When it comes to industrial motors, there are two main types: slip ring motors and induction motors. Both of these motors have their own advantages and disadvantages, and depending on the application, one may be more suitable than the other. In this article, we’ll take a look at the differences between slip ring motors and induction motors, and how they are used in industrial applications.

Slip Ring Motors

Slip ring motors are AC motors that use a rotating set of rings to transfer electrical power from the stationary part of the motor to the rotating part. This allows for the motor to be used in applications where the motor needs to rotate continuously, such as in conveyor belts or in wind turbines. Slip ring motors are also known as wound-rotor motors, and they are typically used in applications where high starting torque is required.

Induction Motors

Induction motors are AC motors that use an electromagnet to induce a current in the rotor, which causes it to rotate. This type of motor is typically used in applications where the motor needs to run at a constant speed, such as in fans or pumps. Induction motors are also known as asynchronous motors, and they are typically used in applications where high efficiency is required.

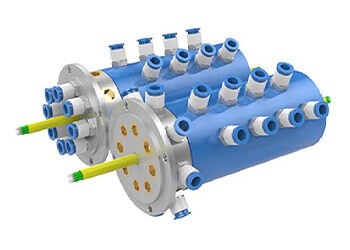

Collecting Ring

A collecting ring is a device used in slip ring motors to transfer electrical power from the stationary part of the motor to the rotating part. The collecting ring is typically made of copper and is connected to the rotor of the motor. The collecting ring is used to collect the current from the stationary part of the motor and transfer it to the rotating part, allowing the motor to rotate continuously.

Slip ring motors and induction motors are two of the most common types of industrial motors. Slip ring motors are typically used in applications where high starting torque is required, while induction motors are typically used in applications where high efficiency is required. Collecting rings are used in slip ring motors to transfer electrical power from the stationary part of the motor to the rotating part, allowing the motor to rotate continuously.

See What We Can Do