Subsea operations have become increasingly complex and demanding due to an expanding range of applications and technological advancements. Ensuring the reliability and efficiency of components working in underwater environments is crucial. Among these components, subsea slip rings play a vital role in addressing the unique challenges of the marine world. As such, navigating the subject of subsea slip rings is essential for professionals involved in this field. This article is curated to serve this exact interest, bringing coherence and clarity to the complex world of subsea slip rings.

The purpose of this article is to provide a comprehensive understanding of the key aspects concerning subsea slip rings, as well as to offer expert guidance based on practical experience. Written from a designer and manufacturer’s standpoint, this piece will delve into the importance, features, benefits, and considerations of subsea slip rings, making it a valuable resource for novices and experienced industry professionals alike.

The insights shared in this article can potentially benefit readers in multiple ways. For those at the beginning of their subsea journey, gaining a firm grasp on the fundamental concepts and applications surrounding subsea slip rings will allow for a strong professional foundation to emerge. Likewise, for experienced professionals, the article aims to enhance their knowledge, enabling them to make informed decisions in deploying and optimizing the use of these critical components.

Throughout the article, we make a conscious effort to maintain coherence and connectivity between the various sections, ensuring that the ideas flow seamlessly; illustrating the importance of subsea slip rings and the role they play in successful underwater applications. Whether you’re an engineer, operations manager, or an industry decision-maker, our goal is to provide you with valuable, actionable information that bolsters your understanding and decision-making capabilities regarding subsea slip rings.

The Importance of Slip Rings in Subsea Applications

Subsea applications encompass a variety of activities – from exploration and extraction of oil and gas resources to underwater archaeology and scientific research. In each of these activities, reliable data and power transmission between static and rotating parts is crucial. Here, slip rings display their critical role. As electromechanical devices, they ensure the continuous flow of power, and data signals in rotating systems, thereby enabling seamless operation of crucial subsea equipment such as Remotely Operated Vehicles (ROVs) and sonar systems. Without slip rings, dynamic rotational movements in underwater environments would be rendered ineffective, underlining their importance in subsea operations.

To help further illuminate the criticality of slip rings in subsea applications, I will share insights amassed over years of experience working as a designer and manufacturer in this industry. The very essence of my expertise lies in designing these robust devices to withstand the harsh marine environment, highlighting their uniqueness and indispensable role.

From the moment a subsea slip ring is conceptualized to its manufacture and its actual operational implementation, there’s an overarching theme that transcends the process: the necessity of these slip rings in ensuring operational efficiency and reliability. These devices quite literally bridge the gap between stationary and rotating components, carrying data and power across the divide.

In the following sections, we will delve into the profound depths of subsea slip rings, exploring their design considerations, key features, and unparalleled benefits. We will also help you navigate the installation process, troubleshoot common issues, and stay updated with futuristic trends in the realm of subsea slip rings. By maintaining a coherent progression of subtopics, we aim to build a comprehensive understanding of these essential devices and their impact on the subsea world.

Understanding Subsea Slip Rings

As we traverse deeper into the subject, it is essential to elucidate what subsea slip rings are, their key functions, and the components that form these indispensable devices. A thorough understanding of subsea slip rings forms the groundwork for appreciating their paramount importance in underwater operations.

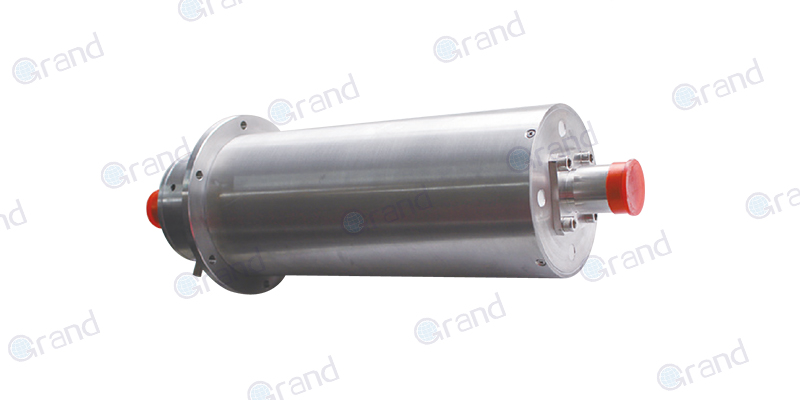

Subsea slip rings are specialized electromechanical devices that facilitate the transmission of electrical power and data signals between static and rotating parts in underwater environments. With multiple applications in areas such as Remotely Operated Vehicles (ROVs), oceanographic winches, and underwater communication systems, subsea slip rings need to withstand high pressure, temperature fluctuations, and corrosive seawater. As such, they are built to be extremely robust and customizable, meeting the stringent demands of various subsea applications.

By shedding light on my experience in designing and manufacturing slip rings, I bring forth insights that reveal the complexities and fine art of creating these functional devices. A typical subsea slip ring comprises several key components, including:

- Housing: This robust, pressure-resistant enclosure safeguards the internal components from the surrounding underwater environment. It is built from materials that offer high resilience against corrosive seawater and extreme pressure encountered in subsea applications.

- Rotating Assembly: A crucial part of the subsea slip ring, the rotating assembly consists of a central shaft, brushes, and slip rings. The shaft supports the torque, enabling smooth rotation, while brushes make contact with slip rings to form the sliding electrical path for transmitting power and data.

- Slip Rings and Brushes: These critical components are responsible for creating the electrical connections between the stationary and rotating elements. They are formulated from specialized materials that ensure reliable signal transmission and durability under adverse conditions.

- Seal Systems: Custom-designed seals protect the slip rings from the ingress of water, ensuring the internal components remain unaffected by the harsh environment.

- Bearings: Bearings facilitate swift and effortless rotation of the assembly while maintaining optimal functionality throughout the operational lifespan.

Drawing from my expertise in the design and manufacturing process, it becomes clear that the performance of a subsea slip ring is a culmination of the synergy between each of these components. By cohesively delving into the various aspects that make up a subsea slip ring, we establish a contextual, interconnected understanding of these integral devices.

Key Features of Subsea Slip Rings

In this section, we delve into the salient features of subsea slip rings. Each aspect of these devices is purpose-designed to handle the extreme conditions typical of underwater environments, accounting for their uniqueness and catering to specific operational requirements.

As a manufacturer, I can attest to the crucial importance of these key features:

- Robust Construction: A subsea slip ring is constructed to withstand extreme external pressures, significant depth variations, and corrosive marine conditions. High-grade materials, including marine-grade stainless steel, are employed to ensure resilience against these conditions.

- Sealed Design: To prevent the ingress of seawater, subsea slip rings feature specialized seals. These seals protect the internal components, ensuring smooth operation and longevity of the device.

- Reliable Data and Power Transmission: One of the defining features of a subsea slip ring is its ability to transmit electrical power and data signals reliably, continuously, and without interruption across rotating components.

- Performance at High Pressures: Subsea slip rings are designed to operate flawlessly even under extremely high-pressure conditions, which is typical in deep-sea applications.

- Temperature Resistance: These devices are capable of functioning optimally across a wide temperature range, ensuring reliability amidst the temperature variations in underwater environments.

Drawing from my experience as a manufacturer, it can be noted that the technological advancements in the design and fabrication of subsea slip rings pivot around improving these core features. For instance, improved seal designs are continuously developed to prevent water ingress, even at significant depths. Similarly, advancements in manufacturing processes and the use of novel, robust materials are oriented toward enhancing the device’s durability and resistance to harsh conditions.

The key features of subsea slip rings are interlinked and blend together to equip these devices with the fortitude needed to operate in high-pressure, corrosive marine environments. While understanding each feature provides insights into their individual function, it’s the collective ensemble of these features that truly exhibits the power of subsea slip rings in underwater applications.

Benefits of Using Subsea Slip Rings

Utilizing subsea slip rings in underwater operations yields a multitude of benefits that extend across efficiency, reliability, and longevity. By drawing from my practical experience in the field, these real-world advantages become increasingly apparent.

- Optimized Efficiency: Subsea slip rings enable uninterrupted data and power transmission between stationary and rotating components. This promotes seamless operation of critical systems, such as ROVs and winch systems, reducing downtime and enhancing the overall efficiency of subsea operations.

- Increased Reliability: Designed to resist harsh marine environments, subsea slip rings offer consistent performance under high pressure and corrosive conditions. Top-quality materials and construction fuse together to create a device with steadfast reliability, making it a dependable choice for subsea applications.

- Long-lasting Service Life: Subsea slip rings are engineered to withstand the tests of time. By employing durable materials and advanced sealing technology, these devices retain their operational integrity for extended periods, rendering them a cost-effective option in the long run.

- Customization: Subsea slip rings can be tailored to specific application requirements based on factors such as the number of channels, voltage, and communication protocols. This adaptability allows for precise integration into a range of underwater systems, maximizing the benefits offered by slip rings.

- Ease of Maintenance: Owing to compact designs and high-quality materials, subsea slip rings require less maintenance than conventional alternatives. Moreover, the modular structure of these devices eases the process of replacing components like brushes and bearings, further streamlining maintenance efforts.

- Energy and Environmental Advantages: The precise and accurate transfer of data and power facilitated by subsea slip rings contributes to reduced energy consumption in underwater systems. Moreover, the long-lasting nature of these devices mitigates the environmental impact by reducing the need for frequent replacements.

Having personally witnessed the remarkable difference in performance, reliability, and service life of subsea operations thriving on the employment of slip rings, the validity of these benefits is undeniable. By contextualizing each benefit in real-world applications, we establish a coherent understanding of the positive outcomes facilitated by subsea slip rings, underscoring their integral importance in underwater endeavors.

Considerations When Choosing Subsea Slip Rings

When selecting subsea slip rings for specific applications, potential users ought to contemplate a variety of factors that will ensure optimal results across the domains of quality assurance, maintenance, and compatibility. Drawing from these observations, I outline essential considerations that customers should heed in their decision-making process:

- Application Requirements: An in-depth comprehension of the requirements of your subsea application is paramount. Considerations such as the desired transmission type, data rate, number of channels, and operating depth will influence the slip ring specifications needed to satisfy your project objectives.

- Quality Assurance and Standards: Investigate the manufacturers’ adherence to rigorous quality-control protocols and industry standards. These assurances underscore the reliability and durability of the subsea slip rings, ensuring optimal performance in harsh underwater environments.

- Compatibility: Ensure that your chosen slip ring exhibits compatibility with other components in your underwater system. Factors such as the connection interface, electrical specifications, and communication protocols will govern seamless integration and interoperability.

- Materials and Construction: The resilience of subsea slip rings hinges on the quality and adaptability of materials employed in their construction. Prioritize slip rings that utilize marine-grade stainless steel, corrosion-resistant alloys, and advanced sealing materials tailored for underwater conditions.

- Maintenance and Support: Engage with manufacturers who offer comprehensive after-sales support, including detailed maintenance guidelines and responsive technical assistance. Informed support bolsters your ability to keep subsea slip rings operating efficiently and to promptly address any unexpected challenges that may arise.

- Customizability: Opt for manufacturers who provide customization options, as bespoke designs cater to the unique demands of different subsea applications. Customizable slip rings present the opportunity to fine-tune specifications, ensuring optimal performance and durability within your particular operation.

By orienting the discussion around potential users’ concerns, the considerations outlined above furnish a cohesive and practical context for choosing appropriate subsea slip rings. These guidelines enable customers to make informed decisions that align with their requirements, thereby ensuring the smooth functioning and longevity of their underwater systems.

The Installation Process of Subsea Slip Rings

Proper installation of subsea slip rings is critical to guarantee seamless functioning, reliability, and longer service life. Drawing from my experience as an expert in this domain, the following step-by-step guide highlights the crucial steps involved in the installation process, providing insights into valuable secrets gleaned from industry professionals.

- Preparation: Before diving into installation, it is imperative to thoroughly examine the user manual and consult the manufacturer’s technical staff for any clarifications. Gather the necessary tools to facilitate a smooth installation process.

- Site Preparation: Ensure the installation site is clean, well-organized, and devoid of any debris or contaminants. This preparation will minimize potential issues arising from inadequate environmental conditions that could compromise the slip ring’s operation.

- Visual Inspection: Conduct a comprehensive visual inspection of the slip ring and its components to identify any damages or defects that may have occurred during shipping. Report any discrepancies to the manufacturer promptly.

- Device Orientation: Determine the correct orientation of the subsea slip ring as per the manufacturer’s guidelines. Correct orientation is critical to achieve optimal performance and prevent undue stress on the device.

- Mounting and Connection: Securely mount the slip ring in place, ensuring a stable, firm connection with the system. Pay close attention to torque specifications provided by the manufacturer to avoid over-tightening, which may lead to damage.

- Cabling: Properly route and connect the cables to the slip ring’s terminal blocks or connectors, taking care to avoid sharp bends, twists, or tension in the cables. Ensure that the connections are firm, and secure, and abide by the system’s wiring diagram.

- Testing: Prior to full operation, perform functional tests to verify correct data and power transmission, and be certain that the slip ring is functioning as anticipated. Consult the manufacturer’s guidance on specific testing procedures.

- Documentation and Record-keeping: Document the installation process, including any testing results, to streamline future maintenance and troubleshooting efforts.

The secrets to a successful installation are rooted in thorough preparation, careful attention to detail, and adherence to manufacturer guidelines. By embracing a meticulously structured installation process, potential users can rest assured that their subsea slip ring will perform optimally and withstand the rigors of underwater applications.

Maintenance and Troubleshooting of Subsea Slip Rings

Maintenance and prompt troubleshooting are pivotal components in preserving the operational integrity and longevity of subsea slip rings. Given my extensive professional experience in this sector, this section encapsulates a wealth of practical knowledge pertaining to upkeep and problem-solving.

Maintenance

Regular and preventive maintenance can considerably extend the life of a subsea slip ring and advocate optimal performance.

- Regular Inspection: Periodic visual inspections can help detect signs of wear, loose connections, or cable damage. An assessment of the slip ring’s protective casing for potential leaks or corrosion is also crucial.

- Cleaning: Use manufacturer-recommended cleaning agents to remove any residue on slip ring systems. Care must be taken to follow the specific instructions and cautionary advice provided by the manufacturer.

- Parts Replacement: Pay attention to components that require regular replacement, such as brushes or seals. Changes in performance may indicate that a part replacement is required, and these components should be replaced as per the manufacturer’s guidelines.

- Lubrication: Ensure proper lubrication of rotating parts to reduce friction and wear, following the manufacturer’s specific instructions and recommendations for lubricant type.

- Professional Check-ups: Schedule regular professional check-ups to prevent potential issues. Experienced technicians can detect early signs of problems and support preventive action.

Troubleshooting

Despite preventive maintenance, issues may still arise. Here are some common problems and steps for troubleshooting:

- Signal Loss: If signal loss or interference occurs, examine the connectors, cables, and brushes for any visible defects. Replacing any worn-out brushes or damaged cables may resolve this issue.

- Noise or Vibration: Should the slip ring emit abnormal noise or vibration, it may be due to misalignment or wear. Inspect and realign the slip ring assembly and replace any worn-out parts.

- Unexpected Power Cycling: If the slip ring powers down and restarts unanticipatedly, possible causes could be a loose connection or a fault in the power supply. Check all connections and the power supply for any inconsistencies.

Synergizing the context of routine maintenance with proficient troubleshooting strategies underscores the importance of proactive monitoring and problem-solving in sustaining the efficacy of subsea slip rings. This comprehension, fashioned by my practical experience, serves as a guiding light for those endeavoring to maximize their benefits from these integral devices in underwater operations.

Future Trends in Subsea Slip Rings Technology

As an expert in the field, I am privy to various technological advancements that drive the evolution of subsea slip rings. Delving into the foreseeable future, I examine the emerging trends and innovations that have the potential to reshape the industry landscape and further optimize subsea slip ring capabilities.

- Advanced Materials and Coatings: With subsea environments exerting considerable demands on slip rings, the adoption of cutting-edge materials and coatings will likely gain momentum. High-quality alloys, advanced ceramics, and low-friction coatings can improve the performance, corrosion resistance, and durability of slip rings subjected to extreme conditions.

- Smart Monitoring and Diagnostics: Integrating sensors and real-time monitoring systems within the slip rings can provide valuable data on their performance and condition. This technology will enable operators to quickly detect potential issues, efficiently schedule maintenance, and minimize the chances of unexpected failures, propelling the subsea slip rings sector towards smarter, more reliable solutions.

- Further Miniaturization and Modular Design: The future of subsea slip rings may inhabit increasingly compact and modular designs. Continuing to reduce the size and weight of these devices while retaining their robustness will facilitate ease of integration, streamline maintenance, and expand their applicability to additional underwater systems.

- Enhanced Data Transmission Rates: With the growing demand for swift and seamless data transfer in subsea operations, advancements in data transmission technologies will play a pivotal role. New protocols and techniques, such as fiber-optic communication, can help subsea slip rings accommodate ever-increasing data throughput.

- Green Technologies: As environmental concerns become increasingly urgent, the development of eco-friendly subsea slip rings will likely witness a surge. Employing materials and manufacturing processes with minimal ecological impact and reducing overall energy consumption could emerge as prime objectives in the coming years.

- Customization and Application-Specific Solutions: In response to the diversification of subsea applications, the future could see a proliferation of customizable and application-specific slip rings. These tailored solutions will enable a more nuanced approach to addressing the requirements of specific industries and endeavors, ultimately enhancing the slip rings’ performance and longevity.

By offering insights into the potential future developments in subsea slip ring technology, we paint a vivid picture of a rapidly evolving sector driven by the desire to optimize performance and capabilities. As the industry keeps pace with innovation and embraces modern solutions, we can expect a bright, transformative future for subsea slip rings and their applications.

Conclusion

Subsea slip ring technology, with its multitude of advantages and potential, presents a fascinating study. With this article, I hope to have illuminated the notable aspects of these devices, enriching your understanding and reinforcing the importance of their role in subsea operations. As we embark on a technology-fueled future, understanding and leveraging these devices will only ascend in importance.

See What We Can Do