Founded in 1923, Valeo is a renowned multinational company headquartered in France. The organization excels in the conceptualization, manufacturing, and distribution of comprehensive automotive parts, state-of-the-art systems, and modules tailored to the automobile industry. Serving an extensive clientele from auto manufacturers to private customers, Valeo propels innovation by offering cutting-edge solutions that bolster emission control and simplify driving. A steadfast commitment to research and development sets Valeo as a vanguard in the sphere of progressive automotive technologies. Notably, among its diversified product portfolio, Valeo introduces the “Valeo Slip Ring,” an integral component optimizing electrical power management within vehicles.

Definition of Slip Rings

Slip rings, otherwise known as rotary electrical interfaces, rotating electrical connectors, or electrical rotary joints, serve a vital role in an electromechanical system. They are devices that provide the transfer of power and electrical signals from a stationary to a rotating structure. A slip ring can be used in any electromechanical system that requires rotation while transmitting power and signals.

Importance of Slip Rings in Various Applications

The importance of slip rings cannot be understated as they’re the linchpin in many complex systems. They are found in several applications that require continuous 360° rotation and transfer of power and signals such as wind turbines, closed-circuit cameras, MRI machines, and other power generation units. In the automotive industry, slip rings play a crucial role in parts like the alternator, which generates electrical power in a vehicle. They facilitate seamless, uninterrupted energy transmission, making them indispensable components in a wide variety of electromechanical systems. An understanding of their function and maintenance is pivotal in ensuring these systems continue to run efficiently.

Valeo Slip Ring Features and Benefits

High-Quality Materials

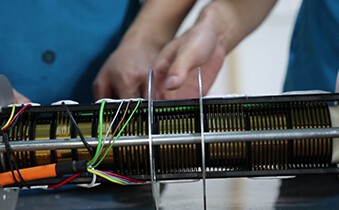

Valeo slip rings are designed with high-quality conductive materials, ensuring maximum efficiency in the transmission of electrical signals and power. From the use of excellent copper and brass, which offer superior conductivity, to the incorporation of wear-resistant alloys for extended product longevity, the materials utilized are meticulously chosen and sourced without any compromise on performance or safety.

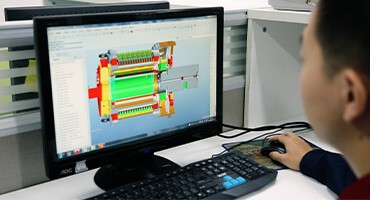

Advanced Manufacturing Process

Valeo leverages advanced manufacturing technologies to produce slip rings that meet the demanding standards of the automotive and industrial sectors. Their manufacturing process emphasizes precision, anticipating all possible stressors in various operational conditions. Through stringent quality control measures, each slip ring undergoes rigorous testing for conductivity, resistance, and durability, ensuring only the finest products reach the end users.

Durable Designs

One of the core reasons behind Valeo’s industry reputation is its commitment to product durability. The design of their slip rings takes into account both typical and extraordinary operating conditions. By focusing on robustness and resistance to wear and tear, Valeo slip rings offer continuity of service over extended periods, reducing the need for frequent replacements.

Wide Range of Applications

The versatility of Valeo slip rings is demonstrated in the broad spectrum of their applications. From slip rings designed for the precise requirements of the automotive sector, which include steering wheel and alternator slip rings, to industrial slip rings for applications such as wind turbines and cranes, Valeo caters to a wide array of necessities. This adaptability makes their products suitable for both niche and broad markets.

OEM (Original Equipment Manufacturer) Product Quality

Being an OEM, Valeo follows a strict compliance matrix that aligns with the expectations of original equipment standards. This implies that their slip rings aren’t just replacements but adhere to stringent manufacturer specifications. The hallmark of Valeo’s products is consistency, assuring that your replacement part will perform as well as the original one. This commitment to excellence fortifies Valeo’s position as a trusted brand in the automotive and industrial sectors.

Types of Valeo Slip Rings

Automotive Slip Rings

Within the automotive sector, Valeo presents a variety of slip rings to cater to various requirements.

Alternator Slip Rings: These are a critical component found in the alternators of many automobiles. Alternator slip rings allow for the transfer of current between a spinning rotor and a stationary stator in the alternator. This transmission of electricity aids in converting mechanical energy into electrical energy, crucial for recharging the car battery and powering electrical systems within the vehicle. Valeo’s alternator slip rings are designed for efficient transmission of power, leading to optimal functioning of the alternator.

Steering Wheel Slip Rings: Also known as a clock spring, the steering wheel slip rings are an essential part of modern vehicles. These slip rings are responsible for maintaining a consistent electrical connection to the steering wheel’s rotating airbag system, regardless of the wheel’s rotation. It ensures the functionality of crucial safety systems, audio, and cruise control systems in the steering wheel. Valeo’s steering wheel slip rings ensure uninterrupted connectivity, reliable performance, and driver safety.

Industrial Slip Rings

To cater to the demands of the industrial sector, Valeo provides slip rings that can withstand industrial-grade conditions.

Wind Turbine Slip Rings: Wind turbines require special slip rings that can transmit electrical signals between the stationary nacelle and the rotating blades. These slip rings need to operate in severe conditions, including very high and extremely low temperatures, without compromising on efficiency. Valeo’s wind turbine slip rings are constructed to withstand these demanding requirements ensuring consistent and optimal performance.

Get in touch with our sales team by filling out the form below.

Crane Slip Rings: Cranes involve heavy rotational movement, and Valeo’s crane slip rings play a key role in electro-mechanical operations. The crane slip rings allow smooth transfer of power and signals between the stationary cabin and the rotating boom, aiding in a seamless lifting operation. With a focus on high load-bearing capacity, Valeo’s crane slip rings contribute to the efficient operation of these colossal machines.

Installation and Maintenance of Valeo Slip Rings

Consistent operation of Valeo slip rings depends heavily on their correct installation and regular maintenance.

Proper Installation Techniques

The effectiveness and durability of slip rings largely depend on the accuracy of their installation.

- Tools Required: A correct set of tools is integral to the proper installation of slip rings. This usually includes a good set of screwdrivers, pliers, a torque wrench to fasten the rings securely, safety glasses, and gloves for personal protection. Furthermore, an ohm meter or multimeter may also be required to check the electrical continuity and resistance of the installed slip rings.

- Step-by-step Installation Guide: Detailed installation guides are key to ensuring that the slip rings are installed correctly and safely. Valeo provides comprehensive instructions for their slip rings, which should be strictly adhered to. This typically involves the precise positioning of components, meticulous assembly, and final testing for secure operation.

Maintenance and Troubleshooting Tips

Like all mechanical devices, slip rings also require routine maintenance for sustained, top-quality performance. Essential maintenance practices include:

- Regular Inspections: Consistent monitoring of Valeo slip rings is pivotal to ensure their healthy operation. A regular visual inspection to check for signs of wear such as surface pitting or grooving can identify potential issues early.

- Cleaning and Lubrication: Dust and dirt can cause wear and tear on the slip rings and degrade performance. Regular cleaning with approved cleaning agents is essential. Similarly, periodic lubrication helps decrease friction, thus preventing overheating and premature wear.

- Identifying Common Issues: Common slip ring issues include increased electrical noise, reduction in performance, and physical abnormalities. Understanding these common problems can expedite troubleshooting. If noticeable issues like uneven wear patterns or increased resistance are observed, it may be indicative of a need for part replacement or a more in-depth examination.

By adhering to these guidelines in the installation and maintenance of Valeo slip rings, the user can ensure maximum product performance and lifespan.

Customer Concerns and Frequently Asked Questions

Valeo understands its customers may have questions or concerns about their slip ring products. Following are some common customer queries.

Price and Availability

Customers often inquire about the price range for Valeo slip rings and their availability. Valeo offers a broad selection of slip rings catering to various requirements and budgets. Prices can be found through authorized Valeo distributors or online retailers. Availability may vary by region and product type.

Warranty Details

Warranty is a crucial aspect when it comes to automotive and industrial products. Valeo is committed to providing top-quality slip rings and backs their products with a warranty. Specific warranty details, including its duration and extent of coverage, may vary based on the product and region. Refer to product documentation or contact an authorized Valeo dealer for detailed warranty information.

Compatibility with Different Systems and Products

One of the common concerns pertains to ensuring compatibility between Valeo slip rings and the customers’ existing systems or products. Valeo slip rings are designed in adherence to standardized specifications, making compatibility with most systems a given. However, it is always advisable to verify compatibility using product documentation, consulting with a Valeo expert, or checking with an authorized dealer.

Where to Buy Original Valeo Slip Rings

Obtaining original Valeo slip rings is essential for guaranteed performance and safety. Valeo highly recommends purchasing products through authorized dealers or reputable online retailers to ensure authenticity and uphold product quality. Buying a genuine Valeo slip ring not only ensures impeccable performance but also provides access to warranty, support, and maintenance services.

Conclusion

With their significant role in various applications, Valeo slip rings stand as a testament to the company’s commitment to quality and innovation. Whether you’re in the automotive business or the industrial sector, choosing Valeo means investing in reliability and efficiency. Harness the power of rotary electrical transmission with Valeo slip rings.

See What We Can Do