Slip ring motors have long been a cornerstone of electrical engineering, powering a vast array of applications across industries. Today, we dive into the fascinating world of slip ring motors, examining their advantages and disadvantages. This exploration promises to shed light on the capabilities and limitations of these motors, providing valuable insights for engineers, manufacturers, and industry professionals.

The advantages of slip ring motors lie in their unique design and performance characteristics. These motors offer:

High Starting Torque: Slip ring motors are known for their ability to deliver high starting torque, making them well-suited for applications that require the acceleration of heavy loads. The ability to handle significant starting torque ensures efficient operation in various industrial settings, from conveyor belts to pumps and crushers.

Speed Control: Slip ring motors provide excellent speed control capabilities. By adjusting the resistance connected to the rotor windings through the slip rings, engineers can precisely control the motor’s speed. This versatility allows slip ring motors to adapt to different operating conditions, making them ideal for applications that demand variable speeds and precise control, such as cranes, mills, and hoists.

Flexibility: Slip ring motors offer a higher degree of flexibility compared to other motor types. The external resistance connected to the rotor windings can be adjusted, allowing for changes in torque characteristics and starting current. This adaptability makes slip ring motors suitable for a wide range of applications that require customizable performance.

Suitability for Harsh Environments: Slip ring motors are robust and can withstand harsh operating conditions. They are designed to handle high temperatures, dust, humidity, and other challenging environments commonly found in industrial settings. Their rugged construction ensures reliability and longevity, minimizing maintenance requirements and downtime.

While slip ring motors possess numerous advantages, it is important to consider their disadvantages as well. Some notable limitations include:

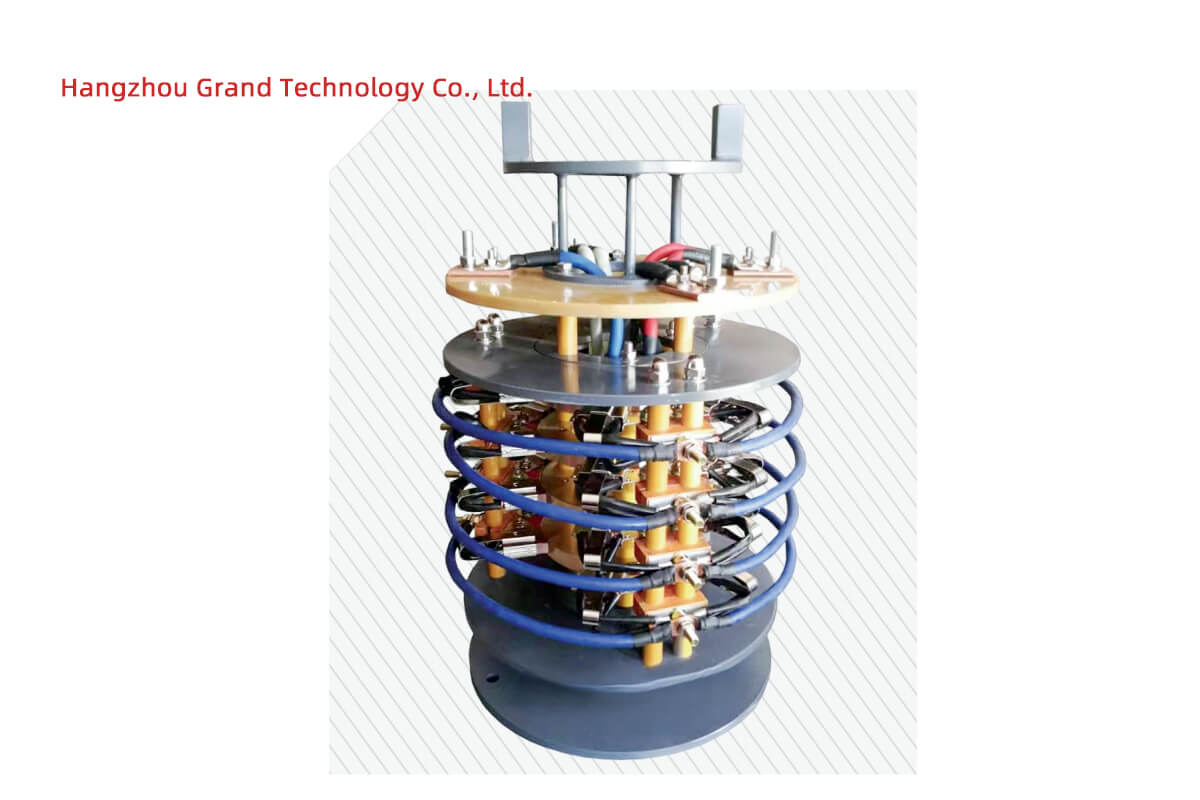

Complex Construction: Slip ring motors have a more intricate design compared to other motor types, such as squirrel cage motors. The presence of slip rings, brushes, and external resistance adds complexity to the motor’s construction and maintenance. This complexity can increase the initial cost of the motor and require additional care during operation and maintenance.

Higher Maintenance Requirements: Slip ring motors require regular inspection and maintenance due to the presence of slip rings and brushes. The brushes can wear out over time and may need to be replaced periodically. Additionally, the slip rings require cleaning and lubrication to ensure proper functioning. These maintenance activities can result in increased downtime and maintenance costs.

Lower Efficiency: Slip ring motors typically have lower efficiency compared to squirrel cage motors. The additional losses associated with the slip rings and brushes can reduce the overall efficiency of the motor. This lower efficiency translates into higher energy consumption and operating costs.

Limited Speed Range: While slip ring motors offer excellent speed control, their speed range is typically limited compared to some other motor types. Achieving extremely high or low speeds may be challenging with slip ring motors, restricting their suitability for applications that require extreme speed variations.

Understanding the advantages and disadvantages of slip ring motors is essential for selecting the right motor type for specific applications. Engineers and industry professionals must carefully consider the requirements and constraints of their projects to determine whether slip ring motors align with their needs.

As the field of electrical engineering continues to evolve, slip ring motors remain a reliable and versatile solution for various industrial applications. By weighing the advantages and disadvantages of these motors, engineers can make informed decisions and leverage the strengths of slip ring motors while mitigating their limitations.

See What We Can Do