A slip ring, or a rotary electrical joint as it is sometimes referred to, is a device that revolutionizes the way electrical power and signals are transmitted. These devices play a vital role in systems where a consistent electrical interconnection is required during device rotation.

They are meticulously engineered to allow power and signal transfer between stationary and rotating parts of a system, ensuring continuous operation with little to no interruption. They fulfill this role by creating an electrical pathway, serving as a bridge between rotating equipment and static systems.

From simple home appliances to the most advanced robotics, slip rings find their utility across a broad range of applications. They facilitate free, unhindered movement in devices that require rotational motion while maintaining the critical transmission of data or power. Notably, the variety and multiplicity of slip rings are vast, from as simple as a 2-wire slip ring to as complex as a 12-wire slip ring. This variety is pivotal in addressing diverse technological needs and accommodating the complexities associated with different systems.

The implications of their role are far-reaching. By providing reliable, stable connections in a sophisticated or even straightforward design, they have a direct influence on the overall efficiency and effectiveness of those devices. This piece will delve into the nuances of different slip rings, offering insights into the characteristics, applications, and any associated considerations to bear in mind. This knowledge is fundamental, especially when faced with the difficult task of selecting the most suitable slip ring for a particular need or application.

Individual Introductions

2-Wire Slip Ring

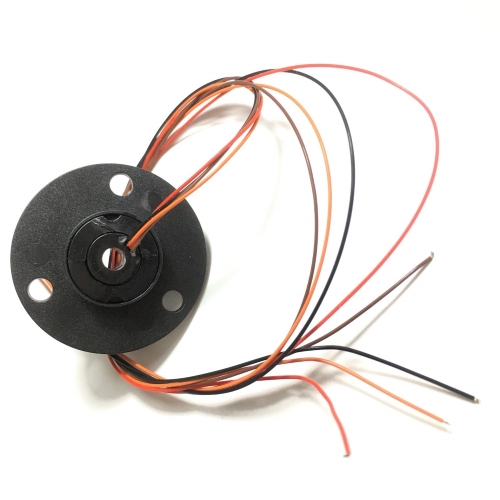

The 2-wire slip ring represents the most basic and uncomplicated configuration among slip rings. As the name implies, it contains two wires or conductors and typically forms one electrical circuit. This fundamental setup is designed to transfer power or signal between the stationary and rotating equipment in a variety of applications.

Despite its simplicity, this type of slip ring plays a critical role in many systems. Its design consists of a rotating part (rotor) and a stationary part (stator). The rotor is usually wired to the moving component of the system, while the stator is connected to the static part, creating a path for electrical signals or power supply to pass through without hindering the overall movement.

Typically, this variant doesn’t carry many channels or circuits, making it less suitable for complex applications that require multiple independent signals or power lines. However, the 2-wire slip ring does well in scenarios where only a single circuit is necessary, catering to the more straightforward transmission requirements.

The 2-wire slip ring finds its utility primarily in smaller, less complex systems. Echoing its simplicity, its applications also tend to be less sophisticated but are equally important. Small-scale wind turbines often utilize these slip rings to transfer generated power. Moreover, closed-circuit television cameras (CCTVs ) are another common place where you’ll find 2-wire slip rings. They facilitate the camera’s rotational movement while ensuring continuous data and power transmission. Precisely, any system that requires a steady transfer of power or a single set of signals during rotation will find the 2-wire slip ring a useful fit. Despite the complexity level, the overarching role remains the same: keeping devices powered and operational during rotation.

3-Wire Slip Ring

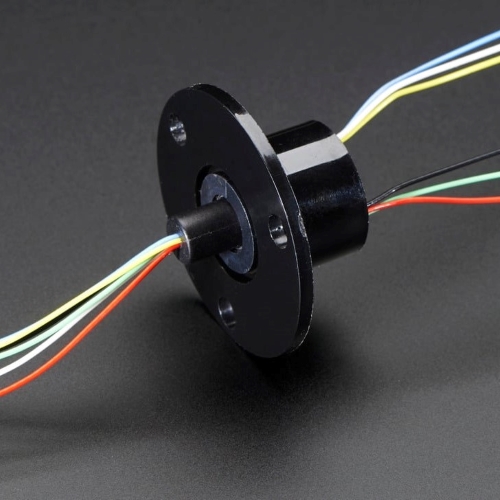

The 3-wire slip ring, another type of rotary electrical interface, marks a progression from the basic 2-wire configuration. In essence, it is a device engineered with three conductors or wires, typically enabling two separate circuit paths. This added functionality, compared to the 2-wire model, expands the scope of its applicability, placing it in a slightly more complex category.

Much like the 2-wire counterpart, the 3-wire slip ring consists of a rotor and a stator. However, the extra wire broadens the spectrum of signal or power transmissions that it can handle, offering a bit more versatility. This additional channel caters to applications that require more than one independent signal or power path, accommodating the requirements of slightly multifaceted designs.

Notwithstanding, the three conductors’ arrangement also means that the rotary electrical interface’s overall size might be slightly larger than the simpler 2-wire versions. This aspect can influence the integration of the 3-wire slip ring into various systems, but the more advanced functionality generally offsets this slightly increased bulk.

The ability of the 3-wire slip ring to handle multiple simultaneous signals and power lines renders it suitable for fairly complex systems. It aligns itself neatly with specific types of industrial machinery, which necessitate more than one circuit for successful operation. Likewise, it proves critical in telecommunications equipment, handling separate power and data transmissions. Furthermore, certain automation and control systems, which require a couple of independent signal lines, also make use of this variant of slip rings.

In the grand scheme of mechanical design and operation, the choice of slip ring—including opting for a 3-wire—will always depend on the system’s unique requirements and constraints. The objective remains constant; to ensure a constant, reliable flow of power or signals during rotary operation, contributing to overall device efficiency.

4-Wire Slip Ring

The 4-wire slip ring is a step further in complexity and versatility when compared to its 2-wire and 3-wire counterparts. Comprising four conductors or wires, it can manage up to three independent circuits. This additional capacity allows these slip rings to tackle more demanding applications and systems characterized by multiple concurrent signal or power transmissions.

Similar to other slip rings, the 4-wire variant features a rotor and a stator. The increased number of conductors, however, brings with it more sophisticated operational capabilities, thus catering better to devices that deal with multiple power and signal lines. As expected, it may also have a slightly larger size than the more basic slip rings due to this increased capacity, which is a factor that can impact system integration.

Despite its comparatively enhanced functionality, the slip ring 4 wire remains compact enough to comfortably fit into many applications, ensuring stable transfer of signals and power between rotating and stationary parts.

Given its capacity to handle multiple circuits, the 4-wire slip ring lends itself to diverse applications where several independent paths are in use. For instance, certain motors, servos, and other rotational systems require separate channels for power supply, feedback signals, and commutation signals. By accommodating these multiple channels, the 4-wire slip ring plays a pivotal role in optimizing system efficiency.

Additionally, rotary sensors often benefit from the versatility of the 4-wire slip ring. These sensors may need multiple channels for transmitting power, ground connections, and output signals, with the 4-wire slip ring efficiently serving this purpose. Furthermore, 4-wire slip rings can be found in certain lighting systems, facilitating continuous electrical connections as the system rotates.

In summary, the 4-wire slip ring presents an advanced option for devices or systems with more complex requirements. It ensures seamless operation, continued flow of power, and signal transmissions in systems that require multiple concurrent power and signal paths, ultimately contributing to improved performance and reliability.

6-Wire Slip Ring

A 6-wire slip ring, with its increased number of conductors, represents an even more advanced variant of slip rings. Featuring six internal wires, it can handle up to five distinct circuits, providing even more flexibility and capacity for handling multiple signal or power transmissions concurrently.

Comprising the standard rotor and stator configuration, the 6-wire slip ring successfully transfers electrical power or signals between the stationary and rotating parts of a system. Its ability to manage multiple circuits sets it apart, catering to quite intricate applications.

Naturally, with the increased number of conductors comes a potentially larger form factor, which might pose a consideration in terms of system integration. However, the enhanced functionality it offers, especially in systems requiring multiple concurrent connections, justifies this slight increase in size.

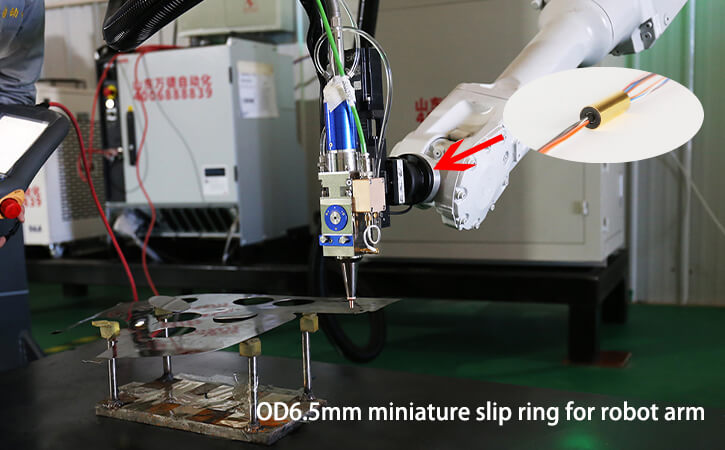

The 6-wire slip ring, given its capacity to handle several circuits simultaneously, finds its place in numerous advanced systems. Sophisticated automation setups and some robotics rely on this type of slip ring for their operations. These applications often need separate channels for power, control signals, sensor data, and actuator commands, making the 6-wire slip ring an excellent fit.

In addition to complex robotics, industrial machinery that necessitates more intricate power and signal configurations often employs the 6-wire slip ring. It might also be found in certain pan-tilt devices and surveillance systems, where the need for managing power distribution and multiple data transmission channels is essential.

In conclusion, the 6-wire slip ring is a prime choice for considerably complex applications that demand independent multiple electric circuits. As always, the goal is to provide a reliable connection during rotation, maintaining the functionality and efficiency of the system at hand.

12-Wire Slip Ring

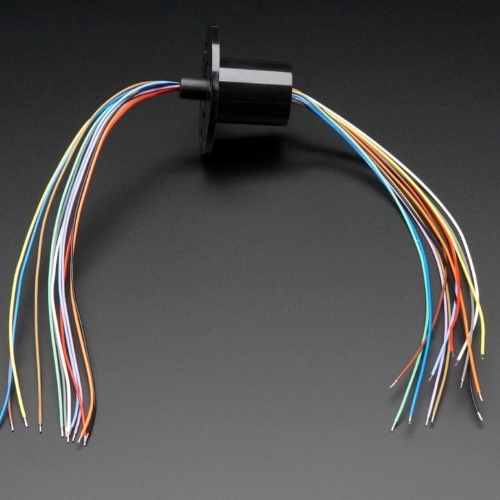

The 12-wire slip ring represents one of the more advanced and complex iterations of the slip ring family. As the term suggests, it incorporates twelve wires or conductors, paving the way for the management of up to eleven distinct circuits simultaneously. This breadth of capacity opens the doors for this type of slip ring to be utilized in numerous specialized applications, particularly where a volume of separate signal or power transmissions is required.

In line with the fundamental design of slip rings, the 12-wire slip ring features a rotor and stator. However, its advanced configuration implies a heightened ability to handle multiple circuits through the twelve wires involved. Indeed, this brings forth enhanced versatility, albeit potentially greater size and complexity, which must be taken into account when integrating it into any system.

Nonetheless, the benefits offered by the 12-wire slip ring do offset such considerations. Its complex design allows it to serve in highly intricate systems seamlessly. These include multi-channel systems that need to maintain individual signal integrity while undergoing continuous rotation.

The 12-wire slip ring is a natural fit for high-end and complex applications that necessitate multiple independent signals or power transmissions. In many advanced robots, the numerous wires can manage separate channels related to power, control signals, sensor data, and actuator commands.

Additionally, sophisticated medical imaging devices, such as CT scanners, frequently employ 12-wire slip rings to manage various signal and power channels concurrently. Another area could be high-performance industrial machinery that requires intricate power distribution and multiple data transmission paths.

Wind turbines also benefit from the multi-channel capacity of 12-wire slip rings. With numerous sensors and multiple power systems involved, this device ensures a continuous and smooth transmission of power and data across its many channels.

In conclusion, with its markedly advanced features, the 12-wire slip ring offers an optimal solution for complex applications that demand the simultaneous handling of multiple circuits. As always, the fundamental role remains the facilitation of a reliable connection and operation during rotation, contributing significantly to system efficiency and reliability.

Comparison among 2-Wire, 3-Wire, 4-Wire, 6-Wire, and 12-Wire Slip Rings

Number of Conductors

The primary differentiation among 2-wire, 3-wire, 4-wire, 6-wire, and 12-wire slip rings lies in their number of conductors or wires, which directly governs the number of circuits these devices can handle concurrently. It is essential to understand the correlation between the wires and the circuits being used in a slip ring since this dictates the slip ring’s applicability and compatibility in various systems and applications.

- 2-Wire Slip Ring: With just two conductors, the 2-wire slip ring can accommodate one independent circuit. It is a basic and cost-effective solution for connecting rotating and stationary components in systems requiring the constant transfer of power or signal between two contact points. However, it is limited to simpler applications that demand only one independent path.

- 3-Wire Slip Ring: The 3-wire slip ring increases the number of conductors to three, enabling it to manage two separate circuits. Its slightly more complex design allows for greater functionality while maintaining a compact size. This variant caters to applications that necessitate more than a single independent signal or power path.

- 4-Wire Slip Ring: A 4-wire slip ring houses four conductors, allowing up to three independent circuits to operate simultaneously. This advanced configuration makes it suitable for a wider range of applications that require multiple concurrent signals or power transmissions. Its capability to handle three circuits grants greater versatility in systems with more complex needs.

- 6-Wire Slip Ring: The 6-wire slip ring possesses six conductors, which can manage up to five distinct circuits. It is designed to accommodate more intricate and demanding applications, providing stable connections for multiple signal or power transmissions. The 6-wire slip ring is suitable for advanced systems that need several independent electrical paths.

- 12-Wire Slip Ring: Boasting twelve conductors, a 12-wire slip ring can handle up to eleven separate circuits concurrently. This highly advanced slip ring variant allows for complex and highly specialized applications requiring numerous independent signal or power transmissions. Given its multi-channel capacity, 12-wire slip rings find their place in highly intricate systems that demand multiple concurrent connections.

In summary, the number of conductors in a slip ring directly influences the number of circuits it can manage, which ultimately determines its suitability for various applications. As the number of wires in a slip ring increases, so does the complexity of the systems it can accommodate. Ultimately, selecting the appropriate slip ring depends on the unique requirements and constraints of the system in question.

Power and Signal Transmission

The ability of a slip ring to transmit power and signal depends on the number of conductors or wires present within the slip ring. As the number of wires increases, so does the capacity of the slip ring to handle a more diverse and intricate mix of signal and power transmission pathways. The following discussion details how the number of wires in a slip ring can affect the mix of signal and power transmission, which ultimately determines its compatibility and effectiveness in various applications and systems.

- 2-Wire Slip Ring: With only two conductors, the 2-wire slip ring is limited to basic applications that either require power transmission between the rotating and stationary components or a single signal transmission. Due to the restricted number of channels, it cannot handle both power and signal transmission concurrently and is best suited for applications with simpler requirements.

- 3-Wire Slip Ring: The 3-wire slip ring, with three conductors, can handle two independent circuits, enabling a mix of power and signal transmission. While still relatively simple, this slip ring can accommodate scenarios in which power and a single signal need to be transmitted between rotating and stationary parts. This makes it favorable for applications with slightly higher complexity.

- 4-Wire Slip Ring: A 4-wire slip ring, featuring four conductors, can manage up to three separate circuits. As a result, it opens the doors for more versatile power and signal transmission pathways. For example, it could handle two power channels and one signal channel (or vice versa). Its increased capacity grants it greater applicability in systems that require multiple concurrent connections while still maintaining a relatively compact size.

- 6-Wire Slip Ring: The 6-wire slip ring, containing six conductors, can accommodate up to five independent circuits, resulting in an even greater diversity in power and signal transmission combinations. Such a slip ring can maintain multiple power circuits alongside separate signal pathways, or a mixture of both, depending on an application’s requirements. It is ideal for advanced applications that demand a higher level of concurrent channels for power distribution and data transmission.

- 12-Wire Slip Ring: The 12-wire slip ring, boasting twelve conductors, can handle up to eleven distinct circuits, effectively addressing the most intricate power and signal transmission configurations. This configuration supports the concurrent transmission of multiple power and signal channels, catering to highly specialized and advanced systems. The 12-wire slip ring is particularly suitable for complex scenarios that necessitate numerous independent power and signal paths.

In conclusion, as the number of wires in a slip ring increases, so does its capacity to handle a diverse mix of signal and power transmission pathways. While a higher number of conductors offers greater versatility, the selection of an appropriate slip ring should be based on the specific requirements of the system it is intended for. Balancing the needs of the application with the performance capabilities of the selected slip ring is crucial for seamless integration and optimal performance.

Slip Ring Size

When comparing different types of slip rings, the size becomes a pivotal factor due to its impact on the slip ring’s integration within a system. The number of wires or conductors present in a slip ring largely determines its size and, as a result, its applicability and compatibility with various systems. The following discussion recounts how the number of wires in a slip ring can affect the variations in size among the 2-wire, 3-wire, 4-wire, 6-wire, and 12-wire slip rings.

- 2-Wire Slip Ring: The 2-wire slip ring, possessing only two conductors, is generally the smallest in size. It is the fundamental and simplest variant, suitable for applications with space constraints that require a compact and efficient means of signal or power transmission between a stationary platform and a rotating part.

- 3-Wire Slip Ring: The 3-wire slip ring, with an additional wire providing accommodation for a second circuit, experiences a slight increase in size. While still maintaining a rather compact profile, it offers more functionality than the 2-wire slip ring, making it a favorable candidate for situations demanding a balance between size and simultaneous transmission capacities.

- 4-Wire Slip Ring: A 4-wire slip ring, housing four conductors, sees a further increase in size to incorporate the additional functionality. Even though this increase might limit its application in space-restricted systems, the enhanced versatility due to the capability of handling up to three independent circuits balances the size consideration favorably.

- 6-Wire Slip Ring: The 6-wire slip ring is larger yet, to accommodate its six conductors and manage up to five distinct circuits. The increase in size directly relates to a significant increase in functionality. While the larger size might pose a challenge for compact installations, it is an excellent choice for advanced systems where larger space allocation is compensated by the requirement for versatile signal and power transmission pathways.

- 12-Wire Slip Ring: The 12-wire slip ring is the largest among the discussed types due to the presence of twelve conductors. Although the increase in size could potentially limit its suitability for compact systems, it provides an unmatched level of versatility and capacity through its ability to handle up to eleven separate circuits concurrently. This makes 12-wire slip rings the obvious choice for complex, high-end systems where accommodating a broad diversity of independent signal and power paths is the chief requirement.

In summary, an increase in the number of conductors in a slip ring directly contributes to an increase in its size. While a larger slip ring offers greater functionality in terms of concurrent power and signal transmission, it must be carefully chosen to ensure compatibility with the available space within a system. A balance between size, integration needs, and transmission requirements should be struck when choosing the optimal slip ring.

Advantages of Each Type of Slip Ring

2-Wire Slip Ring

- Simplicity: Easy to install and maintain due to its basic design.

- Cost-Effective: Lower cost compared to higher-wire slip rings, making it an economical choice for simple applications.

- Minimal Maintenance: Fewer components mean less wear and tear, leading to a longer lifespan and reduced maintenance needs.

- Compact Size: Typically smaller in size, ideal for applications where space is limited.

3-Wire Slip Ring

- Basic Grounding Capability: Allows for a grounded connection, which is useful in many electrical systems for safety and stability.

- Enhanced Functionality: Slightly more versatile than the 2-wire slip ring, enabling simple control and power applications.

- Still Cost-Effective: While slightly more expensive than the 2-wire version, it remains a budget-friendly option for basic systems.

4-Wire Slip Ring

- Power and Signal Transmission: Capable of transmitting both power and basic signals, making it more versatile than 2- and 3-wire slip rings.

- Moderate Complexity: Provides more functionality without significant increases in size or cost, suitable for a wider range of applications.

- Flexibility: Allows for greater flexibility in circuit design, accommodating more complex requirements.

6-Wire Slip Ring

- Increased Versatility: Can handle more complex systems with multiple power lines and signal transmissions.

- Combination of Power and Signal Handling: Offers the ability to transmit a combination of power and data signals, making it suitable for more advanced applications.

- Scalability: Provides a good balance between complexity, size, and cost, suitable for mid-range systems that require more than just basic power transmission.

12-Wire Slip Ring

- High Versatility: Ideal for highly complex systems that require multiple circuits for power, grounding, and data transmission.

- Simultaneous Transmission: Capable of transmitting multiple power supplies and data signals simultaneously without interference.

- Advanced Applications: Suitable for high-end industrial and medical applications, where reliable and complex signal handling is critical.

- Customization: Often customizable to meet specific needs, allowing for tailored solutions in sophisticated systems.

Overall Advantages Across All Types:

- Continuous Rotation: All slip rings enable continuous rotation without tangling wires, which is crucial for rotating systems.

- Reduced Wear: By eliminating the need for physical connections, slip rings reduce wear and tear on wires and connectors.

- Improved System Reliability: Slip rings increase the reliability of systems by ensuring consistent and stable connections during rotation.

- Flexibility: Available in various configurations, slip rings can be tailored to suit different application needs, from simple power transmission to complex signal handling.

Each type of slip ring offers specific advantages depending on the complexity and requirements of the application, with higher-wire slip rings providing greater functionality at the cost of increased size and complexity.

Complexity and Cost

The complexity and cost associated with different types of slip rings correlate with the number of wires each variant features. As the number of wires or conductors within the slip ring increases, so does the ability to service more channels, adding to the device’s complexity and, consequently, the cost. The following comparison offers a deeper understanding of how the number of wires influences the complexity and cost amongst the 2-wire, 3-wire, 4-wire, 6-wire, and 12-wire slip rings.

- 2-Wire Slip Ring: The 2-wire slip ring, with its basic design and one independent circuit capability, is the least complex and most cost-effective slip ring variant. Due to its simple nature, it requires less manufacturing precision and material, leading to lower production costs. This makes it a budget-friendly choice for systems with basic power or signal transmission requirements.

- 3-Wire Slip Ring: The 3-wire slip ring, capable of handling two independent circuits, adds a layer of complexity and incurs slightly higher costs. The introduction of an additional wire and circuit requires greater manufacturing precision and more material, leading to increased production costs. While offering greater functionality, it remains a relatively cost-effective solution for less complex systems.

- 4-Wire Slip Ring: The cost and complexity rise further with the 4-wire slip ring that can manage up to three separate circuits. Given the increased capacity, the fabrication requires higher precision and a larger quantity of materials, which directly affects the cost. However, the enhanced versatility it offers makes it a cost-efficient choice for more complex scenarios.

- 6-Wire Slip Ring: Featuring six conductors and managing up to five independent circuits, the 6-Wire slip ring encapsulates greater complexity reflected in higher manufacturing costs. However, the increased number of circuits it can handle concurrently offers improved functionality and versatility, rendering it a sound choice for systems needing a substantial signal or power transmission capacity.

- 12-Wire Slip Ring: The 12-wire slip ring, housing twelve conductors and operating up to eleven separate circuits, marks the epitome of complexity and cost among the discussed slip rings. With an intricate design, high manufacturing precision, and a greater need for materials, this variant comes with a higher price tag. However, considering the extensive functionality it offers, it is a valuable investment for complex, advanced systems that demand superior performance.

To conclude, while the number of wires, and hence the complexity and cost of a slip ring, increase simultaneously, choosing the right slip ring depends heavily on the specific system requirements and budget constraints. Often, the enhanced functionality and performance offered by more complex slip rings justify their higher costs. It is critical to carefully assess the demands of the system and balance them against the appropriate slip ring’s cost-effectiveness to ensure optimal performance and smart budget utilization.

Applications

Different applications and system requirements necessitate the use of varying slip rings, ranging from simple 2-wire slip rings to the more advanced 12-wire slip rings. The number of wires dictates the functionality and performance capabilities of a slip ring, thereby influencing its suitability for various applications. The ensuing discussion elaborates on how different application requirements may call for different types of slip rings.

- 2-Wire Slip Ring: Given its simple construction and lesser functionality, the 2-wire slip ring is ideally suited for basic applications involving either power or signal transmission. For instance, simple rotary tables, wind turbines, or basic electrical test equipment would benefit from this type of slip ring due to its cost-effectiveness and straightforward operation.

- 3-Wire Slip Ring: The 3-wire slip ring, with its ability to handle two independent circuits, is useful in applications requiring a simultaneous mix of power and signal transmission, but still maintaining a level of simplicity. It could be beneficial in slightly complex rotary systems, certain types of electrical generators, or moderately advanced testing machinery.

- 4-Wire Slip Ring: The 4-wire slip ring, with its capacity to manage up to three separate circuits, expands its applicability to more diverse systems. These could include more intricate robotic systems, comprehensive packaging machines, or advanced surveillance systems where independent handling of multiple signals or power channels is necessary.

- 6-Wire Slip Ring: The 6-wire slip ring, capable of managing up to five independent circuits, aligns well with more complex and versatile applications. Examples could comprise sophisticated automation equipment, multi-channel data communication systems, or advanced radar platforms, where substantial signal and power transmission paths are warranted.

- 12-Wire Slip Ring: The 12-wire slip ring, with the ability to operate up to eleven separate circuits, caters to the most complex and high-end applications. These could encompass highly advanced robotics, state-of-the-art medical imaging systems, or comprehensive telecommunications systems where a wide range of independent signal and power paths are requisite.

Slip rings are electromechanical devices that allow the transmission of power, electrical signals, or data between stationary and rotating structures. They are widely used in various industries, including heavy machinery, aerospace, wind turbines, medical devices, and robotics. The number of wires (or circuits) in a slip ring often correlates with its application, determining the complexity and functionality of the device. Here’s an overview of the applications for 2-wire, 3-wire, 4-wire, 6-wire, and 12-wire slip rings:

2-Wire Slip Rings

- Simple Power Transmission: 2-wire slip rings are often used in applications where only a single-phase AC or DC power needs to be transmitted from a stationary to a rotating part. This is common in basic rotating devices like small wind turbines, turntables, or basic rotating signs.

- Low-Complexity Devices: These are also used in low-complexity devices where minimal signal or power transfer is needed, such as in rotating video Surveillance cameras or in simple laboratory equipment.

3-Wire Slip Rings

- Three-Phase Power Transmission: 3-wire slip rings are frequently used in devices requiring three-phase power transmission, such as certain types of motors or generators. These are common in industrial equipment where the motor must rotate continuously while receiving power.

- Basic Sensor Applications: In some cases, 3-wire slip rings are used to transmit simple sensor signals, such as temperature or pressure, in rotating systems.

4-Wire Slip Rings

- Three-Phase Power with Ground: In applications where three-phase power is needed with an additional ground wire, a 4-wire slip ring is used. This configuration is often found in industrial motors and drives, where grounding is essential for safety and signal integrity.

- Data and Power Transmission: 4-wire slip rings can also be employed where power and data signals (e.g., Ethernet or simple communication signals) need to be transmitted simultaneously in low-power, low-complexity systems.

- Wind Turbines: They are used in wind turbines to transmit both power and control signals from the rotor to the control system.

6-Wire Slip Rings

- Complex Sensor and Power Systems: 6-wire slip rings are used in applications that require the transmission of power along with multiple signal types, such as data, control signals, or different sensor inputs. These are common in medical devices like CT scanners, where multiple signals and power sources need to rotate with the imaging system.

- Robotics: In robotic applications where multiple motors, sensors, or actuators are used, 6-wire slip rings allow for the transmission of power and control signals without entangling wires as the robot arm or body moves.

- CCTV and Surveillance Systems: Used in more advanced CCTV systems where multiple signals, such as video, power, and control, need to be transmitted simultaneously.

12-Wire Slip Rings

- Advanced Industrial Machinery: 12-wire slip rings are typically used in complex industrial machinery where multiple power circuits and numerous control or data signals need to be transmitted simultaneously. These are found in packaging machines, robotic arms, and automated manufacturing systems.

- Wind Turbines and Large Rotating Systems: In large wind turbines and similar systems, 12-wire slip rings are used to handle various power, control, and sensor signals, allowing for sophisticated monitoring and control.

- Aerospace and Defense: In aerospace applications, 12-wire slip rings can transmit multiple sensor signals, power, and control signals to rotating parts, such as in radar systems or satellite antennas.

- Medical Imaging Equipment: In advanced medical imaging systems like MRI or CT scanners, 12-wire slip rings allow for the transmission of high-definition data, multiple sensor signals, and power to the rotating imaging components.

In conclusion, the specific requirements and complexity level of an application largely dictate the type of slip ring best suited for its operation. Smaller numbers of wires generally align well with simpler systems, while a greater number of wires accommodates higher-end, more complex applications. The selection of the right slip ring should hinge on an in-depth understanding of the system requirements to ensure seamless operation and optimal performance.

How to Choose 2-Wire, 3-Wire, 4-Wire, 6-Wire, and 12-Wire Slip Rings

Choosing the right slip ring involves considering several factors based on your specific application needs. Here’s a step-by-step guide to help you make the best choice:

1. Determine the Number of Circuits Needed

- Power Lines: Calculate the number of power lines required. If you only need to transmit power to a rotating component, a 2-wire slip ring might be sufficient.

- Signal Lines: If your application requires data or signal transmission (e.g., Ethernet, video, or sensor data), you’ll need additional circuits. Count the number of distinct signals to determine the required number of wires.

- Grounding: If grounding is necessary for your application, ensure to include an additional wire for grounding.

2. Identify the Type of Signals

- Analog or Digital: Digital signals (e.g., Ethernet) may require specific slip rings designed to handle high-frequency signals without interference.

- Signal Sensitivity: Sensitive signals, such as those from sensors, may need a slip ring with low electrical noise.

- Power Transmission: Determine the voltage and current ratings needed for the power circuits.

3. Assess the Power Requirements

- Voltage and Current Ratings: Ensure that the slip ring can handle the maximum voltage and current of your application. Higher power needs may require more robust or multiple circuits.

- Power Type: Consider whether you need AC or DC power transmission and choose a slip ring designed for that purpose.

4. Consider the Physical Size and Space Constraints

- Size of the Slip Ring: Larger slip rings with more wires may not fit in space-constrained applications. Ensure that the physical dimensions of the slip ring match the available space.

- Mounting Requirements: Determine how the slip ring will be mounted within your system and ensure compatibility with your setup.

5. Evaluate Environmental Conditions

- Operating Environment: Consider the operating environment (e.g., temperature, humidity, dust, vibration). Some slip rings are designed for harsh environments, while others are meant for clean, controlled environments.

- IP Rating: If the slip ring will be exposed to water or dust, choose one with an appropriate IP rating (e.g., IP65 or higher).

6. Consider the Rotation Speed

- Rotational Speed: Determine the maximum rotational speed of your application. Some slip rings are designed for low-speed applications, while others can handle high-speed rotation.

- Duty Cycle: Consider the duty cycle, especially if the slip ring will be used in continuous operation versus intermittent use.

7. Assess Reliability and Maintenance

- Durability: Choose a slip ring with a proven track record of durability and long life, especially if it will be difficult to access for maintenance.

- Maintenance Requirements: Some slip rings are designed for minimal maintenance, while others may require regular inspection and cleaning.

8. Budget Considerations

- Cost vs. Features: Balance the cost of the slip ring against the features and performance it offers. Higher-wire slip rings will typically be more expensive but offer greater versatility.

- Total Cost of Ownership: Consider not just the initial cost but also the maintenance and replacement costs over time.

9. Check for Customization Needs

- Custom Solutions: If your application has unique requirements, consider whether a custom slip ring solution is necessary. Many manufacturers offer customizable slip rings tailored to specific applications.

- Modularity: Some slip rings offer modular designs, allowing you to add or remove circuits as needed.

10. Manufacturer and Support

- Reputation: Choose a slip ring from a reputable manufacturer with good customer support.

- Warranty: Check the warranty and support options, especially for critical applications.

Summary

- 2-Wire Slip Ring: Ideal for simple power transmission.

- 3-Wire Slip Ring: Suitable for basic systems requiring grounding.

- 4-Wire Slip Ring: Good for applications needing both power and signal transmission.

- 6-Wire Slip Ring: Versatile for more complex systems with multiple power and signal lines.

- 12-Wire Slip Ring: Best for highly complex applications with extensive power and signal transmission needs.

Choosing the right slip ring is about balancing your application’s electrical, mechanical, and environmental requirements with your budget and space constraints.

2-Wire, 3-Wire, 4-Wire, 6-Wire, and 12-Wire Slip Rings Other Important Considerations

Lifespan and Maintenance

The expected lifespan and maintenance needs of slip rings are essential considerations when selecting a slip ring. These aspects are often influenced by the complexity of the slip ring, with more complex types typically requiring more maintenance and care to maximize their operational lifespan. The comparison below provides insights into the expected lifespan and maintenance needs of 2-wire, 3-wire, 4-wire, 6-wire, and 12-wire slip rings.

- 2-Wire Slip Ring: The 2-wire slip ring, being the simplest configuration, often enjoys an extended lifespan given its modest operational demands. As there are only two wires, the internal wear and tear are minimal, leading to longer effective periods of operation. Maintenance needs for 2-wire slip rings are correspondingly lower due to their less complex configuration, making them easier to diagnose and repair.

- 3-Wire Slip Ring: The 3-wire slip ring has slightly increased maintenance needs owing to an extra wire and a second circuit. Although its lifespan can match that of a 2-wire slip ring under well-maintained conditions, the extra wire does add a level of complexity that can affect the longevity of the device if maintenance procedures are not adequately followed.

- 4-Wire Slip Ring: 4-wire slip rings, catering to up to three independent circuits, require regular maintenance due to their more intricate configuration. This increased complexity might slightly reduce the average lifespan compared to simpler variants. Nevertheless, proper management and maintenance can still ensure a long and productive operational life.

- 6-Wire Slip Ring: The 6-wire slip ring, with up to five independent circuits, has more components that can potentially wear down over time, translating to a higher maintenance requirement. Regular check-ups and proper preventative measures are necessary to extend its lifespan and ensure reliable performance.

- 12-Wire Slip Ring: The 12-wire slip ring, under handling up to eleven separate circuits, represents the highest complexity level and therefore needs the most rigorous maintenance routine. Due to the numerous wires and circuits, potential faults can be harder to isolate and rectify, impacting its overall lifespan if not managed adequately.

In conclusion, the complexity of a slip ring often directly impacts both its expected lifespan and maintenance needs. While simpler slip rings typically require less maintenance and tend to have extended lifespans, more complex slip rings demand more rigorous maintenance routines to ensure their reliable operation over a long period. Hence, when choosing a slip ring, it’s crucial to consider not only the application requirements but also the associated maintenance commitments and expected operational life.

Installation and Integration

The installation and integration of a slip ring into a system is an essential process that may vary depending on the type of slip ring. Issues such as the number of wires, housing design, and connector types, among other things, can make the process more complex. The nature of the system where the slip ring will be embedded can also affect the installation and integration process.

- 2-Wire Slip Ring: 2-wire slip rings are relatively straightforward to install due to their simple configuration. They fit comfortably into various systems ranging from basic wind turbines to simple rotating tables. The minimal number of wires makes integration into the system less tedious. Since there are fewer connectors, it is generally easy to keep track of the electrical connections during the setup process.

- 3-Wire Slip Ring: With an additional wire, the 3-wire slip ring is a bit more complex in terms of installation and integration. However, it can easily fit into systems that require multiple circuits but still maintain some level of simplicity, such as electrical generators or basic rotating systems. The installation process may require a bit more care to distinguish between the assigned roles of each wire.

- 4-Wire Slip Ring: Having four wires, the 4-wire slip ring demands careful attention during installation to ensure the correct assignment of each wire to the respective components within the system. This slipped ring fits well into more complex rotating systems or machines that require separate handling of multiple power or signal channels.

- 6-Wire Slip Ring: Installation of the 6-wire slip ring necessitates a keen understanding of the system configuration due to the higher number of independent circuits. Complex systems like advanced radar platforms or multi-channel communication systems that require multiple transmission paths are the ideal homes for these slip rings. Installation can be more time-consuming given the additional wiring.

- 12-Wire Slip Ring: The 12-wire slip ring represents the highest order of complexity and requires an experienced technician for its installation. Primarily seen in sophisticated robotics or comprehensive telecommunications systems, the integration process can be quite time-consuming and may require careful planning and execution due to the large number of circuits involved.

In conclusion, as the complexity of a slip ring increases, so too does the difficulty of its installation and integration. It’s crucial to understand the system requirements along with the wiring scheme of the respective slip ring to ensure successful integration. Additionally, the complexity of the slip ring should align with the sophistication of the desired system to maximize performance while ensuring proper installation.

Rotational Speed

Rotational speed represents an essential characteristic that governs the performance of a slip ring in a given system. Factors such as the number of wires, contact materials, and overall design significantly influence the rotational speed of a slip ring. Understanding how these factors link with wire numbers in various types of slip rings is crucial in selecting an appropriate slip ring for a specific application.

- 2-Wire Slip Ring: With just two wires, the 2-wire slip ring generally features the most straightforward structure, resulting in lower torque resistance compared to other types. Consequently, these slip rings can typically achieve higher rotational speeds. They are well-suited for applications where low-to-moderate speeds are required, such as simple turntables or basic wind turbines.

- 3-Wire Slip Ring: As the complexity increases with the addition of a wire, the 3-wire slip ring may exhibit a slightly higher torque resistance compared to 2-wire versions. While they can still achieve satisfactory rotational speeds, in some cases, they may fall short of the speed that 2-wire variants offer. Their ideal use case would be in systems where moderate speeds are necessary, like in some electrical generators or less complex rotating systems.

- 4-Wire Slip Ring: The 4-wire slip ring, featuring up to three independent circuits, encounters increased torque resistance due to its more complicated construction. As a result, their rotational speed may be somewhat reduced compared to simpler slip rings. However, they can still deliver adequate speeds for applications like sophisticated robotics or advanced surveillance systems where multiple power or signal channels need to be managed smoothly.

- 6-Wire Slip Ring: The 6-wire slip ring comes with an even greater level of complexity that can affect its rotational speed due to the higher torque resistance stemming from additional wires and contacts. While capable of providing reliable performance and smooth operation, these slip rings are more suited to intricate applications that demand multiple independent circuits, like multi-channel communication systems or advanced radar platforms.

- 12-Wire Slip Ring: The 12-wire slip ring, operating with the highest number of wires and greatest complexity, generally experiences the most significant torque resistance among all the slip ring types. Consequently, their rotational speed tends to be the lowest among the variants. Their optimal application is in highly advanced systems like comprehensive medical imaging devices or state-of-the-art telecommunications where numerous separate signal and power paths are necessary, even if it means sacrificing the rotational speed.

In conclusion, the rotational speed of a slip ring is highly dependent on its complexity resulting from the number of wires and contacts used. Simpler slip ring designs tend to offer higher rotational speeds, whereas the more complex variants observe reduced speeds due to increased torque resistance. Ideally, the slip ring type should be chosen based on its compatibility with the system’s desired rotational speed while considering other factors such as the number of independent circuits and overall performance.

Conclusion

Whether you select a 2-wire or a 12-wire slip ring, it all boils down to your interactive system’s specific requirements. It’s vital to balance your needs for channels, power and signal transmissions, complexity, and cost to determine the perfect fit for your applications. Using this guide, you should be better equipped to make an informed decision about which type of slip ring suits your needs best.

Need assistance with slip ring selection? Contact our experts by filling out the form.