Welcome to our comprehensive guide on one of the most intricate yet vital pieces of equipment used in various industrial applications – umbilical winch slip rings. These electromechanical devices are critical for continual signal and power transmission between the stationary and rotating parts of an umbilical winch among many other applications.

Written by an experienced and well-respected industry professional, this article aims to shed light on the fascinating technical world of slip rings. The author carries a wealth of practical experience in the design and manufacturing of these essential parts, offering a unique and knowledgeable perspective on the topic.

Throughout this piece, we will uncover the significance and functionality of umbilical winch slip rings, delve into the key aspects involved in their design, and guide you in selecting the correct device for your specific requirements. We aim to equip our readers with a solid understanding of these components, providing them with the knowledge needed to operate, maintain, or even choose an umbilical winch slip ring effectively.

Looking beyond the purely technical aspects, we’ll also touch on real-life situations where these pieces of equipment become indispensable and explore how future technological advances will affect their design and application.

This in-depth overview of umbilical winch slip rings is much more than an academic read. It is a practical guide designed to assist everyone involved in operations that rely on these mechanisms, from engineers and technicians to project managers. By the end of this article, we aim to offer our readers a firm grasp on the use, design, and selection of umbilical winch slip rings, thereby aiding their decision-making in related fields.

What Are Umbilical Winch Slip Rings?

As we delve deeper into the fascinating realm of umbilical winch slip rings, it is essential to begin by explaining their fundamental principle and operation. This section will help lay the foundation by breaking down the intricacies involved and shedding light on their role within various systems.

Definition and Working Principle of Umbilical Winch Slip Rings

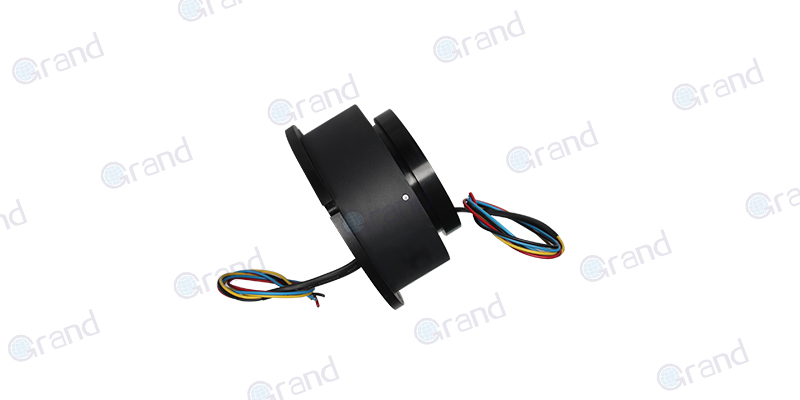

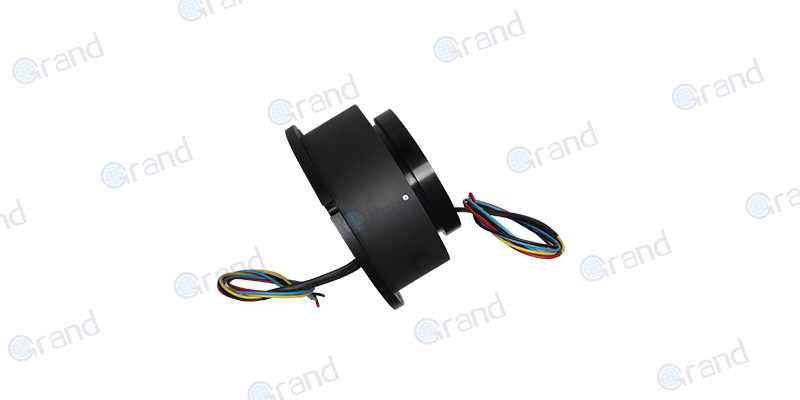

At their core, umbilical winch slip rings are specially designed electromechanical devices that allow the seamless transfer of electrical power and signals from a stationary part of a system to a rotating one. Their primary function is to maintain uninterrupted electrical connectivity while permitting continuous rotation, thus eliminating the risk of cable twisting or damage.

A slip ring comprises rotating and stationary parts, with electrical contacts in both sections. The rotating part, often called the rotor, is connected to the rotating part of the system, while the stationary part, or the stator, is attached to the stationary portion. As the rotor moves, it maintains contact with the stator, continually transmitting power or signals as it rotates.

Advantages of Using Slip Rings in Umbilical Winch Systems

Implementing slip rings in umbilical winch systems presents an array of benefits. Some of the most notable advantages are:

- Uninterrupted power and signal transmission: Slip rings ensure continuous electrical connectivity during rotation, allowing for hassle-free operation.

- Greater flexibility: Slip rings offer more extensive system design options, as they enable 360-degree rotation without limitations from entanglements, tangles, or cable strain.

- Enhanced durability: By preventing cable twisting or damage, slip rings prolong the life of a system’s electrical wiring and contribute to the overall durability of the equipment.

- Ease of maintenance: With proper design considerations, slip rings can be easily accessed and replaced, simplifying maintenance tasks for operators and engineers.

Importance of Slip Rings in Ensuring Efficient and Reliable Connections in These Systems

Umbilical winch slip rings are not merely a luxury in the systems they serve; they’re a necessity. In applications where smooth, continuous operation is crucial, such as industrial or offshore equipment, slip rings guarantee that electrical connections remain reliable and functional.

These devices become even more indispensable in harsh or demanding environments where the risk of cable damage or interference is higher. By employing slip rings, operators can ensure the integrity of signal transmission and system operation, leading to increased efficiency and minimal unexpected downtime.

Design Considerations for Umbilical Winch Slip Rings

Creating an effective and reliable umbilical winch slip ring involves meticulous attention to detail and careful consideration of several critical design factors. Balancing these essential aspects is crucial for ensuring functionality, efficiency, and durability. In this section, we will delve into some of the key design elements and discuss methods to overcome the unique challenges specific to umbilical winch slip rings.

Key Design Aspects to Ensure Functionality and Efficiency

- Electrical requirements: Consider the capabilities and specifications of the slip ring, such as voltage, current ratings, and signal types. Evaluate the overall power needs of the system to determine the most suitable solution.

- Rotation speed: Determine the maximum rotational speed of the application, and choose a slip ring accordingly. This factor affects both the design and materials used for the contacts, housing, and bearings.

- Configuration and dimensions: Customize the configuration to fit the system’s space constraints and desired layout. Shape, size, and mounting options should be considered during the design phase.

- Environmental conditions: Assess the operational environment, including temperature, moisture, and pressure, to ensure the slip ring’s performance remains unaffected. Select components and materials that can withstand extreme conditions.

- Contact materials: Choose appropriate contact materials that provide minimal friction, optimal electrical conductivity, and corrosion resistance for a prolonged lifespan.

- Sealing and protection: Implement appropriate sealing methods to protect the slip ring against contaminants and ingress, such as dust, moisture, and corrosive elements.

- Lifespan and maintenance: Estimate the expected lifespan and maintenance requirements of the slip ring based on the application, intended usage, and the frequency of rotations. Opt for designs that facilitate easy access and replacement of components.

- Cost-benefit analysis: Analyze the total cost of ownership and cost-effectiveness of the slip ring, taking into account efficiency, lifespan, maintenance demands, and replacement components.

Addressing Unique Challenges Specific to Umbilical Winch Slip Rings and How to Overcome Them

Umbilical winch slip rings are often deployed in demanding environments, like offshore and marine applications, where they face extreme challenges standard slip rings may not endure. Some of these challenges include:

- Risk of seawater intrusion: Exposure to seawater can cause severe corrosion and damage to internal components. Design slip rings with adequate sealing mechanisms and use marine-grade materials to protect against saltwater ingress.

- High operational pressures: Umbilical winch slip rings can be subject to high pressure, both from surrounding environments or internal forces. Reinforce the housing and internal components to handle elevated pressure levels.

- Corrosive environments: Certain chemicals or substances may have a corrosive effect on slip ring components. Employ corrosion-resistant materials and coatings, such as stainless steel and specialized platings, to shield against these dangers.

- Vibration and shock: Occurrences of shock and vibration can lead to premature wear or compromise the slip ring’s structural integrity. Incorporate shock absorption and vibration-dampening measures to address these concerns.

When designing umbilical winch slip rings, diligent consideration of the factors mentioned above not only ensures optimal functionality, efficiency, and longevity but also helps to overcome some of the more challenging aspects of these specialized devices.

Choosing The Right Umbilical Winch Slip Ring

Selecting the ideal umbilical winch slip ring requires careful analysis of the system’s requirements and performance needs, as well as a thorough understanding of the components involved. In this section, we’ll examine the factors to consider when determining the perfect umbilical winch slip ring for various applications, taking into account system specifications, environmental influences, and cost-effectiveness concerns.

Factors to Consider for Selecting Umbilical Winch Slip Rings Based on System Requirements

- Electrical specifications: Analyze the system’s required voltage, current ratings, and signal types to help narrow down the slip ring options. Ensure that the selected slip ring accommodates the system’s power demands.

- Rotational speed: Identify the maximum rotational speed of your application and opt for a slip ring designed to withstand this rate, reducing the risk of performance issues or premature wear.

- Integration and dimensions: Ensure the slip ring’s configuration, shape, and size align with the system’s spatial constraints, physical configuration, and mounting requirements.

- Contact materials: Consider the specific electrical conductivity, friction, and corrosion resistance properties desired and select corresponding contact materials that fulfill these aspects.

- Number of channels: Determine the quantity of electrical channels required for your application, considering the possibility of future expansion and technological upgrades.

Environmental Factors That Affect the Selection and Performance

- Temperature: Evaluate the temperature conditions under which the slip ring will operate, and choose a device designed to withstand temperature extremes.

- Moisture and humidity: Assess the level of moisture and humidity the slip ring will encounter, and opt for a component with suitable sealing mechanisms and materials that resist corrosion.

- Pressure: Identify the operational pressure range and select a slip ring constructed to endure these pressures without compromising performance.

- Corrosive elements: Ascertain whether the slip ring will face exposure to any corrosive elements, and choose materials or designs resistant to the corrosive effects.

- Shock and vibration: Assess the level of shock and vibration that the slip ring may experience and select a device that incorporates shock-absorbing components and vibration-dampening measures.

Cost-Effectiveness and Maintenance Considerations

- Initial investment: Ascertain the slip ring’s initial purchase cost, and determine if the investment is justifiable based on performance expectations and contribution to overall system efficiency.

- Maintenance demands: Evaluate the slip ring’s ease of maintenance, accessibility of components, and frequency of required servicing tasks. Cost-effectiveness extends beyond the initial purchase price and encompasses maintenance and replacement costs.

- Lifespan: Assess the expected lifespan of the slip ring, taking into account the effect of its design, materials, and intended usage on the component’s longevity.

- Total cost of ownership: Gauge the overall cost-effectiveness of the slip ring, including factors like efficiency, replacement parts, maintenance demands, and overall contribution to system performance.

Understanding the factors governing the selection of an ideal umbilical winch slip ring enables a better-informed decision, one that provides an optimal balance between performance, durability, and cost-effectiveness. By carefully considering the aspects mentioned above, you can identify the most suitable slip ring for your system’s unique needs and environmental conditions.

Real-Life Applications of Umbilical Winch Slip Rings

Umbilical winch slip rings play a vital role in a variety of real-world applications, ensuring smooth, continuous operation across multiple industries. Their reliable and efficient functionalities ensure that systems remain functional even in challenging environments. In this section, we’ll explore the different industries that rely on umbilical winch slip rings and present case studies showcasing their use and impact in these settings.

Industries That Rely on Umbilical Winch Slip Rings to Ensure Smooth Operations

- Offshore and Marine: Slip rings are widely employed in offshore oil and gas platforms, seabed exploration, oceanographic research, and underwater vehicles such as remotely operated vehicles (ROVs) and autonomous underwater vehicles (AUVs) to maintain connectivity between surface equipment and subsea systems.

- Renewable Energy: Umbilical winch slip rings are essential components in wind turbines, ensuring seamless transfer of power and signals between the stationary base and the rotating blades without cable tangles or damage.

- Defense: In military applications, slip rings are deployed in communication systems, radar equipment, and naval vessels. They facilitate the continuous operation of rotating devices and antennas without restricting freedom of movement or risking signal loss.

- Robotics and Automation: Industrial robots and automated systems often include umbilical winch slip rings to provide electrical connectivity during rotational movement. These slip rings enhance operational flexibility, allowing for a full range of motion without hindrance.

- Heavy-Duty Equipment: Slip rings are essential for heavy-lifting and material-handling equipment, such as cranes and winches. They facilitate the seamless transfer of power and data between stationary and rotating sections during load hoisting and maneuvering.

Case Studies Illustrating the Use and Impact of Umbilical Winch Slip Rings in These Settings

- Case Study – Offshore Oil and Gas Platform: On an offshore drilling platform, an umbilical winch slip ring is integrated into the umbilical tower winch system, allowing for seamless transmission of power and signals between the deck control room and the subsea installation. Utilizing slip rings helps stabilize and manage the heavy and complex umbilical cables, ensuring uninterrupted communication between surface and subsea infrastructure. This integration minimizes downtime, increases operational continuity, and enhances overall productivity.

- Case Study – Wind Turbine: Within a wind turbine’s nacelle, an umbilical winch slip ring is installed, providing a reliable electrical connection between the rotating turbine blades and the grounded, static components. This slip ring enables the transmission of power generated by the blades to the ground-based generators, while simultaneously supplying power and control signals back to the turbine. As a result, the slip ring ensures the uninterrupted operation of the wind turbine, maximizing energy production and contributing to a greener, more sustainable energy source.

- Case Study – Remotely Operated Vehicle (ROV): In underwater exploration, a remotely operated vehicle (ROV) relies on an umbilical winch slip ring to maintain continuously powered and controlled operations. The slip ring is incorporated into the ROV’s tether management system, allowing for smooth, tangle-free deployment and retraction of the umbilical cable connecting the ROV to the surface. This integration ensures that the ROV can work at variable depths and distances while preserving signal and power quality from the surface controls, thus promoting efficient and effective underwater exploration and research.

These real-life applications demonstrate the versatility and necessity of umbilical winch slip rings across various industries, showcasing their ability to contribute significantly to the smooth operation of critical equipment and systems.

Future Developments in Umbilical Winch Slip Ring Technology

As technology continues to advance and expand across various industries, umbilical winch slip rings will likely follow suit, incorporating innovative designs and materials to meet evolving demands. In this section, we will explore some of the latest trends and anticipated advancements in umbilical winch slip ring technology and discuss the potential impact these innovations may have on the industry and its users.

Innovations Driving the Design and Use of Umbilical Winch Slip Rings

- Advanced contact materials: The development of new materials and coatings designed to enhance the performance of electrical contacts will improve the lifetime and efficiency of slip rings. These materials must demonstrate minimal friction, high conductivity, and increased resistance to corrosion.

- Smart slip rings: The integration of sensors and monitoring systems within slip rings will enable real-time monitoring of performance, wear, and potential faults. Predictive analytics and data analysis can help identify maintenance requirements in advance, reducing downtime and maintenance costs.

- Compact and lightweight designs: Advancements in materials and design methodologies will lead to smaller and more lightweight slip rings without compromising performance. This will be essential to accommodate the growing trend towards miniaturization and more comprehensive integration in a variety of applications.

- High-speed operations: As system requirements evolve to demand higher rotational speeds, slip ring designs will need to adapt accordingly. Innovations in bearing technology, improved materials, and advanced contact designs will contribute to the development of slip rings capable of maintaining electrical connections at increasingly high speeds.

- Wireless power and data transmission: Research into wireless power and data transmission could influence future slip ring design, potentially reducing the need for mechanical contacts while maintaining uninterrupted connectivity between rotating and stationary parts.

How These Advancements Affect the Industry and Users

- Enhanced performance: Improved materials and designs will result in increased efficiency, reduced wear, and longer-lasting performance. This benefits users by decreasing the frequency of maintenance and replacement requirements.

- Optimized maintenance: Smart slip rings and integrated monitoring systems will revolutionize maintenance strategies, allowing for more precise planning while reducing unnecessary downtime. This leads to cost savings for users and improved overall system reliability.

- Expanded applications: Compact, lightweight, and high-speed slip rings will open up new possibilities across industries, making them suitable for applications that were previously unachievable. This advancement will contribute to the growth and versatility of slip ring applications globally.

- Reduced total cost of ownership: Enhanced slip ring performance, longer lifespans, and optimized maintenance strategies will ultimately lower the total cost of ownership for users. As a result, businesses can allocate resources more effectively without sacrificing system effectiveness or performance.

- Adaptability: As industries continue to evolve, umbilical winch slip ring technology must adapt and innovate to meet increasing demands and changing requirements. This adaptability ensures that slip rings remain an essential component for a wide range of applications and industries.

Future developments in umbilical winch slip ring technology promise significant advancements and improvements in performance, efficiency, and reliability. By embracing these innovations, industries can benefit from enhanced capabilities, reduced operating costs, and expanded applications to support their growth and success.

Conclusion

Understanding umbilical winch slip rings—how they work, how to choose them, and their practical applications—can make a significant difference in the efficiency of related operations. So whether you are an engineer, a buyer, or an enthusiast wishing to delve deeper into this topic, remember: that selecting the right slip ring is crucial. Explore further, ask questions, and continue to harness the power of knowledge in this fascinating realm!

FAQs about Umbilical Winch Slip Ring

This section will address frequently asked questions about umbilical winch slip rings, covering topics such as technical details, pricing, maintenance, and application inquiries. We will also provide expert advice and tips to help users get the most out of their umbilical winch slip rings.

Q: What basic considerations do I need to make when selecting an umbilical winch slip ring?

A: When choosing an umbilical winch slip ring, consider the system’s electrical requirements (voltage, current ratings, and signal types), rotational speed, environmental factors (temperature, moisture, and pressure), integration and dimensions, contact materials, and the number of channels needed.

Q: How much do umbilical winch slip rings cost?

A: The cost of umbilical winch slip rings varies depending on factors such as size, materials, performance specifications, and the number of channels. It is essential to balance cost with performance requirements and durability to ensure a cost-effective solution that meets your application needs.

Q: How often do I need to maintain my umbilical winch slip ring?

A: Maintenance frequency depends on factors like the slip ring’s design, materials, usage, and environmental conditions. Regular visual inspections and performance monitoring are recommended. Some slip rings may require periodic cleaning, lubrication, and replacement of worn components, while others may be designed for long-term, low-maintenance operation.

Q: In what applications are umbilical winch slip rings commonly used?

A: Umbilical winch slip rings are used in various applications such as offshore oil and gas platforms, wind turbines, remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), communication systems in defense, robotic and automated systems, and heavy-lifting equipment like cranes and winches.

Q: How can I extend the life of my umbilical winch slip ring?

A: To prolong the life of your umbilical winch slip ring, follow these tips:

- Choose a slip ring that meets your system requirements and environmental conditions.

- Regularly monitor performance and check for signs of wear or potential faults.

- Conduct timely cleaning, lubrication, and required maintenance to prevent premature wear and damage.

- Replace worn or damaged components promptly to avoid more significant issues, and use manufacturer-recommended replacement parts.

- Evaluate your application’s unique operational conditions and follow any specific maintenance recommendations provided by the manufacturer.

Remember, regular maintenance, careful monitoring, and adherence to manufacturer guidelines can significantly contribute to the longevity and reliability of your umbilical winch slip ring.

See What We Can Do