In the electrifying world of electronic systems, every component comes together like an orchestra to produce a symphony of operations. One silent virtuoso in this ensemble, offering an unmissable performance despite its inconspicuous nature, is the element of the slip ring. Frequently overlooked, slip rings form an integral part of countless electronic systems that we interact with each day.

Slip ring electronics pertain to the design, operation, and application of these crucial devices which facilitate electrical connections in rotating assemblies. They are not just another cog in the machine but bridges that sustain the constant flow of electrical power or signals between stationary and rotating parts. With this continual transmission, they enable systems to work efficiently without interference caused by movement.

From the ceiling fan spinning tirelessly above our heads to the advanced turbines harvesting the power of the wind to generate electricity, slip rings make many modern conveniences possible. They essentially breathe life into these devices, ensuring their smooth operation. In more technical applications, slip rings greatly contribute to advanced robotics, satellite communication, medical imaging devices, and several others where rotational motion is a critical function.

However, even professionals and hobbyists in the field, occasionally underestimate the relevance of slip ring electronics due to their simplicity in concept and application. They seem to fade into the background of more flamboyant, complex components. This lack of recognition often leads to overlooking their significance in circuitries, resulting in unintended errors or faulty operation of electronic devices.

Hence, this article aims to shed light on the realm of Slip Ring Electronics, providing a comprehensive understanding of their basic structure and symbol to their diverse applications, challenges, and future prospects. As we delve into the fascinating world of slip ring electronics, we will unravel the marvels of electronic systems and appreciate the hidden gems that make these wonders possible.

Anatomy of Slip Rings in Electronics

To fully appreciate the role of slip rings in electronics, one must first understand their anatomy and the principles governing their operation. At the most fundamental level, slip rings are electromechanical devices. They form an essential connection, creating a bridge between a stationary structure and a rotating component within an electronic system.

Imagine a wheel turning continuously without any wires tangling or hanging off—it’s all thanks to the humble slip ring. The primary feature that distinguishes it as an electromechanical device is its ability to transfer electrical power or signals from a static source — called a ‘stator’ — to a part that is in rotation — referred to as a ‘rotor’, and vice versa. This seemingly simple action is, in reality, a feat of mechanical and electrical engineering.

Dissecting a typical slip ring, we are introduced to its basic components: the contact brush, the ring, and the hub. The contact brushes, loaded against the ring, maintain a continual, yet friction-optimized, interface that allows for the electrical signal’s flow. The ring part, concentrically stacked around the hub, serves as the pathway for this electrical conductance. Finally, the hub provides the necessary support for the rotating assembly.

Where the magic happens, is in the interaction between these components. As the hub and ring rotate, the brush retains its station, meaning electricity can be passed into the rotating assembly without the need for obstructive and potentially dangerous wires. Due to their ingenious design, slip rings also minimize friction and wear, allowing for efficient, continual function over an extended period.

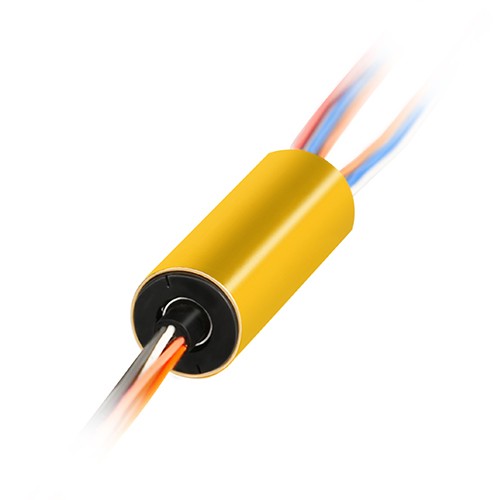

Understanding that, it’s key to note that not all slip rings are created equal. Their designs can range from simple single-channel versions—transferring a singular electrical signal or power—to complex, multi-channel systems capable of handling diverse types of signal and power transmissions. Their structural variety can also accommodate a vast gamut of electronic requirements—for instance, capsule slip rings for compact spaces, pancake slip rings for flat-profile applications, and wireless slip rings for scenarios where absolute minimal friction is required.

The journey through the anatomy of slip rings gives us a macroscopic understanding of their crucial role within electronic systems. From relatively simple electronic devices to complex, sophisticated systems, their strength lies in their design intricacies and the purpose they fulfill, cementing their importance in the electronics field.

Deciphering Slip Ring Symbols in Electronics

In the abstract world of electronic schematics, where every line, dot, and squiggle carries weight, the symbols representing slip rings hold extraordinary significance. Adeptly decoding these symbols provides us with a powerful tool to comprehend the operational characteristics of electronic systems.

Typically, a slip ring is symbolized as a square with an intervening line on one side that represents the rotating part, while the two lines extending from the opposite side indicate the brushes making contact with the ring. It is the interplay between these elements that is symbolically captured and that conceals the operational principle of slip rings.

In essence, the symbolic representation serves as a visual shorthand. It offers a quick, efficient way to document and communicate the presence of a slip ring, its location, and its connection within a larger schematic. Moreover, it is a universal language that transcends geographical and linguistic boundaries, making it an integral part of the global language of electronics.

However, despite its apparent simplicity, interpreting these symbols, especially for beginners extrapolating complex electronic systems, can be akin to deciphering hieroglyphs. Common errors include misidentifying the sides representing rotating and stationary parts, leading to faulty representation, and consequently, malfunctioning electronic systems. Similarly, confusion can also arise when attempting to differentiate symbols of single-channel and multi-channel slip rings used in more complex systems.

The antidote to these pitfalls often lies in a comprehensive understanding of the slip ring system’s operational principles, bolstered by thorough familiarity with electronic schematic symbols. Furthermore, practicing sketching and recognizing these symbols in varied contexts can fortify this understanding. Using accurate references, cross-verifying multiple sources, and seeking guidance from experts help circumvent common drawing errors. Interactive learning resources and tutorials can also provide a practical learning experience in grasping these symbolic representations effectively.

All things considered, the symbolic language of slip rings offers a fascinating peek into the heart of electronics. Decoding this language is crucial to understanding the broader electronics tapestry’s intricate design, adding another effective tool to our electronics toolkit, honing our skills, and fostering our ongoing interactions with the mesmerizing world of electronics.

Slip Rings at Work – Applications in Electronic Devices

Peering beyond the blueprint lines and schematic symbols, it’s time to witness slip rings in their natural habitat – working with efficiency and diligence within various electronic devices. To truly appreciate the versatile, transformative nature of slip rings, let’s delve into two common, yet diverse applications: electric motors and wind turbines.

In the realm of electric motors, slip rings play a crucial role. From the simplest appliances such as ceiling fans to complex industrial machinery, electric motors are omnipresent and varied in design. At the core of these devices, the slip ring is responsible for transferring power from the stationary structure, the stator, to the rotor, the part in continual motion.

Breaking it down further, imagine the ceiling fan. The fundamental operation relies on a magnetic field that interacts with coils of wire to produce a rotational motion. The electricity required to produce the magnetic field is delivered through the stationary part (stator) to the rotating assembly (rotor). Here, slip rings perform a vital function. Engaging with the stationary brushes, they form an incessant electric path, even when in motion, fueling the fan’s operation while eliminating any risk of tangled, inflexible connections.

Now let’s step outside, where giant, majestic wind turbines capture the essence of wind energy. Here too, slip rings are the unsung heroes. Within the turbine assembly, when the blades rotate with the wind, a generator converts the mechanical energy into electrical power. The generated electricity needs to be transmitted to a stationary collection point while the turbine continues to rotate; a seemingly impossible task if not for our trusted slip ring.

Just as they do in motors, slip rings come to the rescue in wind turbines, forming an uninterrupted connection between the rotating generator and the stationary electricity grid. Regardless of the wind’s intensity or the turbine’s rotational speed, they maintain consistent power flow, thus proving integral to clean, renewable energy production.

These two widely different implementations underscore the adaptability and indispensability of slip rings across electronic devices. While offering a glimpse into their operation, these instances solely scratch the surface of their myriad of applications. From providing comfort in our homes to powering our industries and furthering renewable sources of energy, slip rings truly are the silent custodians of the seamless symphony that is electronics.

Addressing User Pain Points in Slip Ring Electronics

Like any electronic component, slip rings have their share of users’ challenges and concerns. They may range from wear and tear due to friction, electrical noise, and signal interference, to more complex cases like dealing with high-speed applications or high-voltage conditions. However, understanding these challenges can guide us to make more informed decisions and put into practice measures that expand the lifespan and performance of slip rings.

One of the most common issues with slip rings is deterioration due to friction between the brushes and the ring. Over time, this friction can lead to wear and tear, reducing the efficiency of power or signal transmission. Regular maintenance, including periodic cleaning and light lubrication, can significantly mitigate the rate of deterioration and ensure a longer service life.

Electrical noise and signal interference are other significant concerns. In an environment crowded with electronic devices, the risk of interference is higher, which may affect the accurate transmission of signals. Using shielded cables for connections and incorporating noise suppression techniques in the design can alleviate such issues.

For applications with high operating speeds or high electricity voltages, ordinary slip rings may face difficulties in maintaining reliable contact, leading to erratic electrical flow or even component failure. In such cases, using specialized slip rings designed to handle these stringent conditions becomes paramount.

On a broader scale, the key to overcoming these challenges often lies in the blend of careful selection, diligent use, and regular maintenance. This includes choosing the right type of slip ring that matches specific application needs, regular routine checks for any signs of damage or uncharacteristic operation, and promptly addressing any issues identified.

By focusing on these corrective and preventive measures, users can effectively navigate the common pain points in slip ring electronics, enhancing their performance, expanding their lifespan, and reaping the benefits they offer to their fullest extent. After all, in the world of electronics, the devil is often in the details, and those who pay attention to these details are bound to find harmony in their devices’ performance.

Navigating the Future with Slip Ring Electronics

In the rapidly advancing world of electronic technology, the future of slip ring electronics promises a voyage brimming with innovations and novel applications. As demands for more highly specialized, complex, and robust systems rise, so too does the call for slip rings capable of meeting these challenges. Exploring recent advancements and future prospects, we stand at the precipice of a new era in slip ring technology.

One such innovation already making waves is the advent of wireless slip rings, also known as rotary inductive or contactless slip rings. In scenarios where ultra-low friction, high-data-rate signal transfer, and resistance to environmental factors are of utmost importance, these non-contact-based devices offer a significant step forward. Employing principles of magnetic induction, they establish a connection without physical touch, extending lifespan and reducing the need for maintenance. Wireless slip rings are poised to make a considerable impact in fields like robotics, space technology, and artificial intelligence.

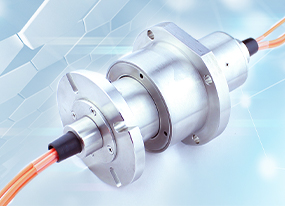

Another emerging trend is the use of high-precision slip rings in data-centric and optical-based applications. Fiber optic rotary joints (FORJs), for instance, focus on transferring optical signals between stationary and rotating assemblies. With the growth of high-speed data transmission systems, the demand for FORJs to facilitate seamless, high-fidelity signal transfer is only set to rise.

Looking further ahead, the ongoing integration of slip rings with new materials and techniques offers intriguing possibilities. Nanotechnology, for example, can open up prospects for creating ultra-thin slip rings, minimizing footprint, and enabling their application in minute, intricate electronic devices. Simultaneously, developments in materials science may unveil alternative contact materials that enable higher electrical conductance and longer wear life, catering to the most demanding of applications.

While evolutionary in nature, these trends, among others, serve as a testament to the enduring influence of slip rings in the ever-evolving landscape of electronics. From simple mechanical contraptions to advanced, specialized systems, the journey of slip ring electronics has just begun. As we navigate into the future, it is the fusion of tried-and-tested principles and cutting-edge innovations that will shape the course of slip rings, enriching their legacy and carving out new horizons in electronic systems.

Conclusion

So there we have it, a deep dive into the world of Slip Ring Electronics. As we’ve explored, slip rings play a vital role in the operation of electronic devices. Hence, understanding them is more than just academic; it is fundamental to truly appreciate the marvel that is Electronics. Whether you’re an industry professional, an electronics hobbyist, or simply a curious reader, we hope this exploration has been enlightening and sparked your curiosity to delve deeper!

See What We Can Do