The world of electrification and power is wide and full of fascinating components. Among these, the 110v slip ring plays an instrumental role. Whether you’re in the field, an eager learner, or simply curious, understanding this device will benefit you significantly.

Introduction to the 110v Slip Ring

A 110v slip ring, both a humble yet complex device, plays a critical role in our electricity-powered world. The primary function of this component is to provide a continuous electrical connection between stationary and rotating parts. Despite its common title as a ‘slip ring’, it is often referred to as a rotary electrical interface, collector, swivel, or an electrical rotary joint in certain sectors. This function is crucial in numerous applications from wind turbines to motion picture production and closed-circuit television (CCTV).

The very existence of the 110v slip ring has paved the way for significant advancements in technology. By permitting unrestrained, continuous rotation while transmitting power and maintaining an electrical connection, the slip ring helps prevent wire twisting and tangling. By doing so, they open up a whole new realm of design possibilities, directly leading to the creation of more flexible, efficient, and reliable rotating systems.

The slip ring finds applications in myriad sectors. For instance, in wind turbines, slip rings transfer power generated in the rotating wind turbine blades to the grid. Similarly, in the broadcasting industry, they assist in capturing 360-degree coverage without limiting the camera’s movement. Ethernet slip rings further enhance these applications by enabling high-speed data transmission while maintaining continuous rotation. These advanced slip rings support Ethernet networks in rotating systems, ensuring efficient communication in dynamic environments. Consequently, the 110v slip ring, alongside Ethernet slip rings, plays a crucial role in the operation, efficiency, and advancement of a multitude of mechanisms that shape our modern world. Without these, the productivity and smooth operation of rotating systems could be severely hampered. Therefore, comprehending the subtle complexities of these components highlights how pivotal both 110v slip rings and Ethernet slip rings are to the innovative mechanisms we rely upon daily.

How Does a 110v Slip Ring Work?

The operation of a 110v slip ring is indeed a blend of both sophistication and simplicity. The purpose of a slip ring is to maintain a consistent electrical connection between a stationary (stator) and a rotating (rotor) structure. With this function, they allow for an uninterrupted transmission of power or signals, contributing considerably to the fluent operation of many rotating devices.

The 110v slip ring’s operation revolves around two central components: Conductive Rings and Brushes. The rotating part of the device, typically connected with an electric motor or a rotating assembly, comprises the conductive rings. On the other hand, the brushes, in contact with these rings, are on the stationary part of the device.

As the rotor spins, the brushes, which are held against the surface of the rings by a spring mechanism, glide over the conductive rings. This action allows for the transmission of electrical power or signals between the brushes and the conductor rings, hence keeping an electrical connection while the system rotates. This mechanism ensures that power and signals can cross from the stationary component to the rotating component, or vice versa while allowing the joint to rotate continually.

For instance, consider a wind turbine. The blades (rotating structure) rotate to generate electricity. The 110v slip ring carries this generated power from the rotating blades to the stationary grid. It does so by transmitting the power across its rotating conductive rings to the stationary brushes, and ultimately to the power grid. This simple yet ingenious mechanism underpins the working of the 110v slip ring, making it integral to any rotating system where power or signal transmission is crucial. Understanding this operation not only provides insight into the slip ring but also imparts a greater appreciation for the devices it benefits.

Types of 110v Slip Rings

As the need for 110v slip rings spans numerous industries and applications, it’s only natural that they come with a wide array of variations. Different slip ring designs cater to specific requirements, such as size constraints, signal integrity, transmission speed, and environmental conditions. By delving into the variety of 110v slip rings, you can better understand which type aligns best with your intended use.

Cylindrical Slip Rings

The most common type of slip rings, cylindrical slip rings, consist of a central rotating shaft with conductive rings around it. Brushes, often made of precious metals like gold or silver, make contact with the rings to provide a stable electrical connection. The cylindrical design enables these slip rings to offer more conductive paths and handle higher voltages and currents. They are ideal for various applications, including wind turbines, rotary tables, and cranes.

Pancake Slip Rings

Pancake slip rings adopt a flat, disk-like structure, where the conductive rings lay flat on a surface, resulting in a more compact design. These slip rings have a lower profile and often boast a lower weight compared to their cylindrical counterparts. Pancake slip rings find use in applications where there is limited space or weight constraints, such as robotics and cable reels.

Through-bore Slip Rings

These slip rings cater to scenarios where a central hole is essential for allowing the passage of additional components, such as a shaft or other cables. The design boasts a stationary core, surrounded by conductive rings, and its brushes contact from the inner diameter towards the outer. Though similar to cylindrical slip rings in basic structure, through-bore slip rings contribute to space optimization and versatility in various industrial applications involving rotary tables or imaging equipment.

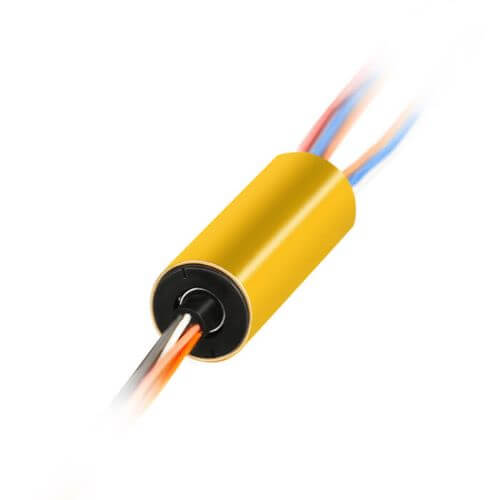

Capsule Slip Rings

Capsule slip rings are miniaturized versions designed for use in smaller, more delicate devices. Typically intended for transmitting low-power signals and featuring gold-alloy brushes, these slip rings find their purpose in applications like medical equipment, security cameras, and miniature motors.

Understanding the diversity of the 110v slip rings enables users to choose the most suitable device for their specific needs. The interplay between device design and its intended applications is crucial for selecting the right slip ring, which ensures seamless operation and the efficient functioning of your rotating systems.

Applications of 110v Slip Ring

Specifications of 110v Slip Ring

Here is a detailed specification for a typical 110V slip ring, commonly used in industrial and automation applications. If you have specific needs, we can refine this further:

1. General Specifications:

- Voltage Rating: 110V AC/DC

- Number of Circuits: Typically ranges from 2 to 24 circuits, depending on the model and application.

- Current Rating per Circuit: Standard models can carry between 2A to 20A per circuit, with higher current models available upon request.

- Operating Speed: Typically up to 300 RPM, though high-speed models can go up to 1000 RPM.

2. Mechanical Specifications:

- Outer Diameter: Usually ranges from 22mm to 50mm for standard models. Custom sizes are available.

- Length: Depends on the number of circuits, typically ranging from 35mm to 150mm.

- Material:

- Housing: Aluminum or stainless steel for durability and corrosion resistance.

- Rotor/Slip Rings: Brass or silver-plated copper for enhanced conductivity.

- Brushes: Gold alloy or graphite brushes for improved contact and longevity.

3. Electrical Specifications:

- Insulation Resistance: Greater than 1000 MΩ at 500VDC.

- Dielectric Strength: 1000VAC @ 50Hz between each circuit and the housing for one minute without breakdown.

- Contact Resistance: Less than 30 mΩ per circuit.

- Signal Types: Capable of transmitting power, analog signals, and digital signals such as Ethernet, USB, and others. Specialized slip rings can handle mixed signals without interference.

4. Environmental Specifications:

- Operating Temperature: Standard models are rated from -20°C to +80°C. High-temperature models can operate up to +150°C.

- Humidity: 0 to 85% RH, non-condensing.

- IP Rating: Standard models typically have an IP51 rating. For harsh environments, IP65 or higher models are available.

- Vibration Resistance: Standard models can withstand 10G peak-to-peak vibration. Enhanced models for higher vibration environments are available.

5. Mounting and Installation:

- Mounting Options: Flange-mounted, through-hole, or end-of-shaft mounting, depending on the application.

- Cable Entry: Radial or axial cable entry options.

- Connector Types: Standard models include lead wires. Options for connectors (e.g., terminal blocks, plugs) can be provided based on the application.

6. Special Features:

- Maintenance-Free: Many models are designed for long life without the need for maintenance.

- Customizable: Slip rings can be tailored to specific needs, including circuit count, current, voltage, size, and environmental protection.

7. Certifications:

- Compliance: RoHS, CE, and other industry-specific certifications.

- Testing: Each slip ring is tested for electrical performance, insulation resistance, and mechanical integrity before shipment.

This specification provides a comprehensive overview of a standard 110V slip ring. If your application has specific needs—such as a higher current rating, special environmental conditions, or unique mounting requirements—these can be addressed with a custom solution.

110v Slip Ring Current Rating

The current rating for a 110V slip ring can vary depending on the specific design and application requirements. Below are some typical current ratings for 110V slip rings, which can be customized based on the number of circuits and the intended use:

Low Current Applications

- Current Rating: 2A to 10A per circuit

- Typical Use: Used for signal transmission or low-power applications where the slip ring needs to transmit control signals, data, or small amounts of power. These are common in applications like robotics, medical devices, and small rotating equipment.

Medium Current Applications

- Current Rating: 10A to 30A per circuit

- Typical Use: Suitable for medium-power applications such as rotary tables, packaging machinery, and some types of industrial automation equipment where the slip ring is used to transmit power to motors or other electrical devices.

High Current Applications

- Current Rating: 30A to 100A per circuit

- Typical Use: Used in high-power applications, including large industrial equipment, wind turbines, and cranes where substantial amounts of power need to be transmitted across the rotating interface.

Very High Current Applications

- Current Rating: Over 100A per circuit (up to 500A or more, depending on design)

- Typical Use: Custom slip rings are available for applications requiring very high current, such as large-scale industrial machinery, heavy-duty cranes, and certain types of energy generation equipment.

Factors Affecting Current Rating

- Number of Circuits: The total current carrying capacity can be distributed across multiple circuits, allowing for higher total current.

- Slip Ring Size: Larger slip rings generally can handle higher currents due to larger contact areas and better heat dissipation.

- Material Selection: The use of high-quality conductive materials like silver-plated copper can enhance current carrying capacity.

- Cooling Mechanisms: Some high-current slip rings may incorporate cooling features to manage the heat generated by high current.

The current rating must be carefully matched to the application to avoid overheating and ensure reliable operation. For specific applications, manufacturers can design slip rings with custom current ratings and features.

110v Slip Ring Installation Process

Installing a 110v slip ring may seem like a challenging task, especially for those without much technical experience. However, with the correct tools, a detailed guide, and a careful, patient approach, the installation process can be accomplished efficiently. Here is a basic guide to help you with the installation:

Pre-installation Steps:

To get started, you will need to know the exact type of slip ring you will be handling and the specific installation requirements for that model. These details can usually be found in the user manual provided by the slip ring manufacturer. You might also need some basic tools such as a set of wrenches, pliers, wire strippers, and a multimeter for electrical testing, depending on your exact needs.

Installation Steps:

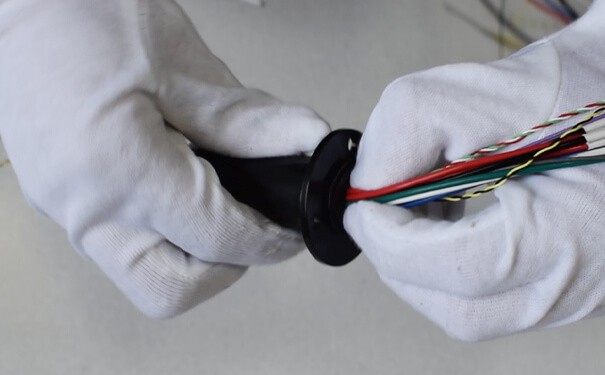

- Power Disconnection: All power sources connected to the system should be disconnected to ensure safety during the installation process.

- Device Placement: The slip ring should be positioned on the rotating part of your device accurately. Be cautious not to impose excessive force, as it could damage the slip ring or your equipment.

- Wire Connections: Electrical wires from your power source or control module should be connected to the stationary part of the slip ring (brush side). Similarly, wires leading to the rotating part of your device should be connected to the rotating part of the slip ring (ringside). Be sure to confirm the correct wiring pattern as per your slip ring’s manual.

- Checks and Testing: Once all the connections are made and secured, thoroughly inspect your system for any improper connections or potential issues. Test the setup using a multimeter (or any other recommended device), ensuring proper electrical connection before restoring power.

Do’s and Don’ts during Installation:

- Do read and follow the user manual thoroughly.

- Do disconnect all power sources before starting your work.

- Don’t use excessive force or aggressive tools during the installation process.

- Don’t overload the slip ring beyond its specified power rating.

- Do inspect the slip ring and the entire system before and after installation.

- Do conduct proper electrical testing before restoring power.

The installation process, though technical, can be simplified by adhering to the manufacturer’s guidelines and using the recommended tools. Adhering to these instructions and maintaining the utmost care will result in a successful 110v slip ring installation, ensuring optimal performance from your rotating system.

110v Slip Ring Maintenance and Troubleshooting

To prolong the service life and ensure the reliable operation of the 110v slip ring, regular maintenance, and effective troubleshooting are critical. Implementing timely maintenance can prevent common issues from becoming serious problems, while troubleshooting can help quickly resolve unexpected difficulties.

Maintenance Practices:

Here are some recommended practices to maintain your 110v slip ring:

- Regular Inspection: While slip rings are designed for prolonged use, regular inspection is advised. Look out for worn-out brushes, excessive dust build-up, or any visible damage.

- Cleaning: Dust and foreign particles can disrupt conductivity between the brushes and the ring. Regular cleaning with a dry, non-abrasive cloth helps to prevent this.

- Lubrication: Ensure that there is sufficient lubrication between the brushes and the ring. The specific type and frequency of lubrication may vary, and this information should be available in your slip ring’s manual.

- Replacement of Parts: Over time, specific components, especially the brushes, may wear out and require replacement. Always use replacements specified by the manufacturer to maintain optimal performance.

Common Problems and Troubleshooting Techniques:

Certain issues can arise during the operation of a 110v slip ring. Here are some common problems and how you can troubleshoot them:

- Noise and Vibration: If your slip ring starts creating excessive noise or vibrations, it could be due to worn brushes or misalignment. Check the brushes for wear and replace them if necessary. If misalignment is the issue, realignment might be needed.

- Electrical Fluctuations: If you are experiencing unexpected voltage or current fluctuations, this could be due to poor contact between the brushes and the rings, perhaps due to dust build-up, lack of lubrication, or worn brushes. Cleaning, lubricating, or replacing brushes could solve this problem.

- Overheating: Overheating could be a result of overloading or friction due to worn brushes or lack of lubrication. Check the load on your slip ring, and if it is within specified limits, consider replacing brushes or improving lubrication.

- Intermittent Functioning: If your slip ring operates intermittently, it could be due to a loose connection or a damaged part. Inspecting and tightening all connections or replacing defective parts should resolve this issue.

In essence, maintaining and troubleshooting your 110v slip ring not only ensures smooth operation but also significantly extends its service life. Remember, always refer to your user manual or consult with a professional when in doubt to prevent potential harm or damage.

110v Slip Ring Buying Guide

Buying a 110v slip ring requires careful consideration of various factors, as your choice can significantly impact the performance and longevity of your rotating systems. Being familiar with prominent models and manufacturers is also beneficial. This guide will help you navigate these considerations, ensuring you make an informed decision.

Factors to Consider:

When buying a 110v slip ring, here are some key factors to consider:

- Type of Slip Ring: As outlined in Section III, there are several types of slip rings each serving different needs. Your choice should depend on the specific requirements of your application, such as spatial constraints or the necessity for a through-bore.

- Load Capacity: It’s vital to choose a slip ring that can handle the electrical load of your system. Overloading can lead to overheating and premature failure.

- Durability & Environment: Consider the build quality of the slip ring and its readiness to withstand your operating environment. For instance, in dusty or outdoor settings, a slip ring with dust and water resistance would be beneficial.

- Required Connections: Count the number of signal and power connections you’ll need to make, and ensure the slip ring you choose can accommodate them.

- Maintenance: Some models may require more regular maintenance than others. Depending on your setup’s accessibility, you might prefer a model that requires less frequent interventions.

Recommended Models/Manufacturers:

Different models and manufacturers offer a variety of slip rings to cater to the unique demands of applications.

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

In conclusion, purchasing a 110v slip ring necessitates a careful examination of your requirements and the offerings of reputable manufacturers in the market. A well-informed decision can lead to greater operational efficiency and longevity of your rotating systems.

Fill out the form to get a quote tailored to your 110v slip ring needs.

110v Slip Ring Safety Measures

While the use of a 110v slip ring significantly enhances the performance of rotating systems, it is important to maintain strict safety measures. This defined guideline will help prevent accidents and unnecessary damage to your equipment or harm to personnel around it.

Safety Precautions:

Here are some safety measures to observe when using a 110v slip ring:

- Electrical Safety: As a slip ring conducts electricity, it is crucial to handle it with care. Always disconnect power before working on its installation or maintenance. Use insulating gloves and tools, if possible, to avoid accidental shocks.

- System Overload: Never exceed the current or voltage limit specified by the manufacturer. Overloading can lead to overheating and, ultimately, failure of the slip ring.

- Correct Installation: To avoid misalignment or imbalance that can cause failure or accidents, follow the installation guide properly. When in doubt, consult the manual or a professional.

- Regular Inspections: Conduct regular checks for signs of wear or damage. Defective parts should be replaced immediately to prevent further harm or damage.

- Safe Environment: Ensure the working environment is dry, clean, and free from flammable materials.

What to Do and Not to Do:

Here is a list of Do’s and Don’ts while handling a 110v slip ring:

- Do disconnect power before working on the slip ring for any purpose – be it installation, maintenance, or troubleshooting.

- Don’t exceed the manufacturer-specified load capacity. Overloading can cause significant damage.

- Do conduct regular inspections to keep tabs on the slip ring’s condition.

- Don’t use a slip ring in an inappropriate environment. For instance, a non-weatherproof slip ring should not be used outdoors.

- Do replace worn-out parts as soon as possible. Prolonged use of defective parts can cause system breakdowns.

Maintaining safety measures while using a 110v slip ring enhances its performance and increases its longevity. Moreover, it ensures a safe environment, preventing potential mishaps. Above all, always remember to refer to your slip ring’s manual as the first point of information and consult professionals when unsure.

110v Slip Ring Potential Upgrades and Future Advancements

As technology continues to advance rapidly, the design and functionality of the 110v slip ring are also evolving. Future advancements could potentially enhance its performance and expand its applications significantly. Let’s delve into the anticipated advancements and how they might shape the future of 110v slip ring technology.

Future Advancements:

Looking into the future, here are some areas where advancements in technology could enhance the performance of the 110v slip ring:

- Materials and Design Innovations: The increased research in materials science could lead to the discovery of innovative materials and designs for slip rings. These new materials could offer superior contact reliability, greater thermal conductivity, and longer lifespan.

- Integration with Smart Technologies: The integration of sensors and smart technologies could route real-time data on the device’s performance, predicting wear and tear, reducing unforeseen downtime, and streamlining maintenance.

- Wireless Technology: Although currently more prevalent in low-power scenarios, the progress in wireless power transmission techniques could influence future designs of slip rings, potentially minimizing physical contact and reducing wear and tear.

Trends and Potential Upgrades:

Several trends suggest potential upgrades for 110v slip rings, which make these devices even more valuable:

- Miniaturization: In response to the increasing demand for smaller, more efficient electronics, manufacturers are focusing on reducing the size of slip rings without compromising their performance.

- Environmentally Robust Models: With an increasing need for slip rings that can perform in more challenging environments such as in deep-sea drills or outdoor weather stations, we can expect more corrosion-resistant and durable designs.

- High-Speed Performance: As rotational speeds increase in many modern applications, the need for 110v slip rings capable of maintaining reliable electrical contact at high speeds will continue to grow.

In conclusion, the journey of technological advancements and the potential upgrades bear promise for the future of 110v slip rings. Integrating modern technologies, innovating materials and designs as well as addressing evolving application needs will undoubtedly bring about significant improvements in slip ring performance, efficiency, and lifespan.

Conclusion

The 110v slip ring, albeit small, is an integral part of our electrified world. From understanding its operation to knowing how to choose, install, maintain, and foresee its future trends, this guide aims to provide comprehensive insights into this humble yet essential component. As technology advances, so too do our needs and understanding—a concept underlined by the evolving saga of the 110v slip ring.

See What We Can Do