Understanding the world of generators may seem mystifying at first, particularly when delving into their intricate inner workings. Yet, no part is too small to deserve attention, given how every cog and wheel plays a part in generating power. One such indispensable unit within the generator set is the slip ring, a component whose importance might remarkably surpass its physical size.

While slip rings may not be the largest parts of a generator, their role is vital in ensuring the smooth operation and effective transmission of electricity from a generator. They form the nodes that carry power and signals from a stationary unit to a rotating one, bridging the gap between these sections and laying the foundation for an efficient power relay system. Neglecting these can lead to operational issues, making it critical to understand their functionality to maintain optimal generator performance.

With our in-depth exploration into the critical role and importance of slip rings in generators, our readers can look forward to gaining a robust understanding of this crucial component. This comprehensively curated guide, imbued with industry insights and professional perspectives, will enlighten any generator enthusiast or technician’s path.

Whether you are a casual reader looking to augment your knowledge or a professional seeking advice on proper slip ring maintenance and troubleshooting, this guide aims to be a valuable resource. By shedding light on concepts easily understood by beginners yet intriguing enough for experts, this article is poised to significantly add to your understanding of the importance and functionality of slip rings in generators.

Prepare to embark on a journey of discovery underpinned by expertise, one that enhances both your base of technical knowledge and your capacity to preserve the health of your generators. By the end, you’ll have a comprehensive understanding of the critical role slip rings play in generators and why their proper maintenance can significantly extend the lifespan of your equipment.

The Fundamentals of Slip Rings in Generators

To fully grasp the importance of slip rings, it is essential to delve into their fundamentals, paying close attention to their basic structure, function, and overall contribution to the generator’s operation.

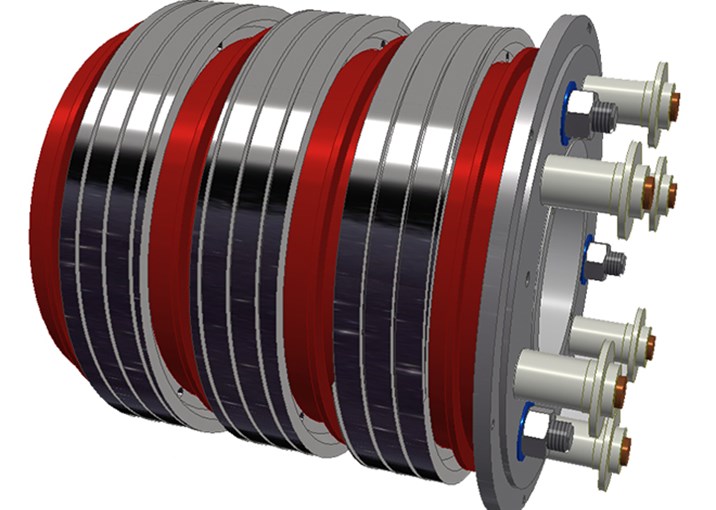

Slip rings, often seen as subtle yet essential components, are electromechanical devices used to transmit electrical signals and power between stationary and rotating parts of a generator. They maintain a continuous electrical connection, preventing disruptions in power flow, even during motion. The design generally features a conductive ring connected to the stationary part (brushes) and another to the rotating part (rotor), allowing for seamless electrical transmission while both parts move at their respective speeds.

The interaction between slip rings and other generator components is a crucial aspect of their functionality. To generate power, a generator relies primarily on two distinct elements, the rotor and the stator. The rotor, as the name suggests, is a rotating component containing slip rings, windings, and magnetic fields. In contrast, the stator remains stationary and houses the conductive coils that generate electricity when the magnetic field rotates around them.

Amidst this elaborate dance, slip rings act as the bridge between the rotor and stator. Their chief responsibility is to ensure that the generated electricity is transferred from the rotor’s windings to the stationary stator, without hindering the movement of either piece. The rotor and stator depend on the proper functioning of slip rings to maintain consistency in electrical generation, highlighting the interdependence that underpins the generator’s overall performance.

In essence, while slip rings may not by themselves directly generate power, they facilitate the smooth relay of electrical currents across complex, moving systems that work in unison. Accordingly, maintaining the proper function of slip rings is of paramount importance, as it allows generators to continue to serve their purpose effectively and efficiently by building bridges between vital components.

The Mechanics of Slip Rings in Generators

Evaluating the mechanics of slip rings affords a more profound comprehension of their critical role in generators. At an elemental level, slip rings broadly involve moving parts (rotor and slip rings) and stationary ones (brushes and stators). Their design and functionality ensure that these sections can operate simultaneously without disrupting the flow of electricity.

The primary duty of slip rings is to pass electric currents from a fixed to a rotating part within the generator. So how do they precisely manage this? Imagine a simple electric circuit involving a battery and a bulb. Now, imagine this circuit having to continually rotate without breaking the electric connection. This is where slip rings come in. They act as the conventional wires in this scenario, able to maintain the connection even while the circuit (or generator) is in motion.

Diving deeper into the matter, we can see that slip rings are typically made of highly conductive metals. As the rotor spins with the slip ring, the stationary brushes (also conductive elements) maintain constant contact with the slip ring, facilitating an unstitched pathway for the electric current to flow.

Understanding this coordination of parts demonstrates how slip rings directly affect generator performance. A well-functioning slip ring ensures consistency in electrical transmission, leading to smooth generator operation. Any dysfunction within the slip ring – be it wear, oxidation, or other forms of damage – can cause intermittent connection, resulting in fluctuations in electricity transmission and inefficient generator performance.

In this light, it becomes evident that slip rings serve as a silent hero within a generator, spinning tirelessly to keep the electric current flowing and the generator doing its job. They stand as an embodiment of the saying, “The whole is greater than the sum of its parts”, highlighting how their subtle, mechanistic roles can greatly influence the overall performance of the larger generator system. Recognizing and maintaining this intricate balance is key to ensuring top-notch generator functionality over time.

Critical Role of Slip Rings in Power Generation

It’s hard to overstate the importance of slip rings in the process of power generation within a generator. These components, mechanical in nature but profound in function, act as conduits for electrical current from the rotor to the stator, enabling the flawless execution of power transfer, a factor that sits central to the primary role of generators.

Electrical energy, as we know, is generated when magnetic fields interact with conductive coils in the stator. However, while power generation is initiated in the rotor, it is the stator where useful electrical energy is finally emitted. The golden bridge enabling this transition is formed by slip rings. By maintaining an uninterrupted connection between the rotor and stator, slip rings facilitate the free flow of generated electrical power. They work in perfect harmony with the rotor and stator, making generous contributions towards the seamless operation of the generator.

Now, imagine a generator devoid of slip rings. Without these components, there would be nothing to ensure an uninterrupted passage of electrical power within the generator system. This lack of connection would cause breakdowns in the transmission cycle, leading to interruptions or total generator failure. Without slip rings, the generator would fail at its one primary job — continuous generation and transmission of power.

This analogy underscores the critical nature of slip rings in power generation, emphasizing that these components are not mere accessories but essential parts of the electrical generator. Above all, understanding the undeniable significance of slip rings drives home the point about why one needs to pay meticulous attention to their maintenance and upkeep. By ensuring the smooth operation of the slip rings, we guarantee the health and efficiency of the whole generator system and, as a result, a reliable power supply.

Choosing and Maintaining Slip Rings in Generators

Choosing the right type of slip ring and maintaining it in peak condition are cardinal elements in the process of managing the longevity and efficiency of a generator. These tasks may sound daunting, but with adequate knowledge and a handful of expert tips, they can be streamlined for a manageable experience.

Selecting the right slip ring for a generator involves various considerations, the most significant being the generator’s model and power requirements. Certain powerful generators may require high-capacity, robust slip rings, and brushes capable of conducting electric currents at high voltages and frequencies. Therefore, it is crucial to understand the generator’s specifications before selecting a slip ring. A specialist’s advice can always be instrumental in this regard, providing guidance based on technical experience and expertise.

Another essential factor to consider in selection is the material of the slip ring. Opting for highly conductive and durable materials like copper or brass is recommended, given their ability to withstand continuous rotation and high temperatures with minimal wear and tear. However, it’s important to balance these characteristics against the cost, as prices for these materials can vary significantly.

Once the appropriate slip ring is chosen, consistent maintenance becomes a determinant of its endurance. Regular inspection of both the slip ring and attached brushes, coupled with timely cleaning and lubrication, can diminish irregularities such as wear, oxidation, and accumulation of dust. Moreover, to ensure precision and effectiveness, it is always best to entrust maintenance activities to a qualified technician.

In cases where troubleshooting is necessary, a common rule of thumb is to first check for excessive wear or deformation. Also, it’s paramount not to overlook the brushes, as they play a key role in maintaining contact with the slip rings. Broken or poorly functioning brushes can result in disrupted electrical transmission, affecting the generator’s performance.

The knowledge of how to select, maintain, and troubleshoot slip rings is informed by real-life industry experiences and is fundamental for promoting the longevity of generators. Mastering this knowledge empowers users and operators to optimally manage their generator systems, guaranteeing them a steady and reliable power supply.

Slip Rings in Generators Innovations Technology

As technology continues to progress in leaps and bounds, so too does the design and functionality of slip rings. These advancements not only promise extended lifespans and improved efficiency for the devices they serve, such as generators, but they also open up a plethora of opportunities for novel applications in various industries.

One of the most significant innovations in slip ring technology is the development of wireless or contactless slip rings, also known as rotary transformers. These designs have entirely done away with brushes, thereby eliminating the problems associated with friction, wear and tear, and the consequent need for frequent maintenance. This evolution in design means less downtime for maintenance, promising increased operational time, and optimized performance of the generator.

Fiber Optic Rotary Joints are another cutting-edge innovation that has carved out its place in modern technology. This type of slip ring facilitates the transmission of data signals over long distances without significant loss. Particularly relevant for generators used in network-intensive applications, fiber optic slip rings ensure a steady, high-speed transfer of data.

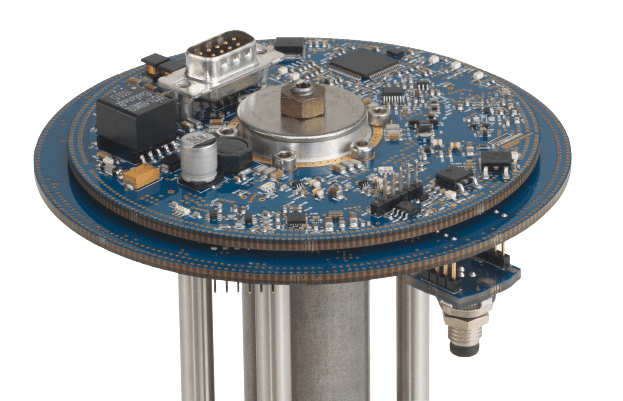

Integration of smart elements, ushering slip rings into the realm of the Internet of Things (IoT), is a game-changing innovation. With built-in sensors and communication technology, these ‘smart’ slip rings can self-diagnose any functional irregularities and share real-time updates with operators, enabling preemptive actions and reducing the likelihood of generator downtimes.

The miniaturization of slip rings is yet another tenet of modern innovations. These compact slip rings are a perfect fit for small-scale devices or portable generators, fostering the growth of mobile power solutions.

It’s crucial to understand that these technological advancements in slip rings not only aim at improving the existing functionalities but also at nurturing a landscape of possibilities, leading the way for new applications and utilities. By embracing these advancements, we can significantly enhance the overall efficiency, lifespan, and capabilities of our generators. These leaps forward propel us into a new era, one in which our power solutions are not just smart, but also more reliable and efficient.

Conclusion

Understanding the role and importance of slip rings in generators is vital for anyone interacting with or maintaining these machines. In closing, this article provides a practical guide to maximize your generator’s efficiency, offering insights into slip rings’ functionality, maintenance best practices, and technological advancements.

FAQs about Slip Rings in Generators

Given that slip rings hold such an essential position in generator systems, it is only natural for users, technicians, and professionals alike to seek a deeper understanding of these components. Addressing frequently asked questions and misconceptions about slip rings allows for the clarification and expansion of knowledge, based on industry experience and technical expertise. Let’s dive into some of these queries and offer insightful responses.

Q: What are the signs of a malfunctioning slip ring?

A: When a slip ring starts to malfunction, a generator may display an erratic performance, with frequent fluctuations in voltage levels, intermittent power supply, or even complete loss of power. These irregularities may be attributed to worn brushes, oxidation, debris, or excessive vibration, which can hinder the electrical conductivity and disrupt the generator’s smooth operation.

Q: How often should slip rings be inspected and maintained?

A: Regular inspection and maintenance of slip rings play a vital role in preventing untimely generator failures. Depending on the usage and generator model, inspections can be conducted on a monthly, quarterly, or as-needed basis. Regular visual inspections of components and electrical readings can help determine when maintenance is due. Communicating with a qualified technician to establish a suitable maintenance schedule for your generator is highly recommended.

Q: What should be done when slip rings or brushes need replacement?

A: While slip rings are designed to be durable and long-lasting, they are subject to wear and tear, especially after prolonged use. If issues like excessive wear, corrosion, or deformation arise, it’s essential to consult with a generator technician or engineer for the proper replacement of the affected components. Replacing slip rings and brushes in a timely manner can prevent more severe issues from occurring and ensure the prolonged functionality of the generator.

Q: Can one generator utilize more than one type of slip ring?

A: Yes, generators can utilize different types of slip rings on a single rotor, depending on the requirements of the system and the different applications for which the generated power is used. Each type of slip ring may have unique specifications for electrical bandwidth, insulation materials, or conductivity, among other factors. Integrating multiple slip ring types in one generator is possible, with careful consideration given to their compatibility and the intended performance.