In the rapidly advancing field of technology and engineering, one silent yet significant player is the ball bearing slip ring—a remarkable piece of equipment that has globally revolutionized numerous industrial and non-industrial applications alike. Offering an innovative solution to the challenge of transmitting power or data between stationary and rotating structures, a ball bearing slip ring has found its presence amidst a wide range of applications. From wind turbines and medical equipment to digital cameras and manufacturing machines, ball bearing slip rings have indubitably become integral components of an abundance of devices. They have played a crucial role in increasing the efficiency and longevity of these devices, while also decreasing maintenance requirements, hereby fostering consistent product performance and reliability. This guide will delve into the core of what slip ring bearings are, their usage, types, and maintenance, while also exploring common questions around them, enabling readers to gain a comprehensive understanding that could aid in informed decision-making.

What Is a Bearing Slip Ring?

A bearing slip ring, or simply a slip ring, is an electromechanical device that establishes an electrical connection between a stationary structure and a rotating assembly. It plays a crucial role in managing the transmission of power and signals between moving parts and the stationary base. The slip ring assembly consists of a central rotating part surrounded by conductive rings and brushes that physically and electrically connect the structure.

In many applications, rotating assemblies need a continuous flow of electricity, signals, or data transmission for their operation. The bearing slip ring ensures that this transmission remains uninterrupted, making it an essential component in devices like wind turbines, satellite dishes, and rotating inspection systems.

The design of a bearing slip ring usually includes a housing that holds and protects the conductive rings and brushes to ensure seamless electrical connections. Furthermore, it incorporates bearings that facilitate smooth rotation and promote the assembly’s mechanical stability, the stability of power and signal transmission, and the reduction of wear over time. The combination of bearings and electrical components within a bearing slip ring makes them an integral part of numerous modern machines and systems.

What Is a Ball Bearing Slip Ring?

A ball bearing slip ring can be viewed as a specialized version of the general bearing slip ring, designed to withstand demanding conditions and requirements. Where a typical bearing slip ring guarantees electrical connection and rotation, a ball bearing slip ring goes a step further, promising superior consistency in operations due to its design.

The unique characteristic of a ball bearing slip ring is the integration of ball bearings that ensures smooth rotation of the assembly while minimizing friction to a significant extent. Ball bearings consist of hardened spherical balls encased in two concentric rings, known as races, with one race generally fixed and the other linked to the rotating assembly.

The ball bearings around the slip ring reduce friction-induced wear and tear, therefore, prolonging the overall lifespan of the slip ring in arduous applications. This is particularly essential in industries and applications where any downtime or requirement for regular maintenance could create significant issues. Ball bearings in the slip ring help maintain an uninterrupted, steady passage of electricity and data, even at higher rotating speeds, thereby ensuring reliable performance under strenuous conditions.

In short, a ball bearing slip ring offers a highly robust solution, uniquely combining electrical and mechanical components to enable both smooth rotation and reliable transmission. This amalgamation of capabilities has led to its widespread application across a vast array of industrial sectors.

Do Slip Rings Typically Have Ball Bearings?

Slip rings come in various forms depending on the specific requirements of their intended application. While the general slip ring assembly ensures smooth electrical transmission between the moving and stationary parts, not all slip rings integrate ball bearings.

The inclusion of ball bearings in a slip ring is often associated with better handling of high rotational loads, providing smoother and more reliable rotation due to this component’s ability to reduce friction. Ball bearings often enhance the performance of slip rings, enabling them to be used under more demanding conditions and ensure uninterrupted, steady connectivity for transmitting power, signals, and data.

Let’s break it down: A large part of a slip ring’s role is to provide a bridge across which electrical current can continue to flow regardless of the component’s rotation. Ball bearings added to this bridge ease the rotation, reducing mechanical stress, and thus limiting the wear and tear on the ring.

In conclusion, while not all slip rings house ball bearings, the use of ball bearings in slip rings is highly dependent on the overall requirements of the mechanical structure. They are notably common in heavy-duty applications, such as wind turbines, or in situations where minimizing friction and maximizing the assembly’s lifespan is particularly important.

Materials Used in Ball Bearing Slip Ring

Ball bearing slip rings utilize a variety of materials selected for their durability, strength, and conductivity to form a reliable and robust structure capable of enduring various operational conditions. These materials come into play in different parts of the assembly, each contributing unique characteristics to the overall performance and durability of the slip ring.

The main assembly or housing of the slip ring commonly uses materials like stainless steel or aluminum due to their strength and resistance to corrosion. This casing serves as the protective cover that shields the inner components from external influences, hence the priority for robust and durable materials.

The conductive rings within the slip ring, responsible for electrical transmission, are typically made of copper or brass. These materials offer high levels of electrical conductivity, ensuring efficient passage of electrical signals between the rotating and stationary parts.

The contact brushes that slide against the conductive rings are often made of precious metals such as gold or silver, or a mix of metal and graphite. Their task is to maintain the desired conductivity, minimize electrical noise, and reduce friction and wear. Gold-to-gold contacts are often used due to their low electrical resistance and superior wear resistance.

The titular ball bearings themselves usually consist of chrome steel or stainless steel. Both are popular choices for their durability, strength, and resistance to wear under rotational stress. The ball bearings reduce friction between the stationary and rotating parts, enabling smoother operation and extending the wear life of the slip ring.

Therefore, the choice of materials in a ball bearing slip ring is a vital factor contributing to its efficiency. It is a carefully orchestrated combination of different metals and alloys, each fulfilling a specific role in order to ensure the slip ring’s longevity and reliable performance in various environments and conditions.

What Is a Ball Bearing Slip Ring Used For?

Since ball bearing slip rings offer a high degree of durability, reliability, and adaptability, they find extensive use in a broad spectrum of applications spanning numerous sectors. The main function they fulfill is to provide an uninterrupted electrical connection between rotating and stationary components while minimizing wear associated with rotation, making them vitally important in equipment featuring rotating parts.

Wind Energy

In wind turbines, ball bearing slip rings play a central role in transmitting power and signals from the nacelle, which houses the power-generating components and turns with the wind, to the static base.

Robotics

In robotics applications, ball bearing slip rings cater to a dual need of transmitting power and data between static and moving parts. This enables uninterrupted operation of robot arms and joints that must move and carry electrical signals simultaneously.

Packaging Machines

Packaging machines often have rotating components like turntables where packages are placed and moved. Ball bearing slip rings in these systems allow for power or signals to be transmitted to the rotating table without interruption.

Defense Systems

In sophisticated military technology, particularly in radar and guided missile systems, ball bearing slip rings facilitate uninterrupted rotation and signal transmission, ensuring the systems’ reliable operation.

Rotary Tables

Rotary tables used in various industries, from manufacturing to construction, often use ball bearing slip rings to transmit power without disrupting the table’s rotation.

Medical Devices

Medical devices, particularly imaging systems like CT or MRI scanners, utilize ball bearing slip rings to ensure smooth rotation of the scanning assembly while reliably transmitting data to the processing unit.

CCTV Systems

In security camera systems that require Pan-Tilt-Zoom (PTZ) functionality, ball bearing slip rings are used in the rotating base to create an uninterrupted electrical connection between the stationary part of the system and the moving camera.

With their enhanced ability to manage the load, withstand high rotational speeds, and maintain a continuous flow of power and signals, ball bearing slip rings have rightly found their place in numerous industries and applications.

Ball Bearing Slip Ring Options & Capabilities

Slip ring assemblies, including ball bearing slip rings, present a wide range of options to cater to the diverse needs across various sectors. These variations can be seen in terms of size, load capacity, number of circuits, types of transmitted signals, environmental considerations, and more.

Size: They can be customized to fit specific equipment and applications, ranging from miniature slip rings for compact devices to large-scale models for industrial machinery.

Number of Circuits: Depending on application requirements, slip rings can have various numbers of circuits. Some may have few for simple power transmission, while others may have many circuits intended for complex signal and power transfer.

Signal Compatibility: Ball bearing slip rings can transmit various types of signals (analog, digital, high-frequency, etc.). They can also handle the transmission of data via popular protocols such as Ethernet and USB.

Load Capacity: Ball bearing slip rings can be customized according to the load they’re expected to handle, related to the speed of rotation and overall weight of the rotating assembly.

Environmental Adaptability: Depending on operating conditions, ball bearing slip rings can be designed to be water-resistant, corrosion-resistant, or capable of operating under extreme temperatures.

Materials: The choice of materials can be customized to optimize different performance aspects, such as improving conductivity or enhancing wear resistance.

Integration with Other Components: Some slip rings may be combined with other rotary components like rotary joints for fluid or gas transfer, to offer more comprehensive solutions.

Overall, the inherent capabilities of ball bearing slip rings – such as reduced friction, increased durability, and smooth operation – combined with the myriad of customization options, make them highly suitable for a wide range of applications across diverse fields.

Types of Ball Bearing Slip Ring

There are several types of ball bearing slip rings, namely, miniature slip rings, high-speed slip rings, explosion-proof slip rings, waterproof slip rings, and wind turbine slip rings. These variations meet distinct application requirements, fulfilling specific functionalities and capabilities, thereby serving different industrial niches and sectors.

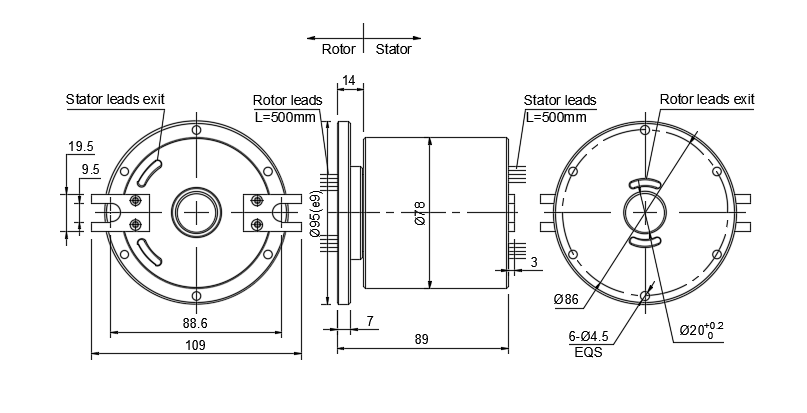

High Speed Slip Ring SHG2078-10P

Slip rings of the SH series are specially designed for high-speed slip rings and precision ball bearings, and the patented fiber brush design allows operation up to 15,000 rpm. Fiber brush technology offers several advantages over conventional slip ring contacts including multiple points of contact per brush bundle, low contact force per fiber, and low contact wear rates.

Description

| Electrical Data | Mechanical Data | ||

|---|---|---|---|

| No. of Rings | 10 rings | ID | 20mm |

| Rated Current | 10A/ring | OD | 78mm |

| Rated Voltage | 0~380 VAC/240VDC | Working Speed | 600-2000rpm |

| Insulation Resistance | 500MΩ/500VDC | Working Temperature | -20℃~+80℃ |

| Dielectric Strength | 500VAC@50Hz,60s | Working Humidity | 60% RH or higher |

| Electrical Noise | <0.01Ω | Structure Material | Aluminum alloy |

| Lead Length | 500mm | Contact Material | Precious metals |

| Protection level | IP54 | ||

Typical drawing

Features

◆ Compact design

◆ No maintenance

◆ Operating smoothly and reliability

◆ Extremely low electrical noise

◆ Convenient to assembly

◆ Compatible with data bus protocols

◆ Precious metal contact ensures long life-span

Typical applications

◆ Electrical test equipment

◆ Indexing tables, Cable reels

◆ Robotics, rotary sensors, urgent illumination equipment

◆ Exhibit/display equipment

◆ CCTV pan

◆ Laboratory equipment

Options

◆ Working speed

◆ Rated voltage

◆ Rated current

◆ No. of rings

◆ Connector

◆ Flange mounting

◆ Housing material

◆ Position of wire outlet, wire length

◆ Protection level (dust and water)

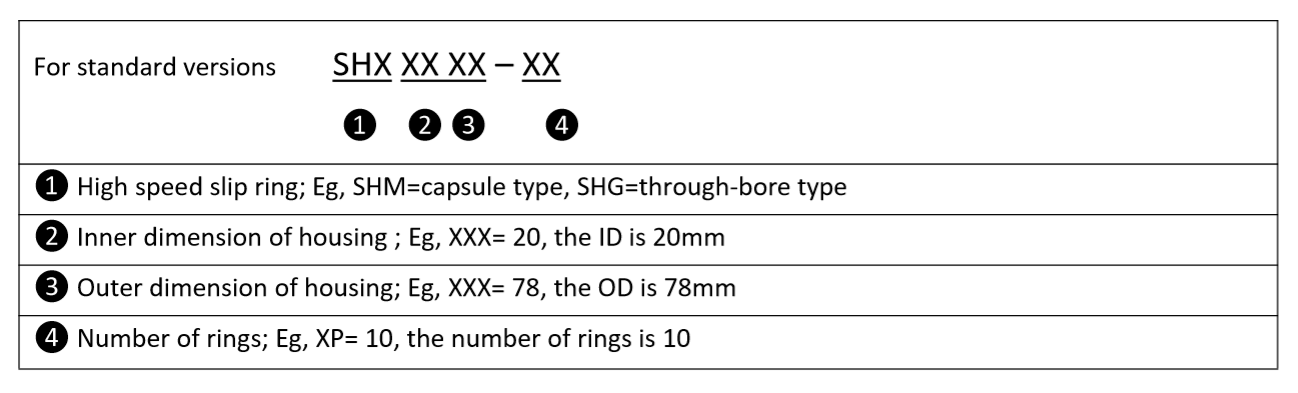

Model designation

| Feature | Standard Slip Rings | High Vacuum RF Slip Rings |

|---|---|---|

| Vacuum Compatibility | Not designed for UHV environments. | Rated for <10^-9 mbar vacuum levels. |

| Frequency Range | Typically supports lower frequencies. | Support GHz-range frequencies (1–40 GHz). |

| Material Durability | Standard materials may corrode. | Corrosion-resistant alloys and coatings. |

| Noise Levels | Higher electrical noise. | Low noise, gold-gold contacts. |

| Applications | General industrial use. | Semiconductor, aerospace, research. |

How to Choose Ball Bearing Slip Ring?

Choosing the right ball bearing slip ring involves considering various factors to ensure it meets the specific requirements of your application. Here are key factors to consider and a step-by-step guide to help you make the right choice:

Key Factors to Consider

- Electrical Specifications:

- Current and Voltage Ratings: Ensure the slip ring can handle the required current and voltage levels.

- Number of Circuits: Determine the number of electrical circuits needed for your application.

- Signal Type: Consider the types of signals (power, data, analog, digital) that will be transmitted.

- Mechanical Specifications:

- Rotational Speed: The slip ring should support the maximum rotational speed of your application.

- Size and Weight: Choose a slip ring that fits the available space and weight constraints.

- Bore Size: If using a through-bore slip ring, ensure the central hole diameter matches your shaft size.

- Environmental Conditions:

- Temperature Range: Ensure the slip ring can operate within the temperature range of your environment.

- Humidity and Moisture: Consider the level of humidity and potential exposure to moisture.

- Dust and Contaminants: Choose a slip ring with appropriate sealing if operating in dusty or contaminated environments.

- Durability and Lifespan:

- Material Quality: Select slip rings made of high-quality materials for longer lifespan and reliability.

- Maintenance Requirements: Consider the ease of maintenance and whether the slip ring needs regular servicing.

- Special Features:

- Hybrid Capabilities: For applications needing both electrical and fluid/gas transmission, consider hybrid slip rings.

- High-Frequency Transmission: If transmitting high-frequency signals, ensure the slip ring is designed for minimal signal loss and interference.

- Fiber Optic Options: For high-speed data transmission, consider slip rings with fiber optic capabilities.

- Customization optionsManufacturers often offer customization options. You should select options that can fulfill your unique requirements, such as mounting options, different materials for better performance, or integrated rotary joints for specific applications.

- Cost and Manufacturer ReputationFinally, keep in mind the cost-effectiveness and the manufacturer’s reputation. The chosen slip ring should deliver value for money, and the manufacturer should have a solid track record for quality and reliability.

Step-by-Step Guide

- Define Application Requirements:

- Clearly define the electrical, mechanical, and environmental requirements of your application.

- Identify any special features needed, such as hybrid capabilities or high-frequency transmission.

- Research Available Options:

- Look for manufacturers and suppliers that offer slip rings meeting your specifications.

- Compare different models and their specifications.

- Check Compatibility:

- Ensure the chosen slip ring is compatible with your existing equipment and setup.

- Verify the mechanical dimensions, electrical ratings, and environmental suitability.

- Evaluate Quality and Reliability:

- Check the quality of materials used and the reputation of the manufacturer.

- Look for reviews, case studies, or references from other users in similar applications.

- Consider Long-Term Costs:

- Evaluate the total cost of ownership, including initial cost, maintenance, and potential downtime.

- Consider the lifespan and reliability to minimize long-term expenses.

- Consult with Experts:

- If needed, consult with engineers or experts from slip ring manufacturers to get recommendations and technical support.

Ready to enhance your equipment with our Ball Bearing Slip Rings? Submit your inquiry, and we’ll provide you with the best solutions.

VFD’s Motors Damage Ball Bearing Slip Ring

Variable Frequency Drives (VFDs) are used to control the speed and torque of electric motors, but they can also have unintended effects on motor components, including ball bearing slip rings. Here are some ways VFDs can potentially cause damage to ball bearing slip rings:

- Electrical Discharge Machining (EDM) Effect:

- VFDs can induce high-frequency voltage pulses that create electrical discharges across the ball bearings.

- These discharges can cause pitting and fluting on the bearing surfaces, leading to premature wear and failure.

- Increased Bearing Currents:

- VFDs can cause circulating currents and shaft voltages that pass through the bearings.

- These currents can damage the bearing raceways and rolling elements, causing overheating and early failure.

- High-Frequency Switching:

- The rapid switching of VFDs generates high-frequency harmonics that can induce currents in the bearings.

- These induced currents can lead to electrical erosion of the bearing surfaces.

- Mechanical Vibration:

- VFDs can introduce mechanical vibrations at various frequencies due to the pulsed nature of the power supplied to the motor.

- These vibrations can cause physical wear and fatigue in the bearings.

- Inadequate Lubrication:

- VFDs can affect the lubrication of bearings by causing overheating or changing the lubricant’s viscosity.

- Inadequate lubrication increases friction and wear, reducing the lifespan of the bearings.

Preventive Measures

To mitigate the potential damage caused by VFDs to ball bearing slip rings, several preventive measures can be implemented:

- Use Insulated Bearings:

- Insulated bearings can prevent electrical currents from passing through the bearings, reducing the risk of electrical damage.

- Install Shaft Grounding Devices:

- Shaft grounding devices or brushes can divert harmful currents away from the bearings.

- Use Bearing Protection Rings:

- Bearing protection rings can dissipate electrical charges and protect the bearings from electrical erosion.

- Apply Proper Lubrication:

- Ensure that the bearings are adequately lubricated with the appropriate type and amount of lubricant.

- Regular Maintenance and Monitoring:

- Regularly inspect and monitor the bearings for signs of electrical damage or wear.

- Use predictive maintenance tools like vibration analysis and thermography to detect issues early.

- Use Filters or Chokes:

- Install filters or chokes on the output of the VFD to reduce high-frequency harmonics and electrical noise.

By understanding these potential issues and implementing the appropriate preventive measures, the lifespan and reliability of ball bearing slip rings in VFD-driven motors can be significantly improved.

Ball Bearing Slip Ring Maintenance and Cleaning

The maintenance and cleaning of a ball bearing slip ring contribute significantly towards operational efficiency and longevity. Proper maintenance ensures smooth, uninterrupted operation, mitigates the chance of untimely breakdowns, and prolongs the slip ring’s lifespan. Below are some general steps to maintain and clean ball bearing slip rings:

Regular Inspection

Routine checks are essential to detect any signs of wear, overheating, or any abnormal noise. Any deviations from normal operation should be immediately addressed.

Cleaning

The conductive rings and brushes should be clean and free from dust, oil, or foreign particles. Use lint-free cloths or specially designed-cleaning solutions to clear debris without leaving residue or causing damage. Avoid abrasive cleaners, as they might damage the metals.

Lubrication

While ball bearings generally come pre-lubricated, they might need re-lubrication over time based on their operating condition and environment. Check the manufacturer’s instructions for any specific lubrication requirements.

Brush Pressure

Brush pressure should be checked periodically. Too much pressure can lead to excessive wear, while insufficient pressure might weaken electrical contact, causing signal disruption. The pressure should be adjusted according to the manufacturer’s recommendations.

Temperature Monitoring

Prolonged over-temperature conditions can degrade the slip ring’s performance and accelerate wear. Regularly monitor operating temperatures and ensure sufficient cooling mechanisms are in place if necessary.

Preventive Replacement

Depending on the usage and the manufacturer’s instructions, consider replacing certain parts of the slip ring assembly proactively to avoid sudden failures.

Specialized Maintenance

For specific slip ring assemblies that are exposed to harsh environmental conditions or used in heavy-load operations, specialized maintenance procedures might be necessary.

Work with Experts

If the slip ring malfunctions or you notice substantial changes in performance, get an expert involved. Trying to troubleshoot complex issues without solid expertise may lead to bigger problems and even safety risks.

Remember, each slip ring comes with unique specifications and requirements, so the maintenance procedure will vary based on these unique aspects. Always follow the manufacturer-provided maintenance guidelines for the most accurate and efficient care instructions.

Alternatives to Ball Bearing Slip Ring

While ball bearing slip rings are widely used due to their durability and reliability, there are alternative technologies that may be more suitable for certain scenarios. These include:

Fiber Optic Rotary Joints (FORJ)

FORJs are used for transmitting optical signals between stationary and rotating parts. They offer high data transfer rates, making them suitable for applications requiring fast, high-volume data transmission, such as advanced radar systems, satellite communication, and high-speed cameras.

Mercury Slip Rings

Using liquid metal (mercury) to establish electrical continuity, mercury slip rings provide low electrical noise, making them ideal for applications that require high precision and stability, such as precision instrumentation and medical devices. However, they are subject to environmental and safety constraints due to the use of mercury.

Pancake Slip Rings

These are used when length is constrained, and only a larger diameter space is available. Although they have a low rotation speed limitation, they are used in certain specific scenarios, such as cable reels and turntables.

Wireless Rotary Joints

These use near-field wireless power transmission or inductive coupling to transfer power or signals between stationary and rotating parts. This eliminates the mechanical wear that can occur with physical connections, though it can introduce challenges with respect to power efficiency and distance.

Hydraulic or Pneumatic Rotary Unions

These are used when fluid (gas or liquid) needs to be transferred between stationary and rotating parts, such as in hydraulic machinery, cooling equipment, and food processing equipment.

The choice between a ball bearing slip ring and its alternatives primarily depends on the specific application, requirements, and constraints. It would involve considerations such as data transmission needs, environmental conditions, rotational speed, maintenance requirements, and cost, among others. Therefore, one should thoroughly evaluate these factors before deciding the most suitable solution.

Causes of Ball Bearing Slip Ring Failure

Ball bearing slip ring failures can result from various factors, which can adversely affect the performance and efficiency of the equipment they are installed in. Identifying the causes of these failures allows for quicker resolution and can prevent such issues from recurring. Some common causes for ball bearing slip ring failures are:

- Excessive friction and wear: Improper contact pressure between the brushes and the slip ring surface can cause increased friction and wear, leading to malfunction or failure.

- Inadequate lubrication: Insufficient lubrication of the ball bearings can result in excessive wear, overheating, and potential failure.

- Overloading: Exceeding the specified load capacity or rotational speed of the ball bearing slip ring can lead to premature wear or sudden failure.

- Ingress of dust, debris, or moisture: The accumulation of dirt or moisture can cause disruptions in electrical connections, corrode contacts, or affect the slip ring operation.

- Misalignment: Misalignment between the stationary and rotating components can lead to uneven wear on the slip ring surface or brushes, and potentially cause failure.

- Improper installation or maintenance: Failing to follow manufacturer-provided installation or maintenance guidelines might result in incorrect assembly, poor performance, or failure.

- Corrosion: Exposure to corrosive substances or aggressive environmental conditions can lead to corroded metallic components, which can cause malfunction and failure.

- Temperature extremes: Operating the slip ring under extreme temperatures, beyond its specified range, may cause the materials to degrade, leading to malfunction or failure.

- Vibration: Excessive vibration in the equipment can affect the proper functioning of the slip ring, causing electrical discontinuities and potential failure.

- Manufacturing defects: Defects in material or workmanship during manufacturing processes can lead to weakened components or suboptimal operation, which may cause the slip ring to prematurely fail.

Recognizing and addressing these causes promptly can help prevent costly downtimes and prolong the life of a ball bearing slip ring. Moreover, implementing regular maintenance and ensuring proper installation, along with following manufacturer-recommended guidelines, can significantly reduce the risk of failure.

Conclusion

Ball bearing slip rings play a vital role in several applications, enabling the transmission of electrical power or signals between stationary and rotating parts. Choosing the right slip ring, therefore, entails careful consideration of various factors like size, design, load capacity, operational speed, and environmental conditions. Despite their versatility and durability, like any mechanical component, ball bearing slip rings can be subject to failure stemming from excessive wear, inadequate lubrication, overloading, or exposure to dust and moisture among others.

While these slip rings offer robust solutions, they are not always the best fit for every application. Alternatives like Fiber Optic Rotary Joints, Mercury Slip Rings, Pancake Slip Rings, and others may be better suited in certain scenarios.

Maintenance and cleaning are critical aspects of ensuring operational efficiency and the prolonged lifespan of ball bearing slip rings. Regular inspection, precise lubrication, and careful cleaning, in line with manufacturers’ guidelines, can help prevent most causes of failure.

By understanding the unique characteristics of your application, adopting sound maintenance practices, and promptly addressing any issues, it is possible to maximize the benefits of your ball bearing slip ring while significantly extending its operational life.

FAQ About Ball Bearing Slip Ring

Q1: Can a ball bearing slip ring transmit data?

Yes, many ball bearing slip rings are designed to transmit power, signals, and data simultaneously thanks to their sturdy construction and advanced technology.

Q2: What is the lifespan of a ball bearing slip ring?

The lifespan of a ball bearing slip ring varies based on operating conditions and maintenance, but typically they can last for millions of rotations with proper care.

Q3: Can a ball bearing slip ring operate under high temperatures?

Yes, they can function under a wide range of temperatures due to their robust materials, but the specific range depends on the specific model and manufacturer specifications.

Tread the path of informed decisions by exploring these intricacies of the ball bearing slip ring. Harness its potential to the fullest and witness your application ascend to unprecedented efficiency and productivity.

See What We Can Do