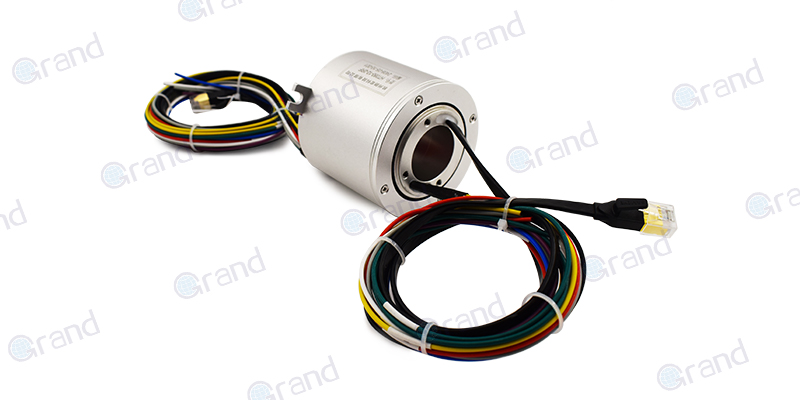

Slip rings are an essential component of many electrical systems. They play an important and intricate role in transmitting power and electrical signals from a stationary source to a rotating component. You can find them in everything from small electronic devices, where they help save space, to large industrial equipment, where they improve performance.

High-end metal slip rings are a specific category of slip rings designed to cater to the more challenging requirements of advanced applications. They’re composed of premium metals such as gold, silver, and copper, which provide superior electrical conductivity and durability compared to standard slip rings. These specialty slip rings are also more capable of withstanding harsh conditions, making them an ideal choice for demanding environments.

This guide’s primary aim is to provide a thorough understanding of high-end metal slip rings. We’ll take you through their definition and use cases, highlighting the industries where they are vitally important. We’ll also delve into their technical aspects and provide tips on selecting the best ones for your specific requirements. Furthermore, we aim to assist you in understanding how to maintain these slip rings properly for optimal performance and extended life.

Whether you’re a professional engineer looking to refine your understanding, a student keen to learn more about this critical technology, or simply curious about how these components work in your day-to-day appliances, this guide’s got you covered. By the end, we aim to impart a comprehensive understanding of high-end metal slip rings, preparing you to make informed decisions and gain a deeper appreciation of the intricacies behind running electrical systems.

What is a High-End Metal Slip Ring?

A slip ring is a specialized electromechanical device that allows the transmission of power and electrical signals from a stationary object to a rotating one. Imagine a simple setup where a light bulb is fixed on a spinning disc. The challenge here is to keep the light bulb powered on while the disc rotates. This is where a slip ring comes in. It’s designed to establish an electrical connection between the bulb and the power source, enabling the bulb to be illuminated constantly, irrespective of the disc’s rotation.

Slip rings use a concept of “sliding” contacts where the stationary part, often referred to as the stator, makes contact with the rotating part, also known as the rotor. The stator holds the electrical wires that connect to the power source, while the rotor connects to the device needing power or data signals.

High-end metal slip rings represent a higher tier in the broad spectrum of slip rings. They are precision-engineered using premium metals like gold, silver, or copper for their contact surfaces —the parts involved in transmitting the signals. This construction not only augments their electrical conductivity, ensuring a more efficient transfer of power and signals but also extends their durability and resistance to wear and tear.

The primary advantages of high-end metal slip rings over their standard counterparts come down to performance, reliability, and durability. They are often preferred for applications that involve high-frequency signals or require high-speed data transfer. They are also more resistant to environmental variables like humidity and temperature changes. This makes them extremely suitable for use in demanding environments like space exploration, wind turbines, or industrial processes where low maintenance and high durability are crucial.

In summary, high-end metal slip rings contribute to more efficient, reliable, and longer-lasting system performance. They represent an evolution of the core slip ring principle, optimized for the most demanding applications.

High-End Metal Slip Ring: Applications and Industries

High-end metal slip rings are versatile and find wide-ranging applications across multiple industries, transforming the way in which power and data are transmitted in rotating systems. The use of these slip rings assumes importance for industries that rely heavily on precision, reliability, and durability. Here are some sectors that capitalize on the applications offered by high-end metal slip rings:

- Aerospace and Defense: This sector demands highly reliable and durable components to withstand harsh environments. High-end metal slip rings are used in various applications such as radar systems, where rotating antennae require power and data transmission without interruption. Missile guidance systems, which require precise data transmission during rotation, also use these slip rings. Surveillance equipment in drones and aircraft generators are other application areas in this sector.

- Wind Energy: Wind turbines are environments where slip rings are used to transfer electrical power from the stationary nacelle to the rotating blades. The durability and weather resistance of high-end metal slip rings makes them an excellent choice for these challenging environments.

- Marine: There are a plethora of applications within the marine sector, notably in ships’ propulsion systems, ROVs (Remotely Operated Vehicles), and underwater communications systems. These slip rings can withstand harsh marine conditions and provide reliable, high-speed data and power transmission.

- Robotics: In robotic systems, slip rings are used in robotic arms, grippers, and sensors requiring rotational movement. They need to transmit electric signals and power continuously during the movement, posing a perfect application for high-end metal slip rings.

- Medical: Medical imaging equipment such as CT scanners and MRI machines require the transfer of power and signals during 360-degree rotation. High-end metal slip rings meet accuracy and safety requirements – they must emit no noise or interference that may disrupt sensitive imaging procedures.

These varied applications across industries underline the importance and relevance of high-end metal slip rings. With the potential for customization and a design focused on superior performance under harsh conditions, they play a critical role in numerous sectors requiring efficient and reliable rotating electrical connections.

High-End Metal Slip Ring: Key Technical Parameters

Selecting the right high-end metal slip ring for a specific application requires careful consideration of various technical parameters. These can be broadly divided into three categories: electrical, mechanical, and environmental parameters.

Electrical Parameters:

Understanding the electrical requirements of your application is crucial:

- Current Rating: This specifies the maximum current (measured in amperes) that the slip ring can safely carry. It would be important to match the current requirements of your application with the slip ring’s rating.

- Voltage Rating: Each slip ring is designed to function safely within a certain voltage range. This rating must align with your system’s voltage level to prevent electrical overload or under-performance.

- Number of Circuits: This refers to the number of separate electrical connections you want the slip ring to handle. Your application may require multiple circuits for different data or power transmission needs.

Mechanical Parameters:

The physical attributes of the slip ring must align with your system design:

- Dimensions: The size and shape of the slip ring need to fit the space allocated within your device or system. The diameter and length can greatly influence its compatibility and performance.

- Rotational Speed: This refers to the maximum speed at which the slip ring can reliably rotate. You will need to ensure this aligns with your system’s speed requirements.

Environmental Parameters:

These deal with the conditions in which the slip ring will function:

- Operating Temperature: Each slip ring is designed to operate within a particular temperature range. Exceeding this range can damage the device, so it’s crucial to match this with your operating environment.

- Humidity: Humidity resistance specifies the level of moisture the slip ring can handle. Corrosion and conductivity issues can arise if the slip ring isn’t designed to withstand the moisture levels in the operating environment.

Considering all these key technical parameters helps you narrow down your options to choose a high-end metal slip ring that best serves your application needs: one that balances performance, durability, and efficiency.

High-End Metal Slip Ring: Materials and Construction

The materials and construction of a high-end metal slip ring determine its performance, reliability, and durability. In this section, we will discuss the variety of materials used in their fabrication and the design features contributing to their efficiency.

Materials:

High-end metal slip rings utilize premium conductive metals in their construction, enhancing their overall performance:

- Gold: Gold is amongst the most popular materials for contact surfaces in premium slip rings. With excellent electrical conductivity, low contact resistance, and high resistance to corrosion, gold slip rings ensure minimal signal loss and healthcare-grade reliability.

- Silver: Another popular choice, silver contacts offer high conductivity and relatively low susceptibility to corrosion. They are generally more affordable compared to gold contacts but may require more regular maintenance and cleaning.

- Copper: Copper contacts provide excellent electrical conductivity and are often used for higher-power applications. They may be plated with other materials like gold or silver to improve their performance further and increase corrosion resistance.

Get in touch with us for High-End Metal Slip Rings quote by filling out the form.

Construction Features:

Several design aspects distinguish high-end metal slip rings from standard ones, optimizing their performance:

- Contact Design: The contact surfaces between the stator and rotor largely determine the slip ring’s efficiency. These surfaces can have a variety of designs like brush-type, precious metal multi-finger, and fluid or gas contacts. The selection depends on the application’s requirements for signal quality, rotational speed, and maintenance needs.

- Sealing: High-end metal slip rings may incorporate advanced sealing mechanisms to protect the internal components from environmental contaminants like dust, moisture, and harsh chemicals. Sealing solutions like o-rings, gaskets, and hermetic sealing improve the slip ring’s reliability and longevity.

- Bearings: High-quality bearings are an essential component for the smooth operation of the slip ring. They reduce friction and wear, consequently affecting the overall life and performance of the slip ring. Ball bearings or self-lubricating bearings can be used, depending on the speed and load requirements of the application.

The materials and construction of high-end metal slip rings have a significant impact on their overall performance. By utilizing premium materials and optimizing design features, these slip rings offer greater reliability, efficiency, and durability for various applications across industries.

High-End Metal Slip Ring: Selection Process

Choosing a suitable high-end metal slip ring is essential to ensure the smooth and efficient operation of your rotating system. This can be achieved by taking the following steps:

- Identifying Your Requirements:

Start by understanding your system’s needs. What kind of electrical load does the slip ring need to handle? Does your application require data transfer alongside power? Answering these questions will guide you towards slip rings designed to meet these specific needs.

- Considering the Technical Parameters:

Analyze the essential technical parameters discussed earlier, including electrical requirements (current, voltage, number of circuits), mechanical constraints (size, speed), and environmental conditions (temperature, humidity). Take note of your system’s specifications and look for a slip ring that matches these parameters.

- Choosing the Right Material:

Depending upon your specific application, you might need to choose a slip ring with specific material properties. Gold might be preferred for low-noise, high-speed data transfers, or silver and copper for more power-intensive applications.

- Checking Relevant Standards and Certifications:

Depending on your sector (military, medical, industrial, etc.), certain standards and certifications may be required. Make sure any slip ring you consider possesses the needed certifications to ensure compliance and safety.

- Consulting with the Manufacturer or Supplier:

Discuss your requirements with potential manufacturers or suppliers. They should be able to guide you in choosing a slip ring that suits your application best.

High-End Metal Slip Ring: Customizing Slip Rings

Some applications may have unique needs requiring customization of the slip ring. Here are a few tips:

- Define Your Unique Requirements:

Identify and specify any unusual parameters or conditions your slip ring must meet. It could be an unusually high rotation speed, a uniquely small space where the slip ring must fit, or an odd-shaped device that requires a non-standard form factor.

- Collaborate with Manufacturers:

Reach out to slip ring manufacturers who offer customization services. Share your specific requirements and work collaboratively to design a bespoke solution. They have the expertise and resources to help you create the most suitable slip ring for your application.

- Prototyping and Testing:

Always prototype and test a custom slip ring before full-scale production. Ensure it works according to specifications and can handle the load and environment envisaged.

By appropriately analyzing your needs and engaging closely with manufacturers, you can find or create a high-end metal slip ring that is tailor-made for your application, ensuring optimal system performance.

High-End Metal Slip Ring: Installation and Maintenance

Implementing a high-end metal slip ring in your system is a two-fold approach – proper installation and consistent maintenance. Here’s a detailed look at both aspects:

Installation:

Correctly installing your slip ring will safeguard its functioning and lifespan. The following guidelines will help ensure this:

- Understand Specifications and Requirements: Before the installation process, thoroughly go through the slip ring’s user manual or installation guide. Make sure your system adheres to the slip ring’s environmental and electrical specifications to avoid potential hazards.

- Component Compatibility: Ensure the slip ring is compatible with all your system’s components. Ensure connections fit correctly and the slip ring is integrated smoothly.

- Professional Assistance: If the installation process seems complex, don’t hesitate to reach out to professionals. Seeking help from the manufacturer or trained technicians can protect your investment and optimize performance.

Maintenance:

Regular maintenance can extend the lifespan of your high-end metal slip ring and improve its performance. Here are some maintenance tips:

- Cleaning: Conduct regular cleaning of the slip ring, particularly at contact points. Accumulated dirt or dust can lead to excessive wear or even electrical faults. Check manufacturer recommendations for cleaning materials and methods.

- Regular Inspections: Schedule regular visual inspections for signs of wear or damage. Check for signs such as overheating, abnormal noises, or decreased performance.

- Lubrication: Some slip rings may require regular lubrication at their bearings to ensure smooth rotation. Always use the lubricant recommended by the manufacturer.

- Follow Manufacturer Recommendations: Always adhere to the maintenance guidelines provided by the slip ring manufacturer. Each slip ring model might come with unique maintenance practices for optimal performance.

- Technical Support: In case of any troubleshooting needs, always reach out to the manufacturer’s technical support. They have in-depth knowledge of the product and can guide you better.

Properly installing and maintaining your high-end metal slip ring directly impacts its functional efficiency and longevity. Sticking to these best practices will ensure the slip ring remains an effective and durable part of your system.

High-End Metal Slip Ring: Pricing and Suppliers

When sourcing high-end metal slip rings for your application, it’s vital to consider factors affecting their costs, choose a reliable supplier, and be aware of the top manufacturers in the market.

Factors Affecting the Cost:

Multiple factors can impact the pricing of high-end metal slip rings:

- Material: The type of metal used (gold, silver, or copper) influences the overall cost. Gold contacts typically cost more, while copper contacts may be more affordable.

- Design Complexity: The complexity of a slip ring’s design, such as the number of channels, customizations, or unique features, affects pricing.

- Certifications: Slip rings that meet certain industry standards or certifications may come at a premium.

- Additional Components: Additional parts like sealing mechanisms, integrated connectors, or specialized bearings can influence the overall cost.

Choosing a Reliable Supplier:

To ensure the best performance and quality, consider the following tips when selecting a supplier:

- Reputation: Assess the supplier’s standing in the industry. Look for reviews, testimonials, or case studies showcasing their products and services.

- Experience: Choose suppliers with a track record of developing high-end metal slip rings for similar applications.

- Customization Options: If your project requires customized slip rings, seek suppliers that can accommodate your unique specifications.

- Technical Support: Opt for suppliers who provide comprehensive technical support for installation, maintenance, and troubleshooting.

- Pricing: Compare the prices and offerings of various suppliers to find the best balance between cost and quality.

Top High-End Metal Slip Ring Manufacturers:

Several manufacturers stand out in the realm of high-end metal slip rings. Some prominent ones include:

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023

By considering these factors, choosing a reliable supplier, and being aware of the top manufacturers, you can source high-end metal slip rings suitable for your application at a reasonable cost while ensuring quality and performance.

Conclusion

High-end metal slip rings provide reliable and durable solutions for a wide range of industries and applications. By understanding their features, applications, and crucial parameters, you can make an informed decision when it comes to selecting, installing, and maintaining the perfect high-end metal slip ring for your needs.

FAQs about High-End Metal Slip Ring:

High-end metal slip rings are intricate components used in a variety of applications. Users often have several questions about their features, operation, and maintenance. Here are some common concerns and queries:

Q: What Are High-End Metal Slip Rings?

A: High-end metal slip rings are electromechanical devices that allow the transmission of power and electrical signals from a stationary structure to a rotating one. They utilize precious metals like gold, silver, or copper for contact materials, delivering superior performance in various demanding applications.

Q: What Applications Use High-End Metal Slip Rings?

A: These slip rings are used in numerous sectors, including aerospace, defense, industrial machinery, medical equipment, wind turbines, and more. Any system requiring electrical continuity between stationary and rotating structures can use these slip rings.

Q: Why are Precious Metals Used in High-End Slip Rings?

A: Precious metals like gold, silver, and copper are used due to their excellent electrical conductivity, resistance to corrosion, and capability to handle a range of electrical loads. Gold, for instance, delivers low noise, facilitating high-speed data transfers, whilst copper can handle more power-intensive applications.

Q: How Do I Maintain a High-End Metal Slip Ring?

A: Regular maintenance involves cleaning, particularly at the contact points, to avoid dirt accumulation that could lead to electrical faults. Regular visual inspections, lubricating, if recommended by the manufacturer, and adhering to the product’s specific maintenance guidelines are also crucial.

Q: Are High-End Metal Slip Rings Expensive?

A: The cost of these slip rings depends on several factors, including the materials used, design complexity, compliance with certain industry standards, and inclusion of additional components. While they tend to be more expensive than the standard variants due to the use of high-quality materials and enhanced features, they provide superior performance and longer service life.

Q: Can a High-End Metal Slip Ring Be Customized?

A: Yes, certain manufacturers offer customization options to cater to unique technical requirements. These adjustments can range from changing the number of channels or materials used, through to tailoring the size of the slip ring to better suit specific applications.

Understanding these common questions allows users to optimize their selection, use, and maintenance of high-end metal slip rings, ensuring a superior and efficient performance in their respective applications.

See What We Can Do