Welcome to this comprehensive guide on understanding camera slip rings, a topic that is often overlooked yet essential to the smooth operation of various camera systems. As photography and videography continue to push the boundaries, having a fundamental knowledge of camera slip rings has become increasingly important for professionals, enthusiasts, and even casual users alike.

In this article, we will explore the ins and outs of camera slip rings, discussing their function, applications, and the various types available on the market. By understanding these intricacies, users will be better equipped to maximize their camera’s performance, troubleshoot issues, and stay current with the ever-evolving industry advancements.

Join us as we delve into the world of camera slip rings with insights from industry professionals, revealing their significance and how they could potentially revolutionize camera systems. With this newfound knowledge, prepare to enhance your understanding and make informed decisions when it comes to these vital components.

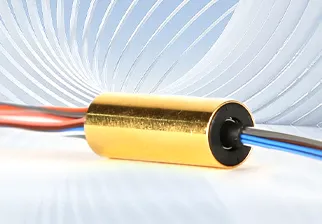

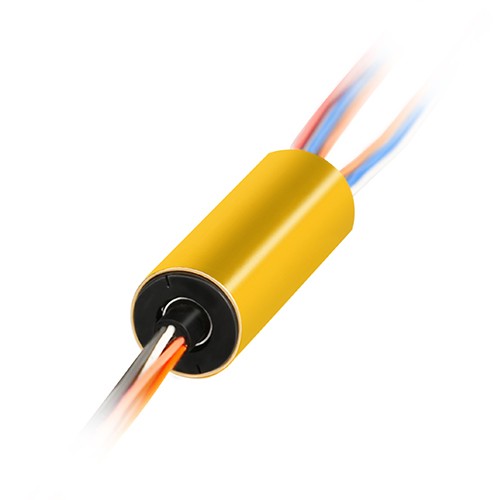

The Basics of a Camera Slip Ring

Before we delve deeper into the applications and implications of camera slip rings, it’s crucial to establish a fundamental understanding of what they are and how they function.

A camera slip ring, in simple terms, is an electromechanical device that allows for uninterrupted transmission of electrical power and signals from a stationary to a rotating component within a camera system. This design enables the camera to capture images and videos without any hindrances in its rotation, ensuring smooth and seamless operation.

Purpose and Functionality

- Continuous Rotation: A camera slip ring allows the camera to rotate 360 degrees indefinitely without the risk of cables tangling or twisting. This is crucial in surveillance systems, robotics, and other applications where continuous rotation is needed.

- Signal Transmission: It enables the transmission of electrical signals, data, and power between the stationary and rotating parts of the camera. This ensures that all the necessary power and signals (like video, control, and power) are transmitted without interruption, even during rotation.

Camera Slip Ring Components

A camera slip ring is a specialized device that allows for the continuous transmission of electrical signals and power between a stationary part and a rotating part of a camera system. To achieve this, camera slip rings are made up of several vital components, which include:

1. Rotor (Rotating Part)

- Function: The rotor is the rotating component of the slip ring, attached to the moving part of the camera system (e.g., a pan-tilt unit).

- Structure: It typically includes conductive rings that rotate along with the rotor. These rings are designed to maintain electrical contact with the stationary brushes as the rotor turns.

2. Stator (Stationary Part)

- Function: The stator is the stationary component of the slip ring, connected to the fixed part of the camera system.

- Structure: The stator houses the brushes (or contacts) that maintain constant electrical contact with the rotating rings on the rotor. The wires from the power source, signal, or data connections are typically connected to the stator.

3. Conductive Rings (Slip Rings)

- Material: These rings are usually made of conductive materials like copper, silver, or gold, depending on the application’s requirements for conductivity and wear resistance.

- Function: The slip rings are embedded in the rotor and rotate with it. They serve as the pathway for electrical current or signal transmission from the stationary part to the rotating part.

4. Brushes (Contacts)

- Material: Brushes are often made of metal (like copper or silver) or carbon. In high-performance slip rings, the brushes might be made of a combination of materials to balance conductivity and wear resistance.

- Function: The brushes are in constant contact with the rotating rings on the rotor, allowing the electrical signals or power to be transmitted from the stator (stationary part) to the rotor (rotating part). The quality of the contact between the brushes and rings directly affects the efficiency and reliability of the slip ring.

5. Housing

- Material: The housing is typically made from materials like plastic, aluminum, or stainless steel, depending on the environmental conditions and durability requirements.

- Function: The housing encases the slip ring’s internal components, protecting them from external elements like dust, moisture, and mechanical damage. It also provides structural support to the slip ring assembly.

6. Bearings

- Function: Bearings are used to ensure smooth rotation of the rotor relative to the stator. They minimize friction and wear, which is crucial for the longevity and reliability of the slip ring.

- Type: Depending on the design, slip rings might use ball bearings, needle bearings, or other types of bearings suited for the application.

7. Wiring and Terminals

- Wiring: Electrical wires are connected to both the stator and rotor components, ensuring that power and signals can be transmitted through the slip ring.

- Terminals: The slip ring has connection terminals or connectors for external wiring, allowing for easy integration with the camera system’s electrical circuits.

8. Insulation

- Material: Insulation materials like plastics or resins are used to separate the conductive components (rings and brushes) and prevent short circuits.

- Function: Proper insulation is critical to ensure that electrical signals or power are transmitted without leakage or interference between adjacent circuits.

9. Connector Assemblies

- Function: Some slip rings come with built-in connector assemblies, making it easier to integrate the slip ring into existing camera systems. These connectors can be used for power, signal, or data transmission.

10. Environmental Seals (Optional)

- Purpose: In outdoor or harsh environments, slip rings may include seals to protect against dust, moisture, and other environmental factors.

- Material: These seals are usually made of rubber or other flexible materials that can maintain a tight seal while allowing for rotation.

These components work together to allow the camera slip ring to perform its primary function: enabling continuous rotation of the camera while maintaining a reliable electrical connection for power, signal, and data transmission. The design and materials used in these components vary depending on the specific application, such as the need for high-frequency signal transmission, high durability, or resistance to environmental conditions.

Camera slip rings come in an array of designs and sizes to accommodate the diverse requirements of different camera systems. Gaining a solid grasp of these basic concepts serves as a useful foundation for understanding the broader implications and applications of camera slip rings in the industry.

Camera Slip Ring: Importance in Camera System

Having established the foundational understanding, we now delve into the critical role of slip rings within a camera system — a role that cements their position as a vital, often indispensable, component.

Primarily, the camera slip ring is a crucial solution for rotational connectivity issues in camera systems. Its ability to maintain an uninterrupted flow of both power and signals in a rotary setting underpins the smooth operation of multiple camera components, especially in devices designed for 360-degree image or video capture. In these cases, the camera slip ring serves as the linchpin, enabling rotational freedom without disrupting power supply or data transmission.

Discussing the mechanism of camera slip rings further highlights their importance. The stationary part of the slip ring (often referred to as the ‘stator’) remains fixed to the camera body while the rotating part (the ‘rotor’) is connected to the rotating component of the camera — be it the lens, the sensor, or another part. When the camera is in operation, the rotor spins on its axis in conjunction with the camera component it’s attached to, while the brushes maintain contact with the conductive rings to ensure uninterrupted power and signal transmission.

In essence, the slip ring system acts as the ‘middle man’, flawlessly translating stationary power and signals to their rotating counterparts. By doing so, a camera slip ring allows for the seamless functioning of a camera system, especially during active operation such as continuous pan, tilt, or even full 360-degree movements. As such, understanding its mechanism and the distinct role it plays can provide valuable insights into the overall performance of a camera system.

The camera slip ring is an essential component in modern camera systems, particularly in applications that require continuous rotation or precise movement. Its importance can be understood through several key aspects:

1. Continuous 360-Degree Rotation:

- Uninterrupted Operation: In systems like pan-tilt-zoom (PTZ) cameras, robotics, and cinematic camera rigs, the camera often needs to rotate continuously in one or more directions. A camera slip ring enables this uninterrupted 360-degree rotation without the risk of cables tangling or breaking.

- Enhanced Mobility: By allowing the camera to move freely, slip rings provide the flexibility needed for complex shot compositions, full-surround surveillance, and comprehensive environmental scanning.

2. Reliable Signal and Power Transmission:

- Stable Connection: Slip rings ensure that electrical signals (such as video, control commands, and data) and power are transmitted reliably between the rotating camera and the stationary parts of the system. This is crucial for maintaining the quality and integrity of video feeds and control signals.

- Minimized Signal Loss: High-quality slip rings are designed to minimize signal degradation, which is vital in applications requiring high-definition video transmission or high-speed data communication.

3. Prevention of Wear and Tear:

- Reduced Cable Stress: In traditional systems without slip rings, cables must twist and unwind as the camera rotates, leading to wear and potential failure over time. Slip rings eliminate this problem by providing a fixed path for power and signals, reducing the mechanical stress on cables.

- Increased Longevity: By reducing cable fatigue and mechanical wear, slip rings extend the operational life of camera systems, lowering maintenance costs and minimizing downtime.

4. Compact and Efficient Design:

- Space-Saving: Slip rings are designed to be compact, fitting easily within the tight confines of camera housings and gimbals. This allows for more streamlined camera designs and the integration of additional features without increasing the overall size.

- Integrated Solutions: Many slip rings are customized to include multiple circuits within a single unit, handling power, video, control, and data transmission simultaneously, which simplifies system design and reduces the need for multiple components.

5. Versatility in Applications:

- Surveillance Systems: In security cameras, particularly in PTZ models, slip rings enable continuous monitoring of wide areas without interruption, providing full coverage and enhanced situational awareness.

- Cinematography: In film and television production, slip rings allow for smooth, continuous camera movements, enabling dynamic shots and complex angles without technical limitations.

- Drones and Robotics: In unmanned aerial vehicles (UAVs) and robotic systems, slip rings are essential for maintaining reliable communication between the control systems and the camera, even as the camera undergoes rapid or continuous movements.

6. Resistance to Environmental Conditions:

- Robust Construction: Camera slip rings are often designed to withstand harsh environmental conditions, such as dust, moisture, and extreme temperatures. This makes them suitable for outdoor surveillance, industrial inspection, and other demanding applications.

- Long-Term Reliability: The durability of slip rings ensures that camera systems can operate effectively in challenging environments, reducing the need for frequent maintenance or replacements.

7. Cost-Effective Operation:

- Lower Maintenance Costs: By preventing cable damage and reducing the need for frequent repairs, slip rings contribute to lower long-term maintenance costs.

- Increased System Uptime: Reliable slip ring operation ensures that camera systems remain operational for longer periods, maximizing uptime and ensuring consistent performance in critical applications.

8. Enhanced System Integration:

- Customization: Slip rings can be customized to meet specific requirements, such as the number of circuits, type of signals transmitted, and environmental resistance. This makes them highly adaptable to different camera systems and operational needs.

- Simplified Wiring: By centralizing the transmission of power, data, and signals through a single slip ring, the complexity of the camera system’s wiring is reduced, leading to easier installation and maintenance.

In summary, the camera slip ring is crucial for ensuring smooth, reliable, and continuous operation of camera systems, particularly in environments that demand high levels of mobility, durability, and signal integrity. Its role in preventing cable damage, enabling compact designs, and maintaining consistent performance makes it an indispensable component in modern camera technology.

Camera Slip Ring: Insights from an Industry Professional

In order to truly appreciate the nuances of camera slip rings, it helps to have insights from someone who has been intimately involved in their design and manufacturing. Let’s consider the perspective of an industry professional with a wealth of experience in this sector.

Having spent years in the design and manufacturing of slip rings, the professional opines that these components are akin to a camera’s heartbeat, ensuring its smooth operation. They share insights about intricate design details required to tailor slip rings to specific camera models and device types, involving precise mechanics, quality materials, and essential durability considerations.

The professional also highlights the vast benefits and potential usage of well-manufactured camera slip rings. The applications run the gamut from commercial photography, cinematography, and broadcast cameras, to surveillance systems and even aerospace equipment. In these fields, camera slip rings enable uninterrupted data transfer and rotation, a crucial element for successful operation.

Crucially, the professional underlines that industry developments majorly influence slip ring design. As technology continues to evolve, so must the slip rings. For instance, the emergence of cameras requiring more significant rotational capabilities calls for slip rings capable of high-speed data transfer with minimal signal loss. Likewise, as cameras become smaller and more portable, the requirement for slip rings to become equally compact is pressing. Thus, the design and manufacturing process is a delicate dance between adapting to advancements while maintaining the core function of the camera slip ring– enabling clean, continuous transmission of power and signal amidst all rotational movements.

Different Types of Camera Slip Ring

Just as cameras come in various shapes and sizes designed for myriad functions, so too do camera slip rings. While all slip rings share the common goal of providing uninterrupted electricity and signal transfer, their configurations and features can widely vary to suit different applications, and understanding these variations is key to optimizing their use.

Here are some common types of camera slip rings:

Capsule Slip Rings: These are relatively small devices typically used in compact cameras where space is at a premium. They consist of precision-engineered miniature parts, designed to provide stable and reliable transmission in tight spaces, ensuring optimal functionality of compact camera systems.

Pancake Slip Rings: Aptly named for their flat, disc-like shape, these slip rings are particularly suited to camera systems with limited axial space. Despite their unique configuration, they maintain efficient transmission capabilities and smooth operation, making them a prevalent choice for specific camera types.

Through-Hole Slip Rings: These slip rings feature a hole or ‘bore’ at the center, allowing additional components or cables to pass through. This configuration grants added versatility and is prevalent in more complex camera systems that require multiple connections.

Fiber Optic Rotary Joints (FORJ): FORJs are a special type of slip ring designed for the transmission of optical signals. Their ability to maintain high-speed, low-loss data transfer across rotational interfaces makes them ideal for camera systems handling extensive digital data, such as high-definition broadcast cameras.

Ethernet Slip Rings: Specifically designed to handle Ethernet protocols, these slip rings are built for systems requiring high-speed data and power communication. They are perfect for modern cameras with integrated network functionalities.

Each type comes with unique features and functionalities that work best for different needs. Therefore, understanding these characteristics allows for educated decisions about which slip ring is best suited for your specific camera system requirements.

Key Considerations for Choosing the Right Camera Slip Ring

Selecting an appropriate camera slip ring is essential for optimizing the overall performance of your camera system. With a wide variety of options available, the process can seem daunting. However, focusing on specific factors that directly influence your camera’s unique requirements can significantly ease the decision-making process. Below are key considerations to keep in mind.

Factors to Consider When Choosing a Camera Slip Ring:

- Camera System Requirements: First and foremost, determine the needs and limitations of your camera system. Consider the camera’s rotation range, power demands, data transfer rates, and any other unique system requirements that affect your choice of slip ring.

- Size and Space Restrictions: Assess the space available within your camera system for a slip ring and choose one that fits perfectly while providing the necessary functionality. Capsule and pancake slip rings might be preferable for compact systems, while through-hole slip rings might be more suited for those with additional cabling demands.

- Material and Durability: Opt for slip rings constructed from high-quality materials that ensure durability and longevity. This choice directly impacts both the slip ring’s performance and the extended lifespan of your camera system.

- Data and Power Transmission: Select a slip ring that is capable of handling the required data transmission rates and power loads for your specific camera system. Ethernet slip rings might be more appropriate for cameras with integrated network functionalities, while fiber optic rotary joints may be better suited for high-speed, low-loss data transfer applications.

- Environmental Factors: Consider the intended operating environment, such as temperature, humidity, and potential exposure to dust or other contaminants, when choosing a slip ring. Make sure the chosen slip ring can withstand these conditions without compromising on performance.

How These Considerations Reflect on the Performance of the Ring and the Camera System:

Paying attention to these factors can significantly impact both the slip ring’s capabilities and your camera system’s performance. For instance, selecting the wrong type of slip ring can lead to inadequate power supply, loss of data, or incompatibility with the camera system’s components. In contrast, the right slip ring ensures smooth operation, high-speed data transfer, and improved reliability. By adequately addressing factors such as size, materials, transmission requirements, and environmental conditions, you pave the way for a well-suited, high-performing, and durable slip ring that integrates seamlessly into your camera system.

The Impact of Technological Advancement on Camera Slip Rings

The world of technology is in a constant state of evolution, and camera slip rings are no exception to this rule. Thanks to technological advancements, the capabilities and designs of slip rings have progressed significantly to meet the demands of increasingly complex camera systems.

How Technology Has Influenced the Evolution of Slip Rings:

Over the years, camera and communication technologies have continued to advance, leading to higher-resolution imaging, faster data transmission, and greater system integration. As a result, slip rings have evolved to handle these increased demands.

For instance, the rise of digital photography and cinematography necessitated the development of slip rings capable of handling higher data rates, leading to the creation of Ethernet slip rings and Fiber Optic Rotary Joints. Also, as cameras became smaller, the need arose for compact, highly efficient slip rings, resulting in the introduction of capsule and pancake slip rings.

Today, slip rings are increasingly adapting to handle more complex electrical interfaces, and high-speed data protocols, offering low noise, and low signal loss solutions that augment the performance of advanced camera systems.

The Anticipated Future Advancements in Camera Slip Rings:

As we look to the future, the only certainty is the ongoing evolution of technology and, by extension, camera slip rings. With advancements in areas such as 5G connectivity, IoT applications, and AI-based surveillance systems, we can expect a new generation of slip rings capable of handling these innovations.

We will likely see slip rings that can cater to higher bandwidth requirements for 5G-enabled cameras, increased robustness for IoT devices exposed to challenging environments, and enhanced data transfer capabilities for AI-integrated systems. Moreover, as the need for sustainable, environmentally friendly technology grows, we might also witness the emergence of slip rings built using sustainable materials or designs aimed at minimizing energy loss.

In summary, the realm of camera slip rings is a dynamic one, shaped significantly by ongoing technological advancements. By staying informed about these changes, you can ensure that you make the most informed decisions when selecting and using these components.

Conclusion

Understanding camera slip rings is a journey into the intricate network of components that make up our beloved cameras. With insights from a professional, this knowledge can enhance camera usage and influence future innovative applications.

Ready to place an order? Provide your details and we’ll get back to you shortly.

FAQs about Camera Slip Ring

When researching or dealing with camera slip rings, several common questions or concerns often surface. Gaining a clearer understanding of these finer details can be instrumental in maximizing the benefit derived from these crucial components. Let’s delve into some of these frequently asked questions and professional responses to them.

Q: Can the slip ring handle the data rates required by my camera system?

A: American slip rings are designed for varied levels of data and power transmission. It’s crucial to identify the necessary transmission rates and power loads for your camera system. Specialized slip rings, like the Ethernet slip ring or Fiber Optic Rotary Joint (FORJ), are designed for high-speed data transfer and might be the right fit for high-resolution or networked camera systems.

Q: I’m worried about the environmental impact on my slip ring’s performance. How can I ensure it withstands challenging conditions?

A: Slip rings can be designed to withstand a range of environmental conditions, from the controlled environment of a studio to the harsh conditions of an outdoor shoot. When choosing a slip ring, consider factors such as temperature range, humidity, and the potential presence of dust or corrosive elements. Opting for a slip ring that is known for its durability and robustness can help ensure optimal performance.

Q: Will installing a slip ring compromise the compact size of my camera system?

A: Slip rings come in various forms to cater to a wide range of application needs. If your camera has compact dimensions, consider capsule or pancake slip rings which are designed for space constraints. These can handle the necessary power and data transmission without compromising the camera’s compactness.

Q: Will my slip ring outlast my camera system, or will it need frequent replacement?

A: The lifespan of a slip ring is greatly influenced by its material composition and operational handling. By selecting a slip ring made from high-quality materials and ensuring that it’s adequately suited to the camera setup, you can reduce the need for frequent replacements.

By addressing these common concerns and questions, you can ensure a deeper understanding of camera slip rings. Furthermore, by considering these points when deciding on a slip ring, you can ultimately ensure your camera system functions at its best.

See What We Can Do