Field artillery vehicles are a crucial component of modern warfare technology, housing intricate mechanical devices engineered to withstand the unforgiving battlefield. Among these components, slip rings play a pivotal role, ensuring smooth operations via seamless power and electrical signal transmission. In this comprehensive guide, delve into the nuances of slip ring applications in armored field artillery vehicles, understand the different types suitable for these machines, uncover the key selection factors, and learn the undeniable benefits of utilizing slip rings in these complex contraptions.

Table of Contents

- The Importance of Slip Rings in Armored Field Artillery Vehicles

- Where are Slip Rings Mainly Used in Armored Field Artillery Vehicles?

- Types of Slip Rings for Armored Field Artillery Vehicles

- Factors to Consider in Selecting Slip Rings for Armored Field Artillery Vehicles Applications

- Benefits of Slip Rings for Armored Field Artillery Vehicles

- Frequently Asked Questions

The Importance of Slip Rings in Armored Field Artillery Vehicles

In armored field artillery vehicles, slip rings are more than mere components; they are integral to their overall performance and efficiency. These devices enable the transmission of power and electrical signals from a stationary to a rotating structure, thereby promoting seamless 360-degree rotation without hindering the links between different vehicle parts. This application ensures that the vehicle’s various rotational components, such as turrets and ammunition handling systems, operate smoothly and efficiently.

Where are Slip Rings Mainly Used in Armored Field Artillery Vehicles?

Slip rings are integral to the operations of numerous systems within armored field artillery vehicles, and their incorporation is often crucial for operational readiness and tactical success.

Turret Mechanism

In any armored field artillery vehicle, one of the primary applications of slip rings is within the turret mechanism. The turret – typically housing a range of tools such as weapons, communication, and surveillance equipment – requires dependable and unrestricted rotation, and slip rings facilitate exactly that.

They connect the stationary part of the vehicle to the rotating turret, allowing continuous 360-degree rotation without constraining the power and signal lines. This uninterrupted rotation ensures that the vehicle can respond quickly in all directions, which is fundamental during combat operations.

Ammunition Handling Systems

Ammunition handling systems also utilize slip rings. These systems need to transmit electrical power and signals, as the shells move from a stationary position in the ammunition storage ring to the rotating gun’s breech. This efficient power and signal transmission allows the process of loading, unloading, and managing ammunition to take place efficiently and reliably.

Radar Systems

In radar-based surveillance and targeting systems, slip rings play a crucial role, ensuring precise and accurate data transmission for effective decision-making.

Rotary Joints

In addition, slip rings are also part of rotary joints in a range of equipment where fluid power needs to be transmitted in conjunction with electrical power and signal handling. These might include hydraulically actuated elements utilized in braking, steering, or suspension systems.

In summary, slip rings primarily feature in rotational elements of armored field artillery vehicles, facilitating seamless power and signal transmission to ensure optimal performance. The applications are diverse, ranging from turret mechanisms and ammunition handling systems to radar systems and rotary joints, each revealing the significance of these essential components.

Types of Slip Rings for Armored Field Artillery Vehicles

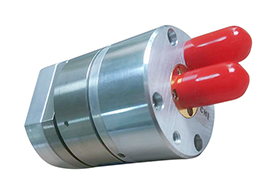

Slip rings used in armored field artillery vehicles can be categorized into various types, each specifically designed to suit different engineering requirements and operational environments.

Electrical Slip Rings:

These are the most traditional form of slip rings, designed to transfer electrical power and signals between the stationary and rotating parts of armored vehicles. They are typically constructed using conductive materials, such as copper or silver, and used in components like turret revolving systems and ammunition handling systems.

Fiber Optic Rotary Joints (FORJs):

FORJs are specialized slip rings that transfer optical signals rather than electrical ones. Light signals are immune to electromagnetic interference, making FORJs useful in environments where avoiding such interference is crucial. They’re typically used in modern digital communication and surveillance systems, requiring the transmission of large volumes of high-speed data.

Fluid Rotary Unions:

Fluid rotary unions, or hydraulic slip rings, allow the transmission of fluid or gas from a stationary part to a rotating mechanism or vice versa. They’re primarily used in hydraulic systems such as steering mechanisms, brake systems, or anything else involving fluid power.

Hybrid Slip Rings:

These rings are a combination of the above types and are designed to transmit both electronic signals and fluid power. The hybrid slip rings are ideal for applications that require the simultaneous transmission of multiple types of signals or power, such as next-generation military vehicles with advanced systems combining hydraulics with complex electronic systems.

RF Coax Rotary Joints:

These slip rings are specifically designed for the transmission of radio-frequency signals. They maintain the impedance of the signal paths while rotating, making them ideal for use in radar and satellite communication systems where signal integrity is of utmost importance.

By understanding these various types of slip rings, one can make an informed decision when designing or servicing armored field artillery vehicles, choosing the right type of slip ring for each specific application to ensure optimal performance. The right slip ring selection can mean the difference between an operational success or failure in the battlefield.

Factors to Consider in Selecting Slip Rings for Armored Field Artillery Vehicles Applications

The selection of appropriate slip rings is determined by several key factors that could significantly influence the vehicles’ operational efficiency. This section delves into each of these crucial selection factors, enabling an informed decision-making process.

Support for Modern Data Communication Technologies:

Given the increasing reliance on technology in modern warfare, slip rings should be compatible with advanced data communication protocols. It enables seamless and effective transmission from the stationary part of the vehicle to the rotating parts.

Full Environmental Sealing Capabilities:

These vehicles operate in a range of harsh environmental conditions, including temperature extremes, high humidity, or dust-laden environments. Slip rings with full environmental sealing capabilities are thus essential to withstand these variable conditions, protecting the internal components from potential damage.

EMI Shielding:

Electromagnetic interference (EMI) can disrupt the regular operation of electronic devices. Therefore, it is crucial to select slip rings with EMI shielding to ensure stable and reliable signal transmission even in EMI-prone environments.

Hydraulic Rotary Joint Options:

When the vehicle’s applications demand fluid power or signal transmission simultaneously, the slip rings with hydraulic rotary joint options are the ideal pick. These variants facilitate fluid transmission along with power and signal transmissions.

Gold-on-Gold Contacts:

Gold-on-gold contact slip rings ensure minimal noise and maximum contact reliability, thus significantly enhancing data integrity. This feature is vital for the successful operation of systems transmitting sensitive information.

Military Shock and Vibration Requirements:

Military vehicles often endure high shock and vibration forces. Thus, the chosen slip rings should meet military shock and vibration requirements, ensuring stable performance in such challenging circumstances.

High Power Capability:

Choose slip rings that can effectively transmit high electrical currents, considering the high-power requirements of military vehicles.

High-Frequency Coax Channels:

This feature is essential for transmitting frequency-sensitive signals without loss or delay, crucial in radar or surveillance systems.

Through-Bore Designs:

These slip rings, suitable for mounting around shafts or feeding hydraulic or pneumatic lines, provide the added flexibility of incorporation within diverse systems.

Cam-Operated Microswitches:

Cam-operated microswitches ensure precise, reliable, and long-lasting performance, enhancing the overall operational efficiency of the vehicle.

High-Speed Data Capabilities:

In modern warfare, fast data transmission can offer significant tactical advantages. Select slip rings with high-speed data capabilities to not compromise on the speed of operation.

By taking these factors into account, you can guide the selection of suitable slip rings that contribute significantly to the smooth and effective functioning of armored field artillery vehicles.

Benefits of Slip Rings for Armored Field Artillery Vehicles

While slip rings might seem like small components, they play a significant role in enabling effective operations of armored field artillery vehicles. The following are key advantages derived from their use:

Effective Power Transmission:

One of the primary benefits of slip rings is the efficient transmission of electrical power from stationary to rotating parts. This function allows the vehicle’s mobile components to operate with continuous power, critical for operations like a turret’s 360-degree rotation.

Optimal Signal Transmission:

In the era of digital warfare, unhindered signal transmission for communication, radar, surveillance, etc., is pivotal. Slip rings ensure smooth data flow from stationary to rotating parts, contributing significantly to effective military tactics and strategies.

Enhanced Maneuverability:

Providing uninterrupted 360-degree rotation, slip rings contribute to improved maneuverability of armored field artillery vehicles, allowing them to respond swiftly during combat situations.

Superior Performance:

By ensuring seamless power and signal transmission, slip rings promote the efficient operation of various systems – from a turret’s rotation to the controls of surveillance systems.

Durability:

Constructed from high-quality, durable materials, slip rings are designed to withstand harsh conditions and high operating loads. They continue to perform efficiently over prolonged periods, reducing the frequency of replacements.

Ease of Maintenance:

The design of slip rings is relatively simple, making them easier to maintain. Some types feature easy plug-and-play replacements, reducing downtime during servicing or replacements.

Improved Efficiency:

The reduced resistance in the rotating components due to the use of slip rings promotes overall vehicle efficiency. This improvement translates into better vehicle performance, including reduced fuel consumption and enhanced operational duration.

Cost-Effectiveness:

Scaled over their lifespan, slip rings prove to be cost-effective. Their longevity and minimal maintenance requirements combine to lower the overall cost of maintaining armored field artillery

vehicles:

These benefits clearly demonstrate why slip rings are indispensable components in armored field artillery vehicles. They provide an array of advantages, from improved power and signal transmissions to superior maneuverability, increased vehicle efficiency, and cost-effectiveness.

Frequently Asked Questions

Q: What are slip rings used for in armored field artillery vehicles?

A: Slip rings are used to transfer electrical power and signals from a stationary part of the vehicle to its rotating parts. They are commonly used in turret mechanisms, ammunition handling systems, radar systems, and more.

Q: What types of slip rings are used in armored field artillery vehicles?

A: Several types of slip rings are used, including electrical slip rings, Fiber Optic Rotary Joints (FORJs), Fluid Rotary Unions, Hybrid Slip Rings, and RF Coax Rotary Joints.

Q: Why are Fiber Optic Rotary Joints (FORJs) used in modern communication systems within these vehicles?

A: FORJs transfer optical signals, which are immune to electromagnetic interference. They are beneficial in environments where the elimination of such interference is crucial.

Q: What are Fluid Rotary Unions, and why are they important?

A: Fluid Rotary Unions or hydraulic slip rings, allow the transmission of fluid or gas between stationary and rotating components. They are primarily used in hydraulic systems such as steering and braking mechanisms.

Q: What is the relevance of EMI shielding in slip rings?

A: Electromagnetic Interference (EMI) can disrupt the operation of electronic devices. EMI shielding in slip rings ensures stable and reliable signal transmission, even in EMI-prone environments.

Q: Why are gold-on-gold contacts important in slip rings?

A: Gold-on-gold contacts in slip rings guarantee minimal noise and optimal contact reliability, enhancing data integrity which is crucial for the successful operation of systems transmitting sensitive information.

Q: What are the benefits of using slip rings in armored field artillery vehicles?

A: Slip rings enhance power and signal transmission, contribute to superior maneuverability, promote efficient vehicle operation, are durable, easy to maintain, improve overall vehicle efficiency, and are cost-effective.

Q: How do slip rings enhance the maneuverability of armored vehicles?

A: By allowing continuous 360-degree rotation of the vehicle’s mobile parts, such as the turret. This facilitates quick responses during combat situations, enhancing overall maneuverability.

Q: Does the design of slip rings contribute to their maintenance ease?

A: Yes, the relatively simple design of slip rings allows for easier maintenance. Some types even feature easy plug-and-play replacements, reducing downtime during servicing or replacements.

Q: Why is high power capability important in slip rings?

A: Considering the high-power requirements of military vehicles, choosing slip rings that can effectively transmit high electrical currents is critical to ensure seamless operations.

To conclude, the significance of slip rings in armored field artillery vehicles is demonstrably high. This guide aims to enhance your understanding of these components – from their vital role to the prerequisites for choosing the apt slip ring, along with the explicit benefits rendered by them. Remember, the key to maximizing the efficiency of these formidable machines lies in the minor details, down to the selection of suitable slip rings. For any further queries, do not hesitate to reach out to experienced professionals in the field.

See What We Can Do