Slip rings, particularly those crafted from copper, are key components that often slide under the radar, despite their significant importance across a plethora of industries. These small yet pivotal components, meticulously engineered mainly from copper, are at the heart of countless mechanical systems that require safe and uninterrupted transmission of electric power or signals.

Copper slip rings, owing to their high electrical conductivity and endurance against corrosive elements, have become the bedrock for many sectors. They have infiltrated an extensive array of industrial applications, ranging from wind turbines and manufacturing assembly lines to cutting-edge medical imaging devices and advanced aerospace and defense systems. This attests to their versatility and indispensability, propelling these humble components to an elevated status in the world of machinery and equipment.

Delving into the raison d’être of a slip ring, we discover that its primary role is to provide seamless electrical connections between stationary and rotating parts in a system. This is vitally important for devices that need to rotate continuously or intermittently while maintaining electrical continuity. Without slip rings, managing revolving equipment, and harnessing the potential of rotational motion in various applications, would be exceedingly complex, if not downright impossible.

Essentially, imagine a system where a component must rotate while processing power, data, or signals from a static structure. Conventional wiring methods would be vulnerable to twisting and tangling, eventually leading to wire fatigue and consequent failure. Enter slip rings—which do away with this predicament. These devices house conductive bands (male part) that rotate with the device, while brushes (female part) maintain a consistent stationary contact. This complete system ensures an unbroken flow of electricity throughout the rotation, ensuring optimal performance of the whole machinery.

In a nutshell, copper slip rings bridge the gap between stationary and moving parts, allowing for the uninterrupted transmission of electrical power or signals. Their role is like that of a skilled conductor, seamlessly orchestrating the various sections of an orchestra, each moving to its unique rhythm, yet all flawlessly in sync to create a harmonious symphony of power transmission.

Advantages of Copper Slip Rings

Unveiling the reasons behind the widespread use of copper in slip rings takes us to a world of inherent advantages that this reddish-brown, ductile metal imparts. Backed by a long history of use in electricity transmission and generation, copper hails as a stalwart ready to handle the demands of rotating electrical connectors.

The first and foremost benefit of copper slip rings, placing them in pole position in the race of electrical components, is their superior electrical conductivity. Copper ranks only second to silver regarding electrical conductivity, but due to silver’s high cost and scarcity, copper has emerged as the preferred conductor for most industrial and domestic uses. From the perspective of slip rings, this property translates into efficient power transmission with minimal power loss.

Whether you are powering a heavy-load industrial machine or transmitting sensitive signals in an advanced electronic device, electrical efficiency is paramount, and copper slip rings deliver precisely that. The high conductivity ensures a free and effortless flow of electrical currents across the slip ring assembly, conveying energy from stationary to rotating parts without significant voltage drops or wastage, optimizing the system’s overall electrical performance.

Apart from excelling in electrical conductivity, copper impresses with its admirable resistance to high temperatures and corrosion. It is a well-accepted fact in the realm of electrical and thermal applications that devices should withstand the heat and corrosive conditions they could be exposed to during operation. Here, copper plays a starring role.

Copper boasts a high melting point, roughly 1085°C, and excellent heat dissipation characteristics, making it capable of withstanding the heat generated during continuous electrical transmission. This ensures the integrity of copper slip rings even under intense operational scenarios, marking a direct contribution towards the durability and longevity of the assembly.

Similarly, copper demonstrates resistance against environmental corrosion, reducing concerns about degradation due to humidity, oxidation, or other corrosive processes. This characteristic makes copper slip rings suitable for a wide range of conditions, thereby widening their field of applications.

Incorporating these inherent strengths of copper, slip rings make for potent enablers in any electrical setup revolving around rotational machinery. They embody the advantages of copper’s superior electrical conductivity as well as its capacity to resist high temperatures and corrosion, offering a reliable, efficient, and resilient solution – all key factors in maintaining constant and uninterrupted connections in rotating equipment.

Applications of Copper Slip Rings

In the journey of exploring the realm of copper slip rings, we now venture into real-world applications where these components flex their muscles. As we proceed deeper, it becomes increasingly clear that copper slip rings are omnipresent across a wide spectrum of industries, exhibiting their prowess in countless operational scenarios.

One of the main arenas where copper slip rings champion is the energy generation sector—specifically, wind turbines. These green energy generators rely heavily on the mechanism of rotation to convert wind power into electricity. Copper slip rings play a critical role in this process, transmitting generated electricity from the rotating blades to the stationary system for storage or distribution.

Additionally, the manufacturing industry is yet another significant beneficiary of these copper devices. Automated assembly lines, high-speed bottling plants, packaging systems, and other rotating machinery prominently feature copper slip rings. In each of these applications, copper slip rings enable seamless transmission of power, ensuring that production processes run continuously and efficiently.

The field of communication and data transfer also reaps the benefits of copper slip rings. In radar systems, for instance—whether aviation-related or meteorological—copper slip rings facilitate the rotation of the antenna, ensuring uninterrupted data flow during constant 360-degree motion, thereby aiding real-time information transfer.

Furthermore, the world of medical imaging technologies including MRI and CT scanners heavily relies on copper slip rings. These devices, which spin around the patient’s body generating images, need continuous power supply and data transfer. Copper slip rings bridge the gap between the rotating and stationary parts, allowing for detailed, real-time imaging that can uncover medical conditions for treatment.

In the same vein, advanced defense systems and aerospace applications also deploy copper slip rings to achieve similar functionalities. Copper slip rings find application in military radar systems, missile launchers, and even in gimbal systems for aerial photography and videography.

The importance of copper slip rings in these diverse applications cannot be overstated. Their primary role—creating a reliable electrical link between rotating and stationary components—becomes paramount in systems where halting rotation for any reason could be costly or even dangerous. Copper’s superior electrical conductivity ensures low resistance and efficient power transmission, while its high-temperature resistance and toughness make it durable and reliable, even in high-demand situations.

Moreover, the unique properties of copper, such as its corrosion resistance, make copper slip rings ideal for harsh environments like seafaring vessels and outdoor turbines, exhibiting their ability to deliver effective performance across different industry applications under varying conditions.

In a nutshell, copper slip rings, with their attributes of durability, efficiency, and resistance align perfectly with the diverse demands of various industries, thereby exemplifying the ability of this versatile device to adapt, perform, and excel.

Types of Copper Slip Rings

As we delve further into the universe of copper slip rings, we encounter a diverse range of these devices, each designed to cater to specific applications and requirements within various industries. Broadly, copper slip rings can be classified into three primary types: pancake, capsule, and miniature slip rings. Each of these types manifests distinct characteristics to address unique challenges and offer fitting solutions for different scenarios.

Pancake Copper Slip Rings

Pancake copper slip rings derive their name from the flattened, disc-like shape they possess. Unlike cylindrical slip rings where conductive tracks are located along the circumference, pancake slip rings feature copper tracks on a flat surface resembling a thin round cake. The brush holder assembly, fitted with the brushes, presses against these tracks creating a stable electrical connection.

This flat configuration significantly reduces the axial length of the device, making pancake slip rings ideal for applications where axial space is limited, such as robotics and camera systems. Despite their compact nature, pancake slip rings offer high current-carrying capacity and, depending on the design, can handle a broad range of currents and voltages.

Capsule Copper Slip Rings

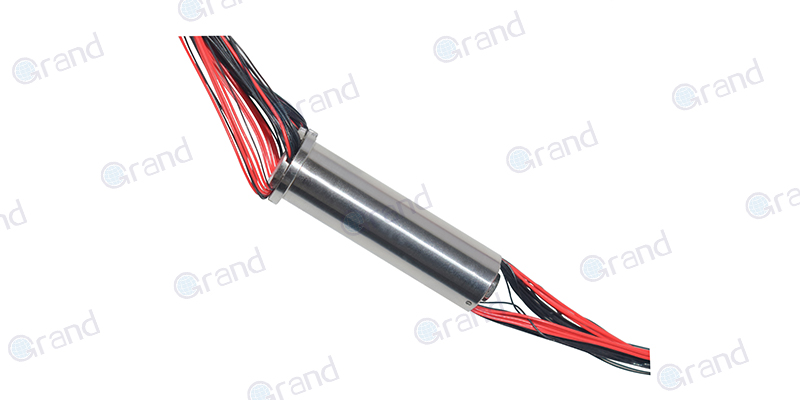

Capsule copper slip rings feature a unique, low-profile design that encompasses a fully enclosed, cylindrical housing. Inside the housing, conductive copper tracks are positioned along the circumference of the capsule, with brushes placed nearby to maintain a reliable electrical connection during rotation.

The prime advantage of capsule slip rings is their compact design, which is perfect for those applications where size constraints are at a premium. They are frequently used in medical devices, security cameras, and smaller wind turbines, among other applications. Although their compactness might limit their current-carrying capacity, they are well-suited for transferring signals and low-voltage power.

Miniature Copper Slip Rings

The miniature copper slip rings, as the name implies, are smaller in size compared to their traditional counterparts. These tiny slip rings have been designed keeping in mind the ever-shrinking sizes of modern electronic devices and the need for smooth electrical connections in rotating systems. Miniature slip rings offer all the benefits of copper, but in a condensed package that can easily be fitted into small devices without real estate issues.

Typical applications for miniature copper slip rings include medical equipment, robotics, test equipment, and RC vehicles, among others. Although their size is small, these slip rings deliver adequate power transfer and signal transmission capabilities, making them a popular choice for compact machinery with rotating components.

In conclusion, the varied types of copper slip rings—pancake, capsule, and miniature—each cater to specific requirements posed by different applications. By carefully evaluating the space limitations, current and voltage needs, and specialized conditions, you can determine the best type of copper slip ring that matches the unique demands of your industry. Rest assured, with the right choice, these copper-centric components will deliver optimal performance and reliability, making the most of your rotating machinery.

Copper Slip Rings: Installation and Maintenance

Given the vital role copper slip rings play in the smooth operation of a multitude of systems, it is critical to install and maintain them correctly. A well-installed and properly maintained slip ring can drastically elevate the performance and longevity of the connected system, marking its significant role in equipment upkeep.

Installation of Copper Slip Rings

Before beginning the installation process, it’s important to have a clear understanding of the equipment and its specific operational requirements. Understanding the rotational direction, speed, environmental conditions, and temperature variations can guide you to install the copper slip ring effectively.

During installation, it is imperative to ensure the concentricity of the slip ring with the rotating shaft. This alignment is crucial for maintaining a constant distance between the brushes and the contact surface, which in turn ensures stable transmission of electrical signals or power.

When connecting the wires to the slip ring, ensure that their weight or tension does not put extra stress on the slip ring. Securely attaching the wires can prevent them from tugging at the slip ring, which can lead to premature wear, malfunction, or even damage.

If the slip ring is designed with a protective cover or housing, make sure it is securely fastened after installation. This cover ensures dust, water, or other damaging particles do not enter the slip ring assembly, protecting its performance and functionality.

Maintenance of Copper Slip Rings

Routine maintenance of copper slip rings is essential for their optimal functioning over an extended period. As a starting point, regularly inspect the contact surface of the slip ring (the area where the brushes rest on to transmit power). Over time, these surfaces may develop wear spots. If any such spot is found, polishing the surface gently with fine abrasive paper can solve the problem.

The brushes that make contact with the copper surface should also be regularly checked for wear and tear and replaced when necessary. They apply a steady, even pressure on the slip ring, which is critical to maintaining a good connection.

If your copper slip ring operates in a particularly harsh environment, periodic cleaning should be performed to remove any accumulated dust or debris. However, always use a cleaner suitable for copper and be cautious not to leave any residual cleaning agent on the slip ring which might affect its performance.

Lastly, maintaining documentation related to maintenance history can be helpful. This log may include details of any repairs, brush replacements, or other events, thereby providing valuable insights during future inspections or troubleshooting.

Adopting these installation and maintenance practices can significantly enhance the performance and longevity of your copper slip rings. They not only encompass technical aspects of handling the device but also foster the habit of regular maintenance and inspections, thus ensuring the reliability and efficiency of your rotating machinery.

Key Factors to Consider When Choosing Copper Slip Rings

The choice of an appropriate copper slip ring is paramount in ensuring the efficient operation of your rotating machinery. This process involves more than merely selecting a device that aligns with the system’s space requirements—it means a careful assessment of several crucial factors that collectively dictate the suitability, reliability, and performance of the slip ring. Among these factors are design, load capacity, operating temperature, and degree of protection.

Design

The design of a copper slip ring significantly impacts its applicability. This encompasses not only the physical dimensions—like the diameter and axial length—but also includes aspects like the type (pancake, capsule, or miniature) and number of channels. For instance, a miniature slip ring may suit compact systems, whereas a high-channel pancake slip ring might be required for complex, high-load machinery. The design must also cater to mounting requirements and, if necessary, adaptations for special environments such as outdoors or underwater.

Load Capacity

Load capacity pertains to the amount of electric current that the slip ring can reliably transmit. This depends largely on the copper track design and the brush material. High-power applications will require slip rings with a high current carrying capacity, while low-power signal transmission might only need smaller, compact slip rings. It’s crucial to understand the current needs of your system to make an informed selection.

Operating Temperature

The operating temperature that the slip ring can withstand without performance degradation is another vital consideration. Elevated temperatures can cause material warp, loss of spring pressure in the brushes, and even meltdown in extreme cases. Therefore, you must choose a slip ring that can handle the maximum temperature possible in your system environment. Thanks to copper’s high thermal conductivity, copper slip rings are usually a safe choice for varying temperature conditions.

Degree of Protection (IP Rating)

The Ingress Protection (IP) rating indicates the slip ring’s degree of protection against solid objects and liquids. This is especially important for slip rings intended for harsh environments—like outdoor systems or seafaring vessels—which may be exposed to dust, water, and other damaging elements. For example, a slip ring with a high IP rating may be required for marine applications, whereas indoor applications might only need a lower rating.

Application Alignment

With the understanding of these factors, it is critical to match your chosen copper slip ring with the specific context of your application. Every scenario presents unique challenges—space constraints, load variations, environmental conditions, and operational demands—that the slip ring must competently address. Therefore, it’s essential to correlate your application requirements with the potential slip ring’s attributes.

In summary, the selection of an appropriate copper slip ring requires a sound understanding of your system needs and the potential slip ring’s capabilities. Considering key factors like design, load capacity, operating temperature, and degree of protection can guide you in mapping your requirements to a suitable slip ring. This thoughtful approach not only bolsters the system’s efficiency and reliability but also extends the operational life of your setup, ensuring maximum return on your investment.

Copper Slip Rings: User Reviews and Experiences

The perspectives of users who regularly interact with copper slip rings can offer invaluable insights into their real-world performance, limitations, and areas for improvement. Understanding both positive and negative reviews not only leads us towards making better selections for our applications but also encourages manufacturers to address reported issues.

Positive Reviews

Many users appreciate the durable nature of copper slip rings, frequently highlighting copper’s robustness and resistance to wear. A common compliment is their high-performance capabilities in terms of load capacity and efficient power transmission. Users note that these advantages have a positive impact on the overall efficiency of their equipment, reducing downtimes and enhancing operational reliability.

Another commonly lauded aspect is the various versatile designs of copper slip rings, catering to an array of spaces and application requirements. Their adaptability to different environments—ranging from pancake designs for space-constrained systems to high IP-rated models for unforgiving conditions—is frequently cited as a significant advantage.

Negative Reviews

Despite the numerous advantages, copper slip rings are not without their potential issues. Some users report occasional electrical noise or signal disruptions. This could be due to material wear, improper brush pressure, or the influence of surrounding electromagnetic fields. Regular maintenance and shielded cables may help address these issues.

In certain high-speed applications, users remark on excessive heating of the slip rings. Excessive rotation speed can result in frictional heating that might exceed the slip ring’s permissible temperature range. This could be mitigated by selecting slip rings designed for high-speed operations or installing cooling mechanisms.

A few users also note the need for regular maintenance in particular environments or heavy-duty usage conditions. For instance, brush and contact surface wear or accumulation of dust and particles can influence their performance over time. Adequate maintenance routines and installations in protected environments can reduce these issues.

Addressing Common Issues

Understanding these reported issues can influence future design improvements and user practices. Regular maintenance checks, appropriate slip ring selection suited to specific working conditions, and proper installation can mitigate several of these issues. Additionally, maintaining an open dialogue with the slip ring manufacturer can yield problem-specific solutions and advice.

In essence, user reviews and experiences shape our understanding of copper slip rings in practical applications. They provide real-world insights into the device’s strengths and weaknesses and guide us toward rewarding choices in copper slip ring utilization. They also prompt manufacturers to evolve their designs, pushing towards maximizing the advantages and minimizing the disadvantages of these indispensable components.

Copper Slip Rings: Pricing and Availability

Copper slip rings’ pricing and availability diversely range and are influenced by multiple factors, like the design, load capacity, IP rating, and the reputation of the manufacturer. Additionally, the overall cost bears a significant relation to the chosen material and is often supported by warranties and after-sales services provided.

Where to Purchase and Price Range

Copper slip rings can be procured from a variety of sources. For industrial users or businesses, renowned manufacturers and suppliers of electromechanical components often market their products through direct sales channels or authorized distributors. In addition, online marketplaces like Amazon, Alibaba, and eBay serve as accessible platforms where individual users or smaller businesses can find a wide range of slip rings catering to their needs.

As for the price, copper slip rings have a broad span due to their varying design specifications. A simple low-load copper slip ring might range anywhere from a few tens of dollars, while large, custom-designed copper slip rings for industrial applications can run into hundreds or even thousands of dollars.

Comparison with Other Materials

Compared to slip rings made of other materials like silver or graphite, copper slip rings tend to offer a balanced blend of performance, durability, and cost. Silver slip rings, though offering slightly superior electrical conductivity, often come at a substantially higher price. On the other hand, graphite, while cheaper, doesn’t match up to the electrical performance and longevity of copper slip rings. Therefore, copper slip rings often present a cost-effective solution for users who seek excellent performance without a colossal investment.

Warranties and Customer Support

Many reputable manufacturers offer warranties on their copper slip rings, providing confidence and a safety net for customers in case of product failure or manufacturing defects. The length of the warranty period generally varies and is commonly up to one year, depending on the product and the amount it is used.

Moreover, manufacturers understand the importance of after-sales support. Hence, they often provide robust customer service that includes installation guidance, maintenance and troubleshooting advice, and even training. This support augments user confidence and ensures seamless operation of the product, securing a beneficial customer-manufacturer relationship.

The pricing, availability, and after-sales services of copper slip rings are a crucial part of the purchasing decision. By understanding what to expect in these areas, prospective buyers can make an informed choice that balances their performance requirements with their budget, ensuring a rewarding, long-term investment.

Conclusion

In essence, copper slip rings, with their superior features and far-reaching applications, are a force to be reckoned with in the world of electrical connections for rotating machinery. They invite you to explore, understand, and adopt them for your specific requirements, setting the stage for unmatched functionality and efficiency.

See What We Can Do