In the industrial landscape, particularly in the oil and gas sector, technology’s role cannot be overstated. One such technological component that plays an indispensable part in these operations is the wireline logging slip ring. These slip rings, suited for extreme conditions, facilitate the smooth operation of wireline logging, which is a crucial practice in assessing well conditions and overall reservoir productivity.

This comprehensive guide is tailor-made for engineers, field service technicians, sector veterans, and those developing an interest in industrial machinery. It provides an in-depth look into wireline logging slip rings and their application in the industry. It equips you with an understanding of how these components function, the critical role they play in oil and gas operations, and how they interact with other parts to give an efficient output.

By plowing through this guide, you’ll get acquainted with the operational aspects, distinct characteristics, and maintenance requirements of the wireline logging slip ring. Moreover, you will gain insights into choosing the right slip ring for your operation, making sense of industry regulations, and an idea about the future trends of these essential industry components. As this guide lays out, what seems like an unassuming part of your machinery holds significant importance in overall operational efficiency and success.

Understanding Wireline Logging Slip Rings

Definition of Wireline Logging

Wireline logging, also often referred to as well logging, is a crucial practice in the petroleum industry. The procedure involves lowering measurement instruments into a wellbore using a long ‘wireline.’ This wireline aids in the transmission of data about the layers of rock or fluid in the drill hole back to the surface.

Historical Evolution and its Significance in the Oil and Gas Industry

The concept of wireline logging originated in the early 1920s through the resourcefulness of two brothers, Conrad and Marcel Schlumberger. The Schlumberger brothers performed the first wireline log in France, revolutionizing subsurface exploration. Wireline logging has since been an integral part of the oil and gas industry.

It plays an essential role in maximizing reservoir exploitation and optimizing drilling strategies. By providing critical data about the subsurface, it helps identify the location and estimate the quantity of hydrocarbons amidst an ocean of complex geological formations.

Brief Overview of Slip Rings

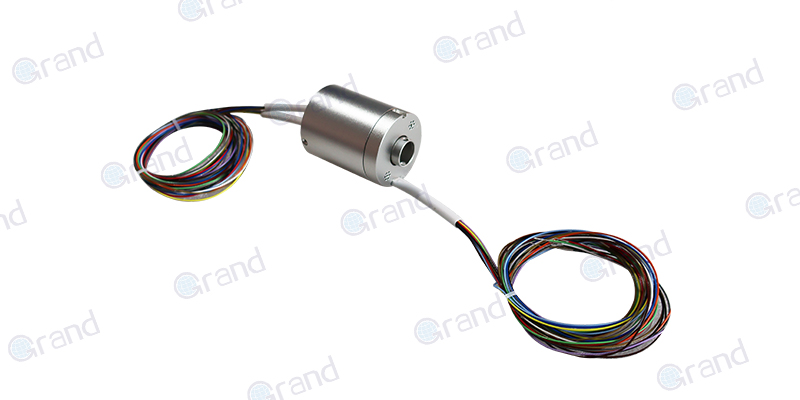

In the context of wireline logging, slip rings serve as a pivotal electromechanical device that permits the transmission of power and electrical signals from a stationary to a rotating structure. The slip ring makes this possible by interfacing with brushes that maintain physical contact as the mechanism rotates. This ensures continuity in the transmission, specifically critical during continuous logging operations.

How a Wireline Logging Slip Ring Operates with its Design and Construction Details

Wireline Logging Slip Rings are specifically designed to meet the robust requirements of an oilfield environment. Constructed to endure challenging conditions, their intricate design includes multiple rings separated by insulating materials. These rings are connected to the rotating wires, allowing for an uninterrupted transfer of data and power.

The design and construction of these slip rings must prioritize resilience, given the drilling site’s typically harsh conditions. As such, high-grade, corrosion-resistant materials are used in their manufacturing to ensure durability and reliable performance under extreme conditions.

The Role of the Wireline Logging Slip Ring in Wireline Operations

The Wireline Logging Slip Ring forms a crucial component in wireline operations. During a wireline logging process, the instruments that measure formations’ various properties are continually rotating and moving. This is where the slip ring plays its part by ensuring an uninterrupted connection, allowing for a constant flow of power, and maintaining data integrity.

Through this detailed understanding of Wireline Logging Slip Rings, we appreciate the integral role they play in the extraction and exploration activities in the oil and gas industry. Their contribution to ensuring seamless data and power transmission is pivotal to achieving operational efficiency and making informed decisions in this formidable sector.

Wireline Logging Slip Rings Operational Aspects

Step-by-step Guide on How to Operate a Wireline Logging Slip Ring

Operating wireline logging slip rings is no small task, it requires understanding, implementation of safety measures, and careful handling of the equipment. Here is a simplistic but comprehensive guide:

- Assemble the Equipment: Prior to beginning any operations, ensure all parts of the slip ring and related assembly are properly configured and in place. This involves attaching the brushes to the slip ring, ensuring proper alignment for rotation.

- Check the Connections: Ensure all electrical connections are proper. This is crucial for the smooth flow of signals and preventing short circuits.

- Start the Operation: Before starting, confirm that the equipment begins rotating smoothly without any resistance. Turn on the power and monitor the slip ring’s functioning continuously.

- Monitor the Signals: Pay careful attention to the signals transmitted. Any discrepancies could indicate mechanical issues that need immediate investigation and rectification.

Precautions to Take and Safety Measures

While operating the wireline logging slip ring, the following precautions and safety measures should be adhered to:

- Personal Protective Equipment (PPE): Ensure all operators are equipped with appropriate protective gear.

- Routine Inspection: Regularly inspect the equipment for wear and tear or damage. This includes checking the brushes for wear, ensuring the insulation is intact, and checking the body for any visible damage.

- Proper Setup: Always follow the manufacturer’s installation guide and ensure the equipment is set up correctly.

- Emergency Protocol: Always have an emergency shutdown and evacuation procedure in place and ensure all personnel are trained in it.

- Hazardous Environment: As wireline logging slip rings often operate in hazardous environments, observe all additional safety regulations applicable to the area.

Maintenance and Servicing of the Wireline Logging Slip Ring

Preventive maintenance and regular servicing ensure the longevity and efficiency of the wireline logging slip ring. Steps include:

- Regular Cleaning: The slip ring components accumulate dust and debris over time. Regular cleaning with recommended solutions can ensure optimal performance.

- Component Inspection: Regularly check all components, particularly the brushes and contact surface, for signs of wear or damage.

- Replacement of Worn Parts: Any part showing signs of significant wear should be promptly replaced to prevent further damage.

- Lubrication: Depending on the manufacturer’s recommendation, some parts of the slip ring might need periodic lubrication to ensure smooth rotation.

By understanding these operational aspects, it becomes evident that effective operation and maintenance of a wireline logging slip ring are crucial for reliable and efficient wireline operations. Not only does this improve the lifespan of the equipment, but it also ensures the safety of operators and the accuracy of data collected.

Characteristics of Wireline Logging Slip Ring

Description of the Essential Features

Wireline Logging Slip Rings are specialized devices engineered with a multitude of remarkable features. They are:

- Robust Construction: These slip rings are designed to withstand harsh environments typical in oil and gas operations.

- Data and Power Transmission: They excel in transmitting electrical signals and power from stationary to revolving parts, enabling uninterrupted data acquisition even during continuous rotation.

- Insulation: Proper insulation between the rings ensures no short-circuiting or cross-connection happens, preserving the integrity of the signals transmitted.

- Long Cable Lengths: These slip rings are often equipped with long cable lengths for deep well measurements.

Durability and Longevity

Durability stands as a strong testament to the wireline logging slip ring’s endurance in the face of rugged, harsh environments. The use of high-grade materials, such as corrosion-resistant metals in their construction, contributes to their long-lasting nature. Their robust build also ensures they can operate for long periods without failure, making them a reliable part of oilfield operations.

Compatibility and Versatility with Other Equipment

One of the primary strengths of wireline logging slip rings remains their compatibility and versatility with various pieces of equipment. They can interface seamlessly with diverse wireline tools and are adaptable to multiple operational configurations.

Their versatile design allows fitting in various logging tools, regardless of their function or operational mechanism. This extends the range of applications where they can be used, giving them an adaptability edge when it comes to their integration in different systems.

Therefore, the wireline logging slip ring is not just any component, but a device that embodies resilience, flexibility, and durability. Its well-thought-out characteristics make it a fundamental part of an industry where reliability, longevity, and adaptability are crucial.

Factors to Consider when Purchasing a Wireline Logging Slip Ring

Acquiring a wireline logging slip ring is not a straightforward task; there are numerous aspects to consider to ensure optimal functionality and value for money. Here are some of the critical factors:

Key Features to Look For

When purchasing a wireline logging slip ring, keep an eye out for the following key features:

- Reliability: The device must be able to transmit data reliably over long periods and in harsh conditions. Look for products that demonstrate proven performance in this area.

- Durability: These slip rings are often used in challenging environments, so they must be built to last. Quality materials and sturdy construction are a necessity.

- Signal Integrity: The device must be able to preserve the integrity of your electrical signals.

- Insulation: Proper insulation between the rings ensures that no short-circuiting or cross-connection occurs.

Price Consideration and Worth

It’s crucial to align the pricing of a wireline logging slip ring against its features and durability. Not all high-priced slip rings mean high quality, and not all affordable slip rings offer poor performance. To make the most of your investment, look for a balance of cost and performance, keeping in mind the specific needs of your operation.

Notable Manufacturers and Suppliers of Wireline Logging Slip Rings

Several reputable manufacturers and suppliers provide high-quality wireline logging slip rings. When choosing one, consider the company’s reputation in the industry, customer reviews, and overall product performance.

Post-Sales Service and Warranty Details

Lastly, after-sale services and warranties can significantly impact the overall cost and performance of the equipment. Always look for manufacturers providing excellent service and support. Consider the length and comprehensiveness of the warranty, as well as the manufacturer’s reputation for honoring their warranty claims and providing prompt and efficient service.

By factoring these critical aspects into your decision-making process, you can ensure that your investment in a wireline logging slip ring is well-directed and fruitful. This way, you will not only acquire a device that caters to your operational requirements exceedingly well but also one that offers optimal value for money.

Wireline Logging Slip Rings Case Studies

Exploring real-world scenarios where Wireline Logging Slip Rings have been used can serve as a valuable resource for understanding their impact and potential. Here, we take a closer look at a couple of those examples:

Case Study 1: Enhancing Data Acquisition in Offshore Drilling

A large multinational oil and gas company engaged a Wireline Logging Slip Ring in their offshore drilling operations, replacing their traditional rotary joints. The pervasive issue of interrupted data transmission during constant rotation was effectively handled by the logging slip ring.

The result was an uninterrupted, cleaner data stream leading to accurate subsurface formation evaluations. This significantly reduced costs linked to redundant drilling and increased efficiency in selecting optimal drilling points.

Case Study 2: Improved Longevity and Reliability

A midsized oilfield services company used a specific brand of Wireline Logging Slip Rings, reputed for their durability and signal integrity. Initially reliant on cheaper alternatives, the company faced recurring issues like reduced operational time and higher maintenance costs due to frequent failures.

Switching to a more durable and reliable Wireline Logging Slip Ring alleviated these issues. The new slip ring boasted a lower failure rate, reducing maintenance costs and operational delays. As a result, the company saw improved efficiency in data acquisition and reduced non-productive time.

These case studies provide insight into the use of Wireline Logging Slip Rings. The varied, real-life examples illustrate how these components can reduce operational costs, improve data accuracy, and enhance overall efficiency. These factors help reinforce the value, reliability, and adaptability of Wireline Logging Slip Rings in the oil and gas sector.

Wireline Logging Slip Rings Troubleshooting Common Issues

When encountering problems with a Wireline Logging Slip Ring, it is essential to understand some of the most common issues and how to troubleshoot them. This section offers a comprehensive guide to identifying and resolving these issues, as well as determining when to seek professional intervention.

Issue 1: Loss of Signal

Potential Causes:

- Dirty or contaminated contact surfaces

- Worn or damaged contact surfaces

Troubleshooting Steps:

- Inspect the slip ring and clean any visible debris around the contact surfaces.

- Examine the contacts for wear and tear. If they are too worn or damaged, replacement might be necessary.

Issue 2: Intermittent Signal

Potential Causes:

- Loose connections or wiring

- Varying contact pressure

Troubleshooting Steps:

- Inspect the wiring and connections to ensure that they are secure and not damaged. Repair or replace as necessary.

- Examine the brush contact pressure. If it is uneven or too weak, adjust the pressure according to the manufacturer’s recommendations.

Issue 3: Excessive Noise or Vibration

Potential Causes:

- Bearing wear or damage

- Misaligned slip ring components

Troubleshooting Steps:

- Inspect the bearings for any visible wear or damage. If necessary, replace the bearings.

- Check the alignment of the slip ring components. If misaligned, reassemble the components according to the manufacturer’s guidelines.

Issue 4: Overheating

Potential Causes:

- Excessive operating current

- Poor heat dissipation

Troubleshooting Steps:

- Confirm that the slip ring is operating within its current rating. If the current exceeds the rating, adjust the load accordingly.

- Inspect the slip ring for proper ventilation and heat dissipation. Ensure that it is not obstructed and that cooling mechanisms (if applicable) are operating efficiently.

When to Seek Professional Intervention

In some cases, professional intervention may be required if self-troubleshooting does not yield results. If you have followed the troubleshooting steps and the issue persists, or if you suspect that specialized knowledge is needed to safely assess the situation, it is recommended to consult a professional or contact the manufacturer’s technical support team.

Maintaining a properly functioning Wireline Logging Slip Ring is critical for efficient data acquisition and operational success. By being mindful of the common problems, understanding the steps for troubleshooting these issues, and knowing when to seek professional help, you can minimize negative impacts on your operations and prolong the life of your slip ring.

Wireline Logging Slip Rings Innovations and Trends

The landscape of wireline logging slip rings is persistently evolving under the influence of technological progress and industry demands. This section provides a breakdown of the recent technological advancements and an overview of anticipated trends governing the future of Wireline Logging Slip Rings.

Technological Advancements

- Improved Materials: Modern Wireline Logging Slip Rings leverage advanced materials that offer enhanced performance and longevity. These include high-grade carbon and precious metal composites that boost the device’s resilience and operational lifetime.

- Higher Signal Integrity: The introduction of advanced shielding and contact design techniques has significantly improved signal integrity. This enables more accurate and reliable data transfer, even in highly dynamic operating conditions.

- Adoption of Fiber Optic Technology: The latest slip rings leverage fiber-optic rotary joints (FORJs), enabling high-speed data transfer over long distances without signal loss, which is crucial for digital wireline logging operations.

Anticipated Trends

- Internet of Things (IoT) Integration: As IoT becomes more prevalent in the industrial realm, expect to see Wireline Logging Slip Rings aligning with IoT to facilitate real-time data access and remote monitoring.

- Miniaturization: With a shift towards operational efficiency and compactness, the industry will likely see the development of smaller, more efficient slip rings that don’t compromise on performance.

- Sustainability: As environmental concerns grow, the manufacturing practices and materials used in producing Wireline Logging Slip Rings will trend towards more sustainable solutions.

Staying abreast of these advancements and trends can allow businesses and professionals to leverage the most efficient, effective, and up-to-date technology in their operations, which will facilitate more successful outcomes in wireline logging and related endeavors.

Wireline Logging Slip Rings Regulations and Standards

A critical aspect of the production and usage of Wireline Logging Slip Rings involves conforming to the relevant regulations and standards. This section gives an overview of these benchmarks and gives guidance on ensuring compliance.

Overview of Relevant Regulations and Standards

Wireline Logging Slip Rings, being an integral part of numerous industries, including oil and gas, are regulated by several industry and safety standards.

- ISO 9000 Quality Management Standards: These international standards ensure that the products are reliable, of good quality, and meet customer needs.

- IEC 60068 Series: These standards relate to Environmental Testing for Electrotechnical Products, including conditions like temperature, humidity, shock, vibration, and pressure.

- ATEX/IECEx Standards: Relevant for products used in explosive atmospheres (like oil and gas), these regulations ensure the components do not ignite an explosion due to arcing or high temperatures.

Ensuring Compliance

- Product Testing: Regular product testing should be conducted as per the standards to ensure that the product is compliant with various conditions.

- Periodic Audits: Scheduling regular audits enables a company to ascertain whether its operational procedure adheres to relevant norms.

- How-To Guides: Be sure to follow setup guidelines and operation manuals provided by the manufacturer, as they typically ensure the user meets regulatory requirements.

- Certifications: Look for products that have certification labels. These serve as a third-party validation of the product’s compliance with an accepted standard.

In this increasingly regulatory environment, being aware of the regulations and standards governing Wireline Logging Slip Rings ensures the safety and efficiency of operations, whilst maximizing the longevity of the product. Compliance is not only a best practice but also obligated by law in many regions, and non-compliance can lead to penalties or legal complications.

Conclusion

In summary, Wireline Logging Slip Rings play a vital role in data acquisition operations, particularly within the oil and gas industry. By enabling continuous contact and smooth transmission of power and data during rotation, these components are essential for efficient and accurate wireline logging processes.

Throughout this guide, we have explored various aspects of Wireline Logging Slip Rings, including:

- Their design and functionality

- Advantages and limitations

- Real-life case studies

- Troubleshooting common issues

- Technological advancements and trends

- Relevant regulations and standards

By understanding these aspects, professionals can make informed decisions when utilizing these components in their operations, optimizing the accuracy and efficiency that slip rings can offer.

As the industry advances, Wireline Logging Slip Rings are expected to become even more efficient and reliable, incorporating IoT integration, miniaturization, and sustainable practices. These innovations will serve to further enhance the oil and gas industry’s performance and the broader scope of industrial applications that employ Wireline Logging Slip Rings.

By keeping up to date with advancements, troubleshooting tips, and relevant regulations, users will be able to harness the full potential of Wireline Logging Slip Rings, ensuring success in their applications and a brighter future for the industry.

FAQs about Wireline Logging Slip Rings

In this section, we will address some common questions about Wireline Logging Slip Rings. These questions and their corresponding answers will provide a more in-depth understanding of the topic.

Q1: What is the primary function of a Wireline Logging Slip Ring?

A: The primary function of a Wireline Logging Slip Ring is to enable the transmission of power and electrical signals from a fixed to a rotating structure. This feature is particularly crucial in wireline logging operations where instruments collecting data about the formations are rotating constantly.

Q2: How durable are Wireline Logging Slip Rings?

A: Wireline Logging Slip Rings are designed with durability as a top priority. They are made from high-grade materials that are resistant to corrosion and designed to endure the harsh conditions of oilfield environments. This makes them extremely robust and reliable.

Q3: Are Wireline Logging Slip Rings compatible with all wireline logging equipment?

A: Yes, one of the significant benefits of Wireline Logging Slip Rings is their compatibility and versatility. They can seamlessly interface with various wireline tools and adapt to several operational configurations.

Q4: How often should Wireline Logging Slip Rings be serviced or maintained?

A: The specific maintenance schedule can depend on the manufacturer’s guidelines and the usage conditions. However, it is generally recommended to regularly inspect and clean Wireline Logging Slip Rings to ensure optimal performance. Any worn or damaged parts should be replaced promptly.

Q5: What safety measures should be adopted while operating a Wireline Logging Slip Ring?

A: Safety measures include, but are not limited to, using appropriate personal protective equipment, regularly inspecting the equipment, and following the manufacturer’s instructions for installation and use. It’s also important to have an emergency protocol in place.

This FAQ section provides answers to common inquiries related to Wireline Logging Slip Rings, aimed at further enhancing understanding of their function, operation, and maintenance.

See What We Can Do