This article provides an in-depth exploration of slip ring applications in shipyards, their applications, key considerations in choosing a slip ring, and emerging trends. Now, let’s dive into the captivating world of shipyard slip ring uses.

Introduction to Slip Ring Applications in Shipyards

In industries where motion is omnipresent, the transfer of electrical energy or data signals between stationary and moving components is a significant challenge. The solution comes in the form of a device known as a slip ring. Although they display myriad forms and sizes to fit various applications, slip rings fundamentally carry out the same function. They transmit power and data signals from a stationary object to a rotating one, thereby enabling continuous, unrestricted movement without compromising the connection’s integrity. One notable example is the slip ring application in marine environments, where they are essential for maintaining the functionality of rotating radar systems, winches, and other critical equipment on ships and offshore platforms.

With the rapid advances in technology, the concept of slip rings has diversified, penetrating various sectors, one of the most prominent being shipyards. Shipyards serve as the heart of the maritime industry, filled with a plethora of machinery and systems revolving around different axes. Here, slip rings have been widely integrated and play a quintessential role in their operations.

The importance of slip rings in shipyards cannot be overstated. These devices serve as vital cogs in the shipyard industry, keeping enormous, heavy machinery as well as delicate data systems in constant, fluid motion without affecting power transmission. Shipyards often house machinery like cranes, winches, or cable reels that need 360-degree unhindered rotation whilst preserving power or signal transmission. Slip rings fulfill this requirement seamlessly, facilitating smooth, efficient operations and preventing potential mishaps associated with interrupted power or signal flow.

In essence, the contribution of slip rings to shipyard applications significantly underpins maritime operations’ efficiency, continuity, and safety. Their function extends not only to power maintenance during machine movement but also to safely channeling data across systems, making their presence indispensable in the shipyard arena.

Types of Slip Rings Used in Shipyards

Considering the unique requirements and diverse machinery in shipyards, different types of slip rings find application in this sector, each suited to specific roles and conditions.

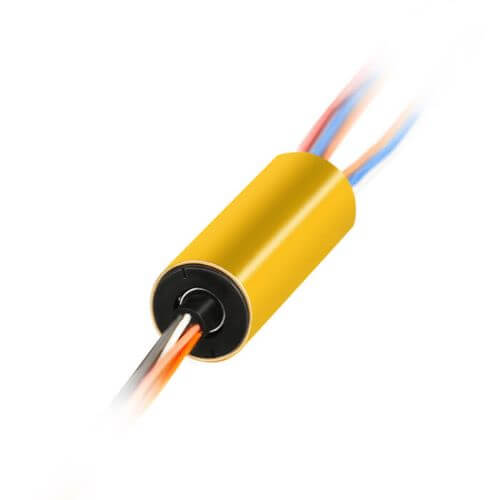

The first type often found in shipyard settings is the Capsule Slip Ring. These are lightweight, compact, and highly adaptable, making them excellent for confined spaces or devices with limited circuit needs. Despite their small stature, they carry substantial power, effectively conducting both signals and power for numerous shipyard systems. Their main advantage lies in their ability to fit into compact spaces where larger slip rings might not be feasible.

Next on the list is the Pancake Slip Ring. Named for their flat, round design reminiscent of a pancake, these slip rings are especially suited for equipment with height restrictions. Even though they have their limitations due to the planar design, such as the reduced capacity to carry multiple circuits, they are unbeatable in situations where the system’s height needs to be as compact as possible.

The Through-Bore Slip Ring forms another integral part of the slip ring family in shipyards. Characterized by their large center hole or ‘bore’, they are designed to allow additional components such as fluid, gas passages, or even shafts to pass through them. This makes them highly versatile and suitable for complex applications demanding more than just power and signal transmission.

Lastly, we have the Ethernet Slip Rings, an advanced type of slip ring crucial for the digital age. In a highly networked environment like shipyards, where real-time communication and data exchange are paramount, Ethernet slip rings are indispensable. They permit the transmission of high-speed Ethernet signals between stationary and rotating components without loss or interruption, a strong pillar of support for the shipyard’s integrated IT and communication systems.

In summary, each of these types of slip rings has its unique characteristics tailored to the varied needs of a shipyard. From power transmission to data exchange, from the jib crane’s top to the ship’s communication systems, these slip rings ensure the smooth rotation and consistent functioning of a multitude of machinery components and systems within the shipyard.

Key Shipyard Applications

A highlight of the shipyard sector is its eclectic assortment of machinery and equipment, each with its unique function and operational demands. Here is an in-depth look at the key shipyard applications that incorporate slip rings.

Cranes and Lifting Systems

Cranes and lifting systems represent the very foundation of shipyard operations, holding the immense responsibility of moving and lifting heavy maritime equipment and loads. Among these, slip rings find crucial applications in the following types of cranes:

- Jib Cranes: With a horizontal member called a jib or boom, these cranes are essential in shipyards for tasks involving the lifting and moving of heavy loads. As the jib structure rotates, slip rings ensure the uninterrupted transfer of power and control signals, permitting a smooth 360-degree rotation.

- Overhead Cranes: Suspended high above the ground, overhead cranes transport heavy items across the shipyard. Their trolleys and hoists, which often require free rotation, utilize slip rings to maintain continuous power supply and control throughout their operation.

- Gantry Cranes: Renowned for their strength and heavy lifting capacity, these cranes are a common sight in shipyards worldwide. When the crane’s gantry or trolleys rotate, slip rings facilitate uninterrupted power and data transfer, keeping the crane fully operational.

Cable Reels

In a bustling shipyard, the management of power cables and hoses is handled by cable reels. As these reels rotate to wind or unwind the cables, slip rings play an essential role in maintaining a constant power supply, preventing potential disruptions during operations.

Vessel Communication Systems

Modern shipyards teem with sophisticated communication systems in the vessels, including radar, navigation, sonar, and other essential electronics. Ethernet slip rings form the backbone of these systems, enabling fast and reliable data transmission between the stationary and rotating parts of the ship’s communication infrastructure.

Remotely Operated Underwater Vehicles (ROV)

In domains like research, exploration, and underwater repairs comes the role of Remotely Operated Vehicles (ROVs). These complex pieces of machinery require highly specialized slip rings. These slip rings not only have to sustain the high pressure and harsh underwater conditions but they also have to ensure the unhindered transfer of signals and power for the best ROV’s performance.

In conclusion, these various applications paint a picture of the omnipresence of slip rings in shipyard operations – playing an essential role in ensuring the yard operates like a well-oiled machine.

Factors to Consider When Choosing Slip Rings for Shipyard Applications

Given the pivotal role slip rings play in shipyard operations, selecting the right ones to match specific applications is crucial. Numerous factors come into play when considering the most suitable slip rings:

- Current and Voltage Requirements: The core competency of a slip ring lies in its ability to effectively transmit electric power and signals. So, the first consideration must be the specific current and voltage requirements of the equipment it will be integrated into. The chosen slip ring must be able to handle these specifications effectively and reliably.

- Environmental Conditions: Shipyards often present harsh environments characterized by increased moisture, corrosive saltwater, and fluctuating temperatures. Therefore, slip rings meant for this purpose should have strong resistance against corrosion, moisture, and extensive temperature ranges to ensure prolonged operation and lifespan.

- Durability and Reliability: Sub-par, unreliable slip rings can not only hamper operations but can also result in safety risks. Hence, it’s essential to choose slip rings proven for durability and reliability, capable of withstanding the rigors of heavy usage over extended periods.

- Integration with Existing Systems: Compatibility with the intended machinery or system is another crucial factor. The selected slip ring should seamlessly integrate into the existing system, both in terms of mechanical fit and capability to handle the power and data transmission requirements.

- Manufacturer’s Reputation and Support: It’s advisable to engage reputable manufacturers known for their quality products and excellent customer support. Reliable support from the manufacturer ensures expert help is available when needed, including set-up, troubleshooting, and maintenance.

- Cost and Maintenance Considerations: Budget constraints and maintenance costs also need to be factored in. While higher-end slip rings may involve a higher initial investment, their lower maintenance, and longer lifespan might make them a better choice in the long run. Understanding the full lifecycle cost of the slip ring, not just the purchase price can lead to a decision that saves time, money, and resources over time.

Taking these factors into account, it becomes clear that choosing the right slip ring for shipyard applications requires a comprehensive understanding of both the demands of the application and the specifications and performance of the slip ring itself. Through their thoughtful selection and implementation, slip rings can significantly contribute to the efficient, smooth, and safe operation of a shipyard.

Slip Ring Applications in Shipyards: Maintenance and Troubleshooting

Slip rings not only find remarkable usage in active operations in shipyards but also play a pivotal role in the maintenance and troubleshooting sector. Whether for regularly ensuring top-notch conditions or facing unforeseen issues, slip rings become indispensable assets.

Importance of Regular Maintenance and Inspection

For consistent optimal performance of the shipyard machinery and systems, regular maintenance and inspection of slip rings are crucial. Routine monitoring acts as a preventive measure – eliminating potential problems before they can trigger failures or shutdowns. Regular inspection can reveal issues such as wear and tear, accumulation of debris, and signs of corrosion, among others. Being timely aware of these issues enables the team to take necessary measures before a critical system failure occurs.

Maintenance activities typically include cleaning, application of lubricants, checks for proper installation, and examination of the brush pressure. These precautionary measures ensure that the slip rings operate smoothly, thereby increasing their lifespan, and in turn, the operational efficiency of the associated machinery or system.

Common Issues and Troubleshooting Tips

Despite regular maintenance, some slip ring-related issues are bound to arise given the heavy-duty nature of shipyard operations. Here are some of the common problems and tips for troubleshooting them:

- Unstable Signals: Unstable or intermittent signals can arise from dirty or worn-out brushes, or even from a faulty contact surface. A comprehensive cleaning of the slip ring and brush or replacing the worn-out parts can resolve the problem.

- Wear and Tear: Although slip rings are designed for continuous operation, they are not immune to wear and tear, which can degrade their performance over time. Regular inspection can help detect premature wear. This can be addressed by ensuring proper installation, maintaining suitable brush pressure, and supplementing with adequate lubrication.

- Noise or Vibrations: Unusual sounds or vibrations often indicate an improperly installed slip ring or issues with the bearing. Rechecking the installation and fixing the alignment can rectify the issue. In the case of bearing problems, it might require professional servicing or replacement.

Hence, regular maintenance and timely troubleshooting of slip rings form an integral part of shipyard operations. Being aware of potential issues and their remedies can prevent unnecessary downtime and ensure the seamless execution of shipyard tasks.

Featured Slip Ring Manufacturers for Shipyard Applications

Understanding the crucial impact of slip rings in shipyard operations, and adhering to quality products from reputed manufacturers is paramount. Here are a few names that have shown exemplary commitment and have achieved a solid track record in the shipyard industry:

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog Inc. | https://www.moog.com/ |

| 3 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 4 | Schleifring | https://www.schleifring.com/ |

Hangzhou Grand Technology

Hangzhou Grand Technology Co., Ltd. started as a special slip ring manufacturer in 2011. Grown into slip rings, rotary joints, and slip ring assembly experts of today with 6,000 square meter manufacture complex.

Obtained ISO9001, Rosh, CE, and GJB9001B certificates a number of slip rings, rotary joint patents, and proud of our products can meet military grade. Collaborated with universities, institutes, and renowned factories across Asia and Europe including Panasonic, SIEMENS, CSIC, SAMSUNG, HUAWEI, etc.

Moog Inc.

Moog is a leading supplier of high-performance slip rings for various industries, including aerospace. Among their offerings, Moog’s SR Series Slip Rings are designed for the demanding environments of helicopters, excelling in performance, reliability, and customization potential.

Stemmann-Technik

Stemmann-Technik, a part of the Conductix-Wampfler Group, offers a broad range of slip rings, including solutions for helicopters. Their Livietta Slip Ring Assemblies are designed explicitly for harsh and demanding environments in the aviation sector, providing reliable signal and power transmission.

Schleifring

Schleifring is a well-known manufacturer of electromechanical systems, including slip rings customized for various industries. Their Aircraft Slip Rings cater specifically to helicopters, offering robust performance, low wear, and high reliability to meet the challenges of aviation applications.

If you want to know more about other slip ring manufacturers, you can read Top 10 Slip Ring Manufacturers in China, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Industry Key Manufacturers 2023.

Looking for custom slip rings? Send us your requirements.

These manufacturers are not only known for their premium-quality slip rings but also for their dedicated customer support and engagement. When robust performance and reliability are prime considerations, opting for products and solutions from these manufacturers is a wise choice for long-term success in shipyard operations.

Slip Ring Applications in Shipyard: Future Trends and Advancements

The maritime industry is always on the move, constantly innovating to overcome challenges and improve efficiency. Slip rings, as critical components in shipyard operations, are no exception. They are being upgraded and adapted to meet the developing demands of the industry.

Innovations in Slip Rings for Shipyard Applications

- Improved Materials and Design: There’s a development focus towards using stronger, more reliable materials in slip ring designs – ones that can endure harsh environments and heavy usage in shipyards. The use of new materials like composites, ceramics, and more effective lubricants is predicted to have lesser wear and tear, enhancing life expectancy.

- Miniaturization: With the rising demand for compact, space-saving devices across industries, even slip rings are not far behind. Engineers are striving for the miniaturization of slip rings, creating smaller models without compromising on their efficacies.

Anticipated Technological Advancements and Their Impact

- Integration with Advanced Systems: Starting from the Internet of Things (IoT) to any advanced integrated systems that could be used for enhanced shipyard operations, slip rings are expected to evolve in tandem. This integration will allow for better remote monitoring and control, preventive maintenance, and overall operational efficiency.

- Wireless Slip Rings: Cutting-edge research is looking at eliminating the physical contact in slip rings entirely. Wireless slip rings, also known as induction slip rings, are being explored as future solutions to overcome a majority of issues encountered with traditional slip rings like wear and tear or issues related to dust and debris contact.

Slip ring technology, in line with other areas of maritime technology, is growing more sophisticated and refined by the day. As engineers continue to innovate and technologies advance, it is safe to predict that the future of slip rings in shipyards is brighter and more exciting than ever before.

Conclusion

The world of shipyard slip ring applications is both broad and diverse. Given their critical role, careful selection, regular maintenance, and staying updated with technology advancements can significantly contribute towards efficient and effective shipyard operations.

See What We Can Do