A fluid slip ring, also known as a hydraulic or pneumatic rotary union, is a mechanical component specifically designed to transmit fluids, such as liquids, gases, or even multiphase media, across a rotating interface while maintaining a steady connection between stationary and rotating parts. This essential function allows for the smooth flow of fluids without leaks, making fluid slip rings a vital component in numerous industrial and commercial applications spanning a vast range of sectors.

These key application areas highlight the crucial role fluid slip rings play in delivering efficient, reliable, and practical fluid transmission solutions across a variety of industries, allowing for optimal performance and functionality. By understanding fluid slip rings and their purpose in these diverse contexts, it becomes clear how indispensable they are in facilitating smooth, continuous fluid flow within a myriad of complex, rotating systems.

Construction and Working of Fluid Slip Rings

Fluid slip rings, known for their complex structure and meticulous construction, are meticulously engineered devices. While they come in diverse configurations to meet specific application requirements, most fluid slip rings share a common, fundamental design. A standard fluid slip ring is made of a stationary part (stator) and a rotating part (rotor). The stator and rotor are essentially the input and output sections respectively, with the stator usually connected to the input fluid source and the rotor connected to the output line of the rotating equipment.

The heart of the fluid slip ring is the seal, which forms an essential barrier between the stator and rotor to prevent fluid leakage while allowing the transmission of fluids under pressure. The seals, usually constructed out of high-grade, durable materials like elastomers or advanced polymer compounds, must contain the fluid within the open space between the stator and the rotor. Furthermore, bearings are included in the design to facilitate the smooth rotation of the rotor relative to the stator.

The working principle of a fluid slip ring revolves around its ability to transmit fluid under pressure from a stationary component to a rotating component, ensuring that there is an uninterrupted flow of fluid during rotation.

As regards the types of fluids that can be transmitted, fluid slip rings prove to be incredibly versatile. Depending on their design and the materials used for construction, they can handle a wide range of fluids, including but not restricted to water, hydraulic oils, coolants, air, steam, and certain chemicals. Some high-end or customized fluid slip rings could also be designed to transmit corrosive or abrasive fluids or handle multi-phase (such as oil-water-gas) flow conditions.

Given their central function, the design and construction of fluid slip rings are critical aspects of their overall performance. Suitable for an expansive array of fluidic mediums, they form an indispensable part of several applications where the persistent and smooth transfer of fluid across rotating components is vital.

Construction

The construction of a fluid slip ring typically includes the following key components:

- Housing: The outer casing or housing, usually made of metal, encloses the internal components and provides the structure for mounting the slip ring.

- Rotor: The rotor is the rotating part of the slip ring, connected to the rotating machine component. It has a smooth and precision-machined surface to ensure a tight seal with the stationary part.

- Stator: The stator is the stationary part of the slip ring, fixed to the machine’s stationary part. It usually contains ports or channels for fluid entry and exit.

- Seals: High-quality seals, such as O-rings or lip seals, are used between the rotor and stator to prevent fluid leakage. The type of seal depends on the fluid being transferred and the operating conditions.

- Bearings: Bearings are used to support the rotor and ensure smooth rotation with minimal friction. They are typically made of durable materials to withstand the operating environment.

- Passages: Internal passages or channels are machined into the rotor and stator to allow the fluid to flow from the stationary to the rotating component.

Working Principle

The working of a fluid slip ring is based on the following steps:

- Fluid Entry: Fluid enters the slip ring through an inlet port on the stator. The stator is connected to the fluid source, which can be a pump, reservoir, or another fluid delivery system.

- Sealing: As the rotor rotates, the seals between the rotor and stator prevent the fluid from leaking out of the slip ring. The sealing mechanism is crucial in maintaining fluid pressure and preventing contamination.

- Fluid Transfer: The fluid flows through the internal passages from the stator to the rotor. Since the rotor is connected to the rotating part of the machine, the fluid is effectively transferred from the stationary to the rotating component.

- Fluid Exit: After passing through the rotor, the fluid exits the slip ring through an outlet port. This outlet port is connected to the rotating component of the machine, where the fluid is needed.

- Continuous Operation: The slip ring allows for continuous fluid transfer even as the rotor rotates at high speeds. The high-quality seals and precision engineering ensure minimal wear and long operational life.

Fluid Slip Rings Technical Specifications

Fluid slip rings are specialized components used in various industries to transmit fluid media (such as oil, water, coolant, or hydraulic fluid) from a stationary part of a system to a rotating part. These slip rings are critical in applications where a continuous 360-degree rotation is necessary without entangling hoses or lines. Below are typical technical specifications that you might find for fluid slip rings:

1. Number of Passages

- Single-Passage: For applications requiring the transmission of a single fluid.

- Multi-Passage: For applications requiring the transmission of multiple fluids simultaneously, typically ranging from 2 to 8 passages.

2. Operating Pressure

- Typically, fluid slip rings are designed to operate at pressures ranging from 0 to 10,000 psi (0 to 690 bar).

- Some specialized designs can handle higher pressures, up to 20,000 psi (1379 bar).

3. Fluid Type

- Compatible with various fluids, including water, oil, air, and other hydraulic fluids.

- Some slip rings are also designed to handle gases and other specialized fluids.

4. Flow Rate

- The flow rate can vary depending on the passage size and fluid type, typically ranging from 1 to 100 liters per minute.

- Larger slip rings can handle even higher flow rates.

- Standard fluid slip rings can handle rotational speeds up to 500 RPM.

- High-speed versions can operate at speeds up to 5,000 RPM or higher.

6. Material Construction

- Body Material: Commonly made from stainless steel, aluminum, or brass.

- Seals: Typically use high-quality seals such as Viton, PTFE, or NBR to ensure leak-proof operation.

- Bearings: Precision bearings are used to minimize friction and wear.

7. Temperature Range

- Operating temperature range usually spans from -20°C to +150°C.

- Some models are designed for extreme temperatures, from -50°C to +200°C.

8. Mounting Options

- Flange mounting or shaft mounting options are typically available.

- Custom mounting solutions are also possible depending on the application.

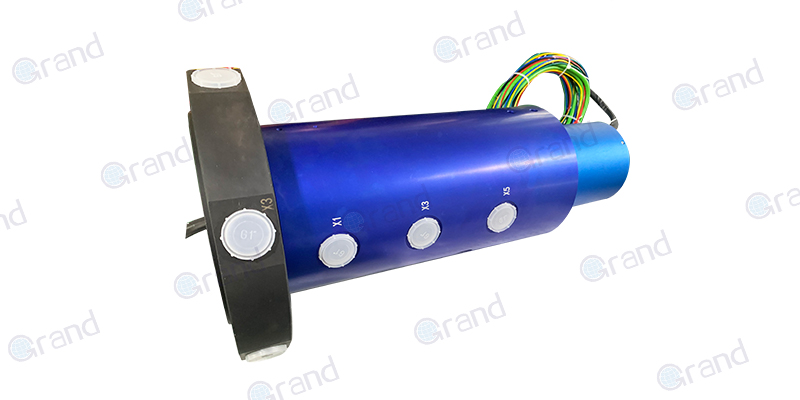

9. Electrical Integration

- Some fluid slip rings are integrated with electrical slip rings to transmit electrical power and signals alongside fluid media.

- The number of electrical channels and their specifications (e.g., voltage, current, bandwidth) vary based on application requirements.

10. Leakage Rate

- Designed to have a very low leakage rate, often specified in milliliters per minute (e.g., <0.1 ml/min).

11. Certification & Compliance

- Many fluid slip rings are designed to meet industry standards such as IP65/67 for ingress protection.

- Certification for specific industries (e.g., ISO, ATEX for hazardous environments) may also be available.

12. Customization

- Fluid slip rings can often be customized in terms of size, passage configuration, material, and other parameters to meet specific application needs.

These specifications can vary based on the manufacturer and the specific application for which the fluid slip ring is intended. Always consult the manufacturer’s datasheet or technical support for the most accurate and application-specific details.

Applications of Fluid Slip Rings

Fluid slip rings are versatile components used in a variety of applications where there is a need to transfer fluids (such as hydraulic oil, coolant, water, or other liquid media) between stationary and rotating parts of machinery. Here are some common applications of fluid slip rings:

1. Hydraulic Systems:

- Rotating Hydraulic Actuators: Fluid slip rings are used to supply hydraulic oil to rotating hydraulic actuators or motors in industrial machinery, construction equipment, and other systems requiring rotational motion.

- Cranes and Excavators: In construction and industrial cranes, fluid slip rings transfer hydraulic fluid to rotating parts, enabling the movement of arms, booms, and other components.

2. Machine Tools:

- CNC Machines: In CNC (Computer Numerical Control) machines, fluid slip rings are used to transfer coolant to rotating spindles, ensuring that the cutting tools remain cool and functional during high-speed machining operations.

- Rotary Tables: In rotary tables, fluid slip rings allow the transfer of coolant or other fluids while the table rotates, enabling precise machining of parts.

3. Wind Turbines:

- Yaw Systems: Fluid slip rings are used in the yaw systems of wind turbines to transfer hydraulic fluid or other lubricants to the rotating parts, allowing the turbine to face into the wind efficiently.

- Blade Pitch Control: They are also used in the blade pitch control systems of wind turbines, where hydraulic fluid is needed to adjust the angle of the blades for optimal energy capture.

4. Marine Applications:

- Winches and Cranes: In marine environments, fluid slip rings are used in rotating winches, cranes, and other deck machinery to transfer hydraulic fluid, enabling the lifting and moving of heavy loads on ships and offshore platforms.

- Propulsion Systems: In some marine propulsion systems, fluid slip rings are used to transfer fluids necessary for controlling the direction and speed of the vessel.

5. Medical Equipment:

- Rotating Medical Scanners: Fluid slip rings are used in rotating medical imaging equipment, such as CT (Computed Tomography) scanners, to transfer cooling liquids or other fluids while the imaging device rotates around the patient.

Medical

6. Packaging Machinery:

- Rotary Filling Machines: In the packaging industry, fluid slip rings are used in rotary filling machines where fluids need to be accurately dispensed into containers as they move along a production line.

- Labeling Machines: Fluid slip rings facilitate the transfer of adhesives or other fluids in rotating labeling machines.

7. Aerospace and Defense:

- Turrets and Weapon Systems: In aerospace and defense applications, fluid slip rings are used in rotating turrets and weapon systems to transfer hydraulic fluid, coolant, or other necessary fluids.

- Flight Simulators: They are also used in flight simulators where fluid transfer is needed for hydraulic systems that replicate flight control surfaces.

8. Food and Beverage Industry:

- Rotary Processing Equipment: Fluid slip rings are employed in food processing machinery where fluids like water, oils, or cleaning agents need to be transferred to rotating parts, such as mixers or conveyors.

- Bottling and Canning Lines: In bottling and canning lines, fluid slip rings facilitate the transfer of fluids necessary for cleaning, sterilizing, or lubricating machinery components.

9. Robotics:

- Robotic Arms: Fluid slip rings are used in robotic arms to transfer hydraulic fluids or coolants to the end effector or tools, especially in applications involving welding, painting, or handling hazardous materials.

10. Rotary Heat Exchangers:

- HVAC Systems: In some HVAC (Heating, Ventilation, and Air Conditioning) systems, fluid slip rings are used in rotary heat exchangers to transfer heat exchange fluids between rotating and stationary parts.

11. Automotive Industry:

- Rotating Testing Equipment: Fluid slip rings are used in automotive testing rigs where rotating components, such as wheels or drive shafts, need to be supplied with hydraulic fluid or coolant during testing.

12. Printing Industry:

- Rotary Printing Presses: In high-speed rotary printing presses, fluid slip rings are used to transfer inks, lubricants, or cooling fluids to the rotating components.

In summary, the vast array of applications emphasized here serves to illustrate the crucial role fluid slip rings play across diverse sectors, owing to their irreplaceable function of facilitating uninterrupted fluid transfer across rotating assemblies. These applications demonstrate the critical role that fluid slip rings play in enabling the reliable transfer of fluids in systems where rotation and fluid flow must coexist. Their ability to maintain fluid integrity under rotation makes them indispensable in various industrial and technological sectors.

Types of Fluid Slip Rings

Variants of Fluid Slip Rings

Fluid slip rings are not a one-size-fits-all solution, rather, they come in a multitude of variants, each optimized for specific applications, working environments, or fluid compatibility. These factors, from construction material to design to pressure handling capacity, significantly affect the performance, efficiency, and overall scope of application of the fluid slip rings.

- Material: Fluid slip rings can be made from various materials, including stainless steel, brass, and plastic polymers such as PTFE (Polytetrafluoroethylene), or PEEK (Polyether ether ketone). The choice of material primarily hinges on the compatibility with the fluid to be transmitted and the demand of the working environment. For instance, metal-based slip rings have excellent mechanical strength and are resistant to high temperatures, making them suitable for heavy-duty industrial applications or high-temperature conditions.

- Design: The design of a fluid slip ring reflects its intended function. Some are simple, featuring a single channel for fluid transmission while others are complex, boasting multiple channels to handle a variety of fluids simultaneously or even incorporating electrical slip rings or fiber optic rotary joints for simultaneous data or power transmission.

- Pressure Handling Capacity: Fluid slip rings differ in their capacity to handle pressure, which can range from low to exceedingly high depending on the application. This attribute is determined by factors such as the type and quality of seals used, the structural integrity of the entire assembly, as well as the material composition of the slip ring. Therefore, selecting one with the correct pressure handling capacity is crucial to avoid failures due to exceeding pressure limits.

The variant of fluid slip ring chosen have a profound impact on its performance and efficiency. The right material ensures compatibility with the fluid, thereby preventing corrosion or degradation that could occur due to an adverse reaction. Similarly, an appropriately designed fluid slip ring can deliver improved performance, handling multiple fluid types or even data and power signals in more sophisticated designs. Lastly, the pressure handling capacity directly governs the ability of the fluid slip ring to operate under a specific pressure range without risking leakage or failure.

Thus, these variants provide ample flexibility, enabling fluid slip rings to cater to a wide scope of applications – from simple tasks requiring the transfer of a single fluid with low pressure to more demanding ones that involve multiple fluid types, high pressures, or necessitate simultaneous data or power transmission.

Advantages of Fluid Slip Rings

Fluid slip rings offer considerable advantages, and their ability to enable a persistent, falter-free flow of fluid across rotating parts stands out as their most remarkable benefit. This critical function equips them with an unparalleled edge when their application in numerous industries is considered.

- Efficient Fluid Transmission: Whether it’s a liquid or a gas, fluid slip rings can transmit them seamlessly between stationary and rotating components. This efficient transmission ensures the uninterrupted operation of a system or machinery, which can significantly improve the overall productivity or effectiveness of an industrial process.

- Rotating Seal Function: Fluid slip rings serve as rotating seals that help maintain a high pressure of the fluid in the system. They effectively isolate the inputs and outputs, which prevents fluid leakage and, in turn, avoids wastage of the medium and potential damage to surrounding components of a system or an application.

- Versatility: Fluid slip rings are versatile in the observation that they can handle a variety of fluids — ranging from water to hydraulic oils to gases. This adaptability allows them to be used in a wide variety of applications across multiple industries.

- Compact Design: Due to their compact and tailor-made design, fluid slip rings can be readily integrated into existing systems, contributing to optimized space utilization in applications where space constraints may exist.

- Continuous Fluid Transfer: Fluid slip rings enable continuous transfer of fluids (such as hydraulic oil, coolant, or other liquids) between stationary and rotating parts without interruption, ensuring that machines and systems can operate smoothly and efficiently.

- Space-Saving Design: Fluid slip rings often combine multiple fluid passages into a single unit, reducing the need for multiple connections and simplifying the overall system design. This is especially advantageous in compact or space-constrained environments.

- Durability and Longevity: Fluid slip rings are built from durable materials that can withstand harsh operating conditions, such as high pressures, extreme temperatures, and corrosive environments. This results in a long service life and reduced maintenance requirements.

- High-Speed Capability: Designed to operate at high rotational speeds, fluid slip rings feature low-friction bearings and advanced sealing technology, allowing them to perform reliably even in high-speed applications like CNC machines or rotary printing presses.

- Customizability: Fluid slip rings can be customized to meet specific requirements, such as the number of fluid passages, pressure ratings, materials, and seal types. This allows them to be tailored to unique applications and operational conditions.

- Integration with Electrical Slip Rings: Some fluid slip rings are integrated with electrical slip rings, allowing the simultaneous transfer of fluids and electrical signals or power. This combination is particularly useful in complex systems like wind turbines, robotics, and medical equipment.

- Reduced Downtime: The ability to maintain continuous fluid transfer without the need for frequent maintenance or replacement reduces downtime, increasing the overall productivity and efficiency of the machinery or system.

- Safety in Hazardous Environments: Explosion-proof and corrosion-resistant fluid slip rings are available for use in hazardous environments, such as oil and gas industries, chemical processing, and marine applications. These specialized designs ensure safe and reliable operation under challenging conditions.

- Minimal Maintenance: Thanks to their robust construction and high-quality components, fluid slip rings typically require minimal maintenance. Regular inspections and occasional seal replacements are often sufficient to keep them in optimal working condition.

- Environmental Protection: By preventing fluid leaks and ensuring proper fluid transfer, fluid slip rings help protect the environment from contamination. This is particularly important in industries where hazardous fluids are used.

- Cost-Effective Operation: The durability, reliability, and low maintenance needs of fluid slip rings contribute to cost-effective operation over the long term. Reduced downtime and extended service life mean lower operational costs.

- Precision in Fluid Control: Fluid slip rings allow precise control over fluid transfer, which is crucial in applications requiring exact fluid quantities, pressures, or temperatures. This precision enhances the performance and accuracy of the entire system.

Certain industries, in particular, derive significant benefits from employing fluid slip rings. In the medical industry, for example, fluid slip rings are critical for functioning imaging devices like CT and MRI scanners. They allow for the transfer of coolants to prevent overheating of the machines — demonstrating how even in a life-saving context, fluid slip rings prove their worth.

The marine industry, too, reaps enormous benefits from fluid slip rings, particularly when it comes to mapping the seabed or oil drilling. As part of ROVs (Remotely Operated Vehicles), fluid slip rings enable the transmission of hydraulic oils for operating underwater machinery, thereby cutting a path for significant advancements in these fields.

The major advantages of using fluid slip rings underscore their centrality in different contexts, highlighting their value to industries that require an uninterrupted and efficient flow of fluids across rotating system components. Whether it’s improving the reliability of an offshore drilling operation or ensuring the smooth operation of a medical imaging device, fluid slip rings facilitate seamless processes in a multitude of sectors.

Disadvantages and Challenges of Fluid Slip Rings

Despite their myriad advantages, fluid slip rings do come with their fair share of constraints and challenges. These span from maintenance needs to pressure handling limitations and can sometimes influence the choice of slip ring for specific applications.

- Maintenance Needs: Fluid slip rings need regular maintenance to sustain their performance over a significant period. This can involve checking for wear and tear of the internal seals, which if not replaced timely, can lead to fluid leakage. Regular maintenance ensures not just the longevity of the fluid slip ring but also the efficiency of the operation it’s utilized in.

- Pressure Handling Limitations: While fluid slip rings can handle a variety of pressure ranges, each specific type has its limitations which mustn’t be exceeded to avert failures. This pressure-handling attribute of fluid slip rings is often a critical consideration in choosing a suitable slip ring for specific application needs.

- Fluid Compatibility: Another potential issue lies in choosing a slip ring that is compatible with the fluid type intended for transmission. Some materials may not be suitable for corrosive or hot fluids, and using an inappropriate slip ring could lead to premature failure and potential damage to the entire system.

- Cost of High-End Fluid Slip Rings: Some applications may need fluid slip rings with very specific material composition, advanced seals, or multi-channel designs. These high-end variants are often expensive, and thus, the cost can be a factor limiting their usage to only highly critical or well-funded applications.

- Slow Response to Rapid Pressure Changes: Typical fluid slip rings are not always capable of handling rapid changes in fluid pressure. This slow reaction time may not be suitable for some applications requiring immediate response to pressure variations.

Unquestionably, fluid slip rings provide a pivotal solution for fluid transmission in many industries, yet understanding their limitations is also critical. By properly addressing the challenges and disadvantages associated with fluid slip rings, and weighing them against the requirements of their intended application, users can ensure they select the most effective and suitable slip ring solution for their specific needs.

Selection Criteria for Fluid Slip Rings

Choosing the correct fluid slip ring for an application is paramount to ensure optimal performance and longevity. This choice should be dictated by several factors such as application needs, rotational speed, pressure, cost, material compatibility, and temperature conditions, among others.

- Application Needs: It’s crucial to understand the specific requirements of the application before selecting a fluid slip ring. You should consider aspects like the types and number of fluids to be transferred, simultaneous need for data or power transmission, space constraints, or any unique requirements of the operating environment.

- Rotational Speed: The rotational speed of the application significantly dictates the suitable type of fluid slip ring. High-speed applications call for slip rings with superior design and materials that can withstand the centrifugal forces caused by the speed while ensuring consistent functionality.

- Pressure: The ability to handle a particular pressure range is another defining characteristic of fluid slip rings. It’s paramount to choose a fluid slip ring that can withstand the system’s pressure without allowing any leaks or breaches, which could potentially compromise the entire operation.

- Cost: Although it shouldn’t be the only determining factor, cost is indeed an essential consideration when selecting a fluid slip ring. High-end fluid slip rings with advanced materials and multiple channels can be relatively expensive. Thus, a cost-benefit analysis should be carried out to ensure the chosen slip ring offers the best value for the investment.

- Material Compatibility: The type of fluid to be transmitted greatly influences the material choice of the fluid slip ring. The material of the slip ring should be compatible with the transmitted fluid to prevent deterioration or damage due to an adverse reaction. For instance, stainless steel might be preferred for transferring high-temperature fluids, while polymers like PTFE could be more suitable for corrosive fluids.

- Temperature Conditions: Extreme operating temperatures may require slip rings made from specific materials that can withstand such conditions without affecting performance. Hence, the operating temperature range of the equipment should be taken into account when selecting a fluid slip ring.

In conclusion, choosing the right fluid slip ring requires deep consideration of all these parameters. This involves a careful evaluation of the application needs, a clear understanding of the fluid properties, and a comprehensive grasp of the operating conditions. By doing so, you can ensure a well-informed choice that not only optimizes system performance but also maximizes the effectiveness and longevity of the fluid slip ring.

Looking for reliable hydraulic rotary joints? Enter your information in our quick inquiry form and get a prompt response from our sales team.

Future Developments in Fluid Slip Rings

As industries and technologies evolve, fluid slip rings are also expected to undergo significant advancements in terms of design, efficiency, and capabilities. These developments are driven by the need to cater to an ever-expanding breadth of applications and the constant technological innovations that shape the associated fields.

- Design Improvement and Efficiency Enhancement: A key area of future development in fluid slip rings lies in advancing their design and efficiency. This includes the introduction of lighter, more durable materials, along with innovative sealing technologies that improve pressure handling and fluid transmission. These enhancements will not only extend the operational life of fluid slip rings but will also help minimize maintenance requirements and energy consumption.

- Integration with Other Technologies: Combining fluid slip rings with other rotary technologies, such as electrical slip rings and fiber-optic rotary joints, will broaden their application potential. This amalgamation of technologies in a single compact unit can enable simultaneous transmission of fluids, power, and data, simplifying system design and space utilization.

- Customizable and Modular Slip Rings: The trend towards customizable and modular slip rings will continue to gain traction, allowing clients to configure fluid slip rings to meet their specific requirements. This flexibility in design will facilitate better integration across a wider scope of applications and industries.

- Smart Slip Rings and IoT Integration: As the adoption of the Internet of Things (IoT) surges across various sectors, the integration of fluid slip rings with sensors and IoT devices is a potential development. Embedding sensors within the slip rings could offer real-time monitoring of fluid properties, component health, and other critical information, thus allowing for predictive maintenance and enhanced operational efficiency.

- Emerging Technologies Impact: In the pursuit of enhancing their performance and reducing environmental impact, emerging technologies, such as additive manufacturing, nanotechnology, or smart materials, will likely play a role in shaping the future of fluid slip rings. These technologies could contribute to the development of stronger, lightweight, and potentially self-repairing fluid slip rings.

Overall, the arena of fluid slip rings is poised for substantial advancements in the years to come. Driven by innovative designs, efficiency improvements, integration with complementary technologies, and the influence of emerging advancements, the future seems promising. These leaps forward will not only expand the applicability of fluid slip rings but will also make them more adaptable and efficient in meeting diverse and evolving needs across numerous sectors.

Conclusion

Fluid slip rings serve as critical components across various industries, offering efficient fluid transmission and reliable performance. Understanding their applications, benefits, and limitations, and carefully considering the selection criteria, will help ensure you choose the right fluid slip ring for your specific needs. As technology continues to advance, fluid slip rings will undoubtedly play an even greater role in a wide range of applications.

See What We Can Do