Power capsule slip rings play an essential role in various industries requiring smooth transfer of electrical power and signals between stationary and rotating components. With the ongoing advancement in technology, the efficiency and applications of these slip rings have expanded, encompassing more use cases than ever before. This guide aims to provide a comprehensive understanding of the fundamentals, types, and significance of power capsule slip rings while shedding light on the process of selecting, installing, and maintaining them. You will also get a glimpse into the latest technological advancements in this sphere along with relevant case studies and available resources.

The importance and functionality of power capsule slip ring cannot be overstated as they ensure the flawless operation of critical equipment in diverse sectors, including aerospace, automation, marine applications, and energy production. As you delve into the following sections, you will gain insights into how these components facilitate seamless motion and uninterrupted signal transmission across various applications while overcoming challenges posed by specific industry requirements.

Basics of Power Capsule Slip Rings

Before diving deep into the applications and selection process, it’s important to understand what power capsule slip rings are and how they function at the fundamental level.

Power capsule slip rings, sometimes known simply as capsule slip rings, are specially designed electromechanical devices that are critical in applications needing electrical power and signal transfer between stationary and rotating components. Their construction features two main parts: a stationary part known as the stator and a rotating part known as the rotor.

In most cases, the stator, which does not move, is connected to the power source and transfers the electrical signals or power to the rotor. The rotor, on the other hand, rotates with the machinery’s moving part and delivers the signals or power it receives from the stator.

This transfer of power and signals is achieved through conductive materials, often known as brushes and rings. The brushes, typically made of carbon or precious metals, maintain electrical contact with the rings as they rotate. The rings are usually made of copper or other conductive metals.

The defining ‘capsule’ characteristic of these slip rings refers to their specific design style, where the entire assembly, including the conductive paths, brush blocks, bearings, and encapsulant is housed in a capsule-like structure. Thus the name, ‘power capsule slip rings’. These encapsulations allow the slip rings to be more compact, protect the internal components from harmful environmental factors, and improve overall functionality.

The theory of operation behind these slip rings is relatively straightforward. As the machinery connected to the rotor turns, the static section (stator) holds the brushes that maintain contact with the rotating rings. This persistent contact allows for the consistent transfer of power or signals, despite the motion. The design manages to prevent any twisted or tangled wiring that would typically result from such a setup, fostering efficiency and longevity.

In the following sections, we delve into the various types of power capsule slip rings and how to identify which type best suits a specific application, industry, or requirement.

Types of Power Capsule Slip Rings

Power capsule slip rings come in various forms, each designed to cater to a unique requirement or application. Understanding these different types and their specific uses can help in determining the ideal solution for your needs.

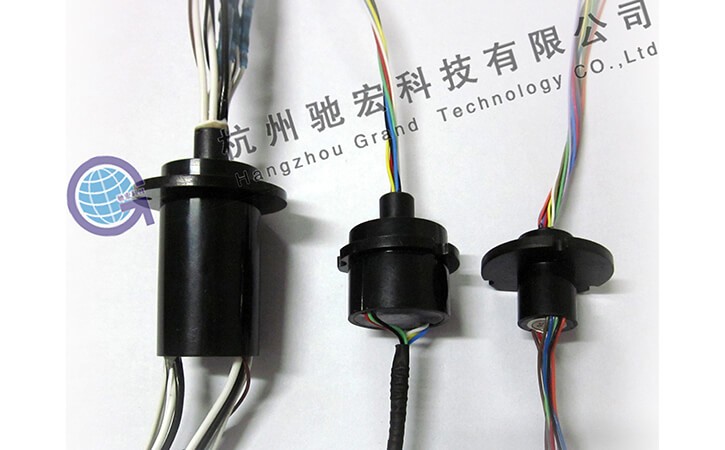

Compact Capsule Slip Rings

Compact capsule slip rings, as the name suggests, are characterized by their smaller size and are designed to fit within space-constrained applications. With powerful performance wrapped in a petite package, these slip rings are primarily used in devices such as security cameras, rotary sensors, and medical instruments.

High-Current Capsule Slip Rings

High-current capsule slip rings tackle applications that demand greater power transmission. Built to handle higher power loads, these slip rings typically include larger-diameter rings and brushes. They find their place in heavy machinery, industrial turntables, and heavy-duty cranes where high power and steady connectivity are paramount.

Hybrid Capsule Slip Rings

Hybrid capsule slip rings carry forward multiple functionalities in one assembly. These models integrate signal and power transfer with other conductions like fiber optics and fluid passages. Industrial automation, marine applications, and radar systems often take advantage of the versatility offered by hybrid capsule slip rings.

Custom Capsule Slip Rings

When standard slip ring solutions do not meet a unique set of requirements, custom capsule slip rings come into play. Tailor-made to fit your specifications, these slip rings accommodate unusual shapes, a specific number of circuits, unique materials, and extraordinary electrical demands that can’t be met by off-the-shelf solutions.

To choose the most optimal power capsule slip ring, a comparative analysis can be of great help. Here are a few points to consider:

- Size: Compact capsule slip rings are ideal when space is a constraint, while other slip rings may offer greater functionalities in a larger form factor.

- Current Handling: High-current capsule slip rings cater well to high power transmission requirements, making them suitable for heavy-duty industrial operations.

- Functionalities: Hybrid slip rings offer extended functionalities, like fluid passage and fiber optics integration. They are a great choice for applications that require diverse functionalities.

- Customizability: If your requirement is very specific and doesn’t align with off-the-shelf options, going for a custom capsule slip ring might be the best option.

Understanding these differences will guide you in the right direction while choosing a slip ring for your application.

The Significance of Power Capsule Slip Rings in Different Industries

Power capsule slip rings prove their versatility and indispensability by operating across various sectors. Each industry utilizes these devices in ways specific to their functionality and requirements. Here’s a detailed overview of several key sectors where power capsule slip rings play a crucial role:

Aerospace

In the high-tech aerospace sector, power capsule slip rings take on vital roles. They help regulate the critical flow of data and power transmission across various systems. These include radar antennas, satellite systems, and other rotating equipment in both aircraft and spacecraft. With reliable connectivity even at high rotations and the capability to withstand harsh environmental conditions, these slip rings become an integral component of the aerospace industry’s operations.

Industrial Automation

The realm of industrial automation greatly benefits from the use of power capsule slip rings. Robots, automated machinery, and assembly line devices all experience consistent rotational motion. The delivery of precise electrical signals is crucial in these applications for accurate, uninterrupted operations. Power capsule slip rings prevent cables from twisting and tangling while maintaining a seamless transmission of power and data, ensuring smooth automation processes.

Marine Applications

Marine applications often involve constant or frequent rotational movements, mainly in equipment such as winches, thrusters, and cranes aboard seagoing vessels. Power capsule slip rings are crucial in maintaining the continuous functioning of these systems despite their ongoing motion. They allow the necessary electrical connectivity to persist irrespective of the rotation, and their robust design stands up to challenging marine conditions.

Wind Energy

Wind turbines, key in eco-friendly energy production, rely heavily on power capsule slip rings. The turbine’s continuous rotation demands a solution that allows for the consistent transfer of power and data. Power capsule slip rings fulfill this requirement effectively, enabling the turbines to generate and transmit energy without interruption. Given their efficiency and reliability, power capsule slip rings remain integral to the wind energy sector’s ongoing growth.

To conclude, power capsule slip rings play a pivotal role in various industries. They address the challenge of continuous rotation without hampering the flow of power and signals, thereby directly contributing to operational efficiency and productivity in numerous fields.

How to Choose the Right Power Capsule Slip Rings

Choosing the right power capsule slip ring is crucial for the optimal operation of your machinery. One must consider several factors to ensure the slip ring aligns perfectly with the application requirements. Here’s a detailed guide to help you with the selection process and avoid common pitfalls:

Factors to Consider:

- Size: Assess the space available for slip ring installation within your machinery or system. Compact power capsule slip rings cater well to applications with limited space, while a larger slip ring may accommodate more circuits, high-current paths, or extra features.

- Current/Voltage Rating: Make sure to select a slip ring that matches your power requirements. High-current power capsule slip rings can handle greater currents, making them suitable for heavy-duty operations.

- Number of Circuits: Understanding the number of circuits (also known as channels), required for your applications is crucial. Each circuit transmits a separate signal or electrical path. If your operation requires multiple independent signals or separate power paths, a higher number of circuits in the slip ring would be necessary.

- Speed of Rotation: Ensure the rated rotational speed of the slip ring matches or exceeds the actual rotational speed of your machinery. Rapid rotations may require slip rings with high-speed capabilities.

- Environmental Conditions</b: The selection of the slip ring should be aligned with the environmental conditions it will be exposed to. Tolerance to elements like moisture, salt, dust, vibration, and extreme temperatures may be necessary based on the working environment.

Common Pitfalls to Avoid:

- Overlooking Customization: People often make the mistake of settling for an off-the-shelf solution when a custom slip ring would serve their specific requirements better. Tailor-made models can accommodate unusual shapes, specific numbers of circuits, unique materials, etc.

- Ignoring Longevity and Maintenance: Thinking of the immediate requirement rather than longevity and ease of maintenance can also be a common mistake. Ensure you take into account the lifespan of the slip ring and the convenience/difficulty of its potential maintenance and repairs.

Checklist for Buying the Right Power Capsule Slip Rings:

- Evaluate your application’s space constraints.

- Determine the necessary number of circuits.

- Ascertain the required current/voltage rating.

- Establish the speed of rotation of your application.

- Consider the environmental conditions.

- Explore custom slip ring options if standard types do not meet requirements.

- Review guidelines for longevity and maintenance.

By carefully considering the factors and avoiding possible pitfalls, one can ensure that they select a power capsule slip ring that not only meets their current needs but also factors in future requirements and ease of maintenance.

Installation and Maintenance of Power Capsule Slip Rings

Proper installation and maintenance of power capsule slip rings are vital in ensuring their optimal performance and longevity. The following sections guide you through the installation process, provide preventive maintenance tips, and address common issues for successful slip ring use.

Step-by-Step Process for Successful Installation:

- Inspect the slip ring: Start by visually inspecting the slip ring for any signs of damage or defects that may have occurred during shipping or handling. Make sure all the components are in place.

- Check compatibility: Before installation, verify that the slip ring specifications are compatible with your application’s requirements, such as the size, current/voltage rating, and number of circuits.

- Mount the slip ring: Install the slip ring as per the specific instructions provided by the manufacturer. Ensure the stator is secured to the stationary part of the equipment, while the rotor is attached to the rotating component. Keep in mind the recommended mounting orientation and torque specifications.

- Connect wiring: Establish the wiring connections according to the manufacturer’s documentation. Use appropriate connectors and cable management techniques to prevent interference, tangles, or loose connections.

- Test the slip ring: After installation, test the slip ring to ensure it functions correctly, and transmits power, and signals without any lapses. Monitor for any unusual noises, excessive heat, or other signs of problems.

Preventive Maintenance Tips:

- Schedule regular inspections: Periodically examining the slip ring assembly can help you identify and fix any potential wear-and-tear before it escalates into a major issue.

- Ensure clean conditions: Keep the environment around the slip ring clean and free of debris. Accumulated dirt or dust can affect the performance of the slip ring by increasing electrical resistance or causing wear to the components.

- Lubricate the bearings: Regularly lubricate the bearings in accordance with the manufacturer’s recommendations. Proper lubrication can reduce friction, increase the lifespan of your slip ring, and prevent unexpected breakdowns.

- Monitor brush wear: Regularly check and measure brush wear. Replace the brushes when they reach the manufacturer’s recommended wear limit, ensuring consistent electrical contact with the rings.

- Secure wiring connections: Keep wiring connections maintained and secured. Loose connections can lead to reduced performance, intermittent faults, or electrical damage.

Common Issues and Troubleshooting:

- Poor contact between brushes and rings: If the slip ring is experiencing poor electrical contact, clean the brushes and rings gently, and ensure the brushes are properly seated or replace them when necessary.

- Excessive noise or vibration: Make sure the slip ring and connected components are secure and properly aligned. Check for bearing wear or damage that might require replacement.

- Overheating: If the slip ring is overheating, verify that it is not operating beyond its specified current/voltage rating. Check for misaligned brushes or bearings that could cause excessive friction. Ensure there are no short circuits or improperly connected wires.

By following these installation, maintenance, and troubleshooting guidelines, you can ensure that your power capsule slip rings perform optimally, reducing the risk of unexpected breakdowns and maintaining their longevity.

Technological Advancements in Power Capsule Slip Rings

The realm of power capsule slip rings is continually evolving. These technological advancements promise more efficient, reliable, and flexible solutions, which open up new possibilities in very diverse sectors.

Latest Technological Developments and Their Benefits:

- High-density Capsule Slip Rings: Advances in miniaturization technologies have enabled the production of high-density capsule slip rings. These devices pack more circuits into a compact form, helping to save space and making it easier to integrate them into intricate systems.

- Wireless Slip Rings: Breakthroughs in wireless technology have paved the way for “contact-free” slip rings, reducing wear and tear, thereby extending lifespan significantly and improving reliability.

- Fiber Optic Rotary Joints (FORJs): This advanced technology has been incorporated into slip rings to handle high-speed data transmission, allowing large amounts of data to be transmitted without any degradation or interference.

- Integrated Slip Rings: The integration of slip rings with other rotary components, like swivels, rotary unions, or encoders, to create a single, robust module offers more convenience and efficiency.

- Environmentally Sealed Slip Rings: Improved sealing technologies ensure the durability of slip rings in harsh conditions, thus significantly broadening their use in diverse environmental conditions.

How They Are Shaping the Future in Various Applications:

- Aerospace & Defense: Miniaturized and robust slip rings can withstand the harsh conditions of outer space or defense environments, enabling more secure communication and control in critical operations.

- Healthcare: The integration of high-speed data transmission in medical equipment has drastically improved real-time patient monitoring and telemedicine.

- Renewable Energy: With environmentally sealed slip rings, wind turbines can operate effectively in various weather conditions.

- Industrial Automation: Wireless slip rings and integrated modules cater to the demands of automated assembly lines for increased productivity and lowered maintenance costs.

- Telecommunication: Fiber Optic Rotary Joints (FORJ) in slip rings pave the way for high-speed data transmission, improving bandwidth, and signal quality significantly.

By staying abreast of these technological advancements, users can make more informed decisions about the type of power capsule slip ring best suited to their application, and industries can harness these innovations to make strides in their respective fields.

Power Capsule Slip Rings Case Studies

Case studies uncover the practical application of power capsule slip rings and the tangible benefits experienced in real-world scenarios. The following examples reveal how specific challenges were addressed and overcome with the help of these innovative devices.

Case Study 1: Improving Wind Turbine Efficiency

Context: A wind farm operator grappled with frequent breakdowns of their wind turbines, often caused by the twisting and tearing of power cables due to the turbine’s constant rotation.

Solution: The operator replaced their traditional wiring system with power capsule slip rings. The slip rings allowed for unrestricted 360-degree rotation of the turbine blades without causing any damage to the power and signal cables.

Benefit: The upgrade significantly reduced maintenance downtime and improved turbine efficiency. This resulted in higher energy harvesting and lower operational costs.

Case Study 2: Enhancing Satellite Communications

Context: A satellite company was facing a problem with the constant rotation of its transmitting antenna. The rotation was necessary for communicating with the Earth-based stations but caused the conventional cables to twist and lose signal.

Solution: The company integrated power capsule slip rings into their antenna design. The slip rings provided reliable power and signal transmission even as the antenna rotated.

Benefit: This improved the consistency and integrity of transmitted data, greatly reduced communication errors and downtime, and significantly improved the company’s satellite communication services.

Case Study 3: Facilitating Advanced Medical Diagnostics

Context: A manufacturer of CT scanners needed to find a way to transmit data and power between the stationary part of the scanner and the rotating components containing X-ray detectors.

Solution: The manufacturer incorporated power capsule slip rings into their CT scanner design. The slip rings enabled the smooth, uninterrupted rotation of the scanner’s gantry while reliably transmitting high volumes of critical diagnostic data.

Benefit: The installation of slip rings enabled faster, more accurate imaging, leading to improved diagnosis for patients. The longevity and reliability of the slip rings also reduced maintenance requirements, keeping the scanners available for patient use more consistently.

These case studies exemplify the role of power capsule slip rings in overcoming specific challenges across diverse sectors – from greener energy production and advanced communications to improved medical diagnosis. As such, they highlight the transformative potential of slip ring technology.

Conclusion

This comprehensive guide has taken us on a journey through the world of power capsule slip rings, from their fundamental function in transmitting electrical power and signals between stationary and rotating components to the nuances of their installation and maintenance.

We have explored the importance of slip rings in facilitating seamless and efficient operation in diverse applications. Their function is crucial to preventing cable twisting, preserving the integrity of the electrical connection, and even enabling unlimited rotation in many systems.

Understanding their specifications helps in selecting the appropriate slip ring that aligns with the needs of a particular system – be it the number of circuits, voltage/current rating, rotational speed, or environment suitability.

When it comes to installation, it is important to adhere to the manufacturer’s guidelines, whether it involves the handling of the slip ring itself, the intricate process of mounting, or the accurate establishment of wiring connections.

Proactiveness in maintenance practices, from scheduled inspections to timely lubrication of bearings and securing wiring connections, ensures the sustained performance and longevity of slip rings. Awareness of common issues and their troubleshooting also aids in maintaining their optimal functionality.

Get a customized quote by completing our Power Capsule Slip Rings inquiry form today.

Recent technological advancements witness remarkable progress, with miniaturization, integration, sealing technologies, and wireless contactless solutions promising more efficient, durable, and versatile slip rings. These developments not only address current limitations but also open doors to exciting applications in industries like healthcare, aerospace, industrial automation, and more.

Through case studies, we have seen the transformative potential of power capsule slip rings in real-life scenarios. These instances reiterate the role of slip rings as a problem-solving essential, whether in enhancing wind energy efficiency, facilitating satellite communications, or enabling advanced medical diagnostics.

To conclude, power capsule slip rings are an instrumental component in the successful operation of rotating systems across numerous fields. With continued innovation, and stringent adherence to best practices in installation and maintenance, these devices are poised to facilitate significant advancements in the future, shaping and enhancing our world in unimaginable ways.

FAQs about Power Capsule Slip Rings

Q: What is a power capsule slip ring, and why is it essential for a rotating system?

A: A power capsule slip ring is a device used in a rotating system to transmit power and electrical signals from a stationary to a moving part. It is crucial to ensure uninterrupted operation by preventing cable twisting during rotation and allowing for continuous data and power transmission.

Q: How do I choose the appropriate power capsule slip ring for my system?

A: Choosing the right slip ring depends on several factors, including your system’s size, current/voltage needs, the number of required circuits, rotation speed, and the environmental conditions it will be subjected to. Always refer to your system’s specifications or consult with a professional for accurate selection.

Q: How do I install a power capsule slip ring?

A: The installation process involves inspecting the slip ring for any visible damages; ensuring it’s compatible with your system; securing the stator to the stationary component and rotor to the rotating part; establishing the wiring connections according to the manufacturer’s instructions; and finally, testing the slip ring for successful power and signal transmission.

Q: How do I maintain a power capsule slip ring effectively?

A: Effective maintenance of a power capsule slip ring involves regularly inspecting it for wear and tear, ensuring a clean environment around the slip ring to prevent dirt or dust accumulation, lubricating the bearings as per the manufacturer’s guidelines, checking brush wear and replacing when necessary, and keeping the wiring connections secured.

Q: What are the common issues faced with power capsule slip rings, and how can I troubleshoot them?

A: Common issues include poor electrical contact between brushes and rings, excessive noise, or vibration, and overheating. Troubleshooting methods involve cleaning or replacing brushes and rings, checking for misaligned components and correcting them, and ensuring no excess current/voltage is passed to prevent overheating. Always consult the manufacturer’s guidelines for accurate troubleshooting.

Remember, it’s always best to consult with a professional or the manufacturer if you face persistent or complicated issues. They can provide more nuanced advice based on their experience and detailed knowledge of your specific model.

See What We Can Do