In the diverse world of electromechanical systems, a key yet often underestimated component is the slip ring holder. A slip ring holder, also known as a rotary electrical interface, rotating electrical connector, or electrical rotary joint, is a device that provides a stable and reliable connection between stationary and rotating parts of a machine or system.

This small fixture was designed to accommodate slip rings, which are crucial for transferring power and signals from a static to a moving part in electromechanical assemblies. The role of the slip ring holder extends beyond just housing; it secures the slip rings in place to ensure they effectively perform their fundamental function of consistent data and power transmission even when in motion.

The importance of slip ring holders cuts across many sectors due to their facilitation of critical technology functions. In the field of wind energy, for instance, they play an essential role in transmitting signals between the stationary and moving sections of wind turbines. Similarly, in the aerospace and automotive industries, slip ring holders prove their relevancy in systems that require rotating connections, such as satellite tracking and electric vehicle charging stations.

Despite their small size, slip ring holders impact the performance, reliability, and durability of larger electromechanical units significantly. With the industry’s progression into developing more efficient, long-lasting, and versatile reserves, their importance is even more pronounced. Understanding the basics and nuances of slip ring holders can provide valuable insight into maximizing these components’ advantages in various applications.

Understanding the Mechanism of Slip Ring Holders

Slip ring holders, despite their understated appearance, embody a sophisticated mechanism pivotal to various equipment’s uninterrupted operation. At their core, they are responsible for providing a steady and reliable connection between the static and rotating parts of a machine. This essential function allows constant transmission of electric signals, power, or data across the rotating interface, ensuring operational continuity and preventing wear and tear caused by wires’ tangling.

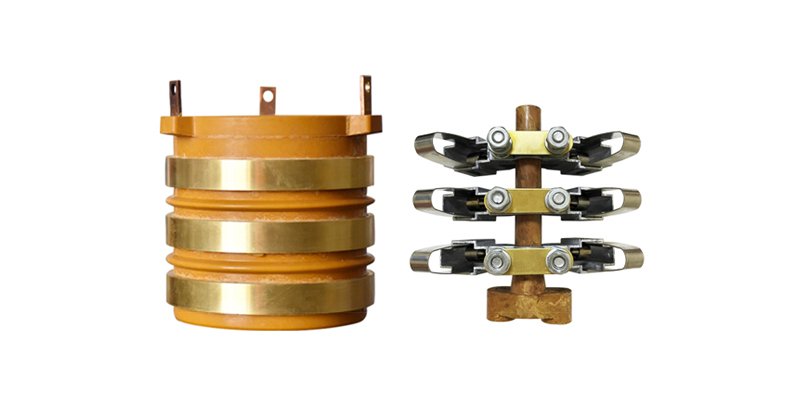

The functional mechanism of slip ring holders can best be appreciated when broken down into its critical components. First and foremost, there’s the housing, a casing designed to secure slip rings in position and shield them from potential environmental hazards such as dirt, dust, and moisture. The housing material, which varies from plastic to metal depending on the application, needs to be sturdy enough to resist breakage while ensuring thermal stability to manage heat derived from power transmission.

Inside this protective housing are the slip rings, usually composed of conductive metal. Connected to the static structure, the rings rotate along with the machine’s moving parts. Each ring corresponds to a circuit, facilitating communication or power distribution between the static and rotating segments.

Accompanying the slip rings in the holder assembly are brushes, typically made of carbon or metal. These brushes glide over the rotating slip rings, acting as the liaison between the stationary wiring and rotating rings. As the ring spins, the brushes maintain constant contact, thus keeping the signal or power transmission unbroken. Simply put, the brushes transform the electrical connections into mechanical connections, enabling the rotary system to work without interruptions.

Supporting the brushes is the brush block, a component holding the brushes in place against the slip rings. Usually spring-loaded, the block ensures that the brushes exert enough pressure to maintain consistent contact with the slip rings, leading to efficient power and signal transmission while not wearing down the rings quickly.

Together, these components make up the operational architecture of a slip ring holder, forming a delicate balance of precision and robustness. Understanding this intricate mechanism gives way to appreciating the holders’ vital role in keeping an array of electromechanical systems performing at their peak.

Types of Slip Ring Holders

The market is rich with a variety of slip ring holders suited to meet a vast range of application requirements. These differ significantly in terms of their design, materials, capacity, and even the way they connect to the slip rings and brushes. Understanding these types is integral to choosing a holder that matches the environment, load capacity, speed, and operational conditions of a specific application.

Common types of slip ring holders on the market include Capsule, Through-Bore, Pancake, and Mercury slip ring holders, each offering specialized functions and advantages.

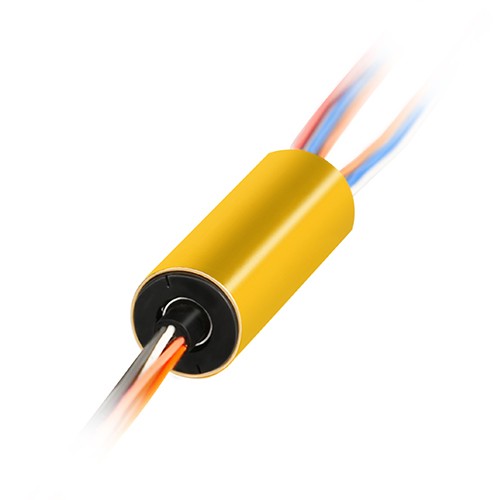

Capsule Slip Ring Holders are compact and designed for enclosing mini slip rings, ideal for smaller spaces. Despite their small size, they’re known for carrying complex signals. Besides, they come in various circuit options, allowing for customization per project needs.

Through-Bore Slip Ring Holders, also known as “Hollow Shaft Slip Rings“, are distinguished by their central hole that allows for routing hydraulic or pneumatic lines. These holders are widely used in scenarios where a device needs to rotate around a large machine shaft, thus accommodating a considerable amount of power and signal circuits.

Pancake Slip Ring Holders are characterized by their flat, disc-like design, a style suited for systems where length is restricted, and larger diameter isn’t an issue. These holders employ a plated ring design which allows for more circuits in less axial length but usually at the cost of a higher rotational torque.

Mercury Slip Ring Holders offer a less common yet highly efficient design that uses liquid metal to transmit signals and power. The primary benefit is their virtually unlimited service life and very low noise, but the downside is that they’re limited to lower currents and must be kept upright to prevent mercury leakage.

Each type of slip ring holder brings unique advantages to the fore, serving the diverse and often complex array of system designs and configurations found in the real world. Whether it’s working within tight spatial constraints or dealing with larger machine shafts, there’s a holder that’s been designed to do the job effectively and efficiently. Understanding the distinct features and benefits of each type can significantly aid in the selection of the most suitable holder for any given application.

Choosing the Right Slip Ring Holder

Selecting the correct slip ring holder is a critical phase in your electromechanical system setup. Factors such as the holder’s size, material, compatibility with the slip rings, electrical and mechanical requirements, and the environment it would operate, play a vital role in determining the efficiency and longevity of the system.

When it comes to size, it’s critical to select a holder that fits the required number of slip rings without being excessively bulky. One has to assess the physical space available for the holder installation and select a holder that fits neatly into that space.

Material is another key criterion. Depending on the environment in which the slip ring holder would operate, select a material that can resist wear and tear due to elements like dust, humidity, or high temperature.

Compatibility with slip rings is also fundamental. Not every holder is designed to accommodate every type of slip ring. Before making a choice, consider the type of slip ring used in the system to ensure the holder can securely house it.

Mechanical and Electrical requirements such as current capacity, signal type (digital or analog), number of circuits, rotational speed, and operating temperature should also influence your decision. Slip ring holders should readily meet these requirements to ensure seamless operation.

Lastly, Ease of Installation and maintainability should be taken into account. It’s always advisable to select a holder that is user-friendly in terms of installation and doesn’t require highly specialized procedures or tools for its maintenance.

Walk-through of the selection process:

- Start by clearly identifying your system’s current and signal requirements. This will help you look for holders designed to meet those specific needs.

- Consider the type of slip ring being used in your system and make sure to match your chosen holder to it.

- Assess the physical space available for the holder. This aids in determining the ideal size and shape of the holder.

- Evaluate the mechanical and environmental conditions in which the assembly will operate. Factors such as humidity, temperature, dust, etc., will influence the material of choice for the holder.

- Lastly, consider the ease of installing and maintaining the slip ring holder for convenience and long-term operational efficiency.

Choosing the correct slip ring holder is key to achieving efficient power and signal transmission. By following these guidelines, you’ll be better equipped to make informed decisions that result in enhanced system performance and durability.

Installation and Maintenance of Slip Ring Holders

Like any electromechanical component, the proper installation and routine upkeep of slip ring holders is essential to ensure their longevity and efficient functioning.

For the Installation process, the general steps are as follows, but please refer to the user manual of your specific slip ring holder model for detailed instructions:

- Clean the area where the slip ring holder is to be installed, ensuring it’s free from dust or debris.

- Depending on the type of slip ring holder, attach it to the mounting system. Always follow the manufacturer’s instructions to decide the orientation and secure attachment of the holder.

- Insert the slip rings into the holder. Again, follow the manufacturer’s guide, taking care to ensure the correct orientation of the rings and their secure fit in the holder.

- Finally, secure the brushes in the holder. Make sure they are in the appropriate position, applying the right amount of pressure on the slip rings, without causing undue friction.

Routine Maintenance is crucial for the continued effective performance of slip ring holders:

- Regularly inspect the slip ring holders, at a frequency suggested by the operating manual. This includes looking for any signs of damage, debris, or wear and tear.

- Clean the slips rings and brushes periodically using a lint-free cloth or equivalent, never use any abrasive material.

- Check the brushes for wear. They should be replaced as soon as they’re worn beyond a specified limit, usually given in the manufacturer’s instructions.

Slip ring holders should also be checked and replaced periodically. Signs that it may be time to replace your holder include excessive wear and tear, unable to hold the brushes or slip rings securely, excessive heat, or visible damage. It’s advisable to enlist professional help for the replacement procedure to avoid any lapses in the installation process.

Remember, the longevity and efficient functioning of your slip ring holder largely depend on how well you maintain it. Therefore, always adhere to the prescribed guidelines and conduct routine inspections and maintenance checks to keep them working optimally.

Common Issues and Troubleshooting with Slip Ring Holders

Like any mechanical component, slip ring holders can sometimes encounter issues that affect their performance. Here, we will address some standard questions and problems often encountered with slip ring holders and offer troubleshooting tips and solutions.

- Holder Overheating

Excess heat is a common issue, typically caused by high currents, overuse, or inadequate ventilation. Inspecting the holder for visual damage and measuring the temperature during operation can help diagnose overheating. Ensure sufficient cooling methods are in place, and check if the current capacity aligns with the holder’s specifications, taking measures to reduce it if necessary.

- Inconsistent Transmission or Signal Loss

This could be due to worn-out brushes or defective slip rings. Start by checking your brushes for wear and replace them if required. If the problem persists, inspect the slip rings for defects or damage. The use of a multimeter to verify continuity can confirm if the slip rings are functioning correctly.

- Vibration or Unusual Noise

Erratic movements or peculiar sounds may indicate slip ring or brush misalignment. Check the brush alignment with the slip rings and correct if needed. Should these symptoms continue, investigate for potential mechanical faults, such as an imbalance in the rotating components or loosening in the holder’s mountings.

- Frequent Brush Replacement

Should brushes require frequent changing, this might imply that the brush is not making proper contact with the slip ring or there’s excessive rotation speed. Look out for spring tension issues or consider switching to brushes with higher wear resistance. If the rotation speed of the system exceeds the prescribed limit, measures must be taken to reduce it.

- Visible Wear or Corrosion

Wear or corrosion is often an environmental issue. If your slip ring holder operates in humid or corrosive environments, consider choosing holder materials resistant to such damage in the future. For immediate relief, cleaning the affected parts and creating a protective barrier can prevent further corrosion, but a long-term solution should be sought to prevent recurring issues.

Consulting the manufacturer’s manual or reaching out to the manufacturer’s technical support can also prove beneficial when troubleshooting issues with your slip ring holder. Always remember that when dealing with electrical and mechanical issues, safety should remain a paramount concern.

Future Trends and Innovations in Slip Ring Holders

The development and design of slip ring holders keep evolving to meet the diversified challenges posed by different industries and technological advancements. Several innovations and trends are surfacing in this field, driving the slip ring holders towards becoming more efficient, enduring, and versatile.

Innovations and Technological Advancements:

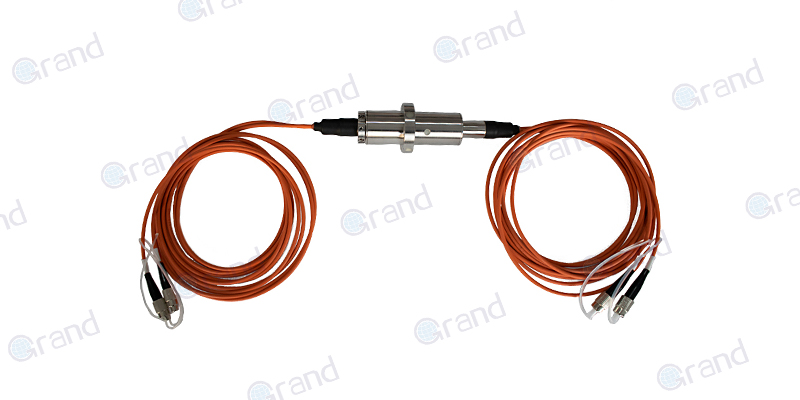

A momentous innovation is the development of contactless slip ring holders. By using magnetic fields or optical fibers to transmit power and data, these holders promise almost frictionless operation and significantly increased longevity. The contactless design means less maintenance requirement, and almost zero generation of debris or dust during operation, greasing the way for more efficient signal transmission and fewer system interruptions.

Material advancements are another remarkable trend, with holder compositions becoming more resistant to harsh conditions and corrosive agents. With the advent of high-end polymers and composite materials, the holders are becoming lighter and sturdier, providing longer service life and enhanced application scope.

Customizability is also receiving increased attention. More manufacturers are offering customizable holder designs to fit specific application needs, empowering industries to achieve enhanced operational efficiency by specifying materials, shapes, sizes, and capacities based on their unique requirements.

Future Prospects and Anticipated Developments:

As for the future, it’s anticipated that slip ring holders will continue to evolve in their capacity to handle higher data rates and power loads. This is due in part to the growing demand for faster, larger data transmission in sectors like communication, industrial automation, defense, and aerospace.

In tandem with the rise of smart devices and IoT, we can expect a rise in the demand for compact, efficient holders capable of fitting in tightly confined spaces while still delivering high-speed, stable transmission.

Future slip ring holders are also predicted to become more energy-efficient and environmentally friendly, aligning with the global emphasis on sustainable technology.

In conclusion, the future of slip ring holders is bright, charged with innovations and advancements that drive them toward becoming more efficient, reliable, and versatile. These forthcoming improvements will undoubtedly serve to advance not only the industries that directly use slip ring holders but also the broader march of technological progress.

Conclusion

Slip ring holders may appear simple, but they form a critical part of any slip ring assembly. By understanding their mechanism, selecting the suitable type, and maintaining them properly, these devices will deliver the desired performance over considerable timespans. As technologies advance, we expect even more capabilities and conveniences from slip ring holders. Staying informed about these developments is thus an investment into a future of smoother, more efficient operations.

See What We Can Do