Welcome to our comprehensive guide on pitch control slip rings. These critical elements may seem small in the grand design of renewable-energy generation, but their role is truly pivotal. They play a crucial part in harnessing wind energy, one of the leading forms of renewable energy today. As climate change urges the world to adopt cleaner energy sources, the understanding of such components, which facilitate this transition, becomes increasingly significant.

In this guide, we intend to delve into every facet of pitch control slip rings—components often unsung yet integral to the successful operation of wind turbines. We’ll explore their basic concept, how they function, the different types available, and their myriad applications. Furthermore, we’ll discover what considerations come into play when choosing a slip ring for a specific application, and how they’re installed, maintained, and even troubleshooted.

The rapid pace of advancements in this field also awaits our attention. As the demand for more efficient and reliable wind turbines grows, so does the technology associated with pitch-control slip rings. Hence, we’ll walk you through the current trends and the predicted future of this technology. Whether you’re a student, an engineer, a researcher, or someone simply interested in renewable energy systems, this guide aims to provide a clearer picture of the part pitch control slip rings play in leveraging the power of the wind. Let’s start this enlightening journey.

What is a Pitch Control Slip Ring?

A pitch control slip ring is a specialized electromechanical device designed for transmitting electrical signals and power between rotating and stationary components of a wind turbine system. Essentially, it enables the continuous, uninterrupted flow of electricity and data, overcoming the constraints caused by the relative motion between the two parts.

Wind turbines rely on these slip rings to achieve precise control of the pitch angle of their blades. This angle is the key factor in harnessing energy from the wind efficiently. As wind conditions fluctuate, the ideal capture of wind energy depends on the blades’ ability to adjust to the most appropriate angles. Consequently, the uninterrupted transmission of electrical control signals and power that pitch control slip rings provide allows for the wind turbine’s blades to align and respond to changing wind speeds and directions effectively.

In a wind turbine, the pitch control slip ring is generally located in the hub that connects the rotor blades and the main shaft. Acting as a subtle yet critical link, it ensures smooth communication and electrical flow between the static systems—like electrical generators, control systems, and power converters—and the dynamic, rotating components, such as the wind turbine’s blades, rotor, and hub. This seamless connection comes to fruition while the entire assembly endures harsh weather conditions and the long-term stress of constant rotation.

Given the significant role pitch control slip rings play in optimizing wind turbine performance and consequently, harnessing renewable energy, it’s vital to understand their underlying principles, design, and capabilities. That way, it becomes easier to envision and appreciate the broader context of their function within the wind-energy domain.

Pitch Control Slip Ring Principle of Operation and Design

Basic Operation

The pitch control slip ring is grounded in the simple yet ingenious idea of maintaining electrical connectivity between stationary and rotating platforms within a wind turbine system. Its functioning revolves around transmitting electrical power and signals through a mechanical interface made up of concentric, conductive rings and brushes.

In a typical pitch control slip ring, multiple concentric rings with a conductive surface form the rotating part, also known as the rotor. Each of these rings corresponds to a specific electrical channel for power or data transfer. Parallel to the rotor, stationary brushes made from conductive materials, such as graphite or precious metals, establish and maintain contact with the rotating rings. As the wind turbine’s components rotate, these brushes slide over the conductive rings, providing consistent connectivity by transferring electrical signals or power from the stationary component to the rotating component, and vice versa.

Design and Structural Arrangement

Pitch control slip rings are designed to maintain a compact and durable structure to withstand the demanding conditions of wind turbines. The slip rings can be found in different forms, including capsule slip rings, pancake slip rings, and modular slip rings. Each design caters to specific requirements in terms of size, weight, and the number of channels or conductors needed.

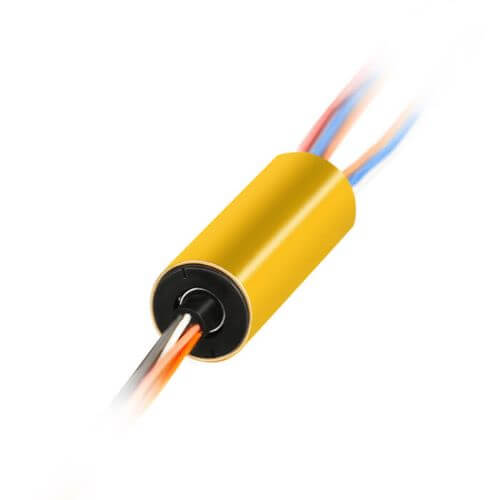

Capsule Slip Rings

They consist of a cylindrical enclosure where the concentric rings and brushes are protected from external contaminants and damage. These slip rings have a small footprint but are limited in terms of the number of electrical channels they can accommodate.

Pancake Slip Rings

Also known as flat slip rings, they have a disc-shaped configuration with concentric rings arranged flatly. This design minimizes axial length, ideal for applications with limited space in the axial dimension. However, pancake slip rings tend to have a larger diameter, and caution must be taken with regard to their rotational inertia.

Modular Slip Rings

Highly versatile in nature, these slip rings consist of individual modules that can be assembled to accommodate a specific set of channel requirements. They offer greater flexibility, allowing for easy expansion or adaptation for custom applications.

Regardless of the design, pitch control slip rings must take into consideration essential factors such as electrical noise reduction, thermal management, and low friction operation. Manufacturers employ material selection, lubrication, and sophisticated engineering solutions to ensure the proper function and longevity of the pitch control slip ring.

In sum, the pitch control slip ring operates as an essential electrical interface to transmit power and signals between the stationary and rotating components of wind turbines. Its design and structure focus on meeting the challenges that arise from this demanding environment while providing a coherent and effective solution for seamless electrical transmission.

Different Types of Pitch Control Slip Rings

Pitch control slip rings come in various forms and configurations. Although the underlying principle remains the same, different designs cater to unique requirements and usage scenarios. Here’s an insight into some of the most common types of pitch control slip rings, highlighting their differences, advantages, and potential drawbacks.

High-frequency Slip Rings

In the context of wind turbines, high-frequency slip rings serve to transmit high-speed data signals amidst the rotation. These slip rings are typically used when the turbine needs to send and receive data from both the stationary and rotating parts at high speed, for instance, to achieve real-time control of the pitch blades.

Advantages: High-frequency slip rings enable rapid, real-time data communication, ensuring that the wind turbine can respond quickly and accurately to changing wind conditions.

Drawbacks: Generally, these seek a more complex design and may require specific maintenance to uphold signal quality, making them more expensive and demanding in terms of upkeep than lower frequency variants.

Ethernet Slip Rings

These slip rings facilitate the transmission of Ethernet protocol signals between the stationary and rotating parts of the wind turbine. With digital transformation sweeping across industries, wind turbines are also adopting connected, IoT-based approaches for their operation and maintenance, rendering Ethernet slip rings more relevant.

Advantages: Ethernet slip rings cater to the needs of Internet-connected wind turbines, enabling seamless communication and data transfers. Furthermore, they provide the bandwidth necessary for surveillance, control, and other data-intensive applications.

Drawbacks: Similar to high-frequency slip rings, Ethernet variants also necessitate particular attention to maintenance to ensure uninterrupted high-speed data transmission.

Hybrid Slip Rings

Hybrid slip rings combine the transmission of power, high-speed data, and rough data in one compact unit. They are increasingly finding use in modern wind turbines that demand diverse communication needs and power transmission simultaneously.

Advantages: Hybrid slip rings offer a highly integrated solution that can simplify installation and potentially reduce costs. They are a versatile choice for complex systems requiring a variety of transmission types.

Drawbacks: While they are versatile, any failure in a hybrid slip ring might lead to a loss in function of several systems simultaneously.

In essence, diverse types of pitch control slip rings cater to diverse needs within wind turbines. While some focus on high-speed data transmission, others cater to the need for internet-connected functionality, and still, others combine a variety of transmission types for an integrated solution. Understanding their distinctions, advantages, and potential drawbacks is crucial in choosing the most suitable fixture for a particular wind turbine setup.

Applications of Pitch Control Slip Rings

As impressive devices enabling consistent electrical conductivity between stationary and moving components, pitch control slip rings find utilization in numerous applications. They are particularly relevant where the transmission of power or signal in a rotating structure is necessary.

Wind Turbines

The most prominent application of pitch control slip rings can be observed in wind turbines. These slip rings play an essential role in changing the angle (or pitch) of the blades relative to the oncoming wind. By adjusting the angle or pitch of the blades, the wind turbine can maximize energy capture at lower wind speeds and protect itself from potential damage at high wind speeds.

Furthermore, the slip rings in wind turbines help transmit power and data signals from the controller to the pitch motor which is located inside the rotating blades. This consistent electrical transmission is crucial for the steady operation of the turbines, optimal energy generation, and mitigating mechanical stresses on the wind turbine’s structure.

Rotating Equipment and Machinery

Apart from wind turbines, pitch control slip rings also find application in other rotating equipment. For instance, in rotating antennas, centrifuges, display turntables, and more. They assist in the transfer of electrical power and signals, ensuring consistent functionality amidst rotation for these devices.

In rotating antennas, for instance, slip rings play a crucial role in the transmission of radio frequency signals during the antenna’s rotation. They ensure the antenna can receive and transmit signals continuously even as it changes direction.

Hostile Environment Equipment

Hostile environment equipment like submersibles and downhole drilling tools also employ pitch control slip rings. These machines operate in environments where the traditional means of electrical transmission may fail or be impractical. Here, slip rings guarantee robust performance despite challenging conditions, thereby ensuring that these machines can perform their intended tasks effectively.

In conclusion, pitch control slip rings make a critical contribution across various fields, enabling the seamless operation of rotating machinery and equipment. They demonstrate their importance in each application by guaranteeing unceasing electrical transmission during rotation, thereby ensuring optimal performance and operational efficiency. By understanding their diverse application contexts, one can better appreciate the importance and versatility of pitch control slip rings.

Factors to Consider When Choosing a Pitch Control Slip Ring

Choosing the right pitch control slip ring is crucial for the optimal operation of a wind turbine or any other rotating machinery. It should meet both the application requirements and the operational environment. Here’s a glimpse into some of the pivotal factors to take into account when selecting a pitch control slip ring:

Size and Configuration

The size and configuration of the slip ring are vital considerations. These are dictated by the space limits within the hosting equipment and the necessary number of electrical channels. Capsule slip rings can be a great choice for smaller spaces while modular slip rings allow for more versatile configuration options to accommodate various power, data, and signal channels.

Durability and Lifespan

Considering the demanding operational conditions, durability, and lifespan are essential factors to consider. Slip rings should be robust enough to endure the mechanical stresses incurred during rotation and have a sufficient lifespan to ensure continuous operation with minimum downtime.

Cost and Manufacturer Reputation

While cost is always a consideration, it is prudent not to skimp on quality for the sake of saving money. Purchasing from a reputable manufacturer can ensure that you get a well-engineered product designed to meet both your needs and industry standards. Consider the total cost of ownership rather than just the initial purchasing cost. A cheap slip ring may need more frequent replacements, leading to higher costs in the long run.

Operating Environment

The environment your slip ring will be operating significantly affects its performance and lifespan. For example, in outdoor applications such as wind turbines, slip rings must be able to withstand diverse weather conditions and be corrosion resistant. Similarly, in applications like downhole drilling, where the slip ring might encounter high temperatures and pressures, choosing one that can withstand these harsh conditions is crucial.

In conclusion, selecting the right pitch control slip ring is a multifaceted decision that involves balancing various factors. These considerations encompass tangible aspects like size, cost, durability, and manufacturer reputation to more complex considerations like the operating environment. By carefully considering these factors, users can ensure they select the most suitable slip ring for their application, ultimately optimizing performance and efficiency in their operations.

Pitch Control Slip Ring Installation and Maintenance

Proper installation and maintenance of pitch control slip rings play a critical role in ensuring their long-term performance, functionality, and safety. Here, we outline a detailed guide on installing pitch control slip rings along with an overview of common maintenance practices and useful tips.

Installation Guide

- Preparation: Read the product manual or documentation thoroughly, ensuring that you fully understand the specific requirements, guidelines, and safety precautions for the slip ring you have chosen. Prepare the necessary tools and materials for the installation.

- Site Preparation: Make sure the installation site is clean and free of any dust, debris, or foreign materials that may compromise the slip ring’s performance. Prepare the mounting surface as recommended by the manufacturer.

- Mounting the Slip Ring: Mount the slip ring in the prescribed orientation and position, following the manufacturer’s guidelines. This may vary with different slip rings. Ensure that the slip ring is secure and stable in its mounting.

- Connecting Electrical Channels: Accurately connect the cables to the rotary and stationary components of the slip ring, while strictly following the wiring map provided. Ensure that cables are properly insulated and strain relief is employed to prevent cable damage due to bending or pulling.

- Testing: Turn on the equipment and run a test rotation to verify the performance of the slip ring connections and detect any issues. Ensure smooth rotation is achieved and electrical continuity is maintained during rotation.

Note: Always follow the specific product and system instructions provided by the manufacturer. The above steps are general pointers that may not directly apply to all slip ring installations, so adhere to the detailed guidelines provided by your manufacturer.

Maintenance Practices and Tips

- Regular Inspections: Conduct regular visual and operational inspections to detect any component degradation earlier. Look for any visible wear and tear like worn brushes, debris accumulation, or damaged cables.

- Cleaning: Keep the slip ring and its environment clean. Regularly clean the surface of the slip rings with a soft cloth or brush. Be cautious not to introduce any moisture or contaminants.

- Lubrication: Some slip rings may require periodic lubrication to reduce friction and enhance longevity. Check the manufacturer’s guidelines for lubrication requirements and follow the suggested lubricant type and intervals.

- Brush Replacement: Over time, brushes may wear out and need replacement. Keep a check on brush wear during inspections and replace them as per the manufacturer’s recommendations.

- Cable Management: Ensure cables are well-organized and free from kinks, strain, or damage. Check for any signs of cable deterioration and replace damaged cables promptly.

In summary, proper installation and maintenance of pitch control slip rings are essential to their optimal operation, longevity, and safety. Always follow the manufacturer’s instructions and guidelines, combine them with best practices and regular inspections, and adopt prompt corrective measures when needed.

Pitch Control Slip Ring Common Problems and Troubleshooting

Even with proper installation and diligent maintenance, problems can still arise with pitch control slip rings. Let’s review some of the most commonly encountered issues and provide some troubleshooting approaches to resolve these.

Intermittent Signal or Power Interruption

This is one of the most common problems. It can be attributed to various causes such as worn-out brushes, dirt or debris on the slip ring surface, or damaged cables.

Troubleshooting Approach: First, check for any visible signs of brush wear. If the brushes are excessively worn or damaged, they will need to be replaced. Then, clean the slip ring surfaces to remove any build-up of dust or debris. Finally, inspect the cables for any damage or loose connections and fix them as required.

Slip Ring Overheating

Overheating can be caused by excessive friction due to lack of lubrication, overloading, or inadequate ventilation.

Troubleshooting Approach: Check the slip ring casing’s temperature during operation. If it’s higher than the manufacturer’s specification, it might be a sign of overheating. Look for signs of inadequate lubrication and apply lubricant if necessary. Ensure the equipment isn’t being overloaded beyond its capacity, and if overheating persists, seek professional help to investigate the cause.

Unusual Noise

Unusual noise during the operation might be a sign of mechanical issues like misalignment, worn-out brushes or bearings, or a loose part in the slip ring assembly.

Troubleshooting Approach: Listen closely to the sound and try to detect its source. Check for signs of misalignment or loose parts and correct them. Inspect the brushes and replace them if worn out.

Loss of Package Integrity

This might occur due to poor maintenance, environmental exposure, or inadequate sealing. Impaired package integrity can lead to issues like moisture intrusion, corrosion, and ultimately, failure.

Troubleshooting Approach: Regularly inspect the slip ring’s physical integrity for signs of corrosion, cracks, or other damage. Rectify any defects promptly and maintain the cleanliness of the slip ring environment to avoid corrosion. If moisture intrusion is suspected, consider contacting a professional or the manufacturer for proper resolution.

In conclusion, encountering problems with pitch control slip rings is not uncommon. However, through regular monitoring and preventive maintenance, many issues can be avoided or at least caught and rectified in their early stages. Understanding common problems and knowing how to troubleshoot them greatly enhances the reliability and longevity of your slip rings.

Future Trends in Pitch Control Slip Rings Technology

Leap-forward advancements in technology have significantly driven innovation and improvements in pitch control slip rings. These innovations, coupled with future trends, are helping shape the future landscape of this crucial equipment. Here’s an overview of the key advancements and what the future holds for pitch control slip rings in terms of efficiency, design, and more.

Key Advancements and Innovations

Over the years, there has been a rise in the demand for wind energy which has propelled significant advancements in pitch control slip ring technology. Advancements have focused on enhancing durability, reducing maintenance, and increasing overall operational efficiency. Developments such as fiber optic rotary joints (FORJs) have radically improved data transmission capabilities.

Researchers and engineers have also been exploring ways to incorporate advanced materials and manufacturing techniques. For instance, carbon nanotube (CNT) brushes have shown promise to increase longevity, reduce wear, and sustain higher speeds.

Future Predictions

Moving forward, trends indicate a few potential directions for pitch control slip ring technology. As wind turbines continue to scale up in size, slip rings would need to adapt to the larger scales and higher transmission requirements. This, in turn, implies larger, more robust, and more complex slip rings.

Digital Transformation is another prevailing trend. With the rise in the integration of the Internet of Things (IoT) in industrial applications, pitch control slip rings might leverage smart features for predictive maintenance and real-time monitoring. This could lead to significant leaps in operational efficiency and maintenance protocols, ultimately elongating their lifespan, reducing downtime, and saving costs

Another potential area of progression is the reduction in friction and wear rates. This could be realized by the ongoing research in advanced materials and coatings. Developments in this area could potentially increase the lifespan of pitch control slip rings manifold, reducing the environmental footprint and maintenance costs.

In conclusion, the future of pitch control slip ring technology is promising, with innovations driven by new advancements in material science and digital technology. While challenges persist, continued research and development efforts aim to deliver more intelligent, robust, and efficient pitch control slip rings that meet the demands of the future.

Conclusion

Pitch control slip rings play an invaluable role in the utilization of wind energy, providing a reliable solution for power and signal transmission. As we anticipate future advancements, understanding these devices’ functioning and applications has never been more critical.

This guide serves as a comprehensive resource for understanding pitch control slip rings, their operation, and their application in various sectors. Remember, regular maintenance and proper selection are key to the optimal operation of these devices.

See What We Can Do