In the pursuit of efficient and continuous power generation, various engineering solutions have been developed and refined over the years. One such solution, integral to the electricity supply we so often take for granted, is the slip ring of generator.

As its name implies, a slip ring generator is a type of electrical generator designed to convert kinetic energy into alternating current (AC) power. The slip ring component allows for a consistent and continuous electrical connection from a rotating structure, like a wind turbine, to a static or stationary position. This is achieved without causing any wires to twist or become dangerously tangled. More precisely, this means that even as parts of the machine are in constant movement, the electricity transfer continues uninterrupted, ensuring a steady power output.

In simpler terms, envision a wheel spinning on an axle. Regardless of how many times the wheel spins, the axle stays in place. A slip ring performs a similar role in the generator, ensuring that electricity can still flow even as parts of the generator rotate.

The purpose of a slip ring generator is multifaceted. At its core, it is designed to provide efficient power generation for a wide range of applications. From remote wind farms where wind power is converted to electricity, to use in large-scale industrial machinery, the role of the slip ring generator is invaluable in various aspects of our day-to-day lives.

Its ubiquitous presence in power generation systems across the world stands as a testament to the importance of the slip ring generator. Throughout this article, we’ll delve into this fascinating technology, uncovering its principles of operation, the functional role of the components, the advantages it brings, and other essential aspects enlightening our understanding of slip ring generators.

Working Principle of Slip Ring Generator

Delving into the intricate world of electrical power generation, we come across the operational mechanics of a slip ring generator. The working principle of a slip ring generator can be likened to that of a standard generator, with a unique twist allowing for continuous electrical contact between the rotating and stationary components.

A slip ring generator primarily consists of a rotor (the moving part of the generator) and a stator (the stationary part of the generator). The rotor features a set of coils which, as they rotate within the magnetic field created by the stator, induce an electric current.

This is where the slip rings and brushes come into play. Attached to the rotor, the slip rings are circular, conductive materials that create a bridge for electricity to flow from the moving rotor to the stationary stator, and ultimately to the external circuit. To maintain electrical continuity, brushes (usually made from carbon or graphite materials) are held against the slip rings, allowing current to flow without interruption even as the rotor rotates at high speeds.

Importance of the Slip Ring and Brushes in Generating Power

Slip rings and brushes are often the unsung heroes of a generator system. They take on a truly significant role in the operation of a slip ring generator, although it’s often overlooked.

Without slip rings, the rotating motion of the rotor would either cause electrical wires to become twisted and subsequently break, or there would need to be a break in the electrical connection every half cycle – both scenarios preventing the successful generation and transmission of electrical power. The slip ring enables the rotor to turn freely without these issues, maintaining an unbroken path for the electrical current.

In contrast, the brushes, positioned against the slip rings, permit the transfer of this electrical current. They help ensure the current generated in the rotating coils of the rotor doesn’t get trapped or lost but instead, flows into the stator, contributing to the overall power generation.

As such, the slip rings and brushes in a generator are not just features, but necessities – intrinsic to the overall operation of the unit. Their importance in power generation is as palpable as their role is indispensable in providing us with a consistent and reliable source of electricity.

Types of Slip Ring Generators

Slip ring generators, like many types of machinery, are not one-size-fits-all. There is a diverse array of slip ring generators, each uniquely adapted to specific applications and needs. These generators vary in their design, power output, size, and other specifications.

In a broad-stroke categorization, slip ring generators can be divided into two major types: Single-phase and Three-phase slip ring generators.

Single-phase Slip Ring Generators: As the name suggests, these generators use a single-phase power supply. They are generally smaller and less complex compared to three-phase generators. Although they produce less power, they are perfectly suited for applications where the power demand is not excessively high. For instance, single-phase slip ring generators might be used for residential purposes or small businesses, where the electricity demand remains relatively moderate.

Three-phase Slip Ring Generators: These generators use a three-phase power supply, significantly boosting their power output. Three-phase slip ring generators are remarkably effective in handling higher-rated currents, making them ideal for industrial applications where the power demand is high. Whether it’s powering heavy machinery or running an entire factory, three-phase slip ring generators prove their worth.

In addition to these categories, there are also tailor-made slip ring generators designed for specific applications, such as those used in the wind turbine industry. These generators need to operate under harsh weather conditions and withstand the powerful mechanical stress caused by the rotating turbine blades.

Understanding the various types of slip ring generators not only extends our knowledge about this crucial technology but also plays an essential role in the criterion for selecting the right generator for any given application. The choice depends on several factors, including but not limited to, power requirements, environmental constraints, and specific application demands.

Slip Ring Generators: Key Components and Their Functions

A slip ring generator, despite its apparent complexity, is composed of a few fundamental components that work together to convert kinetic energy into electrical energy. Understanding these components and their respective functions helps demystify what might otherwise seem a daunting piece of machinery. The primary components of a slip ring generator are the rotor, stator, slip rings, and brushes.

The Rotor: This is the dynamic part of the generator, constantly rotating in response to an external force. Coils of wire, often made from conductive copper, are wrapped around the rotor. When this rotor spins within the magnetic field of the stator, it induces an electromotive force (voltage) in the coils, thereby generating an electric current.

The Stator: Acting as the counterpart to the rotor, the stator remains stationary during the generator operation. It is typically equipped with a magnetically ‘soft’ iron core around which primary and secondary (input and output) windings are coiled. The stator interacts with the rotor to create a magnetic field necessary for inducing a current in the rotor coils.

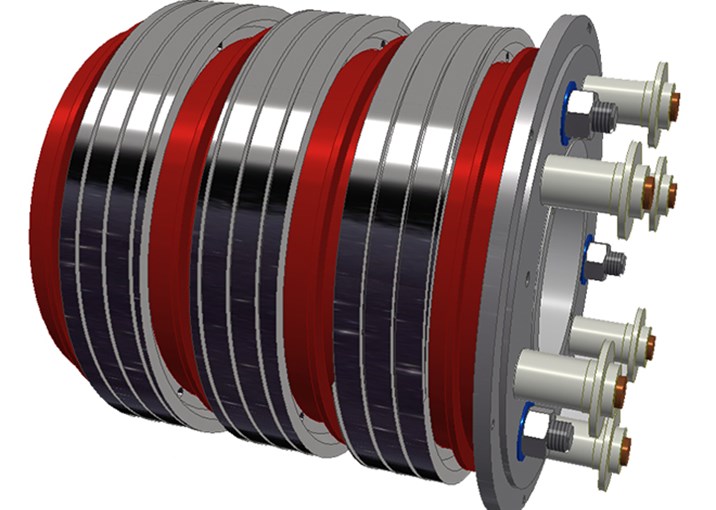

Slip Rings: Attached to the rotor, the slip rings are conductive materials that form a continuous circle. They provide a moving conductive path for the current generated in the rotating rotor, allowing it to flow through to the brushes.

Brushes: These are used to maintain electrical contact with the rotating slip rings. The brushes, often made of carbon or graphite materials, are held against the slip rings, facilitating the transfer of current from the rotating slip rings to the stationary stator and, ultimately, the external circuit.

In concert, these components form a well-orchestrated symphony of electrical power generation. The rotor and stator are the musicians creating the melody of electricity, while the slip rings and brushes allow this melody to be continuously played, taking it from a rotating stage to the static world beyond, without any interruptions or distortions. Understanding the roles they play sheds light on the ingenuity behind electricity production using a slip ring generator.

Advantages of Slip Ring Generators

In the diverse world of power generation, slip ring generators hold a place of considerable importance. This is attributable to the unique advantages they offer over other types of generators.

Uninterrupted Power Transfer: Perhaps the single most significant advantage of the slip ring generator is its ability to transfer power continuously from a rotating structure to a stationary one. This uninterrupted electricity flow is made possible through the slip rings and brushes, even while the rotor spins at high speeds.

Versatility: Slip ring generators are versatile in their application. They can be used in wind turbines, hydroelectric power plants, and other machinery where there is a need to convert rotational energy into electric power. This gives them an edge in multiple sectors, including renewable energy and industrial applications.

Durability: Due to their simple yet effective mechanism, slip ring generators generally have robust and durable structures. This makes them a reliable option for long-term power generation, capable of withstanding harsh conditions and delivering sustained performance.

Reduced Maintenance: The design of slip ring generators allows for lower maintenance requirements compared to several other generator types. While slip rings and brushes may need replacement over time, the core generator components are quite resilient and require little upkeep.

Scalability: From compact, single-phase generators for small businesses, to large, three-phase generators for industrial applications, slip ring generators offer a scalable solution for varied power needs.

While these are some of the advantages slip ring generators have over other generators, it’s important to remember that selecting the ideal generator should always be based on the requirements of the application and the specific operational needs. Despite this, the aforementioned advantages demonstrate why slip ring generators remain an attractive choice in many settings.

Slip Ring Generators: Common Problems and Troubleshooting

As with any electromechanical system, slip ring generators may encounter issues over their operational lifetime. Some problems may be common and relatively easy to rectify, while others may require expert intervention. However, gaining an understanding of potential issues and their associated troubleshooting steps can help in quick fault diagnosis and resolution.

Wear and Tear of Slip Rings and Brushes: Since slip rings and carbon brushes are in constant frictional contact, they are susceptible to wear and tear over time. This could result in ineffective power transfer from the rotor to the stator. In such cases, inspecting the slip rings and brushes for excessive wear should be the first troubleshooting step. If found worn out, they will need to be replaced.

Abrupt Voltage Drops or Spikes: These could be a result of faulty wiring or damaged coils in the rotor or stator. Regular maintenance checks and inspections should help to identify and correct these issues. If the problem persists, it may be necessary to replace the faulty coils or conduct a more extensive repair.

Lack of Lubrication: For smooth operation, maintaining an optimum level of lubrication is crucial. Insufficient lubrication can cause overheating, sparking, and premature wear of components. Regularly inspecting and applying suitable lubricants can mitigate these problems.

Poor Power Output: This could be due to a multitude of reasons, from worn-out components and faulty connections to aging of the generator unit. It may necessitate a thorough inspection to identify and resolve the root cause.

As a general tip for proactive problem avoidance, regular maintenance and proper care of the generator is crucial. This includes keeping the generator clean, ensuring proper lubrication, and timely replacement of worn-out parts.

Though these troubleshooting tips may help manage minor issues and extend the operational life of your generator, expert help should be sought for significant issues or when in doubt, to ensure the safety and reliability of the system.

Slip Ring Generators: Application

Slip ring generators have been instrumental in multiple sectors, thanks to their versatility and continuous power transfer ability. A few of the notable areas where these generators have proved their worth are wind turbines, hydroelectric power plants, and marine applications. Let’s take a closer look.

Wind Turbines: One of the most prevalent uses of slip ring generators is in wind turbines. Wind turbines convert the kinetic energy of wind into electrical energy. As the wind turns the turbine’s blades, it sets the rotor of the generator in motion, producing electricity. The slip ring generator plays a crucial role here, ensuring constant transfer of generated power to the grid, even as the turbine constantly rotates with varying wind directions.

Hydroelectric Power Plants: These plants harness the power of falling or fast-moving water to generate electricity. They use a turbine connected to an electric generator. Here, slip ring generators serve the critical task of transferring the produced electricity from the continually rotating turbine to the stationary power lines. They ensure a reliable and steady electricity supply, which is crucial for the uninterrupted operation of the power grid.

Marine Applications: In ships and submarines, slip ring generators help power electric propulsion systems. They are designed to endure tough operating conditions, such as vibrations, water, salt, and oil. Providing reliable and continuous power makes slip ring generators an essential component of many marine applications.

In each of these sectors, the need for a high-performing, reliable, and continuous power-supply solution is paramount. Slip ring generators, with their unique advantages, have proven to be an invaluable solution, playing a key role in supporting the constant demand for electricity and powering our world.

Slip Ring Generators: Maintenance and Care

Proper maintenance of a slip ring generator is not just essential for its efficient operation but also for maximizing its lifespan. These practical tips can help maintain the equipment’s longevity and ensure its optimal performance.

Regular Inspections: Keep a consistent schedule for checking the condition of all components, with a special focus on the slip rings and brushes, as they are the parts that directly affect power transfer. Look for excessive wear and tear and replace these components as needed.

Cleaning: The generator should be kept clean from dust and debris, as these can lead to unwanted friction or heat buildup. Special care should be taken to keep the slip rings and brush area clear as residue accumulation can affect electrical contact.

Lubrication: Ensure there is sufficient lubrication at all contact points, primarily between the slip rings and brushes. The lubricant not only reduces friction but also aids in heat dissipation. However, it is crucial to use the correct type and amount of lubricant as recommended by the manufacturer.

Correct Operating Practices: Adhere to the rated operating parameters of the generator. Overloading or overheating can lead to strain on the components, affecting their lifespan negatively.

Professional Servicing: Periodic professional maintenance services should be considered, especially for sophisticated or larger-scale generators. These services often include thorough diagnoses and preventive measures that can help avoid future malfunctions.

Environmental Conformity: Ensure the generator is operating under suitable environmental conditions. High levels of moisture, extreme temperatures, or corrosive environments can deteriorate the generator components prematurely.

Regular maintenance and proper care not only sustain the generator’s performance but also detect any potential issues early, preventing costly repairs or sudden breakdowns. Prolonging the lifespan of a slip ring generator fundamentally boils down to a commitment of time, care, and mindful operation.

Slip Ring Generators: Buying Guide

When it comes to purchasing a slip ring generator, there are several crucial factors that potential buyers must consider to make sure they get the most suitable product for their needs:

Power Rating: The power output of the generator should match your application requirements. Ensure the generator can handle the highest load you’ll be operating.

Environment Suitability: Consider the environment where the generator will operate. It should withstand various factors such as moisture, extreme temperatures, dirt, dust, and more.

Quality of Components: The generator should have high-quality parts, especially slip rings, and brushes, considering these have a direct effect on power transfer. High-grade materials will ensure durability and a longer life span.

Manufacturer Support: Look for a product with robust after-sales service and support, including spare parts availability, servicing, and warranty. This minimizes the hassle if problems arise in the future.

Certification: Ensure the generator is certified by relevant standards organizations. This assurance can dictate safety, energy efficiency, and overall quality.

As for brands and models, here are a few recommendations:

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023

Remember, the best generator is the one that meets your specific requirements most effectively. Therefore, it’s crucial to properly assess your expected usage before making a purchase decision.

Conclusion

In conclusion, slip ring generators, with their working principles and advantages, play a vital role in power generation. Understanding these machines better can inform your decision-making, whether you’re involved in industry-level power generation or seeking to meet smaller-scale needs.