In the realm of electrical engineering and industrial automation, innovations continue to shape the way we connect and transmit power. One such breakthrough is the Mercury Slip Ring Connector, a cutting-edge technology that promises to revolutionize electrical connectivity in a multitude of applications. With its ability to transmit high-speed data and power across rotating interfaces, this groundbreaking connector is poised to enhance the efficiency and reliability of various industries. Let’s delve into the inner workings and potential applications of the Mercury Slip Ring Connector.

Unleashing the Power of Mercury Slip Ring Connector

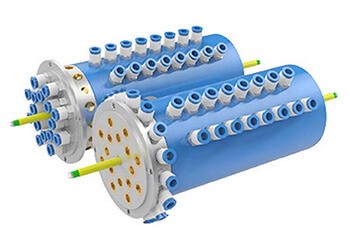

The Mercury Slip Ring Connector is an ingenious device that enables the transmission of electrical signals, power, and data across rotating interfaces. Its unique design incorporates a conductive Mercury pool, which acts as a seamless conductor for electrical current. Unlike traditional slip rings that rely on brush contacts, the Mercury Slip Ring Connector offers significantly reduced electrical noise, enhanced signal integrity, and increased durability.

How It Works

At the heart of the Mercury Slip Ring Connector lies a precisely engineered rotating assembly. The assembly consists of a rotating platform that hosts the Mercury pool, surrounded by a series of concentric rings carrying electrical signals. As the assembly rotates, the electrical current and data seamlessly transfer between stationary and rotating components without interruption, thanks to the conductive properties of Mercury.

Types of Mercury Slip Ring Connector

Mercury slip ring connectors come in various types, each designed to meet specific application requirements. The primary types of mercury slip ring connectors include:

Standard Mercury Slip Ring Connectors

- Description: These are the most common type and are used for general-purpose applications where reliable electrical connection and low-resistance contact are required.

- Applications: Industrial machinery, robotics, and automation systems.

High-Frequency Mercury Slip Ring Connectors

- Description: Designed to handle high-frequency signals with minimal loss and interference.

- Applications: Medical imaging equipment, communication systems, and high-speed data transmission.

High-Current Mercury Slip Ring Connectors

- Description: Built to carry high current loads with low electrical noise and high reliability.

- Applications: Heavy machinery, power generation equipment, and electric motors.

Miniature Mercury Slip Ring Connectors

- Description: Compact and lightweight, suitable for applications with space constraints.

- Applications: Small electronic devices, precision instruments, and compact robotics.

Custom Mercury Slip Ring Connectors

- Description: Tailored to specific customer requirements, these slip rings can be customized in terms of size, number of circuits, and other specifications.

- Applications: Specialized industrial equipment, custom automation solutions, and unique electronic devices.

Key Features of Each Type

Standard Mercury Slip Ring Connectors:

- Feature: Reliable performance with standard electrical characteristics.

- Advantage: Versatile and cost-effective for general applications.

High-Frequency Mercury Slip Ring Connectors:

- Feature: Designed for minimal signal loss and interference.

- Advantage: Ensures high fidelity in signal transmission, crucial for sensitive equipment.

High-Current Mercury Slip Ring Connectors:

- Feature: Capable of handling high power loads with stability.

- Advantage: Suitable for demanding applications requiring robust power transmission.

Miniature Mercury Slip Ring Connectors:

- Feature: Small form factor and lightweight.

- Advantage: Ideal for applications with limited space and weight restrictions.

Custom Mercury Slip Ring Connectors:

- Feature: Fully customizable to meet specific needs.

- Advantage: Provides tailored solutions for unique application requirements.

Considerations for Choosing the Right Type

- Application Requirements:

- Determine the electrical and mechanical specifications needed for your application.

- Environmental Conditions:

- Consider factors such as temperature, humidity, and exposure to contaminants.

- Space and Weight Constraints:

- Assess the available space and weight limitations of your system.

- Signal and Power Needs:

- Evaluate the type and amount of signals or power that need to be transmitted.

- Customization Needs:

- Determine if a standard slip ring can meet your requirements or if a custom solution is necessary.

By understanding the different types of mercury slip ring connectors and their specific features, you can select the most suitable one for your application, ensuring optimal performance and reliability.

Applications in Modern Industries

Robotics and Automation: In the rapidly evolving field of robotics and automation, the Mercury Slip Ring Connector can provide reliable electrical connectivity to robotic arms, allowing them to rotate freely without worrying about cable entanglement. This breakthrough technology enhances the performance and agility of robots in industrial settings, improving productivity and safety.

Wind Turbines: Wind turbines require a reliable means of transmitting power and data from the rotating blades to the stationary components. The Mercury Slip Ring Connector eliminates the limitations posed by traditional slip rings, enabling efficient power transfer and real-time data acquisition, which, in turn, facilitates better monitoring and maintenance of wind turbine systems.

Medical Equipment: Medical devices often rely on the seamless transmission of electrical signals during procedures or diagnostics. The Mercury Slip Ring Connector ensures uninterrupted power supply and data transmission in medical imaging systems, surgical robots, and other critical medical equipment, improving patient care and safety.

Aerospace and Defense: The aerospace and defense sectors demand highly reliable and durable electrical connections in aircraft, radar systems, and missile guidance systems. The Mercury Slip Ring Connector’s robust design and low electrical noise make it an ideal solution for these applications, enhancing system performance and mission success.

Benefits and Advantages

a. Enhanced Reliability: With its brushless design and the absence of mechanical wear, the Mercury Slip Ring Connector offers unparalleled reliability and longevity, reducing maintenance costs and downtime.

b. Reduced Electrical Noise: The elimination of brush contacts minimizes electrical noise and signal interference, resulting in improved signal integrity and data accuracy.

c. Increased Bandwidth: The Mercury Slip Ring Connector enables high-speed data transfer, making it suitable for applications that require extensive data transmission, such as high-definition video surveillance systems and data-intensive industrial processes.

d. Compact and Lightweight: The compact size and lightweight nature of the Mercury Slip Ring Connector make it suitable for various space-constrained applications, where traditional slip rings may pose size and weight limitations.

The introduction of the Mercury Slip Ring Connector marks a significant leap forward in electrical connectivity technology. With its brushless design, seamless power transmission, and reduced electrical noise, this innovative connector is poised to transform a myriad of industries. From robotics and wind energy to medical equipment and aerospace systems, the Mercury Slip Ring Connector offers improved reliability, enhanced performance, and greater efficiency. As technology continues to advance, the Mercury Slip Ring Connector represents a vital component in the pursuit of a more connected and electrified future.

Selection & Installation Considerations of Mercury Slip Ring Connector

Mercury slip ring connectors are critical components used in various applications requiring the transmission of electrical signals or power from a stationary part to a rotating structure. When selecting and installing these connectors, several considerations should be taken into account to ensure optimal performance and safety.

Selection Considerations

- Application Requirements:

- Current & Voltage Ratings: Determine the maximum current and voltage the slip ring will need to handle.

- Signal Types: Identify whether the application involves the transmission of analog, digital signals, or power.

- Speed of Rotation: Consider the operational speed, as higher speeds may require specialized designs to maintain contact integrity.

- Environmental Factors:

- Temperature Range: Ensure the slip ring can operate within the expected temperature range of the application.

- Humidity & Moisture: Consider slip rings with appropriate seals if the environment is humid or exposed to moisture.

- Contaminants & Cleanliness: In environments with dust, chemicals, or other contaminants, select slip rings with adequate protection or enclosures.

- Mechanical Specifications:

- Size & Weight: Choose a slip ring that fits the spatial constraints and weight limitations of your system.

- Mounting Configuration: Verify the compatibility of the mounting options with your existing setup.

- Durability & Maintenance:

- Life Span: Look for slip rings with a long operational life to minimize maintenance and replacements.

- Maintenance Requirements: Consider the ease of maintenance and availability of replacement parts.

Installation Considerations

- Proper Alignment:

- Ensure the slip ring is properly aligned to avoid undue stress and wear on the contacts, which can lead to premature failure.

- Secure Mounting:

- Use appropriate mounting hardware to securely attach the slip ring to prevent any movement during operation, which can cause damage or signal loss.

- Wiring & Connections:

- Follow manufacturer guidelines for wiring to avoid issues with signal integrity or power transmission.

- Use appropriate cable management to prevent tangling or abrasion of wires.

- Testing & Calibration:

- After installation, perform thorough testing to ensure the slip ring operates correctly.

- Regularly calibrate the system to maintain optimal performance.

- Safety Precautions:

- Be mindful of the potential hazards associated with mercury. Handle with care and follow all safety guidelines to prevent exposure or spillage.

- Ensure the installation area is well-ventilated and that all personnel are trained in handling mercury.

- Regular Maintenance:

- Schedule regular inspections and maintenance to detect any wear or damage early.

- Keep detailed records of maintenance activities to track the slip ring’s performance over time.

By carefully considering these selection and installation factors, you can ensure that your mercury slip ring connectors operate efficiently and safely in your application.

Safety & Environmental Concerns of Mercury Slip Ring Connector

Mercury slip ring connectors are known for their reliability and efficiency in transmitting electrical signals and power. However, their use of mercury raises several safety and environmental concerns that must be addressed to ensure safe operation and minimize environmental impact.

Safety Concerns

- Mercury Exposure:

- Hazard: Mercury is a toxic substance that can be harmful if inhaled, ingested, or absorbed through the skin.

- Precautions:

- Handle with care and use protective equipment such as gloves and masks.

- Ensure proper ventilation in areas where mercury slip rings are used or serviced.

- Train personnel on the hazards of mercury and appropriate handling procedures.

- Leakage and Spills:

- Hazard: Accidental leakage or spillage of mercury can lead to contamination and health risks.

- Precautions:

- Regularly inspect slip rings for signs of wear, damage, or leaks.

- Use containment measures and spill kits designed for mercury to quickly address any leaks.

- Dispose of contaminated materials according to local regulations.

- Fire and Explosion Risk:

- Hazard: Mercury can react with certain materials, potentially leading to fire or explosion hazards.

- Precautions:

- Avoid contact with incompatible materials such as acetylene, ammonia, and certain metals.

- Store mercury slip rings away from heat sources and flammable materials.

- Electrical Safety:

- Hazard: Improper installation or maintenance can lead to electrical hazards, including shocks and short circuits.

- Precautions:

- Follow manufacturer guidelines for installation and maintenance.

- Ensure proper grounding and insulation of the slip ring and associated components.

- Conduct regular electrical safety inspections.

Environmental Concerns

- Mercury Pollution:

- Impact: Mercury released into the environment can contaminate water, soil, and air, posing a risk to wildlife and human health.

- Mitigation:

- Implement strict controls to prevent mercury leaks and spills.

- Use mercury slip rings only when necessary and consider alternatives with lower environmental impact.

- Follow proper disposal procedures for mercury-containing equipment and materials.

- Disposal and Recycling:

- Impact: Improper disposal of mercury slip rings can lead to environmental contamination.

- Mitigation:

- Dispose of mercury-containing equipment through certified hazardous waste disposal facilities.

- Recycle mercury and other materials whenever possible to reduce environmental impact.

- Comply with local, national, and international regulations regarding mercury disposal.

- Regulatory Compliance:

- Requirement: Adhere to environmental regulations and standards governing the use and disposal of mercury.

- Actions:

- Stay informed about relevant regulations such as the Minamata Convention on Mercury and local environmental laws.

- Implement compliance programs to ensure adherence to all applicable standards and guidelines.

Best Practices for Safety and Environmental Protection

- Education and Training:

- Educate and train employees on the safe handling, use, and disposal of mercury slip rings.

- Provide regular updates and refresher courses on safety protocols and environmental regulations.

- Monitoring and Maintenance:

- Establish a routine inspection and maintenance schedule to identify and address potential issues early.

- Use monitoring equipment to detect mercury levels in the environment and workplace.

- Emergency Preparedness:

- Develop and implement emergency response plans for mercury spills and exposures.

- Equip facilities with appropriate emergency equipment and supplies, such as spill kits and personal protective equipment (PPE).

- Alternative Solutions:

- Consider using non-mercury slip ring alternatives where feasible to reduce health and environmental risks.

- Evaluate new technologies and materials that offer safer and more environmentally friendly options.

By addressing these safety and environmental concerns through careful handling, regular maintenance, and adherence to regulations, you can mitigate the risks associated with mercury slip ring connectors and ensure a safer and more sustainable operation.

See What We Can Do