The story of slip rings began many moons ago, with simple yet innovative devices that found their humble place within the broader electrical engineering sphere. As rotary, electro-mechanical interfaces, slip rings ingeniously solved the problem of passing electrical signals or power between stationary and rotating components, a feat otherwise laden with complexities.

Emerging from this lineage are high power slip rings, advanced configurations designed specifically for high current transmissions. These high-power devices marry power and precision, providing an uninterrupted, stable electrical connection even while transferring substantial electrical power. Unhindered by continuous or intermittent rotational motion, they facilitate the ‘slipping’ through of powerful electrical signals, thus inspiring the moniker ‘slip ring’.

The journey of high-power slip rings has been one of remarkable evolution and improvement. From being mere prototype concepts in laboratories to their present-day advanced versions, they represent years of meticulous research, engineering prowess, and relentless technological advancement. Their contemporaries boast enhancements that optimize data transfer rates, minimize loss and noise, maximize longevity, and comply with stringent safety standards.

Today, high-power slip rings have assumed significant roles in the grand scheme of technological silhouettes, their applications spanning the length and breadth of industries. In every space where the seamless transmission of substantial amounts of power within a rotating interface is required – be it manufacturing units, communication technologies, medical equipment, or aerospace engineering – they unfailingly leave their impactful imprints. The multifaceted functions of high-power slip rings thus decidedly place them as driving forces in the modern technological narrative, and the story is only set to get more exciting with future developments.

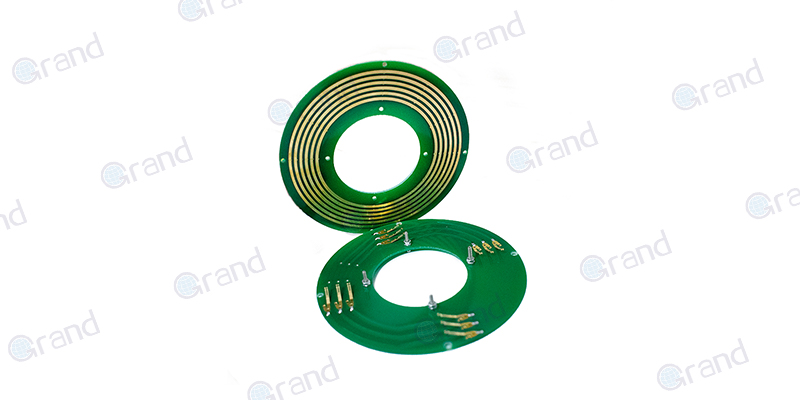

Basic Structure of High Power Slip Rings

Seamlessly powering the motion of essential machines, a high power slip ring may seem intriguingly complex at first glance. However, if we delve deep into the heart of this device, it becomes less of a labyrinth, thanks to an elegant design that incorporates a handful of core components playing prescript roles.

At the center of any high-power slip ring is the concentric arrangement of conductive rings, or the slip ring itself. This primary component is accompanied by brushes – conductive pieces that maintain contact with the rings – and holds a critical function in transferring electrical power between the stationary end and the rotating assembly. Essentially, as the assembly rotates, the stationary brushes glide over the rings, thereby establishing an electrical connection between the revolving and the stationary side.

Premium materials known for their high electrical conductivity and durability constitute the fabric of high power slip rings. Copper and its alloys, often the materials of choice for conductive rings and brushes, provide robust conductivity, while other elements like silver, gold, or even precious metal alloys might be used based on specific requirements. The casing, built from various durable and wear-resistant materials like stainless steel or aluminum, ensures the entire assembly rests within a sturdy, protective housing.

Each component of the high-power slip ring plays a unique part in facilitating an uninterrupted power transmission despite rotational motion. At the heart of its operation, the conductive rings and brushes orchestrate the main power transfer. As the slip ring aligns with the brushes, the electrical signals or power from a stationary source pass through the brushes onto the rotating rings, and from there to the rotating machinery.

Whether the rotation is continuous or intermittent, the transmission remains steady. With all elements working in concert – the conductor rings carrying the power, the brushes ensuring effective transfer, and the hardy housing protecting it all – the seemingly complex system actualizes smooth power delivery in this simple yet effective manner.

Working Principle of High Power Slip Rings

To truly appreciate the operation of a high-power slip ring, one must journey through the inner workings of this innovative device. Comprising relatively simple principles of physics and engineering, the device ensures a delicate dance of electrical and mechanical connections, providing the means for uninterrupted power transmission amid constant rotation.

At its core, the operational mechanism mirrors the tried-and-tested approach of using conductive materials to transmit electric power. In an ideal state of rest, stationary and rotating entities cannot exchange electrical power due to their relative movement. However, by creating a conductive bridge connecting these entities, the high power slip ring makes this seemingly impossible exchange, a vivid reality.

This process arises from a delicate blending of electrical and mechanical science. The electrical connection is realized when the power passes through the brushes onto the conductive rings. The brushes — stationary themselves — remain in continual contact with the rotating slip ring. Thus, as the power is fed into the brushes, they transfer it to the rotating conductive rings which are electrically connected to the moving part of the system.

The uninterrupted transmission of power through these slip rings is precisely where the marvel of mechanical science comes into play. To retain continuity of power, the brushes need to maintain constant contact with the conductive rings, even during rotation. Achieving this requires a brush assembly designed to accommodate the rotational motion of the conductive ring, ensuring a non-stop passage of power regardless of the revolution or speed of the ring.

In essence, it’s this perfect harmony between electrical and mechanical systems that distinguish high power slip rings. This symphony, showcasing intricate physics and engineering marvels, ensures uncompromised power transmission, intrinsically safeguarding against interruptions due to rotation. It is this symbiotic blending of different branches of science that allows high-power slip rings to function as a crucial technological pillar in a host of industries.

Types and Variations of High Power Slip Rings

Meeting the demands of diverse industries, high-power slip rings have matured into a spectrum of types, each with its characteristics tailored for specific situations. With varieties ranging from hydraulic, pneumatic, electrical, and fiber optic to mixed-technology slip rings, understanding their unique attributes and applications is key to making informed choices for specific tasks.

Hydraulic Slip Rings

High-power hydraulic slip rings cater to the unique requirement of hydraulic systems by facilitating the continuous flow of high-pressure fluid between stationary and rotating components. Capable of enduring elevated pressure levels, these slip rings ensure seamless operation of hydraulic machinery. While this type is suited for applications necessitating hydraulic transmission, its utility in context with other forms of transmission falls short.

Pneumatic Slip Rings

Similarly, high-power pneumatic slip rings enable the transfer of compressed air or gas across stationary and rotating parts. In industries reliant on pneumatic systems, these slip rings offer a reliable solution, ensuring smooth operation. However, much like hydraulic slip rings, their usefulness is limited when applied to non-pneumatic transmissions.

Electrical Slip Rings

These types of slip rings are explicitly engineered to transmit high currents amid rotation. Electrical slip rings provide a stable and efficient medium for high-power electrical transfer. While versatile and commonly used across industries, they do not cater to requirements such as data transfer or fluid transfer, which may be necessary for particular applications.

Fiber Optic Slip Rings

Fiber optic slip rings, also known as FORJs (Fiber Optic Rotary Joints), adeptly handle the transfer of optical signals between stationary and rotating components. Boasting minimal signal loss, high-speed data transmission, and resistance to electromagnetic interference, FORJs have cemented their place in communication and defense systems. However, their sole focus on data transmission leaves a gap in contexts requiring high power transfer.

Mixed-Technology Slip Rings

Bridging the gaps between specialized slip rings, mixed-technology variants deliver an all-encompassing solution by integrating different transmission forms into a single device. Often custom-built, these slip rings prove ideal in scenarios where multiple types of connections are needed, encompassing high-voltage electrical power, low-voltage signals, fluid transmission, or optical signals.

No single type of high-power slip ring is a one-size-fits-all solution; each comes with specific advantages and limitations. By analyzing the distinct attributes of hydraulic, pneumatic, electrical, fiber optic, and mixed-technology slip rings, and understanding the ideal scenario for each, users can align their requirements with the appropriate slip ring designs to realize seamless and efficient operations.

Advanced Technologies in High Power Slip Rings

The realm of high-power slip rings has seen considerable advancements in recent years. These technological strides contribute to fostering more efficient, durable, and performance-enhancing slip rings, thus perpetually redefining the boundaries of what these devices can achieve.

In keeping with the digital era, data-capable slip rings have emerged, integrating Ethernet or other data transmission capabilities with traditional power transfer mechanisms. This feature forms a critical enhancement, allowing new applications in areas such as real-time monitoring, remote control, and seamless data transmission within a rotating interface.

The use of new materials plays a significant role in enhancing the durability and performance of high-power slip rings. For instance, the use of fiber brushes has seen increasing popularity due to their advantageous properties; they create minimal electrical noise, offer low contact resistance, and are more durable than traditional brush materials. In addition, advanced alloys with superior conductivity and durability are now utilized for constructing slip rings, enhancing operational longevity.

Advancements in precision engineering have led to more compact and efficient designs. The miniaturization of high-power slip rings allows their application in more space-constrained environments without any detrimental impact on their performance or power capacity.

The arrival of wireless slip ring technology presents a notable leap forward. Utilizing magnetic fields to transfer power wirelessly between rotating and stationary components, wireless slip rings eliminate mechanical wear and tear induced by a physical connection, thus enhancing the lifetime and reliability of the device.

Lastly, integrated units that combine different kinds of transmission—known as mixed-technology slip rings—have grown more advanced, capable, and customizable. They can now combine power, signals, data, and fluid or gas transfer in precise configurations for any given application.

The recurring theme behind these technological developments is a persistent drive for better performance, enhanced efficiency, and increased durability. By integrating new technologies into their designs—whether it’s adopting novel materials, advancing design techniques, or syncing with digital trends—high power slip rings continue to evolve and become an even more indispensable technological cornerstone across wide industry sectors.

Applications of High Power Slip Rings

The array of high-power slip ring applications proves just how versatile these electromechanical devices are. With tailored designs available to meet the needs of differently demanding sectors such as aerospace & defense, renewable energy, heavy machinery & manufacturing, medical equipment, robotics, and marine applications, high-power slip rings have found a crucial role across varied industrial landscapes.

Aerospace & Defense

In both aerospace and defense sectors, the need for reliable, high-quality data and power transmission is crucial. High-power slip rings are often integrated into radar systems, ensuring a continuous power supply and data transmission while the radar antenna rotates. A noteworthy example is satellite communication systems, where signal and power transmission between the stationary base and the orbiting satellite is accomplished using an advanced combination of electrical and fiber optic slip rings.

Renewable Energy

In the rapidly growing field of renewable energy, particularly wind turbines, high-power slip rings are employed to transmit power from the rotating blades to the stationary grid. The slip rings endure harsh weather conditions while maintaining reliable power transmission, thereby ensuring the efficiency and constant operation of the wind turbines.

Heavy Machinery & Manufacturing

High-power slip rings are integral to various heavy machinery, such as cranes and excavators, to confer electrical power and control signals to mobile sections of the machinery. They are also prevalent in automated manufacturing systems where continuous rotational movement is necessary to maintain constant power, signal, and data connections.

Medical Equipment

High-power slip rings have found significant application in the healthcare sector. Notably, in medical imaging systems like CT scanners, high-power slip rings facilitate the transfer of power and concurrent retrieval of image data during the continuous movement of the scanning assembly. The high reliability and precision of these slip rings make them indispensable in such critical applications.

Robotics

In robotics, precision and continuous power supply is key for smooth operation. High-power slip rings are particularly used in robots that require unhindered movement, such as industrial manipulator arms or surgical robots, transmitting power and low-level control signals to the moving parts regardless of their rotational position.

Marine Applications

In marine applications, slip rings are used in a myriad of setups, from propelling electric thrusters to transferring power or signals on rotating radar masts on naval vessels. Their robust design and resistance to harsh environmental factors make them especially suited for maritime environments.

In summary, whether it’s orchestrating the incredible radar sweep in a defense system or providing the power and control needed to operate heavy machinery, drive wind turbines, or aid medical diagnosis, high-power slip rings play a pivotal and often uncredited role. These case studies serve as a testament to the sheer flexibility and diverse application of these technological marvels.

High Power Slip Rings User Concerns

Investing in specialized technology such as high-power slip rings requires careful consideration of numerous factors. Clients often express concerns relating to reliability, lifespan, temperature resistance, integration, customization, cost and maintenance, and safety. Addressing and mitigating these concerns helps build trust in the product, leading to wider adoption across different sectors.

Reliability and Lifespan

Customers overwhelmingly prioritize reliability and lifespan in high-power slip rings due to their significant role in maintaining seamless operations. Challenges such as wear and tear, frictional heat, and erosion can markedly shorten a slip ring’s lifecycle. The use of advanced materials like fiber brushes can help increase the contact lifespan, reduce maintenance needs, and improve the reliability of the slip rings.

Temperature Resistance

High-temperature resistance is crucial, especially in harsh industrial environments. High-power slip rings ought to survive extreme temperatures without performance degradation. Temperature resistance is often achieved by using durable and heat-resistant materials and incorporating designs such as ventilation holes for heat dissipation.

Integration and Customization

Clients often require high-power slip rings that can integrate seamlessly into their existing systems. This demand for customizability underscores the importance of offering different types and designs of slip rings, including mixed-technology slip rings. Manufacturers often provide custom solutions reflecting the specific technological requirements of a client’s application.

Cost and Maintenance

While advanced slip rings provide numerous benefits, they also raise questions about cost and maintenance. Regular servicing to mitigate wear and tear and replace worn-out components can be burdensome. However, modern innovations, such as wireless high-power slip rings and low-wear material usage can reduce maintenance needs, leading to lower long-term costs.

Safety

Safe operation is another significant concern, especially in high-power slip rings that handle large electrical currents. Predetermined contact materials and appropriate design considerations ensure that the slip rings can reliably handle high-power transmissions without posing safety hazards.

In conclusion, addressing these user concerns is critical to putting potential purchasers at ease and ensuring the broadest possible application of high-power slip rings. By spotlighting reliability, temperature resistance, easy integration, cost-effectiveness, and safety considerations, manufacturers can reassure users about the product’s suitability for their specific needs.

High Power Slip Rings Environment and Sustainability

In the age of heightened awareness about environmental conservation, the impact of technologies like high-power slip rings on the environment and their sustainability quotient has come under scrutiny. Manufacturers are turning a significant focus toward green practices in production and the development of more eco-friendly high-power slip rings.

Environmental Impact

High-power slip rings are key components in many systems and machines, and like any manufactured product, they have a certain environmental footprint. This footprint comes from diverse aspects such as the extraction of raw materials, energy consumed during manufacturing, and emissions during production and disposal.

However, the same devices can also contribute positively towards environmental conservation. For instance, their role in renewable energy generation systems, like wind turbines, supports low-emission energy production. Furthermore, the efficient operation of many industrial processes enabled by these slip rings can lead to less energy consumption and lower emissions overall.

Sustainability Practices in Manufacturing

Manufacturers have begun to adopt sustainability practices to lessen their environmental impact. These range from responsible sourcing of materials, and promoting energy-efficient manufacturing processes, to ensuring adequate waste management protocols. They also look for opportunities in recycling and safe disposal methods that minimize harm to the environment. For example, returning worn-out slip rings to the manufacturer for recycling the materials reduces landfill waste and the need for new raw materials.

Current Developments for Eco-friendly High Power Slip Rings

Advancements toward eco-friendly high-power slip rings are multifaceted. From a materials perspective, the industry is looking for sustainable materials that are easily recyclable and have less environmental impact. At the design level, a focus on longevity and efficiency means less frequent replacement and hence minimal disposal.

There are also developments aimed at creating high-power slip rings that consume less energy during operation, thus leading to less greenhouse gas emissions. Wireless slip ring technology, for instance, as a part of this new eco-conscious generation of products, reduces mechanical wear and tear and extends the product’s lifetime, decreasing the instances of replacement and waste generation.

In conclusion, although high-power slip rings, like any industrial product, have an environmental footprint, advancements in technology and sustainable manufacturing practices are helping to mitigate their impact. The continued pursuit of these improvements denotes the industry’s commitment to balancing technological requirements with environmental responsibility.

High Power Slip Rings Selection Criteria and Purchasing Considerations

Selecting the appropriate high-power slip ring for one’s requirements can be a daunting task, given the many options available. It helps to understand the key factors to consider while purchasing a high-power slip ring, along with strategies for successful negotiation with suppliers and manufacturers.

Power Requirements

Understanding one’s power requirements is paramount to selecting the right slip ring. Considering factors such as the power and voltage levels needed, the number of circuits, and the types of signals to be transmitted will guide the choice towards a product that will effectively meet these needs.

Customization Needs

Often, off-the-shelf products may not cater to all requirements. A clear understanding of your system’s specifications and the necessary customizations — from the type of connectors and mounting options to the integration of power, signal, and data transmission — will ensure a more accurate fit for your application.

Environmental Conditions

Environmental conditions where the slip ring is to be installed can greatly affect its longevity and performance. Consider the level of dust, moisture, and temperature range in the environment. Depending upon these factors, one can select slip rings with specific protective features like dust and water resistance or high-temperature tolerance.

Reliability

For most applications, failure of a slip ring translates to halted operations, leading to costly downtime. Evaluating the reliability of a slip ring through factors such as lifespan, wear resistance, maintenance needs, and the reputation of the supplier often pays off in terms of reduced upkeep and fewer replacements.

Cost

Cost is an influential factor in any purchasing decision. However, it is important to look beyond the initial purchasing cost and consider the total cost of ownership, incorporating costs related to installation, maintenance, replacement, and potential downtime due to failures.

Negotiating with Suppliers and Manufacturers

Successful negotiation with suppliers begins with a clear understanding of your needs and the market. Do thorough research and don’t hesitate to ask clarifying questions. Look beyond the price, and consider their technical support, lead times, warranty terms, and track record. This will not only help you get the best deal but also build a strong relationship with the supplier that can be beneficial in the long term.

In summary, selecting the right high-power slip ring requires an astute understanding of your power requirements, customization needs, and operating conditions, accompanied by careful consideration of the product’s reliability and cost. With some diligent research and careful negotiation, you can ensure a wise purchase that satisfactorily serves your needs.

The Future of High Power Slip Rings

The future of high-power slip rings promises to be exciting, characterized by innovative developments shaped by emerging trends and technological advancements. These innovations are bound to maximize their potential by radically changing how they function and are designed.

Predicting Future Trends and Developments

High power slip rings will likely experience significant innovation in the coming years, driven by increasing demand for efficient power systems across various sectors and the continuous march of technology. More compact, durable, and lower maintenance slip rings may become the norm, catering to an increasingly power-hungry and space-constrained industrial landscape.

Wireless technology is an area that holds great promise for future developments. The adoption of wireless power transfer and data transmission could potentially replace mechanical slip rings in some applications, heralding a new era in power transfer systems.

Another important trend is the increased adoption of smart technologies. The integration of sensors and IoT technology to monitor the performance of slip rings in real time for predicting maintenance and managing failures could revolutionize performance management.

Impact of New Technologies

New technologies will undoubtedly impact the design and functionality of high-power slip rings. Fiber optic technology, for instance, can enable even higher data transfer rates, critical for data-heavy industries like telecommunications and healthcare.

Artificial intelligence and machine learning could also come into play, integrating with IoT to create predictive maintenance models, quickly alerting to potential issues before they become critical and costly problems.

Furthermore, advancements in materials science, particularly in the development of materials that minimize wear and tear, could lengthen the lifespan of slip rings, make them even more reliable, and reduce their maintenance needs.

In a nutshell, high-power slip rings are on an intriguing trajectory. With the advent of transformative technology trends, these essential devices are set to become more efficient, reliable, and suitable to meet even the most demanding requirements, fundamentally reshaping their role for the future.

Conclusion

High-power slip rings have indeed carved their niche in modern technology. Understanding their nuances and keeping pace with their evolution will surely illuminate the path to success for industries relying on them. Let’s keep learning, adapting, and embracing the future that high-power slip rings promise today!

See What We Can Do