An overview of the two main types of motors, slip ring and synchronous, can be pivotal to efficiently selecting and operating machinery across myriad applications. This article aims to offer a concise comparison of both slip ring and synchronous motors, highlighting their unique characteristics, performance, and use cases. Furthermore, it delves into a detailed analysis of their differences across multiple facets. Finally, the piece ventures into answering frequently asked questions about these motors, thereby equipping its readers with the knowledge necessary for informed decision-making in motor selection.

Introduction to Slip Ring Motor

Definition of a Slip Ring Motor

A slip ring motor, also known as a wound rotor induction motor or a phase wound motor, is a type of asynchronous motor that consists of a stator, wound rotor, and a set of slip rings to connect the external circuit with the rotor windings. The stator windings generate a rotating magnetic field when connected to the power supply, inducing an electromagnetic current in the rotor windings. The interaction between the stator’s magnetic field and the induced current in the rotor creates the necessary torque for the motor to operate.

Basic Working Principle

The working principle of a slip ring motor is based on the induction phenomena where the rotor does not directly receive any electrical power from the source but rather obtains the electrical energy through electromagnetic induction from the stator windings. The slip rings mounted on the rotor shaft transfer the current generated in the rotor windings to the external circuit via brushes.

When the stator winding is supplied with a three-phase alternating current, a rotating magnetic field is produced, which cuts through the rotor windings. As a result, an induced current is generated in the rotor windings due to Faraday’s law of electromagnetic induction. The interaction between the induced rotor current and the stator’s magnetic field creates a torque, causing the rotor to rotate. The name “slip ring motor” is derived from the slip, which is the difference between the speed of the rotating magnetic field and the rotor’s actual speed.

Common Applications and Use Cases

Slip ring motors are particularly suitable for applications that require high starting torque, adjustable speed, or frequent acceleration and deceleration. This feature makes slip ring motors ideal for various heavy-duty industrial processes, including:

- Compressors: The high starting torque allows the motor to start and run several compressors with ease.

- Pumps: In fluid processing systems and water treatment facilities, slip ring motors provide efficient performance by delivering power with adjustable speed.

- Mills and crushers: The robust nature of slip ring motors enables them to effectively drive grinding, milling, and crushing equipment used in mining, cement, and other industries.

- Lifts and hoists: Elevators, cranes, and hoists benefit from the slip ring motors’ adjustable speed and high-torque capabilities.

- Fans and blowers: HVAC systems and industrial ventilation rely on slip ring motors’ smooth start-up and variable speed control for efficient operation.

- Excavators and winches: The load-carrying capacity and the flexibility provided by slip ring motors serve heavy-duty construction and mining equipment well.

Advantages of Slip Ring Motor

- Low cost

- High starting torque

- Variable speed control

- Suitable for applications with frequent starting and stopping

Disadvantages of Slip Ring Motor

- Low efficiency

- High maintenance

- Requires a power supply with a variable frequency

In summary, slip ring motors are frequently employed in applications that demand reliable and flexible performance. Understanding the essential features and working principles of these motors, as well as common use cases, aids in making informed choices for various industrial and commercial applications.

Introduction to Synchronous Motor

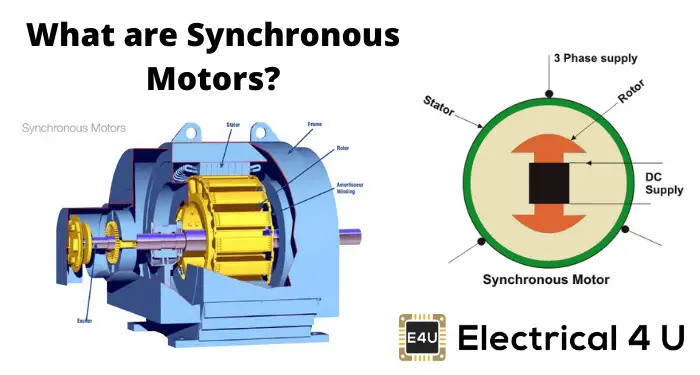

Definition of a Synchronous Motor

A synchronous motor is a type of AC motor in which the rotation of the shaft is synchronized with the frequency of the supply current. Unlike induction motors, the rotational speed of a synchronous motor remains constant regardless of the load, meaning the speed is tied directly to the frequency of the supply current. Synchronous motors typically fall into two categories: non-excited (or reluctance motors), and DC-excited, which may use either permanent magnets or electromagnets to generate the required magnetic fields.

Basic Working Principle

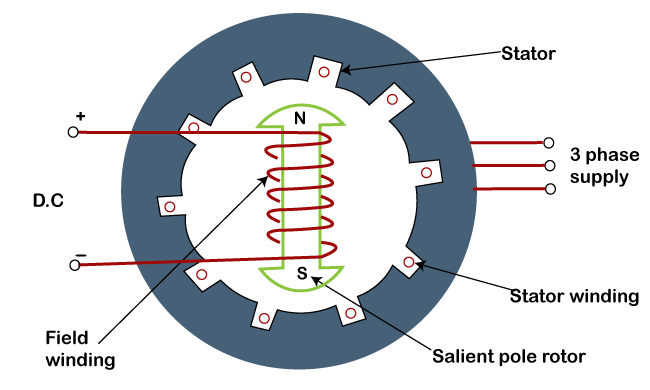

The synchronous motor operates based on the principles of magnetism and the interaction of magnetic fields. At its most fundamental level, the motor comprises a stator, which creates a rotating magnetic field when supplied with three-phase AC power, and a rotor, which either contains permanent magnets or is supplied with a DC current to create a constant magnetic field.

When the motor is supplied with power, the stator’s magnetic field causes the rotor to ‘chase’ it and attempt to align with it. Unlike an induction motor, the rotor of a synchronous motor rotates at the same speed as the stator’s magnetic field — or, in other words, the rotor is synchronized with the frequency of the supply current.

Common Applications and Use Cases

Synchronous motors are ideal for applications that require a constant and precise speed, or a high power factor or are meant to serve as a power factor correction device. Here are some of the common applications:

- Generators: In hydro, thermal, and nuclear power plants, synchronous motors work as generators due to their high efficiency and ability to deliver power at a constant frequency.

- Clocks: Electric clocks utilize synchronous motors as they require the second hand to move exactly once per second, a task made possible by the constant speed of rotation achievable with a synchronous motor.

- Robots: Robots often require precise movement, and the accuracy of a synchronous motor’s rotational speed can be beneficial for these applications.

- Factory machines: Synchronous motors are used when machine operations require specific timing or consistency of operation, such as in manufacturing assembly lines.

- Pumps: They are commonly used in pipeline pumps where constant flow rates are needed, regardless of pipeline pressure variations.

- Power factor correction: These motors are beneficial in industries where power factor is a concern, as synchronous motors can operate at a power factor greater than 1, effectively supplying reactive power to the grid and bringing the overall power factor closer to unity.

Advantages of Synchronous Motor

- High efficiency

- Low maintenance

- High starting torque

- Precise speed control

Disadvantages of Synchronous Motor

- Expensive

- Requires a power supply with a constant frequency

- Not suitable for applications with frequent starting and stopping

In conclusion, synchronous motors are versatile machines designed to offer constant speed and efficient operation. Their applications range from the mundane simplicity of clockwork to the complex systems of industrial plants.

Distinguishing Synchronous Motor and Slip Ring Motor

Synchronous Motor and Slip Ring Motor: Construction and Design

The construction and design of synchronous and slip ring motors exhibit key differences that make these motors suitable for different applications. To understand these distinctions, we must examine their main components, such as the stator, rotor, and method of electrical connection.

- Stator

In both synchronous and slip ring motors, the stator is the outer part of the motor, consisting of a laminated core and windings. These windings are supplied with a three-phase alternating current, which produces a rotating magnetic field.

- Rotor

The rotor in a synchronous motor can be one of two types: a salient pole type with projecting poles (usually found in low-speed applications) or a cylindrical type for high-speed applications. The rotor can contain either permanent magnets or windings fed with direct current, depending on whether it is a permanent magnet synchronous motor or an electromagnet-based synchronous motor. In either case, the rotor generates a constant magnetic field.

In contrast, the rotor in a slip ring motor also referred to as a wound rotor, comprises a three-phase winding connected in a star configuration. Each winding terminates at a separate ring, which collectively forms the slip ring assembly.

- Slip rings and electrical connection

One of the most significant differences in construction between synchronous and slip ring motors is the electrical connection method for the rotor.

In a slip ring motor, the assembly consists of three slip rings mounted on the rotor shaft, which connect the rotor windings to an external circuit via brushes. The brushes maintain an electrical connection with the slip rings during operation, enabling the rotor to receive power from the stator. The brush-slip ring arrangement ensures smooth transmission of power to the rotor, allowing variation in the motor’s speed depending upon the external resistance connected.

By contrast, synchronous motor rotors rely on a different method of establishing an electrical connection. In the case of a permanent magnet synchronous motor, there is no need for direct contact or an electrical connection, as the rotor possesses permanent magnets that produce the desired magnetic field. In a wound field synchronous motor, a direct current is supplied to the rotor windings through brushes and a fixed set of slip rings, separate from the stator input current. The rotor windings generate a constant magnetic field, creating synchronization between the magnetic field’s rotational speed and the rotor’s speed.

In summary, while both synchronous and slip ring motors employ stator windings and rotors, their construction and design reveal key differences that contribute to their distinct performance characteristics and applications. The slip rings and brushes used to maintain an electrical connection between the rotor and stator in slip ring motors allow adjustable speed, while synchronous motors capitalize on the constant magnetic field of the rotor to achieve constant speed.

Synchronous Motor and Slip Ring Motor: Torque and Speed Performance

The torque and speed performance of synchronous and slip ring motors reflect their unique characteristics and applications. Each motor type exhibits particular behavior in terms of speed, starting torque, and torque-speed curve, essential factors to consider when selecting a suitable motor for a specific job. Here, we delve into the performance differences between synchronous and slip ring motors.

- Speed Performance

Synchronous motors maintain a constant speed that is synchronized with the frequency of the supply current, irrespective of the load. Depending on the number of poles in the motor and the power supply frequency, the synchronous speed (Ns) can be calculated using the formula Ns = 120 * f / P, where f is the frequency of the supply current and P is the number of poles. As the rotor turns at this synchronous speed, it achieves perfect alignment with the rotating magnetic field produced by the stator. However, under heavy load, synchronous motors can lose synchronism and stall, thus requiring additional control mechanisms or external excitation to reattain their operating speed.

In contrast, slip ring motors exhibit variable speed characteristics due to the slip between the rotor and stator magnetic fields. Unlike synchronous motors, slip ring motors do not rotate at the synchronous speed. Instead, their actual speed depends on the difference between the stator field’s speed and the rotor’s induced current. The slip ring motor’s speed can be further adjusted by inserting external resistance in the rotor circuit. This functionality allows slip ring motors to work efficiently under changing load conditions, accelerating or decelerating depending on the requirements.

- Torque Performance

Torque performance, particularly starting torque, is another crucial differentiating factor between synchronous and slip ring motors.

Synchronous motors inherently produce no starting torque since their rotor starts at a standstill, and the magnetic fields are not aligned. To initiate rotation, additional devices and methods are utilized, such as a damper winding or an auxiliary induction motor, which provides the necessary starting torque. Once the synchronous motor reaches the required speed, it maintains a constant torque under steady-state conditions by aligning the rotor field with the stator magnetic field.

Conversely, slip ring motors are known for their high starting torque due to the rotor-induced torque caused by the magnetic interaction between the rotor and stator fields. The starting torque can be enhanced further by increasing the rotor’s resistance via the slip rings. By combining high starting torque with adjustable speeds, slip ring motors are suitable for driving heavy machinery and industrial loads that demand consistent performance under varying conditions.

In summary, the torque and speed performance of synchronous and slip ring motors highlights their distinct operational characteristics and capabilities. Synchronous motors deliver reliable performance through a constant speed, while slip ring motors offer high starting torque and adaptable speeds for demanding load conditions. These differences are pivotal when selecting a suitable motor for specific applications and system requirements.

Synchronous Motor and Slip Ring Motor: Power Factor and Efficiency

Power factor and efficiency are critical parameters in assessing the performance of electrical machines. The following section compares the power factor and efficiency characteristics of a synchronous motor versus a slip ring motor.

- Power Factor

The power factor of a motor is the ratio of real power (in watts) to the apparent power (in volt-amperes), and it reflects the effectiveness of power utilization.

The power factor in a synchronous motor can be controlled by adjusting the field current. Synchronous motors can operate under leading, lagging, or unity power factors, depending on the field excitation. When under-excited (i.e., the field current is less than the field current for synchronous speed), the motor operates at lagging power factor, and when over-excited (i.e., the field current is more than the field current for synchronous speed), it operates at a leading power factor. This feature of synchronous motors makes them ideal for power factor correction in industrial environments.

In contrast, slip ring motors typically operate at a lagging power factor. Unlike synchronous motors, their power factor cannot be adjusted to unity or leading, as the rotor windings are inherently inductive. Thus, while slip ring motors are beneficial in applications requiring high starting torque and speed control, they are less suited to improving the overall system power factor.

- Efficiency

Efficiency is another critical factor compared between synchronous motors and slip ring motors. Synchronous motors are generally more efficient than slip ring motors. Maintaining a constant speed under variable loads leads to efficiency gains in synchronous motors.

Slip ring motors, on the other hand, can be less efficient due to the energy losses in their rotor circuit via slip rings and brushes. However, their efficiency is balanced in applications requiring high starting torque and adjustable speed, where the losses may be deemed acceptable compared to the added benefits of speed control and high torque performance.

In conclusion, both the power factor and efficiency aspects of synchronous and slip ring motors underline their distinctive roles in electrical power systems. The synchronous motor shines inefficient operation and power factor control, while a slip ring motor provides stark benefits in scenarios requiring speed control and substantial starting torque. Consideration of these factors is crucial in choosing the right kind of motor for a specific application.

Synchronous Motor and Slip Ring Motor: Voltage and Current Requirements

Voltage and current requirements are essential parameters to consider when selecting an appropriate motor for any given application. This part of the discussion will focus on comparing the voltage and current needs of synchronous motors and slip ring motors, highlighting their unique requirements and dependencies.

- Voltage Requirements

Both synchronous and slip ring motors run on a three-phase alternating current (AC) supplied to their stator windings. The voltage rating for each motor type depends on the design specifications, such as the desired power output and speed. Generally, both motors can be manufactured for a wide range of voltage levels, ranging from low voltage (e.g., 208V, 240V, or 480V) to medium and high voltage applications (e.g., 2kV, 6.9kV, or 13.8kV). However, specific application requirements may influence the choice of the motor voltage level.

- Current Requirements

The current requirements for synchronous and slip ring motors vary in different aspects of their operation.

Synchronous motors utilize two separate current sources to function. The stator winding receives a three-phase AC, while the rotor winding (for wound field synchronous motors) or permanent magnets (for permanent magnet synchronous motors) require a direct current (DC). The stator current is primarily dependent on the motor’s load, and the rotor field current determines the motor’s magnetic field strength.

In contrast, slip ring motors require only the three-phase AC for the stator, with no dedicated power source for their rotor windings. Instead, the rotor draws induced current from the stator windings through the slip rings and brushes. The magnitude of the rotor current depends on the rotor circuit’s resistance and the magnetic slip between the stator and rotor fields.

For starting purposes, slip ring motors typically experience higher current values due to their high starting torque capability. Once running, however, the rotor currents decrease to a steady level in line with the torque requirements of the load. For synchronous motors, the starting current fluctuates based on the chosen starting method, which may involve the induction motor’s current or the use of damper windings.

In conclusion, the voltage and current requirements for synchronous and slip ring motors show crucial differences in their operational principles. While both motors can be designed for a wide range of voltages, the current requirements for each motor depend on their rotor connections and specific application needs. Understanding these dependencies is key when making informed decisions about motor selection and suitability for particular applications.

Synchronous Motor and Slip Ring Motor: Starting and Running Characteristics

Exploring the starting and running characteristics of synchronous motors and slip ring motors will provide valuable insights into their mechanisms, efficiency, and applications.

- Starting Characteristics

In synchronous motors, starting can be a challenging aspect due to the lack of initial synchronicity between the rotor and stator fields. As the rotor starts from standstill while the stator field rotates, there’s no initial interaction between them, leading to a lack of initial starting torque. To overcome this, techniques like damper windings or an auxiliary machine are used to start the motor. Damper windings help to convert a synchronous motor into an induction motor for starting purposes, while auxiliary machines (usually a small induction motor) start the main machine.

In contrast, slip ring motors are known for their smooth and robust starting characteristics due to the presence of external resistors connected to the rotor via slip rings. The external resistance can be adjusted to control the starting current and increase the starting torque. This makes slip ring motors advantageous in applications that require a high starting torque.

- Running Characteristics

Once a synchronous motor reaches its synchronous speed, it runs at a constant speed irrespective of the load, due to its direct link with the supply frequency. This constant speed operation makes synchronous motors ideal for precision and consistency applications, such as timing devices or large industrial machines. However, its inability to adapt to sudden changes in load can be a disadvantage.

On the other hand, slip ring motors continue to perform well even under fluctuating load conditions due to their inherent speed variation characteristics, influenced by the slip between the rotor and stator fields. This makes them suitable for applications that require speed control and a high starting torque, such as elevators or conveyor systems.

In summary, the starting and running characteristics of synchronous and slip ring motors present a clear distinction, making each preferable for different applications. Synchronous motors excel in constant-speed applications that require precision and consistency, while slip ring motors perform well under varying load conditions and applications that demand high starting torque. Understanding these characteristics is pivotal when choosing a motor type for a specific application.

Synchronous Motor and Slip Ring Motor: Speed Control and Regulation

Speed control and regulation play a vital role in determining the adaptability and performance of electrical machines in a range of applications. This section discusses the abilities of synchronous motors and slip ring motors to control and regulate their speed.

- Speed Control

Synchronous motors maintain a constant speed that is directly proportional to the frequency of the supply voltage. They can achieve precise speed control by adjusting the supply frequency. However, this requires external devices like variable frequency drives (VFDs) to alter the frequency. A synchronous motor’s speed control is limited to a range around the synchronous speed; it cannot adjust to extremely high or low speeds. This limitation makes synchronous motors better suited to applications requiring fine speed control within a narrow range rather than a wide spectrum of speeds.

In contrast, slip ring motors can adjust their speeds by changing either the rotor circuit resistance or the supply voltage using a variable voltage supply. Upon inserting external resistance into the rotor circuit via slip rings, slip ring motors can accommodate a wider range of speeds and torque. This adaptability enables slip ring motors to deliver efficient performance in applications that demand variable speeds, like crushers or mixers in industrial plants.

- Speed Regulation

Speed regulation is a measure of how well a motor maintains its rated speed under varying load conditions. Synchronous motors exhibit excellent speed regulation due to their constant-speed characteristics, remaining synchronized with the supply frequency regardless of load changes. However, synchronous motors can lose synchronism under sudden heavy loads, causing them to stall. To reattain synchronous speed and prevent stalling, a synchronous motor may require control mechanisms or external excitation.

Slip ring motors possess a less stable speed regulation compared to synchronous motors, as their speed depends on the degree of slip between the rotor and stator magnetic fields and the load applied. Though the speed variation in slip ring motors allows for efficient operation under fluctuating loads, it could lead to reduced precision when compared to synchronous motors.

In conclusion, synchronous motors and slip ring motors exhibit significant differences in speed control and regulation. While synchronous motors are adept at maintaining a constant speed and operating within a narrow range of speeds, slip ring motors accommodate a broader spectrum of speeds and adapt well to varying load conditions. Understanding these distinctions is critical when deciding on the appropriate motor for specific applications and system requirements.

Synchronous Motor and Slip Ring Motor: Maintenance and Repair

Maintenance and repair practices impact the longevity, reliability, and overall performance of electrical machines. This section explores the differences in maintenance and repair requirements for synchronous motors and slip ring motors.

- Maintenance

Synchronous motors generally require less maintenance compared to slip ring motors. In permanent magnet synchronous motors (PMSMs), there are no brushes, slip rings, or rotor windings, substantially reducing potential wear and breakage points. Even in wound field synchronous motors, which necessitate rotor windings and brushes, maintenance is minimal due to the direct current (DC) supply to the field windings without frequent mechanical contact.

On the other hand, slip ring motors demand higher levels of maintenance, as the rotor windings are connected to the stator circuit through slip rings and brushes. The friction, wear, and dust generation from the continuous contact between slip rings and brushes necessitate regular maintenance, such as cleaning, replacement, and adjustment of brushes and slip rings. Additionally, excessive wear can also cause temperature rises or sparks, leading to further damage and maintenance requirements.

- Repair

Synchronous motors have fewer components prone to wear and tear, resulting in less frequent repairs and extended service life. Nevertheless, when repairs are needed for wound field synchronous motors, aspects like field windings, damper windings, or brushes may demand attention. PMSMs, which do not contain these components, are notably less prone to mechanical failures.

Slip ring motors typically require more frequent repairs due to the wear and tear of their brushes, slip rings, and rotor windings. Additionally, their repair process can be more complicated and time-consuming, as it involves dismantling the motor and troubleshooting complex issues, such as those related to short circuits in the stator or rotor windings, grounding of the rotor circuit, or misaligned shafts.

In summary, synchronous motors and slip ring motors exhibit contrasting maintenance and repair needs, with synchronous motors generally requiring less frequent maintenance and repair compared to slip ring motors. The presence of slip rings, brushes, and rotor windings constitute primary sources of wear and tear for slip ring motors, thus amplifying their maintenance needs and repair frequency. This knowledge is vital when selecting an appropriate motor for specific applications, as it directly impacts the motor’s reliability, performance, and lifespan.

Synchronous Motor and Slip Ring Motor: Cost and Affordability

The overall cost of electric motors impacts the initial investment and ongoing operational expenses. A thorough understanding of the cost and affordability factors of synchronous motors and slip ring motors is crucial in determining the right choice for specific applications.

- Initial Cost

The initial cost comprises the purchase price of the motor, installation expenses, and any ancillary equipment required, like starters or frequency converters. Generally, synchronous motors are more expensive than slip ring motors. This higher cost can be attributed to the additional components required in synchronous motors such as the excitation system, especially for wound field synchronous motors. Permanent magnet synchronous motors, though eliminating the need for an excitation system, are still costly due to the expense of high-quality magnets.

Slip ring motors, on the other hand, are less expensive initially as their design is simpler and does not require separate excitation systems or high-cost permanent magnets. However, the required starters and resistors for speed control might add to the initial cost slightly.

- Operational Cost

The operational cost involves the cost of energy consumption, maintenance, and repair during the motor’s lifetime. Synchronous motors generally have higher efficiency than slip ring motors, leading to lower energy consumption and, therefore, reduced operational costs. Furthermore, as discussed in the previous section on maintenance and repair, synchronous motors require less frequent maintenance and repairs, thus reducing overall operational expenses.

Conversely, slip ring motors might have higher operational costs due to their lower efficiency and greater maintenance needs. The frequent need for repairs, particularly for tasks like replacing slip rings and brushes or troubleshooting, can contribute to higher overall operating costs.

It’s crucial to note that these cost considerations should be evaluated alongside factors such as specific application requirements, maintenance convenience, required lifespan, and potential energy savings. Therefore, despite higher upfront costs, synchronous motors might prove more economical in the long run for applications requiring high efficiency and lower maintenance. In contrast, slip ring motors could provide a more affordable solution for applications prioritizing lower initial investment and the advantages of adjustable speed control.

In conclusion, both synchronous motors and slip ring motors possess distinct cost and affordability characteristics that cater to different operational and economic scenarios. The decision to select one over the other depends not only on the initial budget but also on long-term considerations linked to maintenance, energy consumption, and application requirements.

Synchronous Motor and Slip Ring Motor: Suitability for Specific Applications

The consumption patterns, workload conditions, and specific requirements of an application greatly influence the choice of motor. This section discusses the suitability of synchronous motors and slip ring motors for specific applications.

- Suitability of Synchronous Motors

Synchronous motors, due to their high efficiency and constant speed operation, are ideal for applications requiring precision and consistency. For instance, in power generation plants, synchronous motors can function as synchronous condensers to improve power factor. They’re also used in large industrial machines where consistent performance is crucial. Additionally, their precise speed control ability makes them suitable for timing devices, compressors, and pumps.

With the advent of variable frequency drives (VFDs), synchronous motors have become increasingly common in applications involving variable speed drives that require high efficiency and power factor correction, such as air conditioning systems and pump drives.

- Suitability of Slip Ring Motors

Slip ring motors are well-suited for applications that demand high starting torque and smooth starting. This includes loads that exhibit high inertia or need a rapid start, such as conveyors, crushers, and lifting equipment. The adjustability of the external rotor resistance allows greater speed control, therefore increasing slip ring motors’ viability in heavy load applications with abrupt fluctuations, like rolling mills or elevators.

Furthermore, despite their less efficient performance, slip ring motors offer robust and reliable operation in harsh environments like mines or quarries, as they can sustain significant stress during start-up and regular operation thanks to their robust construction.

Therefore, the choice between a synchronous motor and a slip ring motor greatly depends on the specific needs of the application. By understanding their inherent characteristics and conducting an accurate analysis of load requirements, system operators can select the most efficient and effective motor that ensures optimal performance. In essence, synchronous motors excel in applications requiring precision, high efficiency, and constant speed operation, while slip ring motors are ideal choices for heavy-duty applications requiring high starting torque and load adjustability.

Synchronous Motor and Slip Ring Motor: Environmental Implications and Energy Consumption

The environmental implications and energy consumption of electrical motors significantly contribute to their operational efficiency. This section will explore these aspects in the context of synchronous motors and slip ring motors, shedding light on their environmental impact and energy usage.

- Environmental Implications

Synchronous motors, particularly Permanent Magnet Synchronous Motors (PMSMs), have less environmental impact due to their high efficiency and low maintenance requirements. High efficiency leads to lower energy consumption, resulting in reduced greenhouse gas emissions. Also, PMSMs lack brushes and slip rings, minimizing the generation of airborne contaminants from brush and slip ring wear.

Conversely, the slip ring motor produces more airborne contaminants due to the wear of brushes and slip rings. Also, slip ring motors might produce sparks, which can lead to fire hazards in explosive environments, presenting potential safety and environmental concerns.

- Energy Consumption

Synchronous motors, with their high efficiency and power factor, use less energy compared to slip ring motors. They maintain a stable speed irrespective of the load, minimizing wasted energy. Their efficiency becomes even more apparent with Variable Frequency Drive (VFD) applications, as they can maintain high efficiency over a broader range of speeds and loads.

On the other hand, slip ring motors may consume more energy due to their lower efficiency and power factor. However, by manipulating the rotor’s resistance, they can provide a good starting torque with a comparatively lower starting current, which might lead to energy savings during the starting phase in high-inertia load applications.

Both synchronous motors and slip ring motors exhibit different environmental implications and energy consumption characteristics. Synchronous motors are typically more environmentally friendly and energy-efficient, making them suitable for applications that prioritize sustainability and low operational costs. Slip ring motors, while less efficient and potentially more environmentally impactful, can still be a viable option for specific applications that require high starting torque and adjustable speed. These distinctions are crucial for making informed decisions considering the wider environmental impact and operational costs.

Selection Guide

A. Choosing the Right Motor Based on Application Needs

Selecting the appropriate motor for a specific application is critical to ensure optimal performance, efficiency, and longevity. The choice between a synchronous motor and a slip ring motor depends on various factors related to the application’s specific needs and constraints. Key considerations include:

- Speed Regulation: If the application requires precise and constant speed, a synchronous motor is preferable due to its ability to maintain a constant speed regardless of load variations.

- Starting Torque: For applications that need high starting torque, a slip ring motor is advantageous as it can provide higher starting torque compared to synchronous motors.

- Load Type: Evaluate whether the load is constant or variable. Synchronous motors are ideal for constant loads, while slip ring motors can handle varying loads more effectively.

- Control Requirements: Consider the level of control required over the motor’s operation. Synchronous motors offer better control for applications needing precise speed regulation.

B. Considerations

- Performance Requirements

- Efficiency: Assess the efficiency of the motor under typical operating conditions. Synchronous motors generally offer higher efficiency, especially in applications requiring continuous operation at constant speed.

- Power Factor: Synchronous motors have the advantage of improving the overall power factor of the system, which can lead to reduced power losses and improved voltage regulation.

- Speed Range: Determine the required speed range for the application. Synchronous motors provide a fixed speed, while slip ring motors can offer variable speed control through external resistances in the rotor circuit.

- Cost

- Initial Cost: Compare the initial purchase and installation costs. Synchronous motors typically have a higher initial cost due to their complex construction and excitation systems.

- Operating Cost: Consider the total cost of ownership, including energy consumption. Synchronous motors, with their higher efficiency, can result in lower operating costs over time.

- Return on Investment (ROI): Evaluate the ROI by considering the motor’s lifespan, maintenance costs, and energy savings. Higher efficiency and power factor correction with synchronous motors can provide a better ROI in long-term applications.

- Maintenance

- Maintenance Frequency: Examine the maintenance requirements for each motor type. Synchronous motors generally require less frequent maintenance compared to slip ring motors, which have brushes and slip rings that wear out over time.

- Downtime: Consider the impact of maintenance on operational downtime. Synchronous motors, with fewer moving parts, typically have lower downtime.

- Serviceability: Assess the ease of servicing and availability of spare parts. Both motor types should have accessible service options and readily available parts to minimize maintenance disruptions.

Conclusion

Slip ring motors and synchronous motors each have unique characteristics, making them suitable for distinct applications. Understanding these key differences and similarities equips you with the knowledge to select the correct motor for your application. Therefore, in-depth comprehension of these motors is vital for optimized motor selection and performance.

FAQs about Synchronous Motor and Slip Ring Motor

Q: Why choose one motor type over the other?

A: The choice depends on your specific requirements, such as torque, speed, efficiency, cost, and maintenance considerations.

Q: How does the performance of each motor vary according to specific applications?

A: While slip ring motors are ideal for high starting torque applications, synchronous motors excellently perform in power factor correction and uniform-speed machinery.

Q: What are the key factors to consider when selecting a motor for a specific application?

A: Consider factors like torque requirements, speed control, maintenance, cost, and power efficiency.

Q: How can one optimize the performance and efficiency of these motors?

A: Ensure correct installation, regular maintenance, and use of the motors as per their specifications.