In the grand orchestra of electrical and mechanical engineering, the unsung heroes are often small yet crucial components that allow the symphony to go on – slip rings and roll rings are among such vital entities. Their roles in ensuring seamless power and data transmission between stationary and rotating parts of many devices go largely unnoticed, yet they are highly instrumental in the smooth functioning of these systems.

From the turbines, harnessing wind energy to antenna systems circling in space and the equipment manufacturing our daily necessities, slip rings and roll rings facilitate an uninterrupted dialog between static and moving parts, managing rotation and data flow concurrently. Without these crucial devices, many of the rotating systems we rely on would cease to operate as required, hence underlining their indispensable role in our technologically driven world.

However, despite fulfilling similar roles, a muddle often arises when choosing between a slip ring and a roll ring for a specific application. While their core purpose is the same, their operational methods, structures, and application effectiveness vary. On one hand, slip rings, with their simplicity and efficient power transmission, are often favored for their broad applicability. On the other, roll rings, with their sophisticated design and superior data transmission, find preference where high-speed performance and durability are paramount.

The principal goal of this article is to unravel the complexities of slip rings and roll rings, two crucial devices with numerous engineering applications. By clearly laying out their workings, typical uses, and the principal differentiators through a thorough ‘slip ring vs. roll ring‘ comparison, readers—from engineering scholars, industry practitioners, device makers, or simply the curious—can acquire a deeper comprehension of these intricate components. The comprehensive evaluation offers crucial insights that aid in making correct choices between a slip ring and a roll ring, specifically based on individual requirements and applications. Thus, the objective of the article extends beyond mere dissemination of information to providing guidance, ensuring informed decisions in a domain where even slight component variations can greatly affect technological efficiency.

Understanding Slip and Roll Rings

In the domain of electro-mechanical devices, slip rings and roll rings employ specialized designs to execute a similar yet complex function: transmitting power and data between stationary and rotating components. But to delve deeper and opt for one over the other in an applicative context, it is critical to understand these devices in detail.

Slip Rings

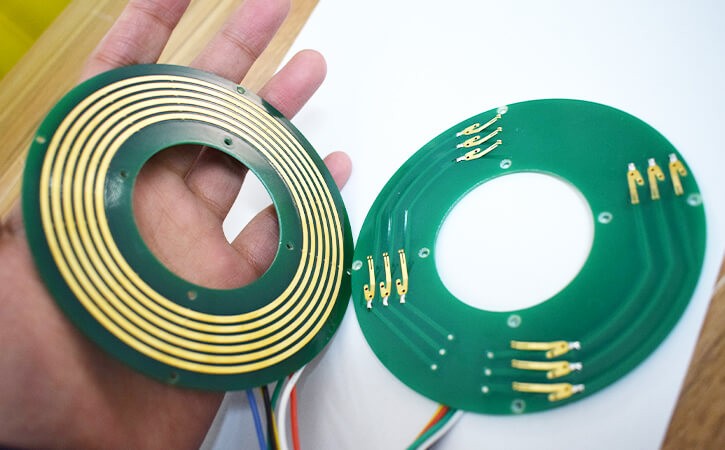

A slip ring is essentially a rotary electrical interface, a device that facilitates the transmission of power and electrical signals from a stationary structure to a rotating assembly. Central to this device are circular tracks loaded with electrical conductors, juxtaposed with brushes that either provide or acquire signals or power. The ‘slip’ refers to the sliding motion of brushes over the ring, allowing a persistent electrical connection, even during rotation.

The primary working principle of the slip ring involves the frictional contact of the brushes against the rotating surface of the ring. As the ring rotates, the brushes maintain constant electrical contact, transferring power or signals without impeding the rotation. It’s this inherent functionality that legitimizes the continuous 360° rotation of some devices.

Common applications of slip rings are abundant due to their rather universal adaptability. Their significant use can be observed in wind turbines, where they efficiently supply power to the rotating blades from the static generator, and in carousel rides, which rotate with lights continuously powered. Slip rings also support various manufacturing processes and healthcare technologies such as MRI machines.

Roll Rings

A deviation from the traditional concept of the slip ring brings us to the roll ring. Devoid of the common brush and commutator system found in slip rings, roll rings employ rolling electrical contacts to enhance power transfer efficiency and attenuate associated electrical noise. This design innovation allowed roll rings a minimize power loss, an essential characteristic in any power/data transmission system.

The working principle of roll rings involves rolling contacts that transfer electrical power or signals to the rotating components from the static ones. This rolling approach significantly curtails the frictional wear and tear common with slip rings, offering a more durable, low-maintenance alternative.

The common applications of roll rings often reside in technologically advancing realms, especially where high-speed data transmission is paramount. These devices are preferred in military communication systems and satellite antennas due to their impressive data-handling capabilities and reduced noise levels. Additionally, they form an essential part of automated industrial machinery and sophisticated medical scanning devices, courtesy of their durability and low-maintenance characteristics.

In essence, while both slip rings and roll rings largely fulfill similar functions, the nuances in their designs, operational principles, and applicative advantages create a distinction, one that is important to comprehend for making an informed choice.

Critical Comparison: Slip Ring vs. Roll Ring

To better inform the choice between slip rings and roll rings, drawing a comprehensive comparison is vital. This comparison explores their respective attributes, including design, operation principles, transmission capabilities, durability, operation at high-speed performance, and resilience under harsh conditions.

Design and Structure

In terms of design and structure, slip rings are relatively simple. They consist of conductive tracks and brushes with the brushes sliding directly on the ring tracks. However, roll rings have a more intricate design. Rather than brushes, they use rolling contacts that interact with tracks on the ring, reducing friction while ensuring efficient power or data transfer.

Operating Principles

The operating principles of both devices differ quite fundamentally. For slip rings, the brushes press against the rotating ring, creating a continuous conductive path for power and data. In comparison, roll rings utilize rolling contacts that roll along the tracks on the ring, leading to electrical contact without substantial frictional wear, which further enhances lifespan and efficiency.

Power and Data Transmission Capabilities

When it comes to power and data transmission capabilities, there’s a notable difference. While both could work for a wide range of applications, slip rings are conventionally used for more power-hungry systems due to their architecture and design. Roll rings, on the other hand, offer superior high-speed data transmission and adaptability to digital signals, thanks to their noise-minimizing design.

Durability and Life Span

Durability and life span are where roll rings take the lead. The reduced friction in roll rings results in less wear and tear compared to their slip ring counterparts. This contributes to a significant extension in the life span of roll rings, often making them more cost-effective in the long run despite the higher initial investment.

High-Speed Performance

When analyzing high-speed performance, roll rings generally prove more resilient. Thanks to the rolling contact mechanics, they can maintain high-speed performance without experiencing a steep decline in efficiency. Meanwhile, slip rings at high rotational speeds may deal with increased brush wear and potential signal disturbances.

Operation under Extreme Temperatures and Harsh Conditions

Both slip and roll rings are resilient enough to operate under extreme temperatures and harsh conditions. However, the rolling electrical contact in roll rings proves advantageous in such scenarios. With lesser direct frictional wear, they tend to perform better under extreme environmental conditions and require fewer maintenance interventions.

In conclusion, a clear perception of these dissimilarities can inform a choice that considerably depends on the specific requirements of an application, including factors such as the power load, the need for resilience to harsh environments, speed requirements, and long-term durability.

Major User Concerns: Slip Ring vs. Roll Ring

When choosing between a slip ring and a roll ring, users will typically have certain apprehensions and concerns that pivot around efficiency, installation, durability, cost, and environmental resilience. The efficacy in addressing these concerns often becomes the decisive factor in opting for either device.

Efficiency and Effectiveness

With regards to efficiency and effectiveness, the roll ring usually scores higher due to its rolling contact design, ensuring minimized friction and power loss. However, in applications where power requirement is substantial, slip rings may offer the necessary effectiveness, despite their simpler design and operational principles. The choice, thereby, would pivot around the specific nature of the application.

Installation, Integration, and Replacement

When it comes to installation, integration, and replacement, slip rings are generally perceived as more user-friendly due to their simpler design and structure. Roll rings, with their more complex structure, may require a higher degree of finesse during installation or replacement. However, advanced roll ring models are being designed with an emphasis on easier assembly and integration, bridging this gap.

Durability and Maintenance

On the front of durability and maintenance, roll rings are a generally preferable choice. Given their inherent reduction of frictional wear, they often considerably outlive slip rings and require less maintenance too. Slip rings, despite their adequacy in many applications, may demand more frequent maintenance due to their brush-track interaction.

Cost – Initial Investment and Operational

From a cost perspective, including both initial investment and operational expenses, the dynamic is more complex. Slip rings often have a more manageable upfront cost, but their recurring maintenance expense could be higher. Roll rings, conversely, have a higher initial cost but can result in potential long-term savings due to lower maintenance requirements and extended lifespan.

Reliability in Different Environmental Conditions

On the matter of reliability in different environmental conditions, both slip rings and roll rings demonstrate robustness. However, roll rings, owing to their reduced frictional wear, may exhibit a slight edge in extreme conditions as they endure less environmental stress.

Weighing these concerns appropriately is vital to ensure that the chosen device aligns well with the specific requirements of the system and the expectations of the user. Understanding and prioritizing these apprehensions could pave the way for a judicious, well-informed decision that optimizes operational efficiency and cost-effectiveness.

Role of Technological Advancements: Enhancing Performance of Slip and Roll Rings

The advent of technological advancements in the electro-mechanical domain has significantly augmented the performance of devices like slip rings and roll rings. Advanced materials, smart technologies, and design innovations have been instrumental in enhancing their durability, reliability, maintenance, efficiency, and integration.

Impact of Advanced Materials on Durability and Performance

The use of advanced materials in the manufacturing of both slip and roll rings has drastically improved their durability and performance. For instance, the incorporation of new brush materials in slip rings has enhanced their lifespan, reduced electrical noise, and provided smoother operation. In roll rings, the introduction of more durable and robust materials for the rolling contacts has resulted in improved power and signal transmission capabilities. These advancements are crucial in extending the operational life of these devices and amplifying their performance specification.

Role of Smart Technologies in Enhancing Reliability and Maintenance

The introduction of smart technologies has brought a revolution in the reliability and maintenance of these electro-mechanical devices. For instance, predictive maintenance technologies can monitor the condition of the brushes in a slip ring, informing users about potential wear and tear and thus precluding sudden breakdowns. Similar technology applied to roll rings enhances their reliability by ensuring that their parts are performing optimally. The eventual aim of smart technologies is to create devices that are more reliable, require fewer interventions, and offer a seamless user experience in numerous applications.

Design Innovations Improving Efficiency and Integration

The design has always been at the forefront of any technological advancement, and it’s no different with slip and roll rings. Design innovations have improved their efficiency and integration capabilities. For slip rings, brushless designs and wireless power transfer technologies have been developed to eliminate mechanical wear completely. Similarly, for roll rings, design improvements have been aimed at minimizing power loss and optimizing data transfer. Innovations in their design also include making them more compact, lightweight, and easy to integrate into various systems, thereby enhancing their application range and utility.

In summary, the continued technological advancement in the field of electro-mechanical systems plays a pivotal role in enhancing the performance of devices such as slip rings and roll rings. They make these devices more versatile, reliable, and efficient to meet the evolving demands and requirements of various applications.

Slip Ring vs. Roll Ring: Future Impact in Various Industries

Both slip rings and roll rings play a significant role in various industries with their applications expanding as technology continues to evolve. These components have a profound impact, particularly in the sectors of industrial automation, communication technologies, renewable energy, and the electric vehicle charging infrastructure.

Role of Slip and Roll Rings in Industrial Automation

In industrial automation, the role of both slip and roll rings is invaluable. They are employed in a wide array of automated equipment to ensure the seamless transmission of power and data. As automation technology becomes more sophisticated, the demands on these components increase. Roll rings might take precedence in high-speed machinery due to their superior performance at high rotational speeds, while slip rings could find their niche in high-power demanding systems.

Role in Communication Technologies

The influence of slip and roll rings in communication technologies is substantial. Roll rings, in particular, provide an excellent solution for transmitting high-frequency signals and maintaining a stable electrical connection, critical for smooth communication. As communication equipment becomes more advanced and the need for reliable, high-speed data transmission grows, both types of rings will likely be essential in addressing these needs.

Role in Renewable Energy (Wind Turbines)

In terms of renewable energy, particularly with wind turbines, both slip and roll rings are critical components. Wind turbines need to rotate freely to align with the wind direction, and these rings transfer power and data signals between the stationary and rotating parts. The application of high-performance, durable roll rings could reduce maintenance efforts and increase the overall operational life of wind turbines.

Impact on the Electric Vehicle Charging Infrastructure

To meet the increasing demand for electric vehicles (EVs), a robust charging infrastructure is required. Here, slip rings can play a role in dynamic charging systems – systems where vehicles can be charged while on the move. These rings can provide continuous power to the charging pads, thereby ensuring a stable power supply. In future scenarios with even higher power demands, adapting these device designs to ensure durability and reliability will be a factor when trying to meet those needs.

In summary, the potential applications of slip and roll rings are vast and diverse. As technology continues to evolve across various industries, the demand for these critical components is expected to rise, leading to further advances in their designs and capabilities.

Slip Ring vs. Roll Ring: Choosing Between Slip and Roll Rings

Choosing between slip rings and roll rings primarily depends on the specific needs of the application. Cost-effectiveness, efficiency, operation speed, the complexity of installation, and maintenance needs must all factor into the decision-making process.

FAQs about Slip Ring vs. Roll Ring

When it comes to the choice between slip rings and roll rings, users often have a slew of questions. This segment aims to address the most frequently asked questions, demystifying the factors that can influence this decision-making process.

Q: What requirements should inform my choice between a slip ring and a roll ring?

A: The choice between a slip ring and a roll ring depends on several factors including the system’s power requirements, the need for high-speed performance, the environmental conditions in which the device will operate, the device’s expected lifespan, and the overall costs involved.

Q: If my system demands high-power transmission, which one should I choose?

A: For systems that demand high-power transmission, slip rings are traditionally a preferred choice. Their design, which usually includes a larger contact surface area, is ideal for coping with heavy power loads.

Q: Which one offers better high-speed performance – slip rings or roll rings?

A: Roll rings generally offer better high-speed performance. Their rolling interface creates less frictional heat and wear, which helps maintain performance even at higher speeds.

Q: Which one requires less maintenance, and why?

A: Roll rings typically require less maintenance as their rolling contacts experience less wear and tear compared to the sliding contacts in slip rings. This leads to a significantly extended lifespan, reducing the need for regular replacement or upkeep.

Q: Is the higher initial cost of a roll ring justified?

A: While roll rings often require a higher initial investment, they may prove more cost-effective in the long term due to their prolonged lifespan and reduced maintenance requirements. It’s essential to consider not only the upfront costs but also the long-term operating expenses while making the decision.

Q: Which device is likely to perform better under harsh environmental conditions?

A: Though both devices can work under extreme environmental conditions, roll rings often have a slight advantage due to their reduced direct frictional wear. This gives them more endurance under harsh conditions, requiring fewer maintenance interventions.

Ready to learn more about our slip rings? Complete the form below to get started.