation, ensuring long-term performance even in challenging environments.Environmental Protection:

For applications exposed to moisture or corrosive environments (e.g., offshore wind turbines), look for slip rings with an IP (Ingress Protection) rating, which indicates their resistance to water and dust penetration. A high IP rating, such as IP65 or IP68, ensures the slip ring remains operational in harsh conditions.Benefit:

By prioritizing durability, you can ensure that the slip ring maintains reliable performance and longevity, reducing the likelihood of system downtime or failure, which is critical in outdoor and heavy-duty applications.

Compare Prices but Avoid Compromising on Critical Features

While cost is an important consideration, it’s essential not to compromise on critical features when selecting a slip ring. Opting for a cheaper slip ring that lacks essential specifications or durability could lead to increased maintenance costs, system failures, or even equipment damage over time.

Features vs. Price:

When comparing prices, ensure that the slip rings meet your required specifications for current, voltage, RPM, and environmental durability. It’s also important to check if they come with features like gold contacts or IP-rated housings, which enhance the slip ring’s performance and lifespan. While these features might increase the initial price, they could save money in the long term by reducing maintenance and improving overall system reliability.Balance Quality and Cost:

Instead of choosing the cheapest option, focus on value for money. Invest in a high-quality slip ring that meets your needs without overpaying for unnecessary features. For example, Grand Slip Rings offers competitively priced models that balance cost with performance, ensuring you get the best value without sacrificing essential features.Benefit:

This approach guarantees that you get the performance, reliability, and longevity you need, without risking additional costs from subpar components.

Consider Future Scalability (e.g., Grand Slip Rings’ Upgradeable Designs)

As your system evolves or your project grows, it’s important to consider the scalability of the slip ring you choose. Will your current slip ring be able to meet the future demands of your system, or will you need to replace it as your needs change? Future scalability is especially important in industries with rapidly changing technologies or expanding systems.

Upgradeability:

Look for slip rings that can be easily upgraded as your system requirements evolve. Grand Slip Rings offers upgradeable designs that allow you to adapt your system by adding more circuits or adjusting the current and voltage ratings without needing to replace the entire slip ring assembly. This scalability ensures that your slip ring can grow with your application, saving you costs and time in the future.Modular Designs:

Some slip rings are designed with modular components, allowing you to customize or expand the system as needed. This flexibility is especially important for industrial systems or complex automation setups, where future expansion is likely.Benefit:

By choosing a slip ring that can be easily scaled or upgraded, you ensure that your investment remains valuable and that your system can evolve without the need for costly replacements or major modifications.

When selecting the right 6-wire slip ring for your application, it’s important to consider key factors such as matching the specifications (current, voltage, RPM), prioritizing durability for harsh environments, comparing prices while ensuring critical features are not compromised, and considering future scalability. By focusing on these elements, you can ensure that your slip ring will perform optimally and efficiently, providing long-term reliability for your system. Grand Slip Rings offers tailored solutions that meet these needs, combining high-quality materials, customization options, and future-proof designs to provide the best value for your application.

FAQs about 6-Wire Slip Ring Price

Q: What is the difference between a collector ring and a slip ring?

A: Collector rings and slip rings are both electromechanical devices used to transmit power and electrical signals between stationary and rotating parts of a machine. However, they serve slightly different purposes and are often used in different contexts.

A slip ring is a more general term that refers to any device that allows the transmission of power and electrical signals from a stationary structure to a rotating one. Slip rings are commonly used in applications where continuous rotation is required, such as in wind turbines, radar systems, and rotating cameras. They are designed to maintain electrical connectivity while the rotating part moves, ensuring uninterrupted power or signal transmission. Slip rings can handle both power and data signals, making them versatile in various industries.

On the other hand, a collector ring is a specific type of slip ring that is primarily used in DC motors and generators. Collector rings are responsible for collecting electrical current from the rotating part of the machine (the rotor) and transferring it to the stationary part (the stator). In DC machines, collector rings are often paired with brushes that make physical contact with the rings to ensure electrical continuity. Over time, the brushes wear down due to friction, which is a common maintenance issue in devices using collector rings.

Q: Do DC motors use slip rings?

A: DC motors typically do not use slip rings; instead, they use a component called a commutator. The commutator serves a similar purpose to slip rings but is specifically designed for DC motors. It is a segmented ring that works in conjunction with brushes to reverse the direction of current flow in the rotor windings as the motor rotates. This reversal of current is essential for maintaining continuous rotation in a DC motor.

However, there are some exceptions. For example, certain types of AC motors, such as wound-rotor induction motors, use slip rings to transfer power to the rotor windings. In these motors, the slip rings are used to control the rotor’s resistance, which allows for better control of the motor’s speed and torque. In contrast, DC motors rely on the commutator to achieve the same goal.

Q: How long do slip rings last?

A: The lifespan of slip rings varies significantly depending on several factors, including the quality of materials used, the operating environment, the amount of electrical current being transmitted, and the rotational speed of the application. On average, a well-maintained slip ring can last anywhere from 5 to 20 years.

In industrial applications, where slip rings are subjected to high loads and harsh conditions, their lifespan may be on the lower end of this range. For example, slip rings used in wind turbines or heavy machinery may require replacement after 5 to 10 years due to slip ring wear and tear caused by continuous operation and exposure to environmental factors like dust, moisture, and temperature fluctuations.

On the other hand, slip rings used in less demanding applications, such as in medical equipment or low-speed rotating cameras, can last much longer—up to 20 years or more. Regular maintenance, such as cleaning the rings and replacing worn-out brushes, can significantly extend their lifespan.

The materials used in the construction of slip rings also play a crucial role in determining their durability. For instance, slip rings made with high-quality conductive materials like gold or silver plating tend to last longer than those made with cheaper materials. Additionally, modern slip rings often incorporate advanced designs, such as fiber optic rotary joints or wireless transmission systems, which can further enhance their longevity.

Q: What is the problem with the slip ring?

A: Slip rings, while essential for transmitting power and signals in rotating systems, are not without their challenges. One of the most common problems with slip rings is wear and tear due to the constant friction between the rotating rings and the stationary brushes. Over time, this friction can cause the brushes to wear down, leading to poor electrical contact, increased resistance, and eventual failure of the slip ring assembly.

Another issue is electrical noise or interference, which can occur due to the imperfect contact between the brushes and the rings. This noise can disrupt signal transmission, particularly in applications where high-precision data transfer is required, such as in medical imaging or telecommunications.

Environmental factors also pose significant challenges. Slip rings used in outdoor or industrial settings are often exposed to dust, moisture, and extreme temperatures, which can accelerate wear and corrosion. For example, in wind turbines, slip rings are exposed to harsh weather conditions, which can lead to premature failure if not properly sealed or maintained.

Maintenance requirements are another concern. Slip rings require regular inspection and cleaning to ensure optimal performance. Neglecting maintenance can lead to the buildup of debris or oxidation on the rings, further exacerbating wear and electrical issues.

Finally, design limitations can also be a problem. Traditional slip rings have a finite number of circuits they can support, which can be a limitation in complex systems requiring multiple power and signal channels. However, advancements in technology, such as the development of fiber optic slip rings and wireless transmission systems, are helping to address some of these limitations.

Q: What is the best material for a slip ring?

A: The choice of material for a slip ring depends on the specific application and the requirements for conductivity, durability, and environmental resistance. However, some materials are commonly regarded as the best due to their superior properties.

Gold is often considered the best material for slip rings, especially in applications requiring high reliability and low slip ring electrical noise. Gold has excellent conductivity and is highly resistant to corrosion and oxidation, making it ideal for use in environments where moisture or chemical exposure is a concern. Additionally, gold-plated slip rings provide a smooth surface that reduces friction and wear, extending the lifespan of the brushes and rings.

Silver is another popular choice, particularly in high-current applications. Silver has the highest electrical conductivity of all metals, making it ideal for transmitting large amounts of power. However, silver is more prone to oxidation than gold, which can lead to increased resistance and electrical noise over time. To mitigate this, silver slip rings are often used in sealed environments or coated with protective layers.

Copper is also widely used in slip rings due to its good conductivity and relatively low cost. However, copper is more susceptible to corrosion and wear compared to gold and silver, making it less suitable for high-reliability applications. Copper slip rings are often used in industrial settings where cost is a primary concern.

For the brushes, graphite or metal-graphite composites are commonly used due to their self-lubricating properties and ability to withstand high temperatures. These materials help reduce friction and wear, ensuring smooth operation and longer lifespan.

Q: What is the life expectancy of a slip ring?

A: The life expectancy of a slip ring can vary widely depending on factors such as the quality of materials, operating conditions, maintenance practices, and the specific application. On average, a well-designed and properly maintained slip ring can last anywhere from 5 to 20 years.

In industrial applications, where slip rings are subjected to high loads, continuous operation, and harsh environmental conditions, their lifespan may be on the lower end of this range. For example, slip rings used in wind turbines or heavy machinery may require replacement after 5 to 10 years due to wear and tear caused by friction, dust, moisture, and temperature fluctuations.

In contrast, slip rings used in less demanding applications, such as in medical equipment or low-speed rotating cameras, can last much longer—up to 20 years or more. Regular maintenance, such as cleaning the rings and replacing worn-out brushes, can significantly extend their lifespan.

The materials used in the construction of slip rings also play a crucial role in determining their durability. For instance, slip rings made with high-quality conductive materials like gold or silver plating tend to last longer than those made with cheaper materials. Additionally, modern slip rings often incorporate advanced designs, such as fiber optic rotary joints or wireless transmission systems, which can further enhance their longevity.

Q: How many slip rings does an alternator have?

A: The number of slip rings in an alternator depends on the type of alternator and its design. In most standard alternators, particularly those used in automotive applications, there are two slip rings. These slip rings are connected to the rotor windings and are responsible for supplying the DC excitation current needed to generate the magnetic field in the rotor.

In more complex alternators, such as those used in industrial or power generation applications, the number of slip rings can vary. For example, some alternators may have additional slip rings to accommodate auxiliary functions or to provide redundancy in case of failure.

Q: What is the function of a slip ring in a CT scan?

A: In a CT (computed tomography) scanner, the slip ring plays a critical role in enabling the continuous rotation of the gantry, which houses the X-ray tube and detectors. The slip ring allows for the transmission of power and electrical signals between the stationary part of the machine (the stator) and the rotating part (the rotor).

Without a slip ring, the gantry would need to stop and reverse direction after each rotation, which would significantly slow down the imaging process and limit the scanner’s ability to capture detailed, real-time images. The slip ring ensures that the gantry can rotate continuously, allowing for faster and more efficient scanning.

In addition to transmitting power, the slip ring also facilitates the transfer of data from the rotating detectors to the stationary computer system. This data is then processed to create the detailed cross-sectional images that are the hallmark of CT scans.

Q: Why do we need slip rings?

A: Slip rings are essential in any application where electrical power or signals need to be transmitted between a stationary and a rotating structure. Without slip rings, it would be impossible to maintain a continuous electrical connection in rotating systems, which would severely limit the functionality of many machines and devices.

For example, in wind turbines, slip rings are used to transmit power from the rotating blades to the stationary generator. In radar systems, they allow the antenna to rotate continuously while maintaining electrical connectivity. In medical imaging equipment, such as CT scanners, slip rings enable the gantry to rotate without interruption, allowing for faster and more efficient scanning.

Slip rings also play a crucial role in industrial machinery, robotics, and even entertainment systems, such as rotating cameras and stages. They ensure that power and data can be transmitted seamlessly, regardless of the rotational movement.

Q: How does a wire slip ring work?

A: A wire slip ring, also known as a capsule slip ring, is a compact device designed to transmit electrical signals and power between stationary and rotating parts of a machine. It consists of a stationary part (the stator) and a rotating part (the rotor), which are connected by a set of wires or conductive rings.

The working principle of a wire slip ring is relatively simple. The stationary part of the slip ring is connected to the power source or signal transmitter, while the rotating part is connected to the load or receiver. As the rotor rotates, the conductive rings or wires maintain continuous electrical contact with the stationary brushes, allowing for the uninterrupted transmission of power or signals.

Wire slip rings are commonly used in applications where space is limited, such as in small motors, robotics, and medical devices. They are designed to be compact and lightweight, making them ideal for use in portable or handheld equipment.

A wire slip ring works by maintaining continuous electrical contact between stationary and rotating parts, allowing for the transmission of power and signals in compact and space-constrained applications.

Q: How many slip rings were present in spiral CT?

A: In spiral or helical CT scanners, the number of slip rings can vary depending on the specific design and manufacturer. However, most modern spiral CT scanners use multiple slip rings to facilitate the continuous rotation of the gantry and the transmission of power and data.

Typically, a spiral CT scanner will have at least two slip rings: one for transmitting power to the rotating X-ray tube and another for transmitting data from the rotating detectors to the stationary computer system. Some scanners may have additional slip rings to accommodate auxiliary functions or to provide redundancy in case of failure.

The use of slip rings in spiral CT scanners is essential for enabling continuous rotation, which allows for faster and more efficient scanning. Without slip rings, the gantry would need to stop and reverse direction after each rotation, which would significantly slow down the imaging process.

Most spiral CT scanners use multiple slip rings to enable continuous rotation and efficient data transfer.

Q: What is the effect of slip rings?

A: The primary effect of slip rings is to enable the continuous transmission of electrical power and signals between stationary and rotating parts of a machine. This has several important implications for the performance and functionality of the machine.

First, slip rings allow for continuous rotation, which is essential in applications such as wind turbines, radar systems, and CT scanners. Without slip rings, these machines would need to stop and reverse direction after each rotation, which would significantly reduce their efficiency and effectiveness.

Second, slip rings facilitate the transmission of data in addition to power. This is particularly important in applications such as medical imaging, where high-precision data transfer is required to create detailed images. Slip rings ensure that data can be transmitted seamlessly, regardless of the rotational movement.

Third, slip rings can reduce wear and tear on the machine by eliminating the need for cables or wires that would otherwise become tangled or damaged due to continuous rotation. This can extend the lifespan of the machine and reduce maintenance requirements.

However, slip rings also have some potential drawbacks, such as the risk of wear and tear due to friction between the rings and brushes, as well as the potential for electrical noise or interference. Proper design, material selection, and maintenance can help mitigate these issues.

Q: What are the rings in a CT scan?

A: The “rings” in a CT scan refer to the gantry, which is the large, circular structure that houses the X-ray tube and detectors. The gantry is a critical component of the CT scanner, as it allows for the rotation of the X-ray tube and detectors around the patient, enabling the capture of detailed cross-sectional images.

The gantry contains several key components, including the slip rings, which allow for the continuous rotation of the gantry without the need for stopping and reversing direction. The slip rings transmit power to the rotating X-ray tube and detectors, as well as facilitate the transfer of data from the detectors to the stationary computer system.

In addition to the slip rings, the gantry also contains the X-ray tube, which generates the X-rays used to create the images, and the detectors, which capture the X-rays after they pass through the patient’s body. The data collected by the detectors is then processed by the computer system to create the detailed images that are used for diagnosis.