Slip rings play a critical role in electromechanical systems, providing seamless electrical connections between stationary and rotating components. Among the various slip ring designs available, 24-wire slip rings stand out due to their unique ability to handle complex data and signal transmission requirements. As their name suggests, these slip rings are equipped with 24 individual wires, allowing them to transmit power as well as data signals in systems that demand high levels of connectivity and multi-channel communication.

In this article, we aim to provide a deep dive into the world of 24-wire slip rings, shedding light on their key features, advantages, and potential concerns users may face. Moreover, we will discuss various industries and applications that benefit from these specialized devices and explore future trends emerging in slip ring technology. By the end of this article, readers will have a comprehensive understanding of 24-wire slip rings, allowing them to make informed decisions if considering the implementation of such devices in their applications and systems.

Understanding the 24-wire Slip Ring

Before delving into the specifics of a 24-wire slip ring, it’s essential to grasp the fundamental concept of a slip ring. A slip ring is an electromechanical device that enables the transmission of power and electrical signals from a stationary to a rotating structure. This process is accomplished through conductive rings attached to the rotating part of the system and brushes that maintain contact with the rings, allowing for constant transmission despite continuous rotation.

Having understood the basics of a slip ring, let’s now explore the 24-wire slip ring. This is a kind of slip ring that stands apart due to its design, which incorporates 24 separate conductive paths or wires. These wires act as channels allowing for simultaneous handling of multiple signals or power lines, and this opens up a whole new level of possibilities.

In the case of a 24-wire slip ring, the greater number of wires allows for an increased volume of data transfer compared to other slip ring designs. This makes it a preferred choice for applications that require complex data handling. Hence, 24-wire slip rings are used extensively in industries and systems involving significant levels of data or signal transmissions.

Another fascinating aspect of 24-wire slip rings is their design flexibility. They are available in different sizes and mounting options, enabling ease of integration into a variety of system layouts. These devices are designed to handle diverse power and load requirements, indicating their broad applicability in various sectors.

In essence, the 24-wire slip ring is not just an ordinary slip ring; it is a highly versatile device built to cater to sophisticated data handling needs in dynamic application environments.

Key Features of the 24-wire Slip Ring

A 24-wire slip ring is a crucial component in many rotating systems where it allows the transmission of power and signals from a stationary structure to a rotating one. Here are the key features of a 24-wire slip ring:

1. Number of Circuits:

- The 24-wire slip ring has 24 independent circuits, each capable of transmitting electrical signals or power. This high number of circuits makes it suitable for complex systems requiring multiple signal or power channels.

2. Compact Design:

- Despite the multiple circuits, the 24-wire slip ring is designed to be compact, minimizing the space it occupies within a system. This makes it ideal for applications where space is a constraint.

3. Versatility:

- This slip ring can transmit various types of signals, including analog, digital, and radio frequency (RF) signals. Additionally, it can carry power alongside signal transmission, making it a versatile component in different applications.

4. Low Electrical Noise:

- The slip ring is designed to minimize electrical noise, ensuring the integrity of signal transmission. This feature is particularly important in sensitive applications such as data communication or signal processing, where even minor disturbances can lead to errors.

5. Durability and Reliability:

- Made from high-quality materials, the 24-wire slip ring is built to withstand continuous operation, harsh environments, and mechanical stress. It offers long service life and reliable performance even under demanding conditions.

6. Low Maintenance:

- The slip ring is engineered for low maintenance, with features such as self-lubricating contacts that reduce wear and tear. This aspect reduces downtime and maintenance costs over the lifespan of the equipment.

7. Customizable Options:

- Many 24-wire slip rings are customizable to meet specific application requirements. This customization can include the size of the slip ring, the length of the wires, and the type of connectors used.

8. High Rotational Speed:

- These slip rings are capable of operating at high rotational speeds, which is essential for applications in industries like robotics, wind turbines, and medical imaging equipment where the system components need to rotate rapidly.

9. Signal and Power Handling Capabilities:

- The slip ring can handle a range of voltages and currents, making it suitable for both low-power signal transmission and higher-power applications. Each of the 24 circuits can be designed to carry different levels of power or types of signals based on the application needs.

10. Environmental Protection:

- Many 24-wire slip rings come with options for environmental protection, such as sealing against dust, moisture, or chemicals. This ensures reliable operation in harsh industrial environments or outdoor applications.

11. Smooth Operation:

- The 24-wire slip ring is designed for smooth rotation, which minimizes mechanical wear and reduces the risk of signal interruptions or power loss during operation.

12. Application Flexibility:

- Due to its capability to handle multiple signals and power channels, the 24-wire slip ring is widely used in various applications, including robotics, aerospace, military, packaging machines, and medical equipment.

These features make the 24-wire slip ring an essential component in systems that require reliable, high-performance rotary connections.

In summary, each of these key features – the number of wires, power/load capacity, mounting flexibility, and materials – collaborate in making 24-wire slip rings the versatile and high-performing devices that they are.

24-Wire Slip Ring Interface

The interface of a 24-wire slip ring is an essential aspect that determines how it connects to and interacts with the rest of the system. Here’s an overview of the key components and features of the interface for a 24-wire slip ring:

key components

1. Wiring Interface:

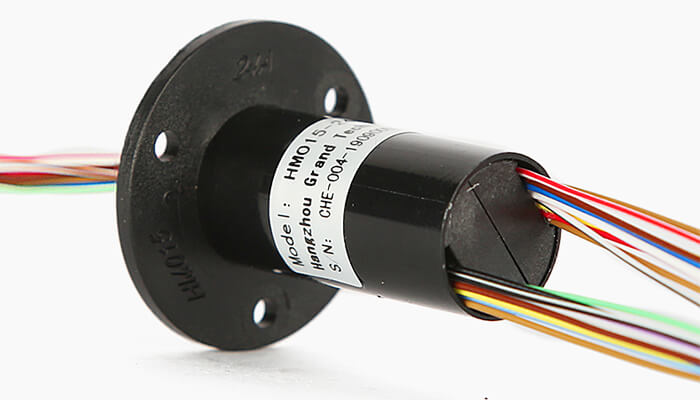

- 24 Independent Wires:

- The slip ring has 24 individual wires, each corresponding to one of the 24 circuits. These wires are used to transmit electrical signals or power between the stationary and rotating parts of the system.

- Color-Coded Wires:

- The wires are typically color-coded for easy identification, making it simpler to connect the correct wire to the corresponding circuit in the system.

- Wire Gauge:

- The gauge of the wires may vary depending on the current-carrying requirements. Thicker wires (lower gauge) are used for higher current, while thinner wires (higher gauge) are used for signal transmission.

2. Connection Terminals:

- Lead Wires:

- The wires from the slip ring terminate in lead wires, which can be connected to the system’s circuitry using various methods such as soldering, connectors, or screw terminals.

- Connectors:

- In some designs, the slip ring may come with pre-installed connectors (e.g., D-sub connectors, terminal blocks) that simplify the integration into the system.

3. Rotary Interface:

- Rotor (Rotating Part):

- The rotor is the part of the slip ring that rotates and is connected to the rotating component of the system. The wires connected to the rotor transmit signals or power to the stationary part.

- Stator (Stationary Part):

- The stator is the stationary part of the slip ring, connected to the stationary component of the system. The wires connected to the stator receive signals or power from the rotating part.

4. Mechanical Interface:

- Mounting Options:

- The slip ring is designed with various mounting options such as flanges, brackets, or through-bore designs, allowing for easy installation into different systems. The mounting type depends on the application requirements.

- Rotation Mechanism:

- The slip ring is designed to accommodate continuous rotation between the rotor and stator, with the mechanical interface ensuring smooth and reliable operation.

5. Electrical Interface:

- Voltage and Current Ratings:

- The electrical interface is designed to handle specific voltage and current levels, depending on the application. Each wire or circuit will have a defined voltage and current rating to ensure safe and efficient operation.

- Signal Types:

- The interface can handle various signal types, including analog, digital, and RF signals, allowing for a wide range of applications.

Features

1. Environmental Protection:

- Sealing and Insulation:

- The interface often includes sealing and insulation to protect the wires and contacts from environmental factors like dust, moisture, and temperature extremes. This protection ensures reliable operation in harsh environments.

2. Customization Options:

- Wire Length and Type:

- The length of the wires can be customized based on the specific needs of the application. Additionally, the type of insulation and wire material can be selected to match the environmental and electrical requirements.

- Connector Type:

- Customization of connector types at the ends of the wires is also possible, depending on the system’s interfacing requirements.

3. Signal Conditioning:

- Filters and Amplifiers:

- In some advanced designs, the slip ring interface might include built-in signal conditioning elements such as filters or amplifiers to maintain signal integrity across the rotating interface.

4. Cable Management:

- Strain Relief:

- The interface includes strain relief mechanisms to prevent damage to the wires due to mechanical stress or movement, enhancing the durability and longevity of the slip ring.

5. Integration with Control Systems:

- Control and Monitoring:

- Some 24-wire slip rings are integrated with sensors or control systems that monitor the operation of the slip ring, providing real-time data on performance and enabling preventive maintenance.

These features ensure that the 24-wire slip ring can be effectively integrated into various systems, providing reliable and efficient transmission of power and signals across rotating interfaces.

24-Wire Slip Ring Specifications

The specifications of a 24-wire slip ring are critical for understanding its capabilities and ensuring it meets the requirements of specific applications. Below are typical specifications that might be provided for a 24-wire slip ring:

1. Number of Circuits:

- 24 Circuits: The slip ring is designed with 24 individual circuits, each capable of transmitting power or signals independently.

2. Electrical Specifications:

- Voltage Rating:

- Typical range: 240V AC/DC (can vary depending on the design).

- Current Rating:

- Typically ranges from 2A to 10A per circuit, depending on the wire gauge and application requirements.

- Insulation Resistance:

- Greater than 1000 MΩ at 500 VDC, ensuring minimal leakage between circuits.

- Dielectric Strength:

- 500V AC or higher, depending on the application, to ensure safe operation under high-voltage conditions.

3. Mechanical Specifications:

- Rotational Speed:

- Maximum operational speed typically ranges from 200 RPM to 5000 RPM, depending on the design and application.

- Contact Material:

- Gold-gold, gold-silver, or silver-silver depending on the requirement, with gold contacts typically offering lower electrical noise and longer life.

- Wire Gauge:

- Typically 22 AWG to 16 AWG, depending on the current capacity required per circuit.

- Housing Material:

- Aluminum alloy, stainless steel, or plastic, depending on the environmental requirements.

4. Environmental Specifications:

- Operating Temperature:

- Typically ranges from -40°C to +80°C, depending on the materials and design.

- Storage Temperature:

- Typically ranges from -50°C to +100°C.

- Humidity:

- Designed to operate in environments with up to 90% relative humidity, non-condensing.

- Ingress Protection (IP) Rating:

- IP54 to IP68, depending on the need for protection against dust and water. Higher IP ratings (like IP67 or IP68) indicate suitability for harsh environments.

5. Physical Dimensions:

- Outer Diameter:

- Typically ranges from 30mm to 100mm, depending on the design.

- Length:

- Typically ranges from 50mm to 200mm, depending on the number of circuits and the application.

- Bore Size (for through-bore designs):

- Typically ranges from 10mm to 50mm, allowing cables or other components to pass through the center.

6. Contact Resistance:

- Typical Value:

- Less than 10 mΩ, ensuring minimal loss of power or signal during transmission.

7. Life Expectancy:

- Operational Cycles:

- Typically exceeds 10 million revolutions under normal operating conditions, depending on the load and speed.

- Maintenance Intervals:

- Designed for low maintenance, with intervals depending on the specific application and operating environment.

8. Signal Specifications:

- Signal Type Support:

- Capable of transmitting various types of signals including analog, digital, Ethernet, and RF.

- Bandwidth:

- Suitable for high-frequency signals, often up to several MHz, depending on the design.

9. Customization Options:

- Wire Length:

- Customizable wire lengths, typically ranging from 200mm to 1000mm or more, depending on installation needs.

- Connector Type:

- Customizable connectors such as D-sub, circular connectors, or direct soldering options.

- Special Features:

- Options for integrated fiber optics, pneumatic or hydraulic channels, and other custom requirements.

10. Mounting Options:

- Flange Mounting:

- Standard flange mounts available for easy installation.

- Through-Bore Mounting:

- Available for applications requiring cables or shafts to pass through the center of the slip ring.

11. Weight:

- Typical Range:

- Varies from 200g to 2kg, depending on the materials used and overall design.

These specifications ensure that the 24-wire slip ring can meet the demands of various industrial, medical, and commercial applications, providing reliable performance in transmitting power and signals across rotating interfaces.

Advantages and Uses of the 24-wire Slip Ring

Advantages of the 24-wire Slip Ring

- High Circuit Density:

- The 24-wire slip ring provides a large number of independent circuits, allowing for the simultaneous transmission of multiple signals and power lines. This high circuit density is ideal for complex systems requiring extensive connectivity.

- Compact Design:

- Despite offering 24 circuits, these slip rings are designed to be compact, making them suitable for applications where space is limited.

- Versatility:

- The slip ring is capable of transmitting various types of signals (analog, digital, RF) as well as power, making it versatile across different applications.

- Low Electrical Noise:

- Designed to minimize electrical noise, the 24-wire slip ring ensures high-quality signal transmission, which is critical for sensitive and precision applications.

- Durability:

- Constructed from robust materials, the slip ring is durable and can withstand harsh operating environments, leading to a long service life.

- Low Maintenance:

- With features like self-lubricating contacts, the slip ring requires minimal maintenance, reducing downtime and overall operational costs.

- Customizability:

- Many 24-wire slip rings can be customized in terms of wire length, connector types, and circuit specifications to meet specific application requirements.

- High Rotational Speed:

- These slip rings are designed to operate at high rotational speeds, making them suitable for applications that require rapid and continuous rotation.

- Environmental Protection:

- Options for sealing against dust, moisture, and other environmental factors are available, ensuring reliable operation in challenging environments.

- Smooth Operation:

- The slip ring is engineered for smooth rotation, which reduces mechanical wear and ensures uninterrupted signal and power transmission.

Uses of the 24-wire Slip Ring

- Robotics:

- Used in robotic arms and other automated systems where multiple signals and power lines need to be transmitted across rotating joints.

- Wind Turbines:

- Facilitates the transfer of electrical signals and power between the rotating blades and the stationary hub, crucial for monitoring and control systems.

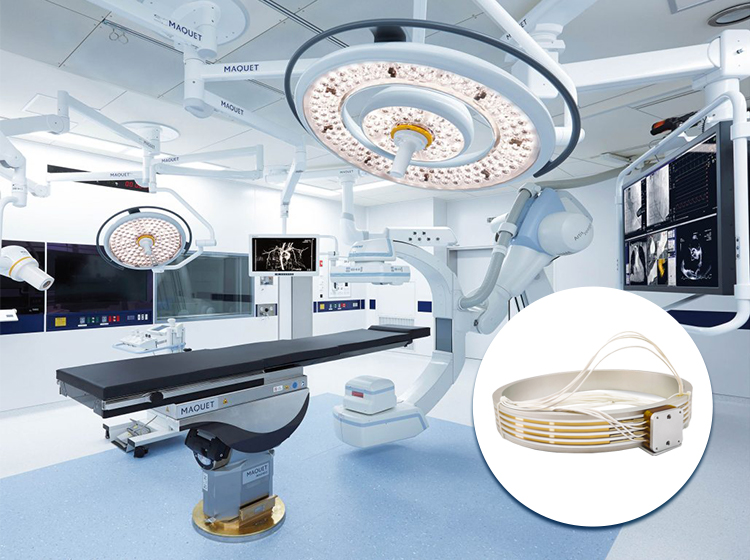

- Medical Imaging Equipment:

- Essential in devices like CT scanners, where continuous transmission of data and power during high-speed rotation is required for accurate imaging.

- Aerospace and Defense:

- Employed in gyroscopes, radar systems, and other aerospace applications where reliable signal transmission in rotating components is necessary.

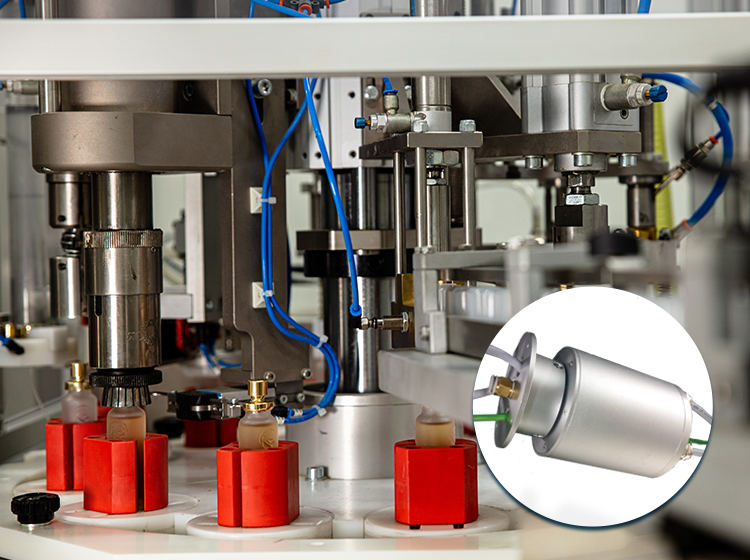

- Industrial Automation:

- Used in automated production lines and machinery to transfer data and power across rotating parts, ensuring efficient and synchronized operations.

- Packaging machinery:

- Enables the transmission of control signals and power in rotating parts of packaging machines, ensuring precise operation.

- Cranes and Rotating Platforms:

- Provides reliable power and signal transmission for cranes, rotating platforms, and other heavy machinery that involves rotational movement.

- Marine Applications:

- Used in marine equipment such as radar systems and rotating antennas, where reliable transmission in a harsh environment is essential.

- Rotary Tables:

- Facilitates the transfer of power and signals in rotary tables used in machining and manufacturing processes.

- Surveillance Systems:

- Employed in rotating surveillance cameras and other monitoring equipment where continuous rotation and signal transmission are required.

Concerns associated with the 24-wire Slip Ring

Despite all the advantages, using 24-wire slip rings is not without potential issues and worries. One of the primary concerns that users might face with these devices revolves around their durability. Just like any physical component, slip rings are exposed to wear and tear due to continuous mechanical contact between brushes and rings. Durability can also be affected by environmental elements such as dust, moisture, vibrations, or extreme temperatures. Thus, users need to consider the operational environment and its potential impact on the slip ring life.

Maintenance is another important aspect to consider. Given their mechanical nature, these slip rings can require regular maintenance for optimum performance. This could involve periodic cleaning to remove accumulated dust or debris, replacements for worn-out parts, and professional servicing. However, this maintenance does not only require time but can also increment operational costs.

Cost is a concern of its own. Higher-end 24-wire slip rings can come with significant initial costs due to the complexity of their design and the quality of materials used. While these costs can be justified by their high performance and increased functionality, they may deter smaller operations or companies with tightened budgets.

Finally, the suitability of these slip rings can be impacted by industry-specific or application-specific factors. For instance, industries such as medical or aerospace may demand compliance with specific regulations or certifications. Understanding these unique requirements is crucial before integrating a 24-wire slip ring into a specific application or environment.

In a nutshell, while 24-wire slip rings hold great potential, understanding their potential challenges and concerns is integral to fully leveraging their benefits.

Care and Maintenance of 24-wire Slip Rings

Caring for and maintaining 24-wire slip rings involves a mix of proactive routine checks, cleaning, and regular servicing. Here are some insights into these aspects:

Regular inspections are an important part of maintaining any mechanical device. For slip rings, look for signs of wear on the brushes and rings, unusual noises, or erratic performance. A decrease in signal quality or a stuttering power line can be an indicator that something may be amiss.

Keep the slip rings clean, as dust and debris can hinder performance and increase wear. Gentle and regular cleaning using compressed air can help remove accumulated dust. In extreme environments where dust accumulation is high, care should be taken to position the slip rings to minimize their exposure to dust. Please remember to follow any specific manufacturer guidelines about cleaning your 24-wire slip rings to avoid any potential damage.

Electrical testing can help keep a check on the operational efficiency of the slip ring. A very high or low resistance could indicate a potential problem like a worn-out brush or a damaged wire. Simultaneously, an insulation resistance test can help detect any breaches in insulation that can lead to short circuits. In general, it’s advisable to follow the manufacturer’s specifications for testing parameters.

Even when your 24-wire slip ring seems to be in good condition, don’t neglect standard servicing. Handling the slip ring only when a problem arises can lead to bigger repairs and potentially impact the equipment’s life span. Regular servicing not only helps catch and solve problems early but also optimizes your slip ring’s function, increasing its overall durability and performance.

In conclusion, caring for your 24-wire slip rings through regular inspections, cleaning, and servicing, along with proper electrical testing, can increase their effectiveness, ensure their durability, and minimize potential downtime.

Future Trends in the 24-wire Slip Ring Technology

As the world moves towards more complex and intelligent machinery, the technology behind 24-wire slip rings continues to evolve. Here’s a snapshot of what the future could hold:

One major trend influencing future designs is the integration of emerging technologies. Technologies like AI, IoT, and machine learning are making their way into numerous application areas, and slip ring technology won’t remain untouched. In particular, 24-wire slip rings could see enhancements in terms of predictive maintenance capabilities, automated performance optimization, advanced diagnostics, and overall better integration with smart systems.

Additionally, miniaturization is a significant trend driving improvements in 24-wire slip ring design. As industries demand compact and weight-conscious solutions, the future could see 24-wire slip rings becoming smaller while still maintaining, if not improving, their data-handling capabilities. This could carry implications for industries like aerospace or mobile robotics where weight and size play critical roles.

Energy efficiency is another key focus area for future designs. With growing emphasis on responsible energy management, future 24-wire slip rings could display better power efficiency, lower power loss in signal transmission, and maybe even energy harvesting capabilities.

Finally, the persistent demand for enhanced performance will continue to influence future designs. Whether it’s higher durability against extreme environmental conditions or faster data transmission speeds, tomorrow’s 24-wire slip rings will likely keep pushing the limits.

To sum up, the future of 24-wire slip rings promises exciting changes. Emerging technologies, miniaturization, a sharper focus on energy efficiency, and ever-increasing performance requirements will continue to guide their evolution. As the adoption of these trends becomes more widespread, we can expect to see these slip rings becoming an even more integral part of modern machinery.

Conclusion

Understanding the key features, advantages, and user concerns related to 24-wire slip rings can help potential users select the most suitable slip ring for their applications. As technology advances, we can look forward to more sophisticated and efficient slip rings that cater to various industries’ increasing demands.

Reach out to our team for detailed 24-wire slip rings specifications.

FAQs about 24-wire slip rings

Q: What does the 24-wire specification mean in a slip ring?

A: The 24-wire specification denotes the number of individual wires or pathways present in the slip ring. Each wire can be used for transmitting a separate signal or power line, providing scope for multi-channel transmission in a single device effectively.

Q: Can 24-wire slip rings be customized?

A: Yes, most manufacturers offer customization options. This can include specific dimensions to fit your application, selection of materials based on the operational environment, or additional features like integrated fiber-optic rotary joints or RF rotary joints.

Q: What maintenance actions should be considered for 24-wire slip rings?

A: Maintenance may include dusting to remove any accumulated debris, periodic inspections for wear and tear of brushes, and replacements if necessary. However, the need for maintenance greatly depends on the operational environment and usage. Always consult the product manual for the manufacturer’s recommendations.

Q: What is the typical lifespan of a 24-wire slip ring?

A: The lifespan of a 24-wire slip ring can vary widely based on various factors such as operating conditions, load, speed, and maintenance practices. Under standard conditions and with regular maintenance, high-quality 24-wire slip rings can be expected to function efficiently for several years.

Q: How do I know if a 24-wire slip ring is right for my application?

A: The best way to determine this is by conducting a thorough analysis of your system’s requirements. Consider the necessary number of power lines or signals that need to be transmitted, the space available for mounting the slip ring, and the specific environmental conditions it will be subjected to. It may be helpful to consult a product specialist or an engineer for professional advice.

See What We Can Do