Harnessing wind energy has taken an innovative turn with the emergence of energy kites, or airborne wind turbines. These high-flying marvels, tethered to the ground, have the potential to tap into powerful, high-altitude winds to generate electricity. A critical component in these systems that often goes unnoticed is the energy kite slip ring.

An energy kite slip ring is an intriguing subject that often intertwines multiple disciplines including renewable energy, electromechanical engineering, and aviation. It involves the application of distinct mechanical designs and technology to function smoothly within a complex system. As the technology underpinning wind energy advances, understanding the nuances of components like slip rings becomes increasingly important.

Understanding energy kite slip rings is crucial for several reasons. For engineers and designers working on wind energy solutions, insights into the design and functionality of slip rings can inform decisions on system design and component compatibility. For stakeholders investing in or adopting wind energy, a deep understanding of slip rings equips them to make informed decisions and anticipate operational challenges. Lastly, as society gravitates toward renewable energy, increasing public understanding of energy kites and their components could drive acceptance and adoption.

Therefore, this guide aims to elucidate energy kite slip rings—their design, operation, and role in the broader context of wind energy harnessing.

What Are Energy Kite Slip Rings?

What is an Energy Kite?

When we mention kites, the imagery that typically springs to mind is a colorful, lightweight structure soaring in the sky, controlled by a string held by a person on the ground. While this isn’t an inaccurate picture, the application of kite technology has gone far beyond recreational use, venturing into the realm of renewable energy generation. That’s where the concept of an energy kite comes into play.

An energy kite, also known as an airborne wind energy system, operates on a significantly refined version of the same basic concept of a kite. These energy kites, which can also be referred to as tethered drones or airborne wind turbines comprise lightweight wings armed with wind turbines. With their long tethers, they fly in strong, reliable high-altitude winds, spinning the turbines to generate power, which is then transmitted down the tether to the grid.

The technology behind energy kites represents a paradigm shift in renewable energy generation, providing several notable benefits. First, energy kites can access faster and more stable winds at high altitudes, which traditional wind turbines on towers cannot reach. This, in turn, allows for greater power generation capacity with fewer materials compared to standard wind turbines, making them a cost-effective choice.

Moreover, the deployment of energy kites causes less impact on the environment and local landscapes, as they require less land, don’t necessitate the installation of large structures, and contribute less to visual and noise pollution. Given their portability and less stringent installation requirements, they may also be deployed in areas that are otherwise unsuitable for traditional wind turbine setup—for instance, offshore or in mountainous terrains, thus opening new possibilities for harnessing wind energy.

Overall, the advent of energy kites amplifies the potential and accessibility of wind power, taking renewable energy technology to fresh heights.

The Role of Slip Rings in Energy Kites

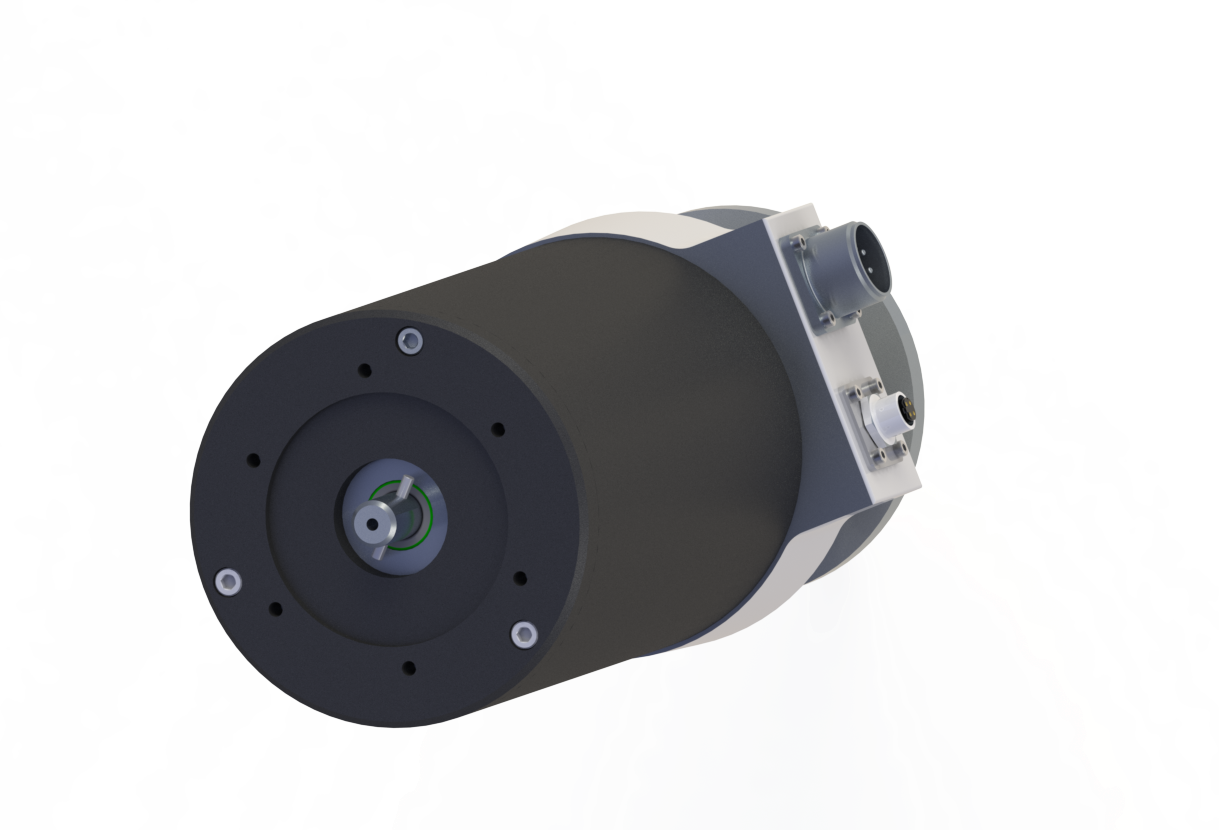

To better appreciate the importance of slip rings in energy kites, it’s crucial first to understand what they are and their broader applications. Slip rings, in the simplest terms, are electromechanical devices used to transmit electrical power, signals, or data from a stationary part to a rotating part. This is usually accomplished through continuous electrical connections, or ‘rings’, made of conductive materials. Common applications for slip rings include wind turbines, radar antennae, and electrical generators, where they effectively resolve the problem of tangled wires during rotation.

As slip rings provide reliable and consistent transmission of electricity while allowing relative rotational movement, their application in the functioning of energy kites is pivotal. Considering energy kites work by reaching great heights to leverage the power of high-altitude winds, their effective operation heavily relies on the ability to maintain free and continuous rotation without compromising electrical transmission.

Slip rings come into play when the energy kite soars and begins to rotate with the wind. They are usually located at the base of the tether connecting the kite and the ground station, ensuring a smooth flow of generated electricity from the soaring kite down to the ground station and subsequently to the grid. They accommodate the continual rotation of the kite that could otherwise tangle a traditional wired system, effectively maintaining a clear path for energy transmission.

Their importance is not just confined to the rotation aspect. As indicated by companies like UEA-inc, Moog, and patents filed on patents.google.com, the specificity of slip rings designed for energy kite applications extends to handling power and data signals. These specially engineered slip rings ensure the safe and efficient transmission of high-capacity electrical power and vital operating data between the ground station and the kite, even under challenging environmental conditions at high altitudes.

In conclusion, the role of slip rings in energy kites is a testament to engineering finesse, solving complex challenges associated with the high-flying renewable energy solution. By understanding slip rings, we gain insight into an essential but often overlooked component of energy kites’ operation.

Design and Features of Energy Kite Slip Rings

The engineering behind the seamless operation of energy kite slip rings calls for a blend of innovation and precision. A deep dive into the design characteristics and features of these slip rings reveals meticulous attention to detail aimed at optimizing the efficiency and reliability of the overall system.

A critical design attribute of an energy kite slip ring is its bore size. The bore size, or inner diameter, of a slip ring, is an essential aspect as it accommodates the tether of the energy kite. According to UEA-inc, one of the leading slip ring manufacturers, the bore size is carefully selected and designed based on the diameter of the tether cable to enable a perfect fit that allows for smooth and uninterrupted rotation without any undue stress on the tether or the slip rings.

Another crucial aspect is the integration of circuits in the slip ring design. Each circuit in a slip ring is dedicated to carrying either a power or a signal connection. The number and configuration of these circuits are tailored to meet the specific demand of the energy kite system, taking into account the power generated and data signals needed to ensure stable operation. Expertise from UEA-inc shows that they design the circuit configurations not just to fulfill the current requirements but also to cater to potential system upgrades or changes in future scenarios.

The importance of these design features can’t be overstated. The suitable bore size ensures that the tether and the slip ring can move in synchronization, reducing wear and tear and thereby enhancing the lifespan of the components. Moreover, optimal circuit configurations safeguard against any disruption in power transmission or data signaling. Adequate circuiting also provides for future scalability and adaptability of the system, without the need for complex and costly hardware modifications.

In essence, the design and features of energy kite slip rings are not simply a matter of engineering decisions. They have a significant impact on the efficient operation of the energy kite system and are therefore key considerations in the overall engineering process.

Maintenance and Troubleshooting of Energy Kite Slip Rings

Like any electromechanical device, energy kite slip rings are subject to wear and tear and occasional malfunction. Understanding common issues with these slip rings and appropriate maintenance strategies can ensure an extended lifespan and efficient operation.

One common issue regarding slip rings in energy kites is wear due to excessive rotation. The contact surface of the slip ring and brushes wear down over time, leading to the need for replacement. If left unchecked, this wear can cause connection disruptions.

The electrical noise, which is generally characterized by sporadic disruptions in the electrical signal, is another common challenge faced with slip rings. This may occur due to a number of factors like dust or foreign object intrusion and surface wear resulting in poor contact. In some cases, this might result in a signal loss or interference, affecting the overall performance of the energy kite system.

For the optimal performance and longevity of slip rings, regular preventive maintenance is vital. This includes periodic inspection of the slip rings and brushes to assess wear and ensure cleanliness. The integrity of the electrical connections should also be checked regularly. Additionally, the insulation resistance of the slip ring should be measured periodically to prevent degradation of the insulation, which might lead to potential short circuits.

In terms of troubleshooting, it’s essential to consider the most probable causes of failure based on symptoms. For example, if there is a consistent reduction in performance, it could be due to surface wear, requiring the replacement of the slip rings or brushes. On the other hand, if an abrupt failure occurs, it might result from dust or debris blockage, requiring a comprehensive cleaning of the assembly.

Bear in mind that while regular maintenance and troubleshooting can mitigate many potential problems, professional help should be sought when the problems persist or appear to be beyond basic maintenance procedures. After all, the intricacies of the slip ring mechanism demand specialized knowledge and skills for correct diagnosis and appropriate intervention.

In essence, vigilant maintenance and troubleshooting are indispensable in maintaining the overall efficiency and viability of the energy kite system, ensuring a sustainable return on investment in this renewable energy technology.

Conclusion

In summary, the advent of energy kites as a renewable energy technology offers a promising avenue for bolstering the generation of wind power with increased efficiency. A crucial but sometimes overlooked element within energy kites is the effective use of slip rings. These components facilitate the smooth transmission of electrical power and data signals from the rotating kite to the stationary ground-based system, ensuring optimal performance.

As outlined, the design and features of energy kite slip rings, including bore size and circuit configurations, are instrumental in optimizing the system’s efficiency and reliability. Moreover, recognizing and addressing common issues relating to slip rings, such as wear and electrical noise, while employing regular maintenance practices, plays a vital role in extending their lifespan and ensuring consistent energy generation.

Those interested in employing energy kites or any airborne wind energy systems should be encouraged by the innovation and engineering finesse displayed in the development of these technologies, including slip rings. Keeping in mind the crucial function of slip rings, further research or expert consultation might be essential for individuals or organizations looking to invest in or optimize energy kite systems for their specific needs.

The ongoing advancements in the field of renewable energy provide new opportunities to harness power from nature in an efficient, clean, and sustainable manner. Energy kites and the underlying technology of slip rings are among the many exciting developments contributing to a future powered by clean, renewable sources.

FAQs about Energy Kite Slip Rings

Given the complex technical nature of energy kite slip rings, many individuals researching them may have some common questions. Contrived from analyzing the ‘People Also Ask’ (PAA) boxes in the Search Engine Results Pages (SERP), this FAQ section attempts to answer some of those frequently asked queries.

Q: What exactly is a slip ring?

A: A slip ring is an electromechanical device that allows the transmission of power and electrical signals from a stationary to a rotating structure. It is a crucial component in rotational devices, including energy kites, where it enables the smooth transfer of electricity and data from the high-flying kite to the grounded station.

Q: How do slip rings work in energy kites?

A: In energy kites, the slip rings are typically located at the base of the tether. These slip rings enable the energy kite to continue rotating with changes in wind direction while maintaining a constant, tangle-free connection for transferring the generated electricity and data signals from the kite to the ground.

Q: What factors determine the design and features of energy kite slip rings?

A: The design and features of energy kite slip rings depend on many factors such as the diameter of the tether (influencing the bore size), the amount of electric power to be transmitted, and the type and amount of data signals to be sent for operational stability. Companies such as UEA-inc specialize in designing these slip rings to cater to the unique requirements of each system.

Q: What are some common problems with energy kite slip rings, and how can they be addressed?

A: Some common issues with energy kite slip rings include wear and tear due to continuous rotation and electrical noise disrupting the signal quality. Regular inspection and maintenance, which include checking for wear and cleaning the slip rings and brushes, can address these problems effectively. In some cases, professional consultation may be required for more complex problems.

Q: Are slip rings necessary for all energy kites?

A: While there can be exceptions based on specific design variations, generally, all energy kites would require slip rings or comparable devices. This need stems from their role in enabling the kite to rotate freely while ensuring an uninterrupted flow of electricity and data signals between the rotating kite and the stationary ground station.

In conclusion, the overall viability and efficiency of energy kites heavily rest on the correct application and maintenance of slip rings, which serve to bridge the connection between the airborne structure and the earthed components. Whilst this FAQ covers some fundamental aspects, more in-depth inquiries may necessitate dedicated research or consultation with a specialist in the field.

Get a quote for your Energy Kite Slip Rings requirements by filling out the inquiry form.