Downhole slip rings are more than just technical jargon – they’re essential components used in a variety of industries, including oil and gas extraction, renewable energy, and manufacturing. These highly engineered electromechanical devices ensure that the transfer of power and communication between stationary and rotating parts of machinery is seamless and efficient. As innovative technology continues to propel these industries forward, Downhole slip rings have proven to be indispensable. In this comprehensive guide, we’ll delve deeper into the world of Downhole slip rings, demystifying their components, functions, applications, and importance across different sectors. By the end of this guide, you’ll have a solid understanding of these crucial devices and the role they play in optimizing machinery and improving overall operations.

What are Downhole Slip Rings

Downhole slip rings are specialized electromechanical devices designed for operation in extreme environments, particularly within drilling operations. As essential elements of the drilling system, they have a definitive purpose: to transmit electrical power and data signals from a static to a rotary component. Downhole slip rings carry this continuous transmission even as one element is in relative motion to another, and they do so without interruption.

Due to their ability to deliver reliable performance under adverse conditions, these devices are a staple in various industries such as the oil and gas industry, renewable energy sector, and drilling operations. They are specially engineered to withstand extreme temperature fluctuations, pressure, and corrosive substances, making them highly durable and reliable.

To better understand why Downhole slip rings are so important and versatile, let’s delve a bit further into the working principles of these devices.

Downhole slip rings use the simple concept of electrical contacts. At its most basic level, their operation involves a rotating part (rotor) and a stationary part (stator). Between them are conducting bands or rings, which serve as the conduit for transferring power or data from the fast-moving rotor to the stationary stator, or vice versa.

The functionality of Downhole slip rings is further enhanced by the use of brushes. These brushes, typically made of precious metals, score over the rotating rings, creating electrical connectivity. This allows for continuous data and power transmission even while parts of the machinery are in relative motion.

Understanding these principles is crucial as it empowers users to make the most out of their applications, ensuring that they not only maintain their operations effectively but also ensure more efficient and long-lasting usage of the Downhole slip rings.

Downhole Slip Rings: Features

Downhole Slip Rings are packed with several necessary features that make them an indispensable component in an array of applications. Here are some of the common features:

- High-Grade Material: These rings are often constructed from high-grade materials such as stainless steel or other non-corrosive precious metals. This not only provides them with durability but also safeguards them against potential wear and tear, ensuring longevity.

- High Rotational Speed Compatibility: A salient feature of the Downhole Slip Rings is their ability to handle high rotational speeds. Regardless of the velocity of the rotating parts, these rings ensure a continuous and seamless flow of data and power.

- Robustness: Given the extreme conditions these devices are often subjected to, they are generally designed to withstand harsh environments, with resistance to high temperatures, high pressures, and corrosive substances.

- Compact Design: Despite their efficiency and complexity, Downhole Slip Rings frequently boast a compact design. This allows them to be utilized in applications with spatial constraints.

Each feature directly correlates with a distinct benefit, which bolsters the performance of Downhole Slip Rings.

High-Grade Material: The use of premium materials means these components exhibit robust resistance to wear and tear. In the long run, this quality extends the life of the device, ensures reliable performance, and brings down maintenance costs.

High Rotational Speed Compatibility: This feature ensures a reliable transfer of signals or power, irrespective of the speed of the rotating parts. It provides unwavering performance, even in machinery operating at high speeds, thus limiting disruption of work and increasing overall productivity.

Robustness: The ability to resist harsh conditions, including high temperatures, pressures, and corrosive environments, ensures the device functions optimally even in the toughest situations. This makes Downhole Slip Rings a reliable solution for extreme industrial needs.

Compact Design: The compactness of Downhole Slip Rings guarantees easy installation in varied types of machinery without them being a spatial burden. This allows industries with space-restricted applications to benefit from the functionality of these rings.

In essence, every feature of Downhole Slip Rings has been carefully designed and implemented, providing unique benefits and making them a vital cog in today’s industrial machinery landscape.

Downhole Slip Rings: Types

Downhole Slip Rings come in various types, each with distinct characteristics and functions that make them ideal for certain scenarios. They vary in key areas like design, material used, and operational properties. Let’s explore some of the common types:

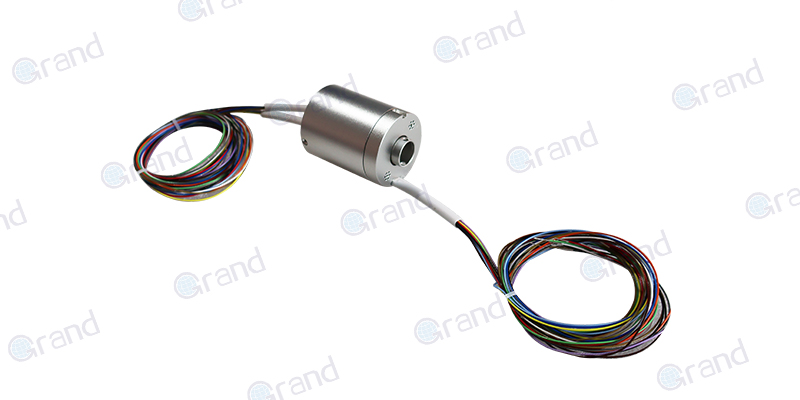

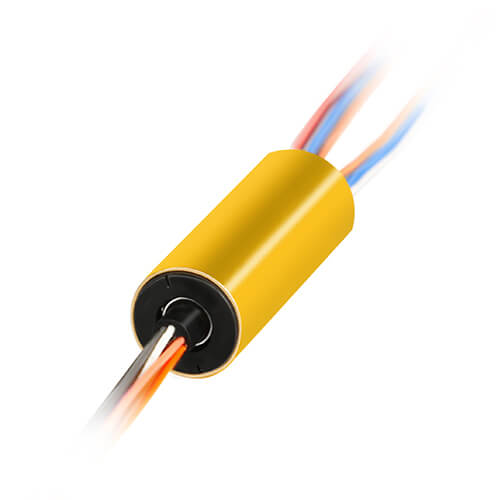

Capsule Slip Rings

These are compact devices designed to function in applications with space constraints. Given their dimensions, they are convenient to install and come in handy in closed system operations.

Mercury Wetted Slip Rings

These use mercury instead of typical brush contacts, resulting in low electrical noise and minimal contact resistance. They perform optimally in high-speed data transmission.

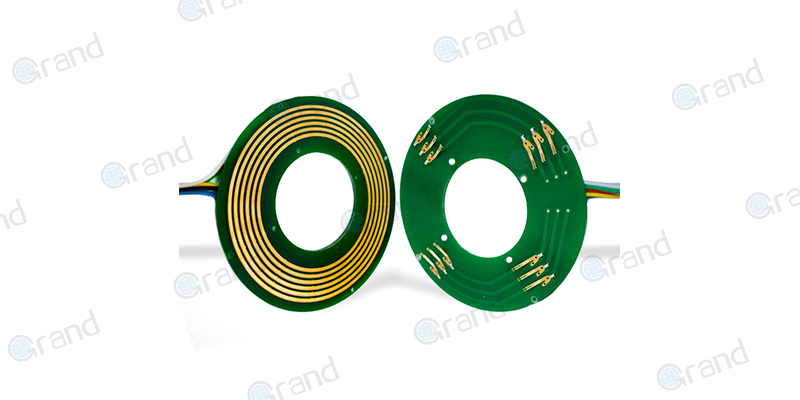

Pancake Slip Rings

They get their name from their structure which is flat like a pancake. They are primarily used in applications where length is limited but the diameter is not a constraint.

Wireless Slip Rings

They are designed to transfer power and data wirelessly. As there are no physical connections, wear and tear are significantly reduced.

Comparing these types, it’s clear that while all Downhole Slip Rings share the primary objective of transmitting power and data, they do so in significantly different ways based on their design and application scope.

For instance, Capsule Slip Rings and Pancake Slip Rings are appropriate for more confined spaces due to their compact and flat structure respectively. On the contrary, Mercury Wetted Slip Rings are better suited for high-speed applications due to their low electrical noise production. Wireless Slip Rings, in comparison, have the benefit of reduced wear and tear because physical contacts are eliminated, although they may be limited by transmission range.

The features and benefits of Downhole Slip Rings vary significantly due to the inherent differences in their design and functioning.

Capsule Slip Rings, being compact, are easy to install and maintain. They are particularly favored in industries where spatial conservation is a priority. Conversely, Mercury Wetted Slip Rings provide exceptional performance in systems that require high-speed data transmission, owing to their low electrical noise. The flat design of Pancake Slip Rings allows them to maintain functionality in applications where length is restricted. Lastly, Wireless Slip Rings provide the unique advantage of reduced maintenance costs and potential downtime, thanks to the absence of physical contacts.

In summary, the preferable type of Downhole Slip Rings often depends on the specific operational requirements and the environmental conditions within which they will be working.

Downhole Slip Rings: Applications

Downhole Slip Rings serve a wide array of industrial applications due to their versatility and durability. Here we shall explore some instances where Downhole Slip Rings enrich operational capabilities:

Oil & Gas Industry

One of the key applications of Downhole Slip Rings is in the oil and gas industry, particularly in drilling operations. They ensure power and signal transmission during the rotation of the drilling rod, contributing to the smooth performance of the entire extraction process.

Wind Energy Sector

In wind turbines, Downhole Slip Rings transmit consistent power and data from the nacelle (the rotor component of a wind turbine) to the stationary part of the turbine. This ensures the seamless operation of the turbine, even when the nacelle is rotating against the wind.

Industrial Equipment

Rotary machines, cable reels, and revolving doors are typical instances in the manufacturing industry where Downhole slip rings find their use. They enable power and signal transmission between rotatory and stationary parts, allowing these machines to function efficiently.

In CT scanners, Downhole Slip Rings transfer power and signals between rotating and stationary parts, allowing for precise and smooth operation.

Now, let’s delve into a couple of case studies for a more detailed look:

Case Study 1 – Offshore Drilling Operations: In the harsh and unpredictable conditions of offshore oil extraction, Downhole Slip Rings proved pivotal in maintaining constant power and data transmission during drilling operations. They were particularly effective in transmitting real-time drilling data, a cornerstone of optimizing extraction efficiency and ensuring the safety of the operations.

Case Study 2 – Wind Power Generation: Downhole Slip Rings played a crucial role in sustainable energy production via wind turbines. Their ability to withstand rough environmental conditions and maintain consistent energy and signal transmission ensured the wind turbines’ continuous operation, playing an instrumental role in maximizing power generation and minimizing downtime.

These applications and case studies demonstrate the essential function of Downhole Slip Rings in a variety of sectors. Regardless of the industry, they ensure optimal performance and efficiency in all operations.

Downhole Slip Rings: Selection Considerations

Choosing the right Downhole Slip Ring for a specific application is crucial to ensure optimal performance, efficiency, and longevity. Here are some important factors that should be considered during the selection process:

- Application Requirements: Analyze the specific function or task the Downhole Slip Ring is required to fulfill. Identify the rotating speeds, power or signal transmission needs, and environmental conditions of the application to narrow down the options.

- Physical Dimensions: Determine the size limitations of the application to identify suitable Slip Ring types. Compact designs such as Capsule or Pancake Slip Rings might be essential in confined spaces, while other dimensions need to be considered in more open designs.

- Environmental Resistance: Take into account the environmental conditions the Downhole Slip Ring will be exposed to, such as extreme temperatures, high pressure, corrosion, and the presence of dust or debris. Choose a Slip Ring built to withstand these factors to minimize maintenance and prolong service life.

- Compatibility: Ensure that the Slip Ring selected is compatible with your machinery and power or signal transmission requirements. This may involve considering the voltage, current rating, and data transfer speed of the application.

The features and benefits of Downhole Slip Rings can significantly impact the selection process. For instance, a Mercury Wetted Slip Ring might be more suitable in applications requiring fast and low-noise data transmission, while Wireless Slip Rings may be sought for reduced maintenance in certain scenarios.

Here are some tips to aid in making optimal selections:

- Research and compare various suppliers and manufacturers to ascertain the overall quality and performance of their products. Reviews or customer feedback can be helpful in this regard.

- Always prioritize your specific application requirements when making a decision. A good understanding of the operational environment and necessary technical specifications will lead to an informed choice.

- Consult with an expert or an engineer who can provide valuable insights on the selection process, tailored to your unique needs.

In conclusion, a meticulous and well-informed approach should be employed while selecting a Downhole Slip Ring, keeping in mind the application requirements, surrounding environment, and compatibility aspects. By considering the various features and benefits, you can ensure that the chosen slip ring will meet operational needs and maximize efficiency.

Downhole Slip Rings: Maintenance and Troubleshooting

Maintenance and troubleshooting are integral aspects to ensure the longevity and efficient operation of Downhole Slip Rings. Here is some guidance and common issues with solutions:

Regular Maintenance

Regular maintenance is crucial to optimize the performance of Downhole Slip Rings and to prevent potential faults. Maintenance practices typically include:

- Regular Inspection: The physical state of the slip ring should be regularly inspected for any signs of wear, damage, or corrosion. This will help identify issues early before they escalate into major failures.

- Cleaning: Keeping a Downhole Slip Ring clean is essential, especially for the rings and brushes which are the main points of contact in the device. It’s important to keep them free of dust and debris, which can cause damage and affect performance.

- Lubrication: Ensuring rings and brushes are suitably lubricated can minimize wear and friction, promoting smoother operation and longer life.

Common Issues and Solutions

- Issue: Poor or inconsistent data transmission: This is often due to worn-out brushes or a buildup of debris. The solution generally includes a thorough cleaning of the contacts or replacing the brushes if they’re excessively worn.

- Issue: Operation failure: Total operation failure might occur due to severe damage or the breaking of a connection within the Downhole Slip Ring. Inspection and testing of all connections will reveal the problem area, which then can be repaired or replaced.

- Issue: Excessive noise or heat production: This could be due to high friction between the rings and brushes or a poor electrical connection. Lubrication of the contacts and inspecting the connections for any damage or debris would be good initial steps.

In the broader context, regular maintenance and effective troubleshooting are at the heart of ensuring Downhole Slip Rings maintain their viability and efficiency. A well-maintained Slip Ring can perform at its optimal level, enhancing the overall operational performance of the device in which it’s installed while minimizing unforeseen downtime.

Conclusion

In this guide, we have navigated through what Downhole Slip Rings are, covering their diverse types and key functions. We explored the myriad of applications where these devices play a crucial role, from the oil & gas industry to wind energy generation, with detailed case studies for a better understanding of their practical implementation.

We also discussed vital factors to consider when selecting a Downhole Slip Ring, emphasizing the importance of application requirements, size limitations, environmental resistance, and inherent compatibility. Furthermore, the guide highlights the significance of regular maintenance and provides an overview of common issues and solutions to facilitate troubleshooting.

Downhole Slip Rings serve as crucial components in many industrial applications, and the right selection, maintenance, and troubleshooting practices can significantly enhance operational efficiency and effectiveness.

For further queries or product recommendations, do not hesitate to reach out. Our team is here to assist you in all matters related to Downhole Slip Rings – be it a complex operational question or a simple product inquiry – ensuring you are well-informed and confident in your decision-making process.

FAQs about Downhole Slip Rings

Q: What are the most common types of Downhole Slip Rings?

A: There are various types of Downhole Slip Rings, such as capsule, pancake, modular, and mercury-wetted slip rings, each suitable for different applications. Some slip rings are designed for specific industries, such as the oil and gas sector or wind energy generation.

Q: Why are Downhole Slip Rings crucial in the oil and gas industry?

A: Downhole Slip Rings ensure power and signal transmission during the rotation of the drilling rod, crucial for the smooth performance of the entire extraction process. They also transmit real-time drilling data, which can be used to optimize operational efficiency and safety.

Q: How can I choose the right Downhole Slip Ring for my application?

A: When selecting a Downhole Slip Ring, consider factors such as application requirements, physical dimensions, environmental resistance, and compatibility. It’s also advisable to research different suppliers and manufacturers, consult with experts, and prioritize specific requirements.

Q: What maintenance practices are essential for Downhole Slip Rings?

A: Regular inspection, cleaning, and lubrication are important maintenance practices. Keep the slip rings and brushes clean, ensuring they’re free of dust and debris, and maintain proper lubrication to minimize wear and friction.

Q: What are some common issues with Downhole Slip Rings and their solutions?

A: Some common issues include poor or inconsistent data transmission, operation failure, and excessive noise or heat production. Solutions generally involve cleaning or replacing contacts, inspecting and testing connections, and lubricating the rings and brushes.

See What We Can Do