In a world of rapidly advancing technology, the need for reliable and efficient power, signal, and data transmission has become paramount. The widespread use of machines that contain moving parts demands solutions that can maintain continuous connectivity without restricting motion. One such solution is the slip ring box, an essential piece of electromechanical equipment designed to seamlessly bridge gaps between stationary and rotating parts in numerous applications. This article aims to provide a comprehensive overview of the slip ring box’s concept, its various types, and its wide range of applications in different industries. We will also delve into its inner workings, address common concerns of potential users, explore innovations within the field, and discuss the future of slip ring box technology. By the end, you’ll gain a clearer understanding of the importance and potential of slip ring boxes in modern-day machinery.

The Basic Concept of a Slip Ring Box

A slip ring box is an advanced electromechanical device that plays a crucial role in transmitting power, signals, or data between stationary and rotating components of machines. It has become an indispensable solution in the realm of machinery containing rotational parts, as it enables consistent and uninterrupted connectivity, ensuring smooth functionality.

The primary function of a slip ring box is to establish a reliable conductive connection without hindering the movement of its connected parts. To accomplish this task, typically a combination of brushes and rotating contacts maintain a constant electrical connection while the rotating components spin. This electrical path allows different types of signals, such as control, communication, or power, to be safely transferred across the interlocking elements without causing mechanical wear or stress on the connected parts.

The incorporation of slip ring boxes has allowed for the enhancement of many machines, providing greater reliability and efficiency while reducing wear and tear associated with traditional rotating contacts or cable systems. By simplifying the transmission of signals and power, the slip ring box ultimately contributes to the seamless functionality and better performance of diverse machinery and applications across various industries.

Types of Slip Ring Boxes

The world of slip ring boxes is vast and diverse, encompassing a variety of types designed to cater to different requirements. Each type has unique characteristics that make it suitable for specific applications according to the operational demand, space constraints, and the nature of the signal transmitted.

Capsule Slip Rings are commonly used due to their compact design and easy installation process. They are designed for transmitting signals, including data and video signals, and are typically used in applications where small size and lighter weight are advantageous, like cameras and smaller robotics.

Through-bore Slip Rings are designed with a central hole, known as the ‘through-bore,’ to accommodate a shaft or other device. These are often utilized in machinery that requires an unlimited, continuous, or intermittent rotation while transferring power, data, or signal from a stationary part to a rotating part. Applications include wind turbines, rotary sensors, and medical equipment.

Pancake Slip Rings are characterized by their flat, disk-shaped design. The pancake-style is suitable when the length is critical and height or diameter is not as important. They are best fitted for applications with limited axial spacing, like radar antenna interfaces and turntables.

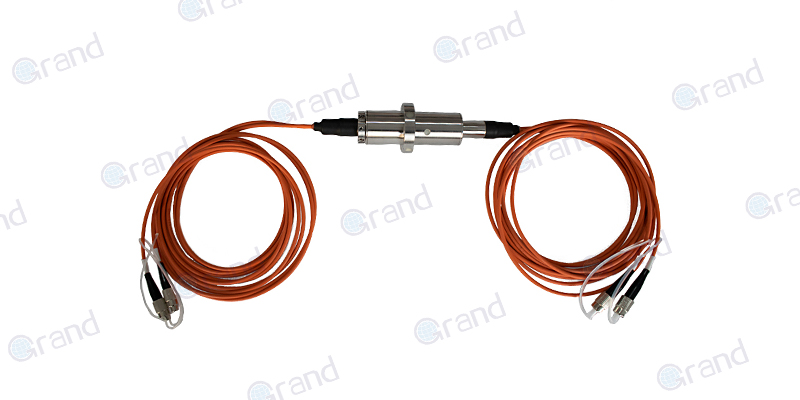

Fiber Optic Rotary Joints (FORJs) are relatively complex and are used for transmitting optical signals alongside electrical connections. These slip rings are particularly beneficial where high data-rate transmission is crucial, such as in radar systems, spacecraft, and digital HD video systems.

These are just a few of the many types of slip ring boxes available. Manufacturers often produce custom slip rings to cater to the specific needs of an operation, offering a bevy of configurations to choose from. The key is to understand the requirements of your application and match them to the most suitable type of slip ring box.

Slip Ring Box: Components and Design

The design and functionality of a slip ring box are fundamentally underpinned by its main components: the rotating contact, the brush, and the housing. Each part plays a critical role, and their combined operation is what facilitates efficient and reliable power, signal, or data transmission in countless applications.

The Rotating Contact plays a pivotal role in the slip ring box as it is the primary liaison that facilitates the transfer of electrical signals from stationary to rotating parts. It is through this contact that the signals are transmitted irrespective of the continual rotational movement. The rotating contact’s proficiency in uninterrupted transmission contributes to the efficient performance of the application in which the slip ring box is used.

The Brush is the indispensable counterpart of the rotating contact. It maintains continuous contact with the rotating part, enabling the transfer of signals. Brushes can be made of a variety of materials including precious metals, carbon, or graphite, each offering different advantages in terms of electrical properties, noise generation, and durability.

The Housing encapsulates the rotating contact and the brush, protecting them from environmental elements and potential damage. Depending on the application, the housing is designed to handle different conditions such as high temperatures, moisture, or corrosive environments, and can be fabricated from materials like aluminum, stainless steel, or engineered plastics.

The meticulous design of these components and their harmonious interaction ensure the slip ring box’s overall efficiency and lifespan. Understanding these essential components provides an insight into the complexity behind the simple yet crucial task of a slip ring box: facilitating power, data, or signal transmission between stationary and rotating parts in a myriad of applications.

How Does a Slip Ring Box Work?

In its most essential form, a slip ring box is built to solve a complex problem with elegant simplicity: ensuring the smooth and uninterrupted transmission of power, signals, or data from a stationary component to a rotating one.

Here’s how it works: as the rotating component of a machine spins, the rotating contact within the slip ring box also rotates with it. Simultaneously, the brush maintains stable contact with this constantly moving element. This continuous touchpoint creates a circuit, allowing the smooth flow of electrical signals, power, or data from the stationary part of the machinery to its rotating counterpart. This enduring connection is made possible even as the machine’s parts rotate at varying speeds and directions.

To make this a little clearer, consider the example of a CT scanner in a hospital – an application where slip ring boxes play a crucial role. The scanner rotates around a patient while rapidly taking multiple X-rays from different angles. Here, a slip ring box is responsible for delivering power for the X-ray tube and sending the signal data from the detectors back to the system for processing, despite the continual rotation of the components.

The function of a slip ring box isn’t limited to sophisticated medical equipment. It’s found in a multitude of everyday devices such as electric generators, wind turbines, or even the carousel at a local theme park, ensuring that while the structure rotates, the lights stay on – all thanks to the humble and vital slip ring box.

Key Features of Slip Ring Boxes

The widespread utility and high demand for slip ring boxes in various industries can be attributed to their beneficial features. These characteristics cater to diverse operational needs and make slip ring boxes an integral part of several machines.

Here, we discuss some key features:

Rotational Speed: Slip ring boxes can function at a wide range of rotational speeds, from slow rotations up to several thousand RPM. High-speed variants are engineered to maintain a stable connection under numerous rotational velocities, making them suitable for high-speed applications.

Life Span: One of the deciding factors in the choice of a slip ring box is its life span. Slip ring boxes, particularly those with precious metal contacts, offer extended life spans and require minimal maintenance, making them a valuable investment for long-term applications.

Noise Level: Slip ring boxes that are designed for signal or data transmission often prioritize low electrical noise, as high noise levels can interfere with the quality of transmitted signals. Many slip ring boxes are designed and built with special brushes and materials to minimize noise levels while ensuring efficient signal transmission.

Number of Circuits: Depending on the requirements of the application, slip ring boxes can contain varying numbers of circuits. Some applications might require only a few circuits for power or signal transmission, while others might require many more for complex data transfers.

Temperature Resistance: Slip ring boxes are designed to function under various temperature conditions. From extreme cold to high-heat environments, they can withstand a wide temperature range, making them adaptable to various industrial operations.

By providing these advantageous features, slip ring boxes enhance the functionality and reliability of rotating machines across numerous sectors. Their flexibility in accommodating a variety of operational conditions is what sets them apart as a prime solution for power, signals, and data transfer in rotating systems.

Applications of Slip Ring Boxes

Slip ring boxes are used across a multitude of industries, offering their unique advantages to an array of applications. Their capability to facilitate reliable and continuous transmission of power, data, or signals in rotating equipment makes them indispensable in diverse sectors.

Here are several examples of industries and machines utilizing slip ring boxes:

Aerospace: Aerospace technology requires high-performance and precise communication systems as any signal disruption could lead to catastrophic results. Here, slip ring boxes are often applied in satellite communication systems, radar antennas, and even spacecraft systems.

Manufacturing Industry: In the production landscape, equipment such as robotic arms, rotating tables on assembly lines, and conveyor belts, utilize slip ring boxes. They ensure smooth rotations while maintaining consistent power supply and signal transmission.

Medical Industry: Complex medical equipment like CT scanners and MRI machines rely on slip ring boxes to transmit power and data while rotating around the patient. These scanners collect images from various angles and need a continuous operation, which would not be possible without slip ring boxes.

Wind Energy Industry: Wind turbines are the epitome of machines that require constant rotations. The nacelle of a wind turbine, for example, needs to turn to face the wind direction, and the slip ring box within ensures that power and data transmission to the rest of the system is not jeopardized by this rotation.

Entertainment Industry: Amusement rides such as carousels and Ferris wheels use slip ring boxes to illuminate the moving parts, providing a spectacular light show. They ensure the rotating sections are well-lit, adding charm to the amusement park’s nighttime aesthetics.

These applications demonstrate how central slip ring boxes are in numerous sectors. Their often unseen yet pivotal role enables machines and systems worldwide to function seamlessly, contributing to numerous industries’ advancement and growth.

Users’ Concerns Regarding Slip Ring Boxes

Understanding user concerns is essential to addressing them effectively. Some common apprehensions regarding slip ring boxes include their durability, maintenance, compatibility, and cost.

Durability

Durability is often a top concern for users, considering the constant rotational movement that slip ring boxes endure. The lifespan of a slip ring box depends on multiple factors such as the operating speed, environmental conditions, and load applied (current or voltage). High-quality slip ring boxes are designed to withstand considerable wear and tear, with prolonged lifetimes that may span several years, particularly those featuring precious metal contacts. As such, despite their continuous operation, slip ring boxes are not a component that needs to be frequently replaced if appropriately selected and maintained.

Maintenance

The maintenance aspect is another potential user concern. Users desire components with low maintenance requirements to reduce downtime and avoid unexpected repair costs. Most modern slip ring boxes are designed with minimal maintenance in mind, often containing self-lubricating brushes that significantly reduce manual upkeep. However, periodic inspections to ensure the integrity of the slip ring box, such as checking for wear on the brush or rotating contact, can be beneficial and extend the unit’s lifespan.

Compatibility

Compatibility also weighs heavily on users’ minds. Not all slip ring boxes are ‘one-size-fits-all,’ so users often worry about finding a slip ring box that fits their exact application. Leading manufacturers usually offer bespoke solutions, allowing for customization to meet specific needs – be it a unique size, an uncommon number of circuits, or a particular material for better environmental resilience.

Cost

Cost is invariably a critical consideration for users. The initial investment for a high-quality slip ring box might be substantial, but this must be balanced against the long lifespan and reliable performance they offer. Low-quality alternatives might come with a smaller price tag but can often lead to frequent failures, maintenance issues, and resultant downtime – all of which translate into higher costs over time. For efficiency and energy savings, well-designed slip ring boxes optimize energy utilization and minimize losses, contributing to better overall system productivity and reduced operational costs.

By addressing these common user concerns, it becomes clear that the selection of a slip ring box is a decision that impacts more than just the initial investment. Its durability, maintenance requirements, compatibility, and true cost play a substantial role in the overall operation of the rotating system wherein it operates.

The Future of Slip Ring Boxes

As technology marches forward, the potential for advancements in slip ring boxes holds great promise. Manufacturers continuously strive for improved efficiency, reliability, and versatility to meet the rapidly evolving needs of various industries. Among many possible developments, contactless slip rings stand out as a promising innovation.

Contactless Slip Rings

Unlike traditional slip ring boxes that operate using physical brushes and rotating contacts, contactless slip rings employ electromagnetic or optical methods to transmit power, signals, or data between the stationary and rotating components. This approach offers several advantages over traditional designs:

- Reduced Wear: Since there is no physical contact between the rotating and stationary parts, the wear and tear commonly associated with brushes and contacts are significantly reduced or eliminated. This results in a longer operational life and lower maintenance requirements for the slip ring box.

- Higher Data Rates: Contactless slip rings are capable of handling higher data rates, which is crucial for the increasing demand for high-speed data transmission in growing sectors like telecommunications, drones, and robotics. The elimination of physical contact enables faster and more seamless data transfer.

- No Contamination: With the absence of physical brushes, contactless slip rings generate no debris or particulates. This feature makes them ideal for cleanroom applications and other sensitive environments where contamination caused by dust or residue must be minimized or eliminated.

- Increased Reliability: The non-contact nature of these slip rings leads to fewer instances of failure due to material wear or damage to the brush-contact interface. This non-contact design results in greater overall reliability and extended life for the slip ring box.

The development of contactless slip rings is a glimpse into an exciting future for slip ring box technology. As industries evolve, so too will their requirements for more advanced and efficient slip ring solutions. With ongoing research and innovation, these developments have the potential to push the boundaries of what slip rings can offer and further expand their applications across a variety of sectors.

Conclusion

Understanding the function and benefits of a slip ring box is crucial in recognizing its indispensability across various sectors. Addressing user concerns and keeping abreast of advancements can help make informed decisions when incorporating this essential equipment into your machines.

See What We Can Do