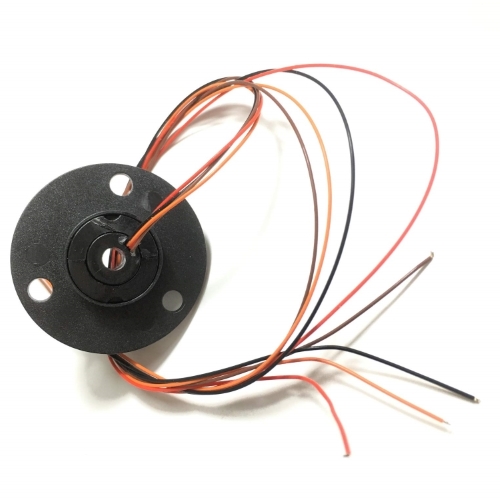

A Rotary Connector, sometimes known as a rotary electrical interface or slip ring, serves an indispensable role in various engineering applications. These specialized connectors enable the transmission of power or data from a stationary part to a rotating part, promising consistent and effective electrical performance.

What is a Rotary Connector?

Rotary connectors, also known as slip rings or rotational electrical interfaces, are specialized devices that facilitate the transmission of power and data between stationary and rotating parts in electrical systems. Picture a gadget that needs to rotate unlimited 360 degrees while still transmitting power or sending signals back and forth; that’s where rotary connectors come into play.

Though this may sound simple in essence, the technology behind it is anything but basic. At the heart of a rotary connector are the rotating and stationary parts which maintain an electrical connection between each other. The rotating contacts are connected to the rotating section of the application and spin, send, and receive electrical signals through it. The stationary part remains still and sends or receives power from the power source to the rotating contacts.

There are different types of rotary connectors available on the market, specialized for various functions and diverse environments. Broadly these can be divided into two categories – electrical rotary connectors and electromechanical rotary connectors. Electrical rotary connectors are used to transmit electrical signals such as power and data, while electromechanical rotary connectors combine electrical and mechanical functionality to transfer fluid, gas, or optical signals along with electrical signals. Each of these types comes with their specific features and benefits.

The technical aspects of rotary connectors range from basic to advanced, depending on the application. While some devices may require precise torque for smooth functioning, others may demand higher electrical capacities. Understanding the rotational speed or how fast a rotary connector can rotate without losing its transfer efficiency is crucial while selecting the rotary connector for your needs. Other technical aspects can include power and signal handling capabilities, vibration and shock resistance, and temperature range tolerance.

Finally, understanding how a rotary connector works is key. As mentioned earlier, a rotary connector’s main function is to transfer power or data from a stationary to a rotating part. To achieve this, the connector’s design contains conductive brushes that slide on a rotating ring surface when the parts move. This contact between the brush and the ring lets electrical signals pass through while the component parts move relative to one another.

By considering the detail and variety of rotary connectors, along with their precisely engineered technical aspects, we can understand their importance in a range of industries and applications.

Applications of Rotary Connectors

Rotary connectors find a wide range of uses across various industries due to their capability to facilitate power and data transmission between stationary and rotating parts.

In the industrial sector, rotary connectors are extensively applied in machinery where a part might need to rotate continually. For instance, heavy-duty rotating equipment like cranes, drilling rigs and wind turbines employ rotary connectors to transfer power from a stationary source to the rotatable part of the device.

The automotive industry is another domain where rotary connectors are central. Key applications include steering systems where rotary connectors are used to transfer electrical signals to safety systems, sensors, and airbags, from the steering wheel that needs to rotate freely.

In the aerospace sector, rotary connectors play an indispensable role. Satellites, for example, which need to align their solar panels towards the sun while orbiting, utilize rotary connectors to maintain power transfer to the rotating units. These connectors not only ensure reliable performance but also deal effectively with harsh environmental conditions in space.

Apart from industrial applications, rotary connectors find their way into everyday tools and gadgets as well. Have you ever wondered how the rotating plate in your microwave oven gets the power to spin? In such appliances, the rotary connector enables the rotating glass plate to receive power uniformly, providing evenly distributed heating. Similarly, rotary connectors are part of rotary phones, medical devices, and even your computer’s hard drive.

Looking to the future, rotary connectors present impressive application prospects. One rapidly developing application is renewable energy systems, particularly wind energy. Here, rotary connectors are fitted in wind turbines between the stationary nacelle and the rotating blades, facilitating efficient power generation. Moreover, with advances in telecommunication, rotary connectors can also find extensive usage in rotating antennas, radars, and other communication devices.

The application versatility and adaptability of rotary connectors underscore their vital role in supporting efficient and reliable functioning, whether it’s in the industrial arena, commonplace appliances, or the promising fronts of the future.

Benefits of Using Rotary Connectors

The incorporation of rotary connectors in diverse electrical applications offers several advantages and benefits that ultimately lead to smoother, more efficient, and long-lasting operations across various domains.

The use of rotary connectors ensures consistent and reliable performance in applications involving rotational motion. These connectors are designed to maintain a stable and durable connection between the stationary and rotating parts, facilitating uninterrupted power transmission or data transfer. This advantage is crucial in applications where time-sensitive or mission-critical functions are involved, such as in the medical, aerospace, or military sectors.

Durability and reliability are essential features of rotary connectors. They are typically constructed with mechanical and functional aspects in mind, aiming to withstand harsh environments, elevated temperatures, or varying air pressure conditions. This robustness allows applications like satellite systems or industrial machinery to operate reliably and effectively even in extreme operational scenarios.

Rotational flexibility is another prime benefit of using rotary connectors. They allow rotating parts to move without restrictions. For example, in vehicles, they enable the steering wheel to rotate continuously in either direction without risking disconnection or loss of electrical signals. This flexibility results in better maneuverability, usability, and safety for the users.

Rotary connectors also ensure efficient power transmission, which is fundamental for any electrical system. By offering a seamless transfer of energy, they enhance the overall efficiency of the connected devices, leading to reduced energy consumption and optimal performance.

When it comes to performance benefits, rotary connectors play a significant role in extending a device’s lifespan. By providing a robust connection and efficient power transmission, they reduce the risk of wear and tear typically associated with rotating systems. This factor, in turn, leads to lowered maintenance costs and extended operational lifespans for the devices.

In summary, incorporating rotary connectors in various applications proves highly advantageous. From providing durability, reliability, and rotational flexibility to ensuring efficient power transmission and performance benefits such as prolonged device life and minimal maintenance requirements, rotary connectors enhance the overall functionality of systems and devices. Their continued advancement and adoption in both industrial and everyday applications only reflect their indispensable value.

Factors to Consider When Selecting Rotary Connectors

Choosing the right rotary connector is crucial since an inappropriate choice can lead to inefficient operation or even premature failure of the application. This section will provide a comprehensive guide on what factors to consider when purchasing a rotary connector.

The first factor to consider is the rotational speed of the rotary connector. Different applications require different speeds; therefore, one needs to be sure of their application’s speed requirement. The rotational speed of a rotary connector is usually measured in RPM (Revolutions Per Minute) and is an important factor as it can affect the stability and performance of the system.

Next on the list is power transmission capabilities. This refers to the amount of electrical power the rotary connector can safely carry from the stationary part to the rotating unit. The power requirement would depend on the machinery or gadget where the connector is going to be used. For example, an industrial-grade machine might require a power rating that’s much higher than a home appliance.

The price of the rotary connector is also a significant factor to consider during the selection process. High-end models with advanced features can be expensive. However, investing in a costlier connector might save you money over time due to better durability and improved performance.

Durability and size are important factors too. Durability often syncs with the materials used in the connector’s construction and its capacity to withstand the wear and tear of continuous usage. Size, on the other hand, should be evaluated against the space constraint in your specific device or system.

Lastly, considering the environmental conditions in which the rotary connector will function is crucial. Whether your set-up is indoors or outdoors, in a high temperature or extreme cold, in a high vibration or stable environment, the connector must withstand all these conditions to deliver optimal performance continuously.

Once you’ve narrowed down your needs in line with these factors, you can then proceed to compare different types of rotary connectors available in the market. You can navigate through their specific features, advantages, and limitations to arrive at one that best suits your individual application’s needs.

In summary, making an informed choice while purchasing rotary connectors involves considering factors such as rotational speed, power transmission capability, price, durability, size, and environmental conditions. Assessing these factors will enable you to effectively compare and choose the most suitable rotary connector for your application, ensuring optimal performance and longevity.

Misconceptions and Commonly Asked Questions about Rotary Connectors

It’s quite common for ground-breaking technology to be misunderstood or misrepresented. Rotary connectors are no exception, and it is important to clarify some of the mainstream misconceptions related to them.

Misconception: Rotary connectors are only used in large-sized industrial machines.

While rotary connectors are frequently used in heavy-duty applications, their utility extends much beyond this. Such connectors are paramount in numerous day-to-day appliances like microwaves, computer hard drives, and even rotary telephones, apart from their extensive use in the automotive and aerospace sectors.

Misconception: All rotary connectors are the same.

Rotary connectors vary widely based on factors like construction material, size, rotational speed, power transmission capabilities, and intended environmental conditions. Therefore, it’s essential to select the one that best fits the individual application needs.

Misconception: It’s challenging to install rotary connectors.

While some applications may require professional assistance for installation due to their complexity, many rotary connectors can be installed simply and swiftly with basic technical knowledge and the right tools.

Now let’s address some of the commonly asked questions about rotary connectors:

Q: What is the functionality of a rotary connector?

A: A rotary connector’s primary function is to provide an uninterrupted path for power or data transmission from a stationary source to a rotating part. This enables gadgets or machinery to maintain full rotational freedom whilst consistently receiving power or relaying signals.

Q: Why are rotary connectors important?

A: Rotary connectors are important due to their ability to facilitate uninterrupted power or data flow in applications with moving parts. This unique functionality ensures smooth operation of devices, extending their lifespan and improving overall reliability.

Q: How are rotary connectors installed?

A: The installation of a rotary connector can vary based on the type of the connector and the application. Generally, it involves aligning the connector with the stationary part, attaching the rotating part to it, and ensuring a secure connection. Some systems might require professional installation, while others can be installed using basic tools and instructions.

In summary, understanding the realities and clarifying the misconceptions about rotary connectors can help users make more informed decisions. Just as importantly, by answering frequently asked questions, we can demystify the concept and use of rotary connectors, promoting their optimum utilization in various sectors.

How to Maintain and Troubleshoot Your Rotary Connectors

Ensuring that rotary connectors function optimally requires regular maintenance and a proactive approach to troubleshooting. This section offers insights and tips on how to extend the lifespan of your rotary connectors and address common issues that might arise.

Firstly, regular inspection of rotary connectors is key to their longevity. This involves checking for signs of wear and tear, possible loose connections, or any noticeable changes in performance. Detecting potential issues early can prevent more significant problems down the line.

Keeping the rotary connectors clean is another essential maintenance tip. Over time, dust and debris may accumulate and cause friction in the rotating parts, leading to diminished performance and a shorter lifespan. Carefully cleaning the connector with the right cleaning agents, as recommended by the manufacturer, can help maintain the connector’s functionality over time.

Ensuring that the rotation is unhindered is also necessary. Lubrication of parts can help if the connector is designed to allow it, but make sure to use manufacturer-recommended products to avoid damage.

Finally, using the rotary connector within its designed specifications (like power transmission capability and rotational speed) is crucial. Overloading or over speeding can reduce the connector’s lifespan and cause immediate technical issues.

Troubleshooting is another critical aspect of maintaining rotary connectors. Common issues include power interruptions and rotational difficulties. Here are some basic troubleshooting steps:

- Power Interruption: Check the connection between the stationary part and the rotating component. Loose or broken connections can interrupt power transfer. If you detect a loose connection, tighten it. If the connector is broken, it might need replacement.

- Rotational Difficulty: If the connector is not rotating smoothly, check for any obstructions. If none are found, the issue might be due to mechanical wear or lack of lubrication. In such a case, refer to the maintenance guide or consult a professional.

Remember, the goal should always be to prevent issues before they occur. Regular maintenance and diligent inspection of your rotary connectors can help identify and rectify potential problems early, contributing to increased device efficiency and longevity.

In summary, maintaining and troubleshooting your rotary connectors involves regular inspection, cleaning, ensuring unhindered rotation, and using the connector within its designed specifications. Understanding basic troubleshooting techniques can prevent minor issues from escalating, promoting longer, smoother operation of your devices.

Conclusion

The significance and versatility of rotary connectors can’t be overstressed. This guide should help you understand their role and choose the right rotary connector based on your specific needs and constraints. As with all technical equipment, knowing your device and understanding your requirements is the key to making the right choice.

See What We Can Do