Amusement rides provide joy, thrill, and an unforgettable experience to millions worldwide. Behind the action of these sophisticated machines lies a world of critical components that ensure their smooth operation. Among these, the slip ring plays a vital part in transmitting electrical current between stationary and rotating parts. This comprehensive guide delves into the world of amusement ride slip rings, explaining their working principles, types, selection criteria, installation processes, and the maintenance needed to keep them at peak performance. Moreover, the guide also explores case studies and discusses future trends in slip rings used in the world of amusement rides.

Introduction to Amusement Ride Slip Rings

Picture an amusement park. Amid the laughter and screams of thrill, it’s easy to overlook the mechanical wonders that power each ride, creating such joy. At the heart of these rides lies a crucial component – the slip ring.

Amusement ride slip rings, often overlooked yet foundational, are electrical devices that ensure seamless energy transmission from a stationary structure to a steadily rotating component of the ride. They are usually situated in the heart of rotating rides, such as Ferris wheels, merry-go-rounds, or roller coasters.

Designed to withstand high rotation speeds and varying environmental conditions, these slip rings are robust and reliable. They demonstrate the remarkable blend of electrical and mechanical engineering that goes into the creation of enjoyable and safe amusement rides.

Purpose and Importance: Why Slip Rings Matter?

Though concealed within the ride structure, slip rings have an undeniable impact on your theme park experience. But their functionality extends beyond just powering the ride. They are also essential in delivering an all-encompassing sensory experience.

For instance, consider the flashing lights on the Ferris wheels or the merry-go-round. These lights, synchronized perfectly with the ride’s rotation, are made possible through slip rings. They transfer electrical power even when the ride is in motion, facilitating the operation of the lights regardless of the position of the rotating parts.

Likewise, slip rings are behind the musical tunes that play uniformly on moving Christmas rides. They allow the transmission of audio signals from a stationary source to speakers installed on the rotating parts of the ride.

But their most crucial function, without a doubt, is ensuring the safe operation of rides. By providing reliable power transmission, they ensure safety mechanisms function correctly at all times. When a ride operator hits the stop button, power swiftly halts, and the ride comes to a safe, controlled stop. This would not be possible without the dependability offered by slip rings.

Without slip rings, amusement park rides would be nothing more than inert frames devoid of life, lights, and safety features. The show truly can’t go on without them!

Working Principle of Amusement Ride Slip Rings

In the journey of understanding slip rings, it is crucial to discern how they function in their basic form. Imagine you need to pass an electric current or signal from a stationary part (stator) to a rapidly spinning part (rotor) of the ride. This is where the magic of the slip ring comes into play.

A slip ring consists of conductive rings mounted onto the rotating portion of the ride. Brushes–made of highly conductive material–are held against these rings using spring pressure. When these brushes come into contact with the conductive rings, an electric current flows. This current is then relayed from the stationary wires connected to the moving parts of the ride.

This mechanism ensures continuous electrical conductivity between the stationary part and the rotating part of the amusement ride. Using this principle, slip rings enable the flow of current, data, signal, etc., even during rotation.

Their Role in Amusement Rides: Elevating the Experience

The versatility of slip rings is extended through their remarkable ability to enhance user experiences. Apart from providing seamless power transmission, slip rings contribute to the visual and audible elements of an amusement ride, such as lighting and music effects. They are part of the thrill, powering fast or slow spinning rides, and ensuring safety controls are fully operative, adding to our sense of excitement and wonder.

For instance, on a Ferris wheel, as visitors enjoy the view from the top, the operator on the ground can control the lights, music, and pace of the ride, all facilitated by slip rings. They keep the lights blinking and the music playing no matter how the wheel spins.

Perhaps the most spectacular implementation of slip rings is in modern simulators. On an interactive 360-degree ride, data transmission for live video streaming is just as important as power transfer to run the ride’s motion bases. By leveraging the ability of Ethernet slip rings to transmit data signals, these rides deliver real-time graphics and instant feedback, immersing riders in a completely interactive experience.

Indeed, from the basic carousel to the most advanced virtual reality ride, slip rings play an integral part in elevating the amusement park experience!

Types of Amusement Ride Slip Rings

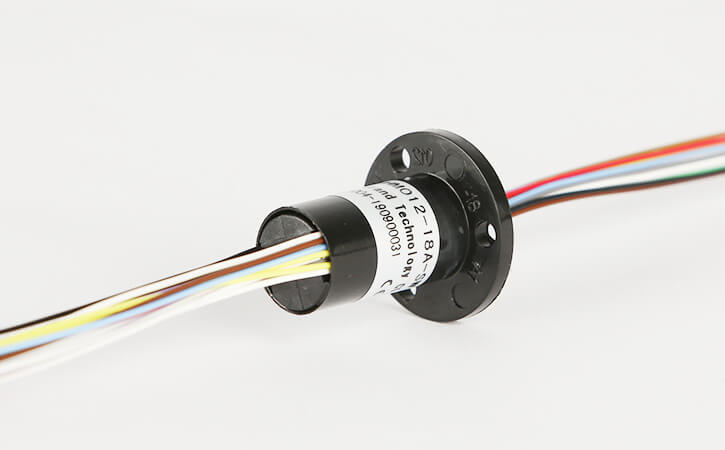

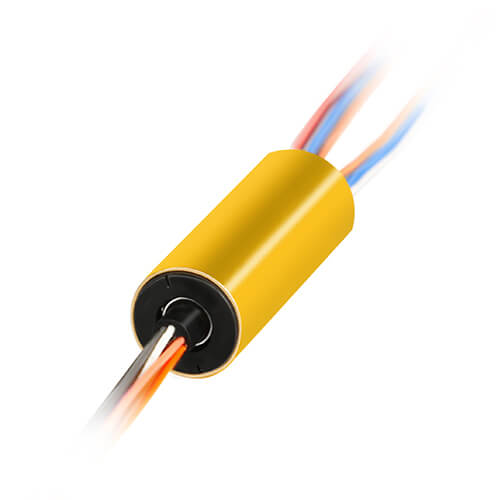

Capsule Slip Rings: Compact and Versatile

For many amusement rides, space constraints, and installation points dictate the type of slip ring required. In these cases, capsule slip rings emerge as a perfect solution. They are known for their compact design, ability to fit into tight spaces, and versatility in applications.

Despite their minimal footprint, capsule slip rings can efficiently handle various electrical requirements. Their design incorporates multiple conductive rings and brushes, allowing for the transmission of power and signals for small-scale, auxiliary functions, and other low-voltage applications. These slip rings cater to rides like kiddie carousels, miniature roller coasters, or spinning tea cups and also serve as ancillary components in larger rides.

Through Hole Slip Rings: Dealing with Large Diameters

In an amusement park, several rides notch up the scale, highlighting the need for specialized slip rings that cater to substantial central rotating structures. Enter through hole slip rings, which are designed to be mounted around the rotating shaft of a ride.

These slip rings provide excellent energy transmission as they directly form a connection through the rotating shaft. Due to their flexible customization options, through hole slip rings

are ideal for rides with large-diameter, rotating parts, such as full-sized Ferris wheels, large carousels, or the imposing pirate ships often found in amusement parks.

Ethernet Slip Rings: Ensuring Connectivity

In the digital age, amusement rides have evolved from purely mechanical systems to interconnected powerhouses merging mechanical, electrical, and data transmission channels. Ethernet slip rings meet this demand, as they are specifically designed to transfer high-speed data and signals while maintaining steady rotations.

Ethernet slip rings cater to current amusement rides with data transmission needs, including high-definition video streaming and real-time audio transmission. Their presence can be felt in rides such as 4D cinemas and virtual reality experiences, where instantaneous data flow is critical for providing riders with an immersive, realistic, and satisfying experience.

As amusement rides continue to become more sophisticated, from lightning-fast roller coasters to futuristic simulators, each slip ring subtype plays a key role in perfecting the experience, propelling the industry into the future with resolute efficiency.

Criteria for Selecting Amusement Ride Slip Rings

Technical and Mechanical Specifications: Understanding the Specs

Ride operators, designers, and engineers don’t choose slip rings on a whim. A clear understanding of technical and mechanical specifications plays a critical role in selecting the right slip ring.

Determining factors include the size of the slip ring, the type of signals it can transfer (analog, digital, or power signals), the need for data transfer, the total number of circuits, the rated speed, operational voltage, and current, to name a few.

For instance, a merry-go-round that requires power, audio, and light show control will need a capsule slip ring capable of handling multiple channels. Likewise, a high-end ride with intense visual effects would require an Ethernet slip ring supporting high-speed, real-time data transfer for a smooth, immersive experience.

Compatibility with the Amusement Ride: Ensuring a Good Fit

Moreover, the slip ring must also resonate with the structural and functional aspects of the amusement ride itself. The selection would vary based on factors such as whether the rotation is continuous or reciprocating, the rotational speed, and the environmental conditions.

Also, the selected slip ring should be capable of enduring physical stress, such as high-speed rotation, or environmental impacts like changes in temperature, pressure, and exposure to water or dust. For example, a ride situated outdoors would benefit from a slip ring designed with high weather-resistance features, ensuring longevity and robust performance.

Durability and Reliability: Choosing for Longevity

Amusement rides endure through countless cycles of operation, high-force movements, rapid speed changes, and varying outdoor conditions. Therefore, durability and reliability remain key considerations when opting for a slip ring.

Ride safety hangs in the balance, making it imperative for slip rings to remain consistently operational, delivering impeccable performance for extended periods. In this light, it is crucial to choose a slip ring known for its high durability, efficient energy transfer, and negligible signal interference.

Also, focusing on manufacturers who offer long-term maintenance and warranty can further ensure that the slip ring remains reliable over time and any arising issues can be addressed swiftly.

In essence, the order of the day is a calibrated choice, an insight-led selection that takes into account a range of factors – from technical requirements to compatibility concerns, right down to durability and longevity, to equip amusement rides with the perfect slip ring.

Installation of Amusement Ride Slip Rings

Preparatory Steps: Getting Ready for Installation

To ensure the successful integration of slip rings into amusement rides, proper preparatory steps are essential. Some key preparatory steps can benefit the installation process:

- Study the Documentation: Thoroughly review the user manual or any technical documentation provided by the slip ring manufacturer. This step helps to gain a clear understanding of the product’s specific features, installation guidelines, and any accompanying risk factors.

- Select the Mounting Location: Identify and prepare the appropriate mounting location for the slip ring based on the ride’s design and the slip ring’s specifications. Ensure that there is enough space for the slip ring to fit comfortably and without any mechanical constraints.

- Inspect the Slip Ring: Visually examine the slip ring for any damage or defects before beginning the installation process. This includes checking for loose connections, damaged brushes, and any other issues that could impact the slip ring’s performance.

- Gather the Necessary Tools: Assemble any required tools and equipment, such as screwdrivers, wrenches, pliers, or specialized mounting hardware that may be specific to the slip ring’s installation.

Installation Process: Step-by-Step Guide

Follow the recommended installation procedures to successfully integrate a slip ring into an amusement ride. While specific installation steps will vary depending on the slip ring’s type and design, below is a general step-by-step guide to help in the process:

- Position the Slip Ring: Position the slip ring onto the selected mounting location, ensuring its proper orientation with respect to the rotating parts of the ride.

- Secure the Slip Ring: Use appropriate mounting hardware to secure the slip ring onto its mounting location, ensuring proper alignment and stability.

- Attach the Stator Wires: Connect the stator wires from the slip ring to the stationary part of the ride, according to the slip ring’s specifications. Use a strain relief, such as cable clamps, to prevent damage from any pulling or twisting motions.

- Attach the Rotor Wires: Connect the rotor wires from the slip ring to the rotating part of the ride, similar to the stator wires. Make sure that any wire routing follows the path of minimal stress or tension.

- Verify Connections: Double-check all connections for a secure fit, and address any loose or disconnected wires.

- Test the System: Run the ride for a short period during a controlled test to ensure smooth operation and confirm the slip ring’s proper function within the system.

Troubleshooting Common Installation Issues: Handling Problems

Encountering issues during the installation process is not uncommon. Proactive troubleshooting can help address common installation problems:

- Poor Connection or Signal: If the slip ring is correctly installed but there is no signal or power transfer, inspect the connections and ensure proper contact between the brushes and conductive rings. Additionally, verify the wiring to avoid incorrect or loose connections.

- Slip Ring Noise or Vibration: Excessive noise or vibration may indicate misalignment, uneven mounting, or damaged brushes. Make sure the slip ring is properly aligned and secured to the ride, and inspect the brushes for any visible damage.

- Overheating or Arcing: If the slip ring becomes excessively hot or there is arcing near the brushes, inspect the connections and contacts for any damage or contamination. This could be due to excessive current, improper brush contact, or debris buildup. Consult the manufacturer’s recommendations to address such issues.

By adhering to appropriate preparatory steps, a structured installation process, and efficient troubleshooting, it is possible to seamlessly integrate a slip ring into an amusement ride, ensuring a fun and electrifying experience for all.

Maintenance and Inspection of Amusement Ride Slip Rings

Routine Checks: Keeping Your Slip Rings Running

As consumer safety and ride performance are of utmost importance in any amusement park, routine checks on amusement ride slip rings are critical. A systematic inspection and service routine will help keep the amusement rides operating safely and efficiently.

Here’s a basic outline for a regular inspection routine:

- Visual Inspection: Regularly check the overall condition of the slip ring. Look for any visible damage, such as chipping, cracking, or excess wear.

- Functional Check: Operate the ride and observe the functionality of the slip ring. Listen for unusual noise, watch for unusual movement, and check for any signs of overheating.

- Contact Inspection: Clean the contacts and brushes regularly to remove any dust or wear debris that may cause signal interference. Check the brushes for physical wear and ensure that they’re coming into full contact with the track.

- Cable and Connection Check: Check the cables and connections for any loose, broken, or worn-out components. Ensure they’re securely connected and replace any damaged parts.

- Lubrication: Follow the manufacturer’s instructions to maintain the right lubrication levels in case of sealing elements.

Identifying and Fixing Common Problems: A Trouble Shooting Guide

Slip rings can experience several common problems over their lifetime. Knowing how to identify these problems and taking prompt action can improve the ride’s safety and performance and possibly extend the life of the slip ring.

Here are the common problems and their solutions:

- Poor Electrical Contact: This could be due to buildup on conductive surfaces or worn-out brushes. Regular cleaning and brush replacement can mitigate these issues.

- Arcing or Overheating: Often caused by excessive currents or voltage, misaligned brushes, or loose connections. Check for proper alignment, secure connections, and adhere to specified current/voltage limits.

- Unusual Noise or Vibration: These could signify bearings failure or issues with alignment. Inspect the bearings and alignment to resolve these issues.

- Signal Interference: Likely caused by dust or debris buildup, worn-out brushes, or issues with shielding. Regular cleaning, brush replacement, and checking the shielding can alleviate such problems.

When to Replace a Slip Ring: Recognizing the Signs

While regular maintenance and repair can extend the life of a slip ring, there comes a time when replacement is the best solution. Here are some signs indicating that it’s time to replace a slip ring:

- Repeated failures or breakdowns, despite maintenance and troubleshooting.

- Severe wear or damage that’s beyond repair, like significantly worn tracks or severely damaged housing.

- Persistent arcing or overheating that cannot be mitigated with routine troubleshooting.

- Poor performance leads to interrupted operation of the ride or compromised safety.

Keeping your amusement ride slip rings in excellent working condition requires ongoing maintenance, effective troubleshooting, and recognizing the signs when it’s time for a replacement. Armed with these guidelines, you’ll be able to deliver consistent enjoyment to your park visitors while ensuring safety and operation efficiency.

Safety Measures and Compliance for Amusement Ride Slip Rings

Safety Guidelines: Protecting Riders and Operators

Ensuring safety in amusement parks is of paramount importance, and slip rings used in amusement rides play a crucial role in maintaining this safety. Following these guidelines can help protect both operators and riders:

- Installation Safety: Only trained professionals should perform the installation of slip rings. This ensures that all safety measures are followed during the setup process and that potential accidents are prevented.

- Routine Maintenance and Inspections: Regular inspection and maintenance of slip rings are vital for identifying potential issues that may affect the safety of the ride. These checks should include visual inspections, contact checks, and functional tests.

- Emergency Shutdown Measures: The operator should have an easy-to-access emergency shutdown switch to immediately stop the ride if abnormal noise, overheating, or any other unusual conditions occur.

- Safety Briefing for Operators: All operators should receive a thorough safety briefing. This includes explaining how the ride and its safety systems work, how to identify potential problems, and what to do in case of emergencies.

- Proper Signage and Instructions: Amusement rides should have proper signage, highlighting any age, height, or health restrictions. These guidelines prevent riders who could be at risk from using the ride and offer general safety instructions.

Applicable Standards and Regulations: Adhering to the Rules

Compliance with applicable standards and regulations is a legal requirement for the operation of amusement rides. These rules help ensure the safety of all parties involved, from designers and operators to the end user – the riders.

- ASTM F2291: It is a common standard for amusement rides and devices, ensuring rides are designed and manufactured to minimize foreseeable risks.

- ISO 17842: It encompasses safety requirements for amusement rides, providing guidance on design, manufacturing, operation, maintenance, and auditing.

- Local Building Codes: Amusement parks must also adhere to local building codes and regulations, especially in terms of electrical installations, which typically dictate how slip rings should be installed and maintained.

- Inspection and Certification: All amusement rides should undergo regular inspections by certified professionals or regulatory bodies. These inspections ensure rides are in compliance with all safety standards and regulations.

- Manufacturer’s Guidelines: Strictly follow the slip ring manufacturer’s guidelines for installation, operation, maintenance, and safety precautions.

Safety measures and compliance with regulations not only ensure that amusement rides are enjoyable, but also that they’re safe for use. Thorough knowledge of safety guidelines and regulations can lead to a better amusement park experience for everyone involved.

Case Studies of Amusement Ride Slip Rings

Success Stories: Slip Rings Doing Great

Case studies of successful implementations of slip rings offer valuable insights into how these important components contribute significantly to the efficient and safe operation of amusement rides.

- Cutting-Edge Ferris Wheel: In one reputed theme park, an innovative and high-tech Ferris wheel installation utilized sophisticated electrical slip rings. These devices seamlessly transferred power and data signals to rotating gondolas equipped with interactive media systems. This fun, interactive element truly boosted the ride’s appeal, making it a hit among park visitors.

- Interactive Carousel: A successful application of slip rings in a modern carousel allowed for the dynamic control of LED lights on each individual horse. Run by a slip ring transmitting power and control signals, the captivating light display, synchronized with music, significantly enhanced the ride experience.

- Rotating Dark Ride: A thrilling, rotating dark ride in a famous amusement park employs heavy-duty slip rings, providing power and real-time data transmission for onboard audio-visual effects as the vehicles spin through the ride. The slip rings’ performance was excellent, ensuring a smooth and fully immersive experience for riders.

Lessons from Failures: What We Can Learn

Learning from failures is as important as taking note of success stories. Case studies involving unsuccessful implementations of slip rings can provide indispensable lessons for future installations.

- Faulty Ferris Wheel: In one incident, a Ferris wheel experienced recurring downtimes due to the premature failure of its slip ring. Investigation revealed that a lack of regular maintenance was the cause. The incident underscores the importance of regular inspections and maintenance to identify wear and tear before it leads to larger problems, ensuring the longevity and safety of the equipment.

- Carousel Catastrophe: A carousel ride encountered a series of electrical issues leading to unscheduled shutdowns. Upon inspection, it was discovered that the slip ring was rated for a lower current than the ride’s system was drawing, resulting in overheating and failure. This emphasized the importance of proper component specification, as well as the dangers of not adhering to the manufacturer’s ratings and guidelines.

- Haunted House Horrors: A rotating dark ride with interactive elements had issues with the inconsistent performance of its interactive elements. The culprit was dust and debris build-up in the slip ring, interrupting proper signal transmission. This failure underscores the necessity of a clean operating environment and regular cleaning of slip rings to ensure top performance.

Accumulating these success stories and learning from past failures go a long way in ensuring the successful implementation and operation of amusement ride slip rings. It not only provides valuable insights for operators and professionals, but it also enhances the overall safety and experience of amusement park visitors.

Conclusion

After exploring amusement ride slip rings in detail, it’s clear their role is vital in ensuring a safe and enjoyable amusement park experience. With advancements in technology, future trends hold exciting possibilities for slip rings, such as increased connectivity and integration with IoT and AR/VR technologies for more interactive rides.

FAQs about Amusement Ride Slip Rings

Answering frequently asked questions can help clarify common misconceptions and provide crucial information to users and operators of slip rings in amusement rides.

Q: How often should I inspect the slip ring?

A: Regular inspections should be carried out as advised by the manufacturer. However, as a general rule, it’s advisable to conduct a visual check before operating the ride each day and carry out a more thorough inspection every month.

Q: What if I notice excessive heating or arcing of the slip ring?

A: If you observe excessive heating or arcing, discontinue use immediately and consult with a professional. Continued use in such circumstances can lead to damage and potentially unsafe conditions.

Q: Can I replace the brushes myself?

A: Brush replacement is a critical task that should be performed by trained personnel only. Incorrect replacement might lead to poor electrical contact, arcing, or damage to the slip ring.

Q: What kind of maintenance does a slip ring require?

A: Routine maintenance includes cleaning contacts, ensuring proper lubrication according to the manufacturer’s instructions, checking for secure connections, and visually inspecting for wear and possible damage.

Q: Can slip rings transmit both power and data signals?

A: Yes, there are multi-channel slip rings available that can transmit power as well as data signals. This feature is particularly useful in modern amusement rides with integrated audio-visual effects.

Q: What should I do if my slip ring is continuously failing despite maintenance?

A: If the slip ring is regularly failing despite maintenance and troubleshooting, it may be due for a replacement. Consult with a professional or manufacturer for further guidance.

Addressing these questions and doubts will facilitate a better understanding and usage of slip rings in amusement rides. This in turn ensures safer and more enjoyable rides for visitors while decreasing potential downtime for maintenance and repairs.

See What We Can Do