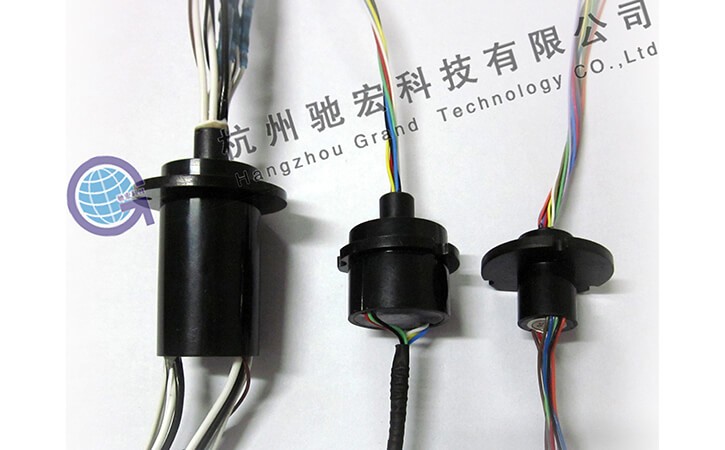

Commonly found in electromechanical systems, slip rings allow electrical power and signal transmission between a stationary platform and a rotating component. They function as a critical pivot in a wide range of equipment, from wind turbines to radar antennas and even in some medical devices.

A slip ring operates by converting the rotary motion into electrical signals, allowing continuous power supply and transmission without hampering rotational movement. It is made up of two primary components: the rotating part (rotor) that connects to the moving device, and the stationary part (stator) that remains attached to the power source.

However, as with any device that deals with electrical signals and energy, slip rings generate heat – a consequence of both friction and electrical resistance. This heat, if not efficiently managed, can lead to damage or failure, severely affecting the performance of the device it powers. It could also lead to safety risks such as overheating, which might affect associated components.

This is where thermal management enters the picture. Ensuring the proper management of heat in slip rings is of paramount importance. It prevents overheating, maintains performance efficiency, extends the lifecycle of the slip ring and the device it powers, and safeguards against potential safety risks.

Without proper thermal management, excessive heat might cause wear and tear of the ring and brushes, thermal expansion, or even melting in severe cases. Each incident, though varying in severity, can disrupt the function of the slip ring and by extension, the operations of the wider device.

Thus the introduction of slip rings and their thermal management sets the stage for a deeper dive within the following sections, exploring in detail the causes of heat generation, the strategies to efficiently manage it, and the innovations charting the course of thermal management in the future.

Understanding slip ring thermal management is crucial, as it sets the foundation for the following sections. We will explore the intricacies of heat generation and dive into strategies for effectively managing thermal aspects. Additionally, we will examine innovative solutions and advancements shaping the future of slip rings and their thermal performance.

Understanding Thermal Management in Slip Rings

Thermal management in slip rings is an essential practice designed to maintain optimum operating temperatures, thereby ensuring the reliability and longevity of both the slip ring and the equipment it powers. It involves monitoring heat generation, employing various cooling methods to dissipate heat, and designing the slip ring and material selection in such a way as to reduce heat generation and promote effective heat dissipation.

Understanding the heat generation in slip rings necessitates a look into the factors that cause it. While friction is the most obvious contributor, there are numerous other factors that can cause heat build-up in the system. For one, electrical resistance plays a significant role in generating heat within the slip ring assembly. Other potential heat sources include imperfect contacts, which can cause sparks and subsequent heating, and excessive current load that increases the electrical resistance and the heat generated.

Furthermore, external environmental conditions, such as ambient temperature and humidity, can also affect the heat generated and the rate at which it can be naturally dissipated. The design, material selection, and installation methods of the slip ring also significantly affect the heat generated and its management. For instance, slip rings made of materials with higher electrical resistance are likely to generate more heat, while poor installation can restrict airflow and limit heat dissipation.

The impact of overheating on slip ring performance can be profound, often leading to diminished performance and even outright failure. At elevated temperatures, the materials’ physical properties can change, causing wear and tear, degradation of electrical contacts, and even melting in severe cases. These physical damages then lead to increased electrical resistance, causing further heat generation in a detrimental loop. Additionally, heat-induced expansion can lead to misalignment or imbalance issues, impacting the operational performance of the slip ring.

Furthermore, the impact of excessive heat isn’t confined to the slip ring itself but extends to the entire equipment. It can cause nearby components to malfunction due to overheating, damaging not only the slip ring but also jeopardizing the overall system’s integrity.

Given the serious consequences that overheating can pose, efficient thermal management in slip rings is not an option, but a critical necessity for maintaining the reliability and performance of the equipment it supports. This necessitates a detailed understanding of the factors causing heat generation and the ways to minimize and manage this heat effectively.

Signs Indicating Thermal Issues in Slip Rings

Managing the thermal aspects of slip rings requires keen vigilance for signs of thermal overload that might indicate potential issues. These red flags, if ignored, can lead to serious consequences, making it essential to understand and recognize them early.

Common indicators of thermal problems in slip rings result from the heat-induced changes in the physical and electrical properties of the slip ring components. For instance, physical deformations such as warping, softening, or even melting could indicate a severe thermal problem. Wear and tear or degradation of the electrical contacts in the slip ring may also suggest excessive heat.

Another clear sign of thermal issues would be an increase in electrical resistance, which can be detected by a rise in the voltage drop across the slip ring. Overheated slip rings can also manifest a smell of burning material or a rise in the surface temperature that you can feel when the system is operating.

Moreover, excessive noise or vibrations during operation often point towards an imbalance or misalignment, which could be the result of heat-induced expansion. An unexplained and gradual decline in equipment performance, such as a reduction in power efficiency or signal quality, can also be indicative of an underlying thermal issue in the slip ring.

Ignoring these signs can have serious implications. The increased heat can further exacerbate physical and electrical degradation, leading to a runaway cycle of rising heat and declining performance – eventually causing the slip ring to fail entirely. In extreme cases, this failure can even lead to sparking or fire, posing a severe safety hazard.

Furthermore, an overheating slip ring can also damage nearby components. Heat can migrate to surrounding parts, causing them to overheat, which might result in a broad system malfunction or failure. Ignoring signs of thermal issues essentially risks not just the slip ring and its immediate components, but also threatens the integrity of the entire system it supports.

Therefore, recognizing these signs of potential thermal problems in slip rings is essential since they can help prevent significant damage, avoid costly downtime, and ensure a longer, more efficient, and safer operation of the wider system.

Strategies for Efficient Thermal Management

Implementing effective thermal management strategies is essential for extending the life of slip rings and maintaining the reliability and performance of the systems they serve. These strategies typically involve heat dissipation techniques, judicious material selection, and best practices in installation, each of which plays a pivotal role in controlling the operating temperature of slip rings.

Heat Dissipation Techniques

Heat dissipation is a critical aspect of thermal management in slip rings. Several techniques can be adopted to prevent overheating and promote optimal heat dissipation:

- Active cooling systems, such as fans or blowers, can be used to increase airflow around the slip ring assembly. This enhanced airflow accelerates heat removal, regulating the operating temperature effectively.

- Passive cooling options, like heat sinks, can be employed to conduct heat away from the slip ring to a cooler area, where it can be more readily dissipated.

- In certain situations, liquid cooling solutions, which offer more efficient heat transfer capabilities, can be considered. These systems circulate coolant through a series of tubes or channels to absorb, transport, and reject the heat generated by the slip ring.

- It is crucial to ensure adequate spacing and ventilation around the slip ring assembly, to promote natural cooling through air circulation and convection.

Material Selection for Slip Rings

The choice of materials used in the construction of slip rings can significantly impact their thermal management capabilities. Materials with higher electrical and thermal conductivity, such as silver, gold, and copper, not only reduce heat generation due to their low electrical resistance but also aid in more effective heat dissipation.

Furthermore, the use of advanced materials, like synthetic diamond coatings or graphene, can offer superior thermal conductivity and reliable electrical contact even at high temperatures, providing a more efficient and durable thermal management solution.

Installation Influencing Procedures

The manner in which slip rings are installed and integrated into the system can greatly impact their thermal performance. Factors to consider during installation include:

- Positioning the slip ring to ensure optimal airflow and ventilation, which is critical for effective heat dissipation.

- Using thermally conductive materials for mounts or brackets in the slip ring assembly allows for more efficient heat transfer without impeding electrical performance.

- Ensuring proper alignment and balance of the slip ring assembly to optimally minimize friction and thermal stress, while maintaining optimal contact quality.

- Separating heat-sensitive components from the slip ring or incorporating thermal barriers, to reduce the impact of heat on the overall system.

By incorporating these strategies for efficient thermal management, slip rings are poised to achieve greater reliability, enhanced performance, and longer service life. Moreover, these methods contribute to a comprehensive approach to thermal management that safeguards the entire system from heat-induced issues, lending a sense of confidence and security concerning the equipment’s overall performance.

Role of Design in Thermal Management

Thermal management is a crucial aspect of slip ring operation that transcends material selection and installation procedures. It’s heavily incorporated into the design phase itself. A thoughtful design approach can alleviate thermal issues, enhance performance, and extend the lifespan of a slip ring and the connected system.

Importance of Design Aspects in Managing Heat

The design features of the slip ring play a crucial role in determining how efficiently it can handle heat. For instance, the arrangement, size, and positioning of the electrical contacts or channels directly impact the heat generated during operation. Similarly, the rotational speed and surface finish of the slip ring play a role in regulating friction – another significant source of heat.

Moreover, many aspects of the design can influence how effectively the slip ring can dissipate the generated heat. Features like spacing between components, which allows for better airflow, and the use of thermally conductive materials, can remarkably reduce heat accumulation.

Furthermore, the design influences how heat-resistant the slip ring is. Attributes like contact pressure, alignment precision, and use of materials that allow for thermal expansion without significant deformation can enhance the slip ring’s resilience to heat-induced degradation or failure.

Incorporating Cooling Features in Design

There are numerous ways an effective design can incorporate cooling features to manage the heat generated during the operation of a slip ring. Here are a few examples:

- Incorporating heat sinks into the design: These components, often made from a highly thermally conductive material, can absorb the heat from the slip ring and dissipate it to the air or any other cooling medium.

- Specifying materials with desirable thermal properties: Certain materials, like aluminum and copper, have excellent thermal conductivity and can facilitate heat transfer and dissipation.

- Incorporating fans or blowers into the design: This can enhance the airflow over the slip ring, thus accelerating the heat dissipation.

- Adaptive designs: These consider the specific thermal environment the slip ring will encounter, allowing the design to cater to precise temperature and heat conditions, preventing overheating and the degradation of components.

By incorporating these strategies into the design of slip rings, effective thermal management can be achieved, ensuring long-lasting, reliable performance. Therefore, design is not just a creative process to build functional units, rather it’s a strategic approach that plays a critical role in managing heat and maintaining the overall performance and lifespan of the equipment.

Innovative Solutions in Thermal Management

The advent of cutting-edge technology and innovative materials has revolutionized the thermal management strategies of slip rings. These advancements enable efficient heat dissipation, leading to improved performance and extended system life.

Use of Advanced Materials for Better Heat Dissipation

Advances in material science have drastically expanded the options available for thermal management in slip rings. Many of these advanced materials have superior heat dissipation capabilities, and some come with added benefits, such as stability at higher temperatures or minimal friction. Here are a few examples:

- Synthetic Diamond Coatings: These coatings provide exceptional thermal conductivity and high electrical insulation, making them an excellent choice for slip rings exposed to extreme conditions. They also enhance durability, even in high-speed operations.

- Graphene: Known for its excellent thermal conductivity, graphene also presents an exciting potential for heat management in slip rings. Plus, its stability at high temperatures proves to be favorable when handling heat loads.

- Ceramic Composites: High thermal conductivity ceramics, such as aluminum nitride and boron nitride, can effectively conduct heat away without compromising their electrical insulating properties. These materials are especially suitable for high-power, high-frequency applications where both heat dissipation and electrical isolation are essential.

Revolutionizing Slip Ring Design for Enhanced Thermal Management

Reimagining the traditional design of slip rings and incorporating innovative cooling features provides for exceptional thermal management. Some innovative design changes include:

- 3D-Printed Slip Rings: With advances in 3D printing, designers have far greater flexibility in incorporating complex heat management structures directly into the slip ring design.

- Integrated Cooling Channels: Designs that integrate cooling channels into the slip ring allow for the use of liquid cooling, transporting coolant directly through the slip ring itself. These systems not only increase the heat dissipation rate but also reduce the heat spread, minimizing its impact on nearby components.

- Heat Spreading Technology: Advanced heat-conducting materials, when included in the design of the slip ring, help disperse heat more uniformly, preventing hotspots and reducing thermal strain on specific components.

These innovative solutions in thermal management are potential game-changers, ensuring higher performance, longevity, and reliability of slip rings. By taking advantage of these cutting-edge materials and design features, engineers and manufacturers can combat thermal challenges effectively and efficiently, affirming positive impacts on the entire system’s integrity and functionality.

Slip Ring Thermal Management: Case Studies

Real-world applications of successful thermal management solutions provide a more engaged understanding of how theoretical concepts are adapted in the industry. The role that novel materials and innovative designs in reducing thermal overload and enhancing operational capabilities becomes evident through these case studies.

Real-World Examples of Thermal Management Solutions

Here, we explore a couple of real-world examples demonstrating how robust thermal management solutions can significantly enhance the performance of slip rings:

- Aerospace Slip Ring Design: In one case involving a slip ring for an aerospace application, the slip ring needed to withstand high temperatures while operating at high rotational speed. For efficient thermal management, the design team incorporated several heat-dissipating features. These included increased spacing for better airflow, the use of copper for its excellent thermal conductivity, and the incorporation of built-in air cooling mechanisms. The slip ring design proved to be extremely successful, maintaining an operational temperature within the safe limit and extending the life of the assembly.

- High-Power Industrial Applications: In another industrial instance, a slip ring was found to overheat during operation, causing frequent system shutdowns. Engineers identified the prevalence of hotspots as the major issue. To counteract this, they opted to use boron nitride in the design. Boron nitride, known for its excellent heat-spreading properties, spreads the heat evenly across the slip ring, eliminating hotspots and enhancing performance. The modified slip ring performed optimally without overheating, reducing downtime and significantly improving productivity.

Through these case studies, we observe the pivotal role thermal management plays in the successful operation of slip rings. They also suggest how innovative solutions can be adopted and tailored for specific applications. By learning from such real-world examples, we can continue to refine and improve our approaches to thermal management, ensuring more reliable, durable, and efficient slip rings.

Maintenance Tips for Effective Thermal Management

Implementing systematic maintenance procedures and adhering to industry best practices can greatly enhance the efficacy of thermal management in slip rings. Not only do these actions ensure the slip ring operates at optimal temperature, but they also extend the equipment’s life and reliability, keeping the overall system in peak condition.

Scheduled Checks and Maintenance Procedures for Thermal Management

The incorporation of routine checks and a set maintenance schedule into your operations can help identify and prevent potential thermal issues early on. Here are some key points to consider:

- Regular Visual Inspections: Regularly inspect the slip ring for any signs of overheating such as discoloration, cracks, or deformities. Pay close attention to areas around the electrical contacts, as these are typically where the heat is generated.

- Thermal Imaging: The use of infrared thermal imaging can help identify hotspots and uneven heat distribution. This, in turn, can facilitate the remediation process if any problems are discovered.

- Cleaning: Ensure the slip ring and associated components are regularly cleaned to prevent dirt and dust build-up that can act as thermal insulators and hinder heat dissipation.

- Scheduled Part Replacement: If the slip ring incorporates wearable components for heat management, like cooling fans, schedule their replacement to avoid sudden failure and potential overheating.

Best Practices from the Industry

The industry has seen many iterations of thermal management and has produced several best practices that have proven successful. Here are a few:

- Select the Right Materials: Start with using materials known for superior heat conductivity and durability in the design. This ensures the overall architecture of your slip ring is inherently equipped to handle heat dissipation.

- Invest in Quality Over Price: It may be tempting to save on initial costs by choosing cheaper alternatives, but investing in high-quality components and materials can save maintenance costs and offer better heat management in the long run.

- Ensure Proper Installation: Make sure the slip ring is correctly installed as per the manufacturer’s guidelines, particularly regarding spacing and alignment. Improper installation can lead to excess heat generation and ineffective heat dissipation.

- Regular Training of Maintenance Staff: Regularly train your maintenance staff to ensure they are updated with the latest techniques and practices concerning thermal management.

- Consider Environmental Factors: Always keep in mind the operating environment. Specific environments may require special consideration, especially those with high ambient temperature or minimal airflow.

Adhering to these maintenance tips and best practices can ensure effective thermal management in slip rings, preventing component failure due to overheating and extending the overall life of the equipment.

Future Trends in Thermal Management

Staying up-to-date with evolving trends in thermal management in slip rings is imperative in this era of constant technological innovation. Predicting future advancements can help strategize designs and operational techniques to stay ahead of the competition. Technology will undoubtedly play a key role in defining these trends and paving the way for innovative thermal management solutions.

Expected Advancements in Thermal Management

As slip ring technology continues to evolve and applications become more demanding, there are several expected advancements in thermal management that we could foresee:

- Nanotechnology: As we harness the power of nanotechnology, materials with nanostructures may be used in the construction of slip rings. These materials can offer improved thermal conductivity and customized thermal properties, enabling superior heat management than possible with conventional materials.

- Integrated Smart Systems: With the rise of the Internet of Things (IoT) and smart systems, more slip rings might employ integrated sensors to monitor the temperature in real-time. With better insights into thermal profiles, we can expect automated and more optimized thermal management strategies in the future.

- Adaptive Cooling: Future designs could include systems that can adjust cooling mechanisms based on the current temperature profile. This concept, known as adaptive cooling, enables more energy-efficient cooling solutions while maintaining optimal temperature conditions.

Role of Technology in Innovative Thermal Management Solutions

The role of technology in designing innovative thermal management solutions is profound. Here’s a snapshot of how it can influence the future:

- 3D Printing: The use of 3D printing technology not only enables designers to create efficient heat management structures but also allows the fabrication of slip rings using advanced materials, further enhancing their thermal management capabilities.

- Machine Learning and Advanced Analytics: With the push towards Industry 4.0, machine learning principles can be applied to create self-optimizing thermal management systems, which learn from past performance to improve future efficiency.

- Advanced Simulation Software: Improved software for thermal analysis and simulation allows for better prediction and management of thermal profiles, paving the way for more efficient design processes and optimal thermal management solutions.

As these trends continue to take shape, we can anticipate even more significant advancements in the way we manage heat in slip rings. Understanding these future trends can help us prepare and adapt, ensuring we leverage the best strategies in thermal management to advance the longevity, reliability, and overall performance of our systems.

Conclusion

Ultimately, managing the thermal aspects of slip rings is important as it significantly impacts the durability, safety, and performance of the systems they empower. By adopting effective thermal management practices, you help ensure your slip rings continue to assist in maintaining system efficiency now and into the future.

FAQs about Slip Ring Thermal Management

Q: Why is thermal management necessary for slip rings?

A: Thermal management in slip rings is crucial for numerous reasons. Heat generated due to electrical resistance or friction can cause materials in the slip ring to degrade or fail, diminishing the device’s performance and lifespan. Proper thermal management techniques mitigate these risks, ensuring stable and reliable performance.

Q: How does the design of a slip ring influence thermal management?

A: The design of a slip ring plays a critical role in thermal management by influencing how much heat is generated and how effectively it is conducted away. Aspects such as spacing between parts, selection of highly conductive materials, integration of cooling features, and accommodation for any thermal expansion all contribute to effective thermal management.

Q: What materials are best for thermal management in slip rings?

A: Materials with high electrical and thermal conductivities, like copper, aluminum, and silver, are often preferred for their ability to reduce heat generation and facilitate dissipation. However, innovative materials such as synthetic diamond coatings or graphene have proven highly effective, offering superior thermal conductivity and durability even at high temperatures.

Q: Can thermal management affect the size and weight of a slip ring?

A: Definitely. Incorporating thermal management features, such as fans, heat sinks, or liquid cooling systems, can increase the size and weight of the slip ring. Therefore, it’s crucial to balance the need for thermal management with practical considerations about the dimensions and weight of the overall system.

See What We Can Do