The world of Alternating Current (AC) motors is both broad and complex; whether it’s the motor in a table fan or a massive industrial machine, each contains carefully engineered components working together diligently. One subtly ubiquitous and critical element in certain types of AC motors slip ring.

What are AC Motor Slip Rings?

AC motor slip rings are electromechanical devices that are designed to transmit electrical power or signals from a stationary structure, often referred to as a ‘stator,’ to a rotating component, known commonly as a ‘rotor’. This transmission process is primarily facilitated through continuous sliding contacts, ensuring that the electrical integrity is maintained even while the motor’s elements are in motion.

While some may overlook the importance of a seemingly small component like the slip ring, it’s essential to consider its significant role in ensuring efficient operation. To give some perspective, AC motors employing slip rings, like wound rotor induction motors, offer better starting conditions, superior torque control, and an overall heightened adaptability compared to their counterparts.

The functionality of slip rings goes hand-in-hand with the chosen motor design. In other words, the nature of the load and operational requirements dictate the use of slip rings in AC motors. Industrial equipment that requires high starting torque like elevators, conveyors, or hoists, more often than not, depend on AC motors with slip rings, taking full advantage of their unique characteristics.

In summary, slip rings in AC motors embody a very specific yet vital purpose. Their existence in the architecture of certain AC motors demonstrates how even the tiniest elements play key roles and makes evident the complex, intricate beauty of engineering that continues to drive our world.

Types of AC Motors and the Role of Slip Rings

AC motors are diverse and versatile, responsible for powering various machines and devices. Owing to their respective advantages and functions, different types of AC motors have been developed to meet specific application needs. This section will provide a detailed breakdown of the most prominent motor types and explore the relationship between slip rings and AC motors further.

AC Motor Types

- Synchronous Motors: As the name suggests, these motors feature a rotor that moves in synchronization with the rotating magnetic field produced by the stator. Synchronous motors usually operate at a constant speed, regardless of the load conditions, and are often utilized in applications requiring high power and stable speeds. Slip rings are typically not used in synchronous motors.

- Induction Motors: Induction motors, or asynchronous motors, are a popular choice, given their low cost, sturdy construction, and simple operation. These motors have rotors that move at a slightly different speed than the rotating magnetic field in the stator. The rotor’s windings in induction motors do not require any direct electrical connections, and thus, slip rings are not employed in these motors.

- Wound Rotor Induction Motors (WRIM): A subtype of induction motors that uses slip rings for unique functionalities. Designed for high starting torque, better control, and greater flexibility, this motor enables adjustments to its external rotor circuitry, leading to optimized performance tailored to the given application. Slip rings are a crucial element in this particular motor design.

Rotor Windings and Slip Rings in Wound Rotor Induction Motors

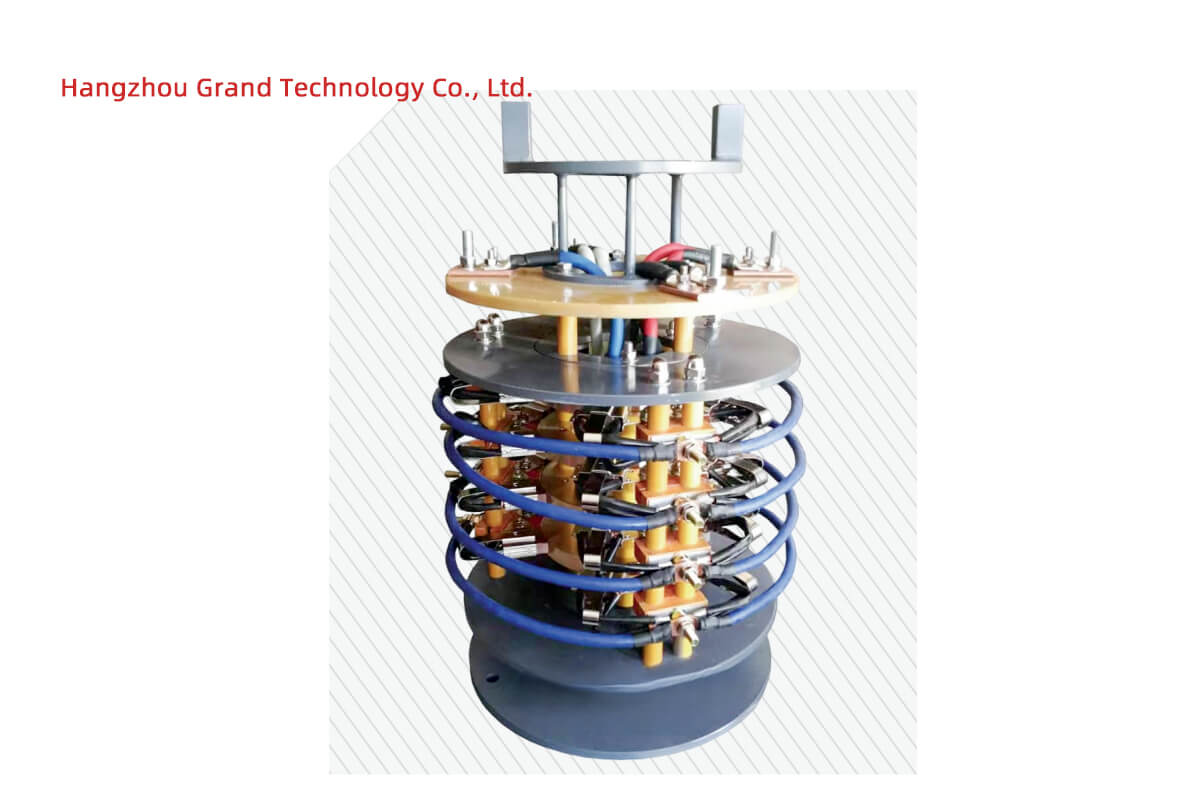

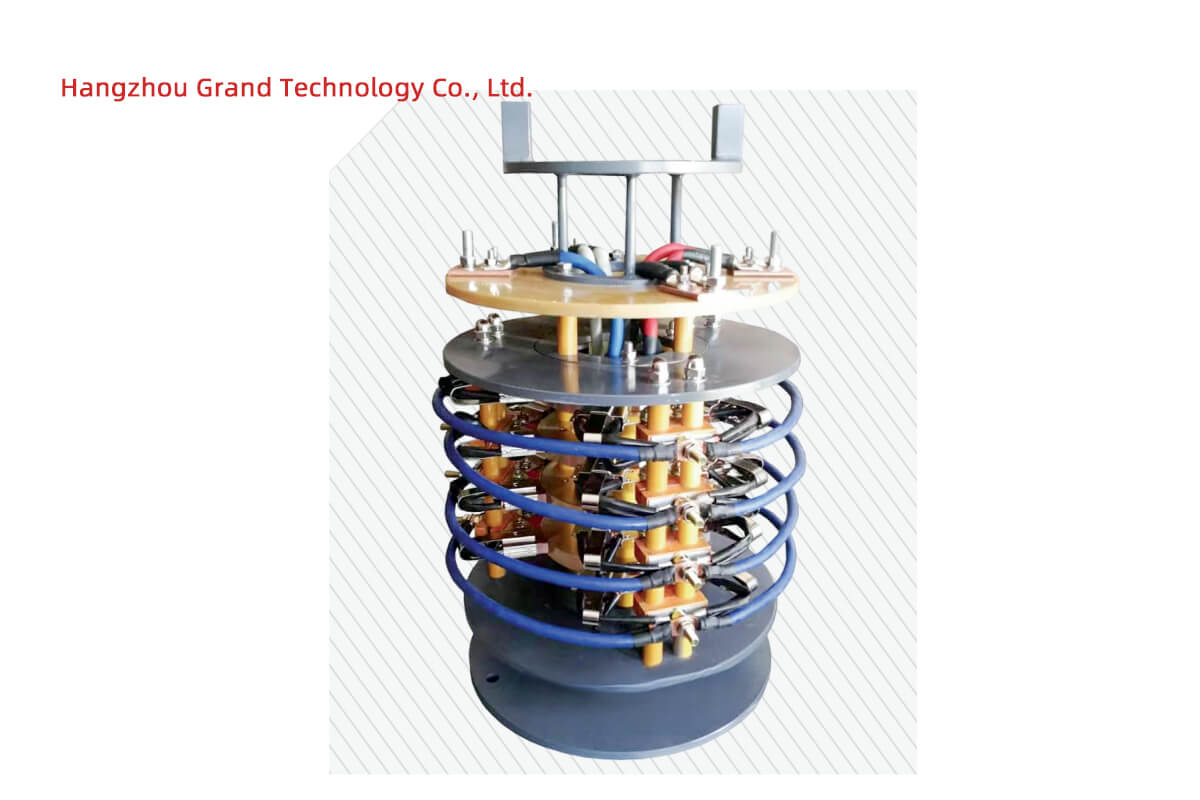

Wound rotor induction motors consist of three primary components: stator, rotor, and slip rings. The stator features an AC supply that produces a rotating magnetic field, while the rotor comprises a set of windings connected to the slip ring assembly.

The purpose of slip rings in the wound rotor induction motor is to transfer electrical power from the stator to the rotor windings. In doing so, they help maintain the magnetic field and effectively control torque, while generating smooth startup conditions for various heavy-duty applications.

When the rotor windings are short-circuited, the motor behaves like a standard induction motor. However, with the addition of external rotor circuitry connected to the slip rings, the motor’s characteristics can be finetuned to meet performance demands effortlessly. By adjusting the external rotor circuitry, the motor’s current, speed, and torque can be effectively managed, improving the overall operational efficiency.

In conclusion, wound rotor induction motors exhibit a strong bond with slip rings, as the latter plays a pivotal role in maintaining and customizing the motor’s performance to yield optimal results. They remain an indispensable component in the design of certain AC motor types, making slip rings a quintessential part of modern motor technology.

Components of an AC Motor Slip Ring

A slip ring assembly is a well-coordinated collection of components working together to ensure successful electrical continuity between a rotor and a stator in AC motors. There are three primary elements in a slip ring assembly: rings, brushes, and housing. Delving deeper into each part’s role and contribution to the assembly’s overall function reveals the intricate nature of these electro-mechanical marvels.

Slip Ring Assembly Components

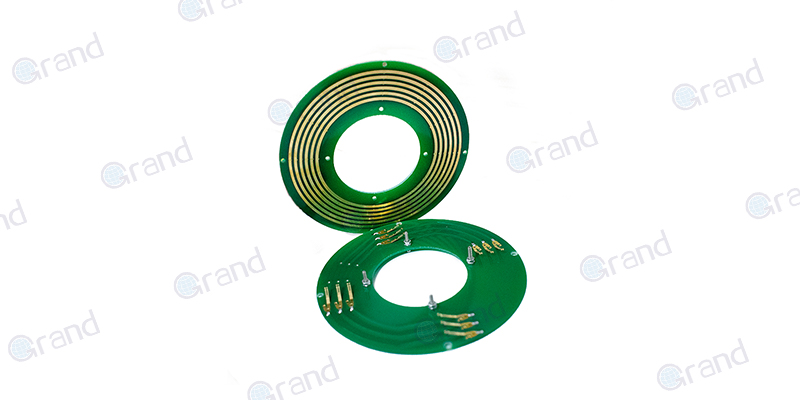

- Rings: Rings form the foundation of the slip ring assembly and are made from highly conductive materials such as brass, copper, silver, or their alloys. These materials not only have excellent electrical conductivity but also exhibit the required mechanical properties for smooth operation. The rings are mounted on an insulating core and attached to the rotating part of the motor, allowing them to carry the electrical current from the brushes to the rotor windings.

- Brushes: Brushes are the complementary counterpart to the rings, ensuring electrical continuity by maintaining physical contact with the rings. They are typically made from materials such as carbon, graphite, or metal-graphite composites, chosen to balance electrical conductivity, friction, and wear resistance. Brush systems can either employ a single brush or multiple brushes per ring, depending on the current density, motor voltage, and design requirements. The pressure applied by the brushes on the rings must be carefully calibrated to ensure optimal contact and minimal wear.

- Housing: The housing is an enclosure that serves as a protective mechanism for both the rings and brushes. Constructed from a variety of materials such as metal or plastic, the housing safeguards the slip ring assembly from debris, dust, moisture, and other environmental factors that could compromise the system’s performance. In some cases, housings can be sealed to resist harsh environmental conditions or even pressurized to prevent explosive gases from entering the assembly. The housing also provides a platform for mounting the brushes to maintain their position and pressure against the rings.

Roles in the Overall Function of Slip Rings

Each component within the slip ring assembly plays a critical role in the overall functionality. The rings act as electrical conductors, transferring electricity to the rotor windings, while the brushes ensure continuous contact and current flow between the stationary stator and the rotating rotor. The housing protects the slip ring assembly from external elements, keeping the system intact and stable.

In essence, slip ring assemblies are a fine balance of carefully chosen materials and meticulously designed components, working in harmony to maintain electrical continuity in AC motors. Their combined roles enable slip rings to deliver reliable, efficient performance, suitable for various applications across numerous industries.

Materials and Manufacturing Techniques

The choice of materials and manufacturing techniques deployed for creating slip rings and their constituent parts play a considerable role in determining the assembly’s functionality, lifespan, and overall performance. This section focuses on the common materials chosen for slip rings and brushes and the manufacturing techniques used to craft these components.

Material Choices

- Slip Rings: High electrical conductivity, durability, and wear resistance are critical requirements for materials chosen for slip rings. Often, metals like brass, copper, silver, or silver alloys, are the preferred choice. These materials not only offer excellent electrical properties but also provide the needed mechanical resilience to withstand rotational stress.

- Brushes: The brushes establish and maintain physical contact with the slip rings, thereby ensuring electrical continuity. Materials selected for this purpose must balance friction, wear resistance, and electrical properties. This balance ensures a long lifespan of the brush and minimal disruption in the electrical connection. Typical materials for brushes include carbon, graphite, or metal-graphite composites.

Manufacturing Techniques

The manufacturing of slip ring assemblies necessitates a blend of technical know-how, precision machinery, and refined techniques. Here are some commonly used manufacturing approaches:

- Machining: Machining techniques such as drilling, milling, and turning are instrumental in shaping and sizing the slip rings and their housing. These processes offer high precision and consistency.

- Surface Treatment: Surface treatments play a crucial role in enhancing the mechanical properties and electrical contact quality of slip rings. Processes such as plating, annealing, and coating are often used to improve the hardness and wear resistance as well as the electrical conductivity of the slip rings.

- Mounting: The brushes and rings must be carefully mounted to maintain the optimal contact pressure and positioning relative to each other. This mounting process often involves precision mechanisms and fasteners to secure the components in place.

Each material choice and manufacturing technique contributes to the end product’s ultimate performance. The selection of materials relies heavily on the specific application and set operational parameters of the slip ring. Similarly, the manufacturing techniques employed must ensure precision, consistency, and reliability in the final product. The intertwined nature of materials and manufacturing methods is critical to the overall functioning and durability of the slip ring assemblies.

Advantages and Limitations of AC Motor Slip Rings

An integral component of many electrical motors, slip rings play a pivotal role in enabling the transfer of electrical power from a stationary system to a rotating one. As with all technologies, AC motor slip rings come with their unique set of advantages and limitations.

Advantages of AC Motor Slip Rings

- Efficient Power Transfer: Slip rings are purpose-designed to efficiently transfer power or data between stationary and rotating parts, a task few other components can handle effectively.

- Versatility: Slip rings can be customized to meet different operational requirements, allowing them to accommodate a variety of electrical loads, speeds, and rotational directions.

- Enable Bidirectional Current Flow: Slip rings are capable of supporting bidirectional current flow, which is beneficial for alternating current (AC) systems that regularly switch directions.

- Flexible Construction: With their diverse construction options, slip rings can be designed to suit a wide array of applications, from miniature devices to large industrial machinery.

Limitations of AC Motor Slip Rings

- wear and tear: Given slip rings involve physical contact between brushes and rings, friction-induced wear is inevitable, leading to a reduction in performance over time. Periodic maintenance and brush replacements are necessary to keep the system running smoothly.

- Susceptibility to Environmental Conditions: Slip rings can be adversely affected by environmental factors such as dust, moisture, or temperature changes. Dust can cause impaired contact, while moisture can lead to corrosion—both may ultimately affect the electrical connections. However, with proper housing and sealing, these challenges can be mitigated.

- Limited Speed: Slip rings are restricted to a certain operational speed due to their construction and the need to maintain reliable contact between the brush and ring. High speeds can cause irregular contact, compromising the quality of the current transfer.

To conclude, while AC motor slip rings present their own advantages and drawbacks, their utility in enabling power transfer between static and rotational parts remains unrivaled. Realizing their full potential requires an understanding of their strengths and challenges, ensuring informed choices on design, material selection, implementation, and maintenance.

AC Motor Slip Rings Applications and Use Cases

AC motor slip rings find extensive applications across various industries owing to their unique functionality of enabling power or data transfer between stationary and rotational elements. This section delves into several real-world examples and discusses specialized slip ring solutions devised for specific applications.

Real-world Applications

- Power Generation: In wind turbines, slip rings are instrumental in transferring generated power from the rotating blades to the stationary grid connection or any other system onboard the nacelle.

- Manufacturing Machinery: Automated manufacturing systems incorporate slip rings in their rotating machinery to supply power and transmit data for rotational part control.

- Medical Industry: In medical imaging devices (like CT scanners), slip rings are employed to provide continuous power and data signals to the rotating gantry while preserving high image transmission quality. A medical equipment slip ring solution is specifically designed to meet the unique needs of such systems, ensuring reliable and uninterrupted performance. These specialized slip rings facilitate the transfer of high-resolution data from the rotating components to the stationary parts, enabling accurate image reconstruction. The medical equipment slip ring solution ensures that the CT scanner operates efficiently, maintaining optimal image quality and ensuring that medical professionals can make precise diagnoses

- Defense and Aerospace: In radar antennas and other rotating systems, slip rings supply power and transmit signals under demanding conditions like high-speed operation, and extreme temperatures.

Specialized Slip Ring Solutions

Slip rings can be tailor-made to address specific industry requirements, giving rise to specialized solutions.

- High-Speed Slip Rings: Developed for applications such as turbines and certain defense equipment, these slip rings can maintain steady electrical contact at high rotational speeds.

- High-Temperature Slip Rings: These are designed to resist thermal distortion and material breakdown in applications that experience intense heat, such as in certain aerospace and industrial settings.

- Fiber Optic Rotary Joints (FORJs): In data-heavy applications where traditional slip rings may not suffice, FORJs are used. These specialized slip rings enable the transmission of data signals with lower electromagnetic interference and offer high-speed communication capabilities.

- Mercury Wetted Slip Rings: Instead of regular brushes, these slip rings use mercury for electrical contacts, providing low electrical noise, which is critical in stringent applications, such as precision instrumentation and control systems.

To summarize, slip rings cater to a multitude of applications across industries due to their versatile nature and the possibility of customization. By understanding the requirements of specific applications, appropriate slip ring solutions can be designed and implemented, thereby optimizing system performance.

Installation and Maintenance of AC Motor Slip Rings

Proper installation and regular maintenance of AC motor slip rings are key for their efficient functioning and longevity. In the following sections, we offer a step-by-step guide for installing slip rings and provide valuable maintenance best practices to ensure their enduring performance.

Installation Process:

These general steps provide basic guidance for slip ring installation, though instructions might slightly vary depending on the specific make and model.

Step 1: Preparation

Gather all necessary installation tools and ensure that the motor is powered off before starting the installation process.

Step 2: Incorporate the Slip Ring Assembly

Attach the slip ring assembly to the rotor shaft, making sure it’s properly aligned. The assembly usually needs to be connected to the rotor or shaft mechanically, often through mounting flanges.

Step 3: Connect the Brushes

Install the brush holder assembly such that the brushes are aligned perfectly with the slip rings. The brushes should be making even and comprehensive contact with the surface of the slip rings.

Step 4: Establish Electrical Connections

Wire up the stationary part of the slip ring assembly, usually where the brushes are placed, to the electrical or control system.

Step 5: Test

Once installation is complete, run an initial test at low speed to observe any anomalies. If the motor operates smoothly and the slip rings effectively transmit power, the installation is successful.

Maintenance Best Practices:

AC Motor slip rings usually require routine maintenance, comprising periodic check-ups and brush replacements.

- Regular Inspection: A routine inspection can help detect signs of wear or damage early. Regular cleaning of the slip ring surfaces is crucial to prevent the build-up of dust or debris that might impair electrical contact.

- Brush Examination: The brushes require frequent attention as they experience wear due to their direct contact with the slip ring. Look for excessive wear, uneven wear patterns, or signs of extreme heat or arcing that may indicate a problem.

- Replacement Signs: If you observe a significant loss of commutation, it can indicate that the brushes or rings need a replacement. Furthermore, severe grooving on the surface of the slip rings, excessive noise, or sparking signifies that maintenance or replacement is overdue.

By following these guidelines, you could ensure the successful installation and optimal maintenance of your AC motor slip rings. However, always refer to the manufacturer’s guide for specific instructions and safety details. Remember, regular upkeep and promptly addressing signs of damage is key to long-lasting and efficient operation.

AC Motor Slip Rings Common Issues and Troubleshooting

In routine operation, slip rings can encounter various issues that adversely affect their performance. Understanding these challenges and being equipped with basic troubleshooting tips can mitigate their impact and prolong the slip ring system’s lifespan. This section discusses commonly encountered problems and offers potential solutions.

Common Issues:

- Excessive Wear and Tear: Normal operation of slip rings inherently causes wear on the brushes and contact surface of the ring due to friction. However, excessive wear can lead to a shorter lifespan and reduced performance.

- Inadequate Contact: An uneven or insufficient contact between the brushes and slip rings may result in unreliable current transmission. Common causes include misaligned brushes, inconsistent brush pressure, or external factors like vibration.

- Environmental Effects: Environmental conditions like dust, moisture, or temperature fluctuations can affect the slip ring system’s operation. Dust buildup leads to poor contact, while moisture can cause corrosion, negatively impacting the electrical connections.

Troubleshooting Tips and Solutions:

- Minimizing Wear and Tear: Ensuring appropriate brush pressure helps maintain optimal electrical contact while reducing friction-induced wear. Using proper materials for slip rings and brushes, along with periodic lubrication, can extend the assembly’s lifespan. Regular cleaning of the slip rings helps prevent dust or debris accumulation that could exacerbate wear.

- Addressing Inadequate Contact: Monitor and adjust the contact pressure of the brushes to achieve consistent contact with the slip rings. Regular inspection, alignment, and replacement of brushes contribute to a stable electrical connection. Reducing vibration through appropriate mounting and balancing of the slip ring system can also help maintain proper brush contact.

- Mitigating Environmental Effects: Using sealed and ventilated housings limits exposure to dust and moisture, thereby protecting the slip ring system. Selecting appropriate materials for slip rings and brushes based on the application’s environmental conditions, or opting for specialized solutions (e.g., high-temperature slip rings), ensures they can reliably perform in specific operating environments.

In conclusion, recognizing and addressing common issues in AC motor slip rings can significantly enhance their performance and durability. Regular inspections, routine maintenance, and understanding both the underlying issues and corresponding troubleshooting solutions are fundamental aspects of a robust and enduring slip ring system.

Latest Trends in AC Motor Slip Ring Technologies

In sync with the evolving technological landscape, AC motor slip ring technologies continue to witness significant advancements. Driven by the pursuit of improved performance, reduced maintenance, and a longer lifespan, these enhancements are shaping the future of slip rings.

Advancements in Slip Ring Technologies

- Wireless Slip Rings: Also known as contactless or inductive slip rings, these devices transmit power and signals between stationary and rotating parts without physical contact. Utilizing magnetic fields to achieve this transmission removes the friction-related wear and tear typical of traditional slip rings.

- Fiber Optic Slip Rings (FORJs): These technology-intensive slip rings transmit optical signals between stationary and rotating components, supporting higher data rates with minimal signal degradation and electromagnetic interference.

- Liquid Metal Slip Rings: Replacing traditional brushes with liquid metal significantly reduces friction, leading to quieter operation, longer lifespan, and minimal maintenance.

- Integration with Other Rotary Joints: Modern slip rings are often integrated with other rotary joints such as hydraulic or pneumatic rotating joints. These combo units streamline the design of complex machinery and systems that require multiple types of transmissions.

Impact of Advancements

- Improved Performance: Modern slip rings, such as FORJs or liquid metal slip rings, offer superior data transmission quality and reliability. Wireless slip rings sidestep the issue of friction-based wear, resulting in a smoother operation.

- Reduced Maintenance: Advancements like contactless slip rings or liquid metal-based versions are reducing the need for periodic maintenance, as friction-induced wear and tear are minimized.

- Increased Lifespan: With reductions in wear and tear due to the elimination of physical contact or the use of durable materials, innovative slip rings are achieving extended longevity, thereby offering longer operational life and reducing the frequency of replacements.

These latest trends in AC motor slip ring technologies are building the pathway to a future where these components deliver enhanced performance with less need for maintenance while supporting an increasingly complex array of applications. As these advancements continue, users can expect even more robust, reliable, and efficient solutions in the realm of slip ring technologies.

AC Motor Slip Rings Safety Measures

The handling, installation, or maintenance of AC motor slip rings should be accompanied by stringent safety measures. By adhering to these guidelines, you can ensure personal safety and prevent damage to the slip ring system or the larger context machinery. In this section, we discuss the critical safety protocols one must follow when working with slip rings.

Safety Guidelines:

- Electric Safety: Always switch off the power before beginning installation, cleaning, or maintenance work on slip rings to avoid electrical shocks or short circuits.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, resistant gloves, and safety shoes, to safeguard against potential hazards during handling, installing, or maintaining slip rings.

- Handling Care: Handle slip rings and brushes carefully to prevent any damage due to falls or impacts. The brushes, in particular, are delicate and can easily break or crack if mishandled.

- Ventilation: Ensure that the maintenance or testing area is well-ventilated, particularly while working with mercury-wetted slip rings or slip rings that have been lubricated. Fumes from these substances can be hazardous.

- Regular Checks: Regularly inspect the brushes and contact surfaces of the slip rings for any wear and tear. Identifying and addressing these issues promptly can prevent further damage and potential safety hazards.

- Manufacturer’s Guidelines: Always follow the manufacturer’s instructions and guidelines for installation, operation, and maintenance, which will be specific to your slip ring system’s make and model.

- Professional Assistance: If you confront an issue that you are unable to resolve, it is advisable to seek professional assistance rather than risk damaging the system or causing personal harm.

Remember, paying heed to these safety measures is not only crucial for personal safety but also plays a significant role in the efficient functioning and longevity of your AC motor slip ring system. These guidelines ensure that your interactions with these components contribute positively to the system’s overall performance and longevity.

Conclusion

AC motor slip rings serve an indispensable function in the wound rotor induction motor. A thorough understanding of their components, functionalities, and applications provides a solid foundation for grasping this technology. Keep learning and explore new advancements to stay informed and optimize your AC motor system.

FAQs about AC Motor Slip Rings

In operating and maintaining AC motor slip rings, several questions and concerns arise. This section answers frequently asked questions, providing clear and concise information to help enhance your understanding of slip rings.

Q: What are the most common causes of slip ring failure?

A: The usual causes of slip ring failure include excessive wear and tear, irregular brush pressure, misaligned brushes, dust or debris accumulation, and corrosion due to moisture exposure. Regular maintenance and inspections help prevent or address these issues in a timely manner.

Q: How often should I inspect and maintain the slip rings?

A: Inspection and maintenance frequency may vary depending on the application and operating conditions. Generally, periodic inspections should be scheduled at least once every few months for early detection of potential problems. However, harsher operating conditions might warrant more frequent checks.

Q: When should I replace the brushes or slip rings?

A: Brushes should be replaced if they show signs of excessive wear, uneven wear patterns, or excessive heat or arcing. Slip rings typically require replacement if significant grooving on the contact surface is observed or if the performance suffers considerably due to wear and tear.

Q: Can I use the same brushes for different slip ring materials?

A: No, it’s crucial to choose brushes that are compatible with the material of the slip rings. Using incompatible brushes can result in poor performance, excessive wear, and a shorter lifespan.

Q: How do I select the best type of slip ring for my application?

A: Selection should be based on factors like power requirements, the number of channels (circuits), data rates, operating temperature, environmental conditions, and the available space for installation. Consultation with an expert or the manufacturer can help determine the most suitable solution for your specific use case.

Q: What are some environmental factors to consider when choosing a slip ring?

A: Key environmental factors to consider include the presence of dust, moisture, high or low temperatures, humidity, and corrosive substances. These factors may influence your choice of materials, sealing options, and additional protective solutions like ventilated housings.

See What We Can Do