In the world of packaging, reliable power transmission is a critical factor that determines the smooth and uninterrupted operation of packing machines. These machines are responsible for efficiently packaging a wide range of products, and any power failures or interruptions during the packaging process can result in costly downtime and production delays. To ensure continuous power supply and seamless operation, slip ring connectors play a crucial role. In this article, we will explore the significance of slip ring connectors in packing machines and how they contribute to reliable power transmission.

Understanding Reliable Power Transmission

Reliable power transmission is the backbone of packing machine operations. In an industry where speed, precision, and efficiency are paramount, any interruption in power supply can lead to significant production losses and compromised product quality. Packaging processes involve various moving components that require consistent power to perform their designated tasks. From conveyor belts to motors and robotic arms, reliable power transmission ensures that these components can operate at their optimal levels, minimizing downtime and maximizing productivity.

The Function of Slip Ring Connectors

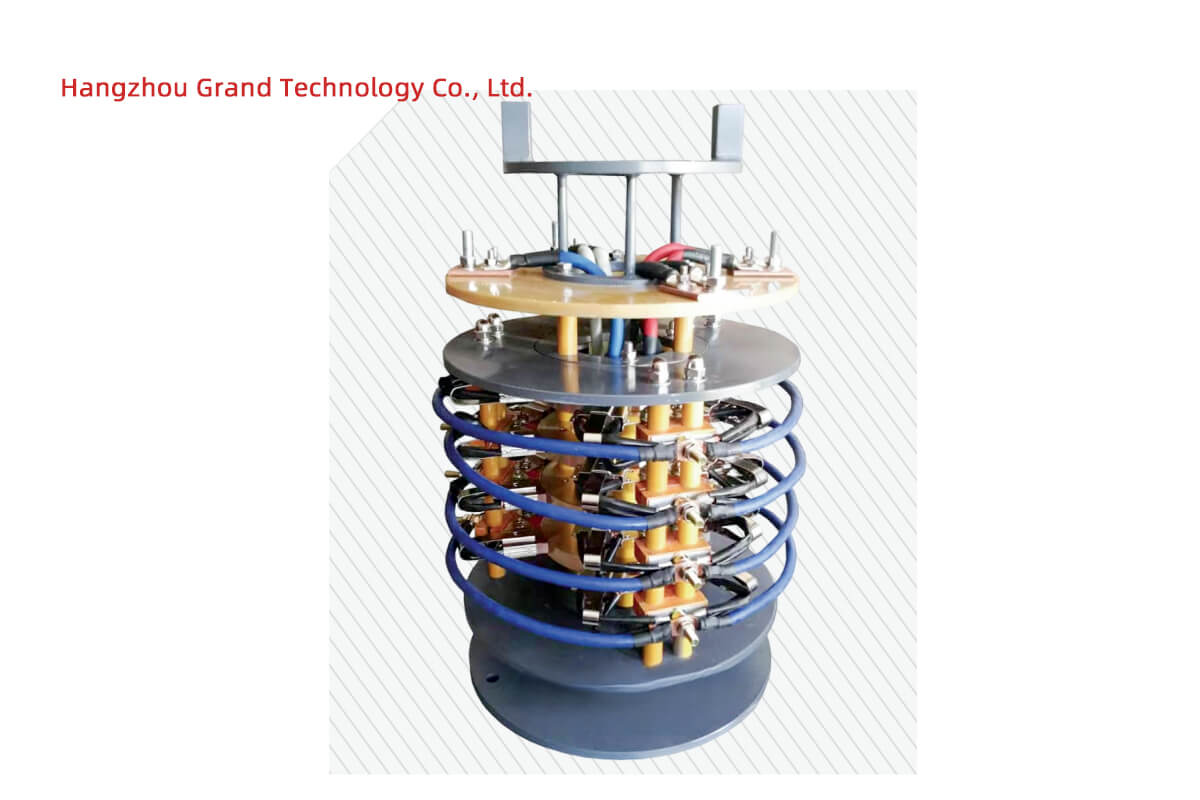

Slip ring connectors, also known as rotary electrical connectors or rotary joints, serve as essential interfaces between stationary and rotating parts in machinery. Their primary function is to transmit power and electrical signals from a stationary component to a rotating component without the need for cables that could restrict rotation or cause tangling. Slip ring connectors consist of a stationary section, called the stator, and a rotating section, called the rotor. The rotor is mounted on the rotating part of the machine, while the stator remains stationary, allowing for continuous power transmission even during rotational movements.

Ensuring Uninterrupted Power Supply

Slip ring connectors play a pivotal role in ensuring uninterrupted power supply in packing machines. They are designed to handle high currents, enabling the efficient transfer of electrical energy to various components within the machine. By effectively managing high currents, slip ring connectors minimize power loss and voltage drops, ensuring that each component receives the necessary power for optimal performance. This reliability in power transmission translates to consistent and uninterrupted operation, reducing the risk of production downtime and maintaining productivity levels.

Moreover, slip ring connectors are engineered to reduce electrical noise and interference during power transmission. The brushes or contacts within slip ring connectors maintain a constant electrical connection between the stator and the rotor, resulting in smooth and stable power transfer. This reduction in electrical noise helps prevent signal degradation and ensures that sensitive components, such as sensors or control systems, receive accurate and reliable signals. As a result, the packaging machine can operate with precision and efficiency, leading to improved product quality and reduced waste.

Importance of Signal Integrity

In addition to reliable power transmission, slip ring connectors also play a vital role in maintaining signal integrity during the packaging process. Packing machines often rely on data signals for various functions such as synchronization, monitoring, and control. Slip ring connectors are designed to preserve the quality and integrity of these signals as they are transmitted from the stationary part to the rotating part of the machine. By minimizing signal loss and interference, slip ring connectors ensure that the data signals remain accurate and free from errors, allowing for precise control and seamless coordination of the packaging operations.

Maintenance and Best Practices

To maximize the performance and longevity of slip ring connectors in packing machines, regular maintenance and adherence to best practices are essential. Routine inspection of slip ring connectors is crucial to identify any signs of wear, damage, or contamination that may affect their performance. Cleaning and lubrication procedures should be performed according to manufacturer guidelines to prevent the accumulation of debris or the drying out of lubricants, which could hinder the smooth rotation and electrical contact within the connectors. Proper installation, grounding, and adherence to safety standards are equally important to ensure the safe and reliable operation of slip ring connectors.

In the fast-paced world of packing machines, reliable power transmission is a prerequisite for seamless and efficient operations. Slip ring connectors serve as the critical link that enables continuous power supply and ensures the integrity of electrical signals during the packaging process. By handling high currents, reducing electrical noise, and maintaining signal integrity, slip ring connectors contribute to the reliability and productivity of packing machines. Proper maintenance and adherence to best practices further enhance their performance and longevity. In the packaging industry, where speed, precision, and efficiency are paramount, slip ring connectors play a vital role in keeping the production line running smoothly and ensuring the delivery of high-quality products.

See What We Can Do