Welcome to our comprehensive guide on traditional slip rings. In this article, we delve deep into what traditional slip rings are, their structure, classifications, and operating principles. We shall also discuss their applications, look into common challenges that users face and how to troubleshoot them, and even give hints on selecting the right slip ring for your requirements. All this while focusing on what users frequently ask about – selection, maintenance, longevity, and resolving issues with traditional slip rings.

Introduction to Traditional Slip Rings

In a world where rotating machinery and mechanisms are pivotal for a plethora of applications, one component stands as a cornerstone for their successful operation – the traditional slip ring. At the heart of numerous technologies, these electromagnetic devices allow an efficient, unbroken transmission of power and electrical signals from a stationary structure to rotating bodies.

The primary function of these slip rings is to provide smooth electrical connectivity between the static and the rotary parts of machinery. They eliminate the limitations set by physical connections which can hamper apparatus movement, ensuring the system remains operational regardless of its relative motion or rotation. This property makes traditional slip rings indispensable to industries ranging from automation, and renewable energy, to defense and healthcare sectors.

In this comprehensive guide, we will navigate through various depths of traditional slip rings, beginning from their basic structure, delving into the principle of operation, and journeying through the numerous types and applications. Further, we step into the practical side detailing the maintenance practices and addressing common challenges faced by users, useful pointers for selection, and concluding with a glimpse of what future trends and innovations lie in store for this technological marvel.

The wisdom embedded in this discourse makes it not just truly beneficial for industrial professionals but also for curious enthusiasts eager to understand these electromechanical devices. After the course of this article, folks interacting with these devices will be more equipped to make informed decisions, maintain their machinery, and even troubleshoot basic issues, given the knowledge they would have rounded up about traditional slip rings.

With coherence lying at the heart of our endeavor, we aim to knit everything holistically, ensuring a seamless understanding for our readers. Let’s embark on this enlightening journey to unravel traditional slip rings and their significant impact on our lives!

The Anatomy of Traditional Slip Rings

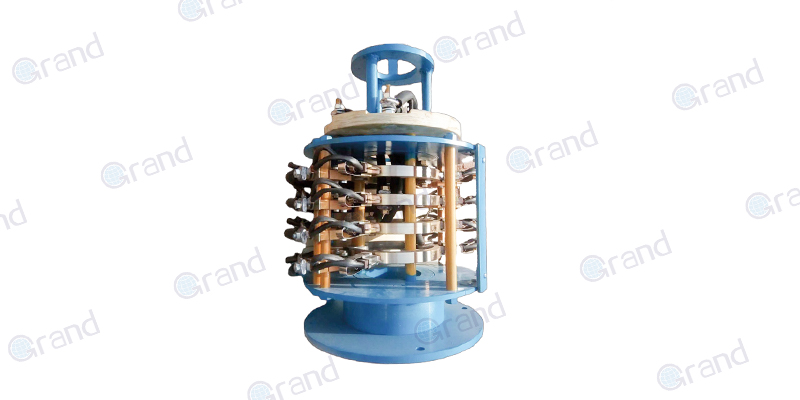

To fully appreciate the workings of a traditional slip ring, it becomes critical to understand its basic structure. Each traditional slip ring, in the simplest terms, is a well-orchestrated assembly of three key components: conductive rings, brushes, and sturdy housing.

A closer look at a slip ring reveals a set of conductive rings and brushes working harmoniously. The conductive rings are essentially electrically conductive tracks, often made of metal like copper or silver. These are neatly placed around the rotor – the rotating part of the slip ring. The number of these rings can vary depending on the number of circuits the slip ring intends to handle. These rings are the crucial pathways for the electric current to traverse between the stationary and rotating sections of a device.

Next in line are the brushes. The brushes, contrary to what the word ‘brush’ may suggest, are usually solid metal (like gold or copper) or graphite blocks. These remain static and are maintained in physical contact with the conductive rings. As the rings begin to rotate with the rotor, the bristles of the brush mechanism ‘brush’ over the rings. This action forms a consistent, sliding electrical contact between the stationary system that the brushes are a part of, and the conductive rings on the rotating system.

Finally, holding these intricate components together and providing mechanical support is the housing. The housing serves as a protective casing for the conductive rings and brushes. It helps maintain alignment among the components and insulates the circuitry from the surrounding environment. It often incorporates design components to handle challenging conditions, such as high-speed rotations, extreme temperatures, or even potential exposure to liquids or dust.

In essence, the coherence of the traditional slip ring’s structure is somewhat akin to an elegant dance. The rotating conductive rings and stationary brushes glide past each other, furthering electrical connectivity, while the sturdy housing safeguards them, ensuring the dance goes on unhindered. Together, these components put forth the seamless operation of a traditional slip ring, making them an integral part of many sophisticated devices today.

Traditional Slip Ring Operating Principles

Understanding the operating principles of traditional slip rings can appear complex, yet it unveils a beautiful interplay of simple concepts of physics and engineering. To grasp the fundamentals, we must focus on the most crucial aspect of slip ring operation – the electrical connectivity between the stationary and rotating components.

The operation of traditional slip rings hinges on one primary principle: the transmission of power or electrical signals between a stationary structure and a rotating one. This principle is remarkably achieved by using the slip ring as a mediator which connects the power source (on the stationary part of the stator) to the power consumer (on the rotating part or the rotor), all the while allowing the rotor to spin freely.

The process starts when an electrical signal or power is introduced into the system. The stationary brushes, connected to this source, carry the electrical input. Each brush is in contact with its respective conductive ring mounted on the rotor. As the rotor begins its rotation, the brushes maintain a sliding contact with these conductive rings, transferring the electrical signals or power in its path.

Despite the motion, the consistent contact between the brushes and rings ensures an unbroken electrical connection between the static and rotational components. Therefore, within this intriguing process, we find a simple yet clever resolution to a significant engineering problem: maintaining electrical connectivity amidst motion.

To visualize, one can imagine a traditional carousel ride. Upon moving, the carousel (rotor) remains brightly lit and functional (thanks to the electrical conductivity) while it is spinning, just like the slip ring enables power flow to the rotating parts of machinery.

The coherence of this operation, while critical, is what makes traditional slip rings an integral part of countless applications. By understanding this principle, users can better appreciate the breadth and depth of their application, revolutionizing everything from small-scale industrial equipment to large wind turbines, and more.

Types of Traditional Slip Rings

Traditional slip rings, as versatile electromechanical devices, vary in material, design, and the type of signals they transmit, catering to the demands of diverse applications. Delve with us into the world of these classifications, uncovering a coherent context that unveils the uniqueness of each type and its use in practical scenarios.

Classification Based on Signal Transmission

The purpose of slip rings primarily lies in the transfer of distinct types of signals or power to execute varied tasks. The major classifications are:

- Power Slip Rings: These slip rings transmit electrical power from a stationary structure to a rotating assembly. They find their use in a multitude of applications, including wind turbines, cranes, and rotating platforms in manufacturing machines.

- Data Slip Rings: Data slip rings specialize in the transfer of sensitive data signals between stationary and rotating components. They can be applied in radar systems or satellite communication antennas, ensuring flawless communication and performance.

- Video Slip Rings: As the name suggests, these slip rings transmit video signals across rotating and stationary components, offering solutions for surveillance systems, broadcast platforms, or medical imaging equipment like CT scanners.

Classification Based on Materials Used

Material choices in slip rings play a pivotal role in determining their longevity, performance, and suitability for various applications. Common materials include:

- Metal Slip Rings: Employing metals like copper or silver for conductive rings and gold, palladium, or silver for brushes, these slip rings are known for their robustness, corrosion resistance, and efficient signal transfer.

- Plastic Slip Rings: These slip rings utilize high-performance engineering plastics, such as PEEK (Polyether Ether Ketone), often for housing or insulation, allowing them to withstand extreme environmental conditions and maintain performance stability.

Classification Based on Design

The design of traditional slip rings is tailored to address different requirements and limitations posed by specific applications. Some prominent design categories are:

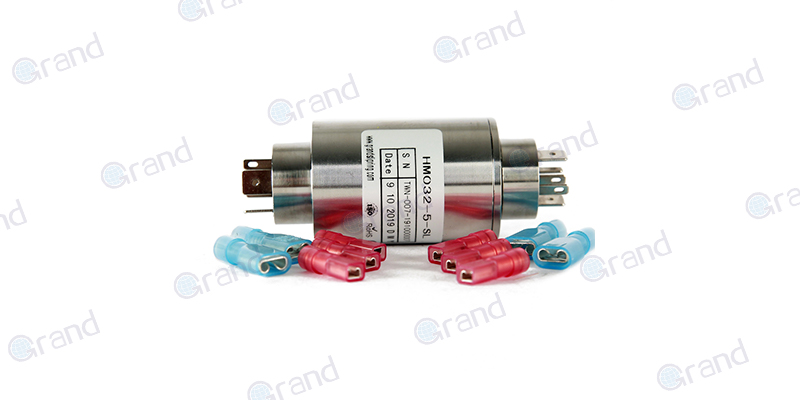

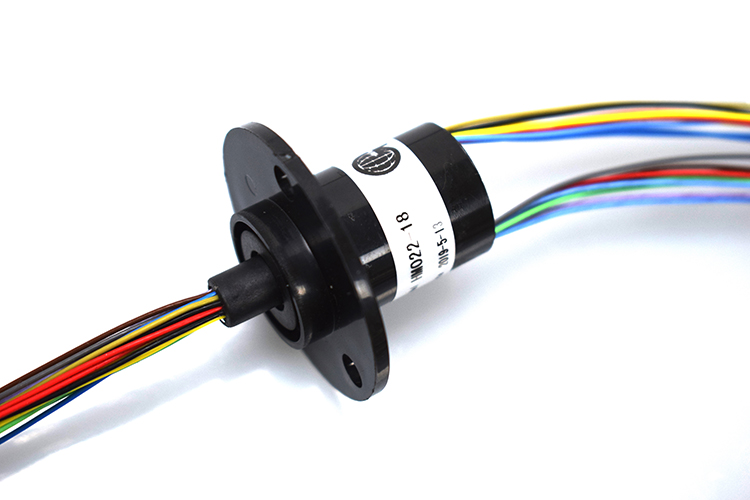

- Capsule Slip Rings: Also known as compact slip rings, these are typically smaller in size with a cylindrical structure, making them ideal for applications with limited space. Examples include robotics, camera gimbals, and small motors.

- Pancake Slip Rings: Characterized by their flat, disc-like design, these slip rings embody a low-profile configuration. They suit applications like rotary tables and indexing systems, where axial length constraints are present.

- Miniature Slip Rings: These slip rings are designed for use in small-scale applications where size restrictions prevail. They find utilization in medical devices and miniature motors, among others.

Understanding the coherence between various types of traditional slip rings and the applications they cater to grants users the wisdom to make informed decisions, ensuring an optimal fit based on material, design, and signal transmission needs.

Applications of Traditional Slip Rings

The utility of traditional slip rings is a testament to their versatility, which has seen them embedded into the fabric of numerous industries. Let us navigate the landscape of their applications across various fields, drawing connections that highlight their indispensable role in modern technology.

Manufacturing Industry

In the realm of manufacturing, slip rings play a pivotal role in the operation of rotating machinery. They are commonly found in:

- Assembly Lines: Slip rings allow for continuous power supply and signal transmission within conveyor systems and rotating tables, ensuring seamless production workflows.

- Robotics: Robotic arms utilize slip rings to maintain the electrical connection while articulating, which is crucial for tasks such as welding, painting, and component placement.

- Packaging Machines: Rotating parts of packaging machinery rely on slip rings to control motion and sensors, enhancing efficiency and productivity.

Communications

The communications industry leverages slip rings in:

- Satellite Antennas: Slip rings enable the rotation of antennas for better signal reception and transmission by relaying data and controlling signals through stationary and moving parts.

- Radar Systems: They ensure continuous 360-degree rotation of radar antennae, facilitating the constant flow of surveillance and navigation data crucial for military and civilian applications.

Security and Surveillance

Security systems greatly benefit from the use of slip rings in:

- CCTV Cameras: Slip rings allow for uninterrupted rotation and operation of CCTV cameras, providing continuous surveillance without limiting the range of motion.

- Thermal Imaging: In security and defense, slip rings are used within thermal imaging equipment to maintain operational capacity while in motion, a critical aspect of nighttime monitoring and targeting.

Healthcare

The healthcare industry incorporates slip rings in several applications, such as:

- CT Scanners: They rely on slip rings to transfer high-resolution imaging data while the scanner rotates around a patient, crucial for accurate diagnostics.

- MRI Machines: Slip rings enable the complex rotation of the imaging components within MRI machines, allowing them to perform full-body scans with precision. A medical equipment slip ring solution is essential in ensuring that these components rotate smoothly while maintaining uninterrupted power and data transmission. Designed specifically for the medical field, these slip rings are engineered to meet the high standards of reliability and performance required in sensitive environments like MRI rooms. By providing a continuous electrical connection between rotating and stationary parts, the medical equipment slip ring solution ensures that MRI machines operate efficiently, producing high-quality images for accurate diagnoses.

Renewable Energy

In renewable energy applications, slip rings find their use in:

- Wind Turbines: Slip rings allow the transfer of power and data signals from the nacelle to the static part of the wind turbine, facilitating continuous monitoring and control regardless of blade rotation.

- Solar Trackers: They are utilized in solar tracking systems to maintain electrical continuity while panels rotate to follow the sun’s trajectory throughout the day.

The coherence lies in how slip rings seamlessly integrate into different industries, facilitating both the transfer of power and data signals which is essential for the uninterrupted operation of equipment. Their adaptability and functionality underscore their significance in complex systems across these sectors, affirming their ubiquitous nature and hinting at the breadth of scenarios where slip rings are not a luxury but a necessity.

Maintenance and Durability of Traditional Slip Rings

To mitigate the inherent mechanical wear and ensure optimal performance, regular maintenance practices must be meticulously followed. Additionally, numerous factors can influence the durability and longevity of traditional slip rings. Let us explore these elements, recognizing how they coalesce to shape the lifetime of these pivotal components within various sectors.

Regular Maintenance Practices

Maintaining slip rings is critical for their reliability and to extend their lifespan:

- Cleaning: Conduct routine cleaning of contact surfaces to prevent build-up of debris and contaminants which can impede electrical contacts and lead to increased wear.

- Lubrication: Apply appropriate lubricants, when necessary, to reduce friction and wear between the slip ring and brush, especially in environments where they may be exposed to corrosive substances.

- Inspection: Regularly inspect for signs of wear or damage, including uneven wear patterns, pitting, and scoring. Immediate attention to such issues can prevent system failure.

- Electrical Testing: Perform routine electrical tests to monitor the integrity of the connections and the quality of signal transmission. Consistency in performance is a good indicator of health.

- Brush Replacement: Monitor brush wear and replace brushes before they reach their critical wear point to avoid damage to the ring surfaces and maintain efficient conduction.

These maintenance practices are not merely periodic tasks; they are part of a comprehensive approach to sustaining the performance and lifecycle of slip rings in a variety of demanding applications.

Factors Influencing Durability and Longevity

Several factors inherently affect the wear and overall longevity of traditional slip rings:

- Material Quality: The use of high-grade materials is vital. For instance, gold alloy brushes and rings offer superior performance and wear resistance compared to other materials.

- Environment: Operating in harsh environments with extreme temperatures, moisture, or corrosive agents can markedly shorten the lifespan of slip rings, necessitating more robust designs or frequent maintenance.

- Load Conditions: The electrical load that passes through the slip ring can affect its durability. Higher currents can lead to increased temperature and wear, while overloading can cause premature failure.

- Design and Manufacturing Precision: The precision of the design and manufacturing process can impact performance. Meticulous engineering can reduce the risk of misalignment and uneven wear.

- Installation and Usage: Correct installation and adherence to usage specifications are crucial. Improper installation or misuse can lead to accelerated wear and shortened lifespan.

- Speed of Operation: The rotational speed at which the slip ring is operated affects wear rates. Higher speeds may increase the demand for materials and design.

The coherence across maintenance practices and longevity factors is clear: a well-maintained slip ring system, designed and used within its specifications and suited to its operating environment, will invariably exhibit a longer and more reliable service life. By recognizing the interplay between maintenance, environmental conditions, material choices, and operational demands, users can not only preserve the functionality of their slip rings but also maximize their investment in these components.

Traditional Slip Rings Common Challenges and Troubleshooting

Despite the pivotal role they play in numerous systems, traditional slip rings are not without their own set of challenges. Common issues encountered include data loss, weak power transmission, and wear. Troubleshooting these complications requires a clear understanding of their causes and appropriate mitigation strategies. Let’s delve into defining these challenges and the remedial steps that provide coherence to this multidimensional narrative.

Common Challenges

There are several common issues that users may encounter with traditional slip rings:

- Data Loss: Occasionally, users might experience interruptions in signal transmission, leading to loss of data. This scenario can result from wear on the slip ring surface, accumulation of debris, or atmospheric interference.

- Weak Power Transmission: Reduced power transfer efficiency may occur due to increased contact resistance, which often results from surface wear or pitting on the slip ring.

- Wear and Tear: The constant motion of brushes against slip rings can cause wear and tear, leading to degraded performance over time and ultimately, component failure.

Troubleshooting Guidance

Addressing these challenges requires a systematic approach:

Data Loss:

- Ensure the slip ring and brush contact surfaces are clean and free of debris or foreign material.

- Use a multimeter to check the integrity of the connections.

- Check for external sources of electromagnetic interference and try to eliminate or isolate them.

Weak Power Transmission:

- Regularly inspect and clean the slip ring and brush contact surfaces.

- Examine the brushes for signs of excessive wear and replace them if necessary.

- If the issue persists, check the system load. Overloading can lead to increased resistance and weak power transmission.

Wear and Tear:

- Conduct regular inspections for signs of wear and tear, and replace any worn components promptly.

- Regular maintenance, such as cleaning and, when necessary, lubrication can reduce friction and delay wear.

- Make sure the system is operating within specified load conditions and rotational speeds.

Understanding these challenges provides insight into the potential weaknesses of slip rings and the importance of regular maintenance. By responding quickly to issues and taking proactive measures, users can reduce downtime, enhance performance, and extend the lifetime of their slip rings. This interplay between challenges and troubleshooting forms the larger narrative: that both the maintenance of slip rings and the ability to diagnose and rectify issues as they arise are integral to their efficient operation.

Selection Criteria: Choosing the Right Traditional Slip Rings

Choosing the appropriate slip ring for a specific application is a decisive task that can greatly influence system performance and longevity. Several critical factors, such as required speed, type of signal to be transmitted, and environmental conditions, must be taken into account to ensure optimal performance and coherence across the application’s specific demands.

Choosing the Best Slip Ring

When selecting a slip ring, certain factors need to be thoroughly considered to ensure you select the best one for your specific application:

- Nature of the Signal: Consider whether you will be transmitting power, data signals, or both. For data transmission, the bandwidth, protocol, and required data rate should be considered.

- Electrical Requirements: The current and voltage ratings of the slip ring should align with your system’s requirements. It’s crucial to avoid selecting a system with insufficient capacity, which may lead to overheating and failure.

- Speed: The rotational speed capability of the slip ring needs to match the rotational speed requirements of your system. Incorrect matching can lead to excess friction and faster wear and tear.

- Size and Mounting: The physical dimensions and mounting specifications should be compatible with the allotted space in your device or machinery.

Additional Factors to Consider

In addition to the parameters above, certain external factors can influence your choice:

- Environment: As slip rings can be deployed in varied environments, it’s crucial to choose one that can withstand specific conditions such as high temperatures, moisture, corrosion, vibration, and shock.

- Lifespan and Maintenance: Depending on usage frequency and operational lifespan, certain models require less maintenance and offer longer lifetimes — factors that reduce downtime and lower the total cost of ownership.

- Cost: The price of the slip ring is an important consideration. Weigh the advantages of a high-quality, yet more expensive slip ring against a lower-cost alternative with potentially less durability.

The coherence in this context lies in understanding the interplay between various selection criteria. The slip ring should be viewed as an integral part of the overall system, where its characteristics need to complement the broader requirements of the application. Being aware of these criteria ensures a suitable selection – a decision that can signify longevity, efficiency, and high performance of not only the slip ring but also the entire operational system it supports.

The Future of Traditional Slip Rings: Trends and Innovations

As we delve into the future of traditional slip rings, it’s essential to recognize the ongoing technological advancements and trends shaping the industry. Innovations are constantly enhancing slip ring capabilities, expanding their applications, and improving their performance. The developments hinge on increasing the efficiency, reliability, and functionality of slip rings to meet the demands of modern, sophisticated systems.

Technological Advancements

The slip ring industry has seen a range of advancements aimed at optimizing performance:

Material Science:

- Innovative materials with enhanced conductive properties and reduced wear are being incorporated, thus increasing the longevity and reliability of slip rings.

- Contacts made from advanced composites or incorporating gold-alloy coatings, for example, exhibit a higher resistance to wear and corrosion.

Miniaturization:

- As devices become more compact, there’s a growing trend in miniaturizing slip rings, enabling their use in smaller applications without compromising on their data or power handling capabilities.

Signal Integrity:

- Maintaining signal integrity for high-speed data transmission has become paramount. Advanced designs and materials are helping to minimize noise and interference, crucial for the accurate and reliable transmission of sophisticated signals.

Industry Trends

Beyond specific tech advancements, there are broader industry trends that influence slip ring development:

Customization and Modularity:

- There’s increasing demand for customized slip rings designed to meet the unique requirements of specialized applications. This trend is leading to the development of modular designs that can be easily adapted or expanded according to user needs.

Integrated Systems:

- Integration of additional functionalities, such as fiber optic rotary joints (FORJs), wireless transmitters, or even electrical rotary unions into a single slip ring unit, is a trend that enhances capability and value.

Maintenance and Monitoring:

- With the advent of IoT (Internet of Things), slip rings are increasingly being equipped with sensors to monitor their health and predict maintenance. This allows for preemptive action before a malfunction occurs.

Environmental and Regulatory Factors:

- Sustainable manufacturing processes and eco-friendly materials are being pursued, influenced by environmental regulations and market demand for greener products.

The context of these trends and innovations suggests a transition from traditional slip ring offerings towards more sophisticated systems that offer better performance, customization, and alignment with the principles of sustainability and digital integration. Such progressions point to an exciting future for slip ring technology: One that is set to provide increasingly efficient, reliable, and application-specific solutions in various fields, including renewable energy, aerospace, robotics, and beyond.

Conclusion

Embracing the understanding of slip ring workings, handling their maintenance, and keeping track of technological advancements can help users fully leverage the potential of traditional slip rings as they continue to be significant across various applications.

FAQs about Traditional Slip Rings

Q1: What is a traditional slip ring?

A1: A traditional slip ring is an electromechanical device that allows the transmission of electrical power and signals from a stationary part to a rotating part of a machine. It consists of a rotating ring and stationary brushes, which maintain an electrical connection between the rotating and stationary parts.

Q2: How many different types of slip rings are there?

A2: There are several types of slip rings, including pancake (flat), through-bore, wireless, mercury-wetted, and capsule slip rings. Each type serves specific applications depending on the requirements for power and signal transmission, physical size, and environment.

Q3: Can slip rings transmit data as well as power?

A3: Yes, slip rings can be designed to transmit various types of signals, including data, control signals, and video, in addition to electrical power. The design parameters of the slip ring are customized to ensure minimal signal interference and optimal performance.

Q4: What are the main causes of slip ring failure?

A4: Slip ring failure is commonly caused by wear and tear due to friction, contamination by dust and debris, corrosion, overheating from excessive current, or improper installation. Regular maintenance and choosing the appropriate type of slip ring for the operating environment can help mitigate these issues.

Q5: How do I select the right slip ring for my application?

A5: The selection of the appropriate slip ring for your application depends on several factors: the type and range of signals or power to be transmitted, the required rotational speed, the operating environment, space constraints, and the expected lifespan. It’s crucial to assess all these aspects to ensure compatibility with your system’s needs.

Q6: Are there wireless alternatives to traditional slip rings?

A6: Yes, there are wireless slip rings, known as rotary transformers, or rotational inductive couplings. These devices use magnetic induction to transfer power and data wirelessly between stationary and rotating components which can be beneficial to reduce wear and maintenance.

Q7: How are slip rings maintained?

A7: Maintaining slip rings typically involves regular cleaning to remove debris and dust, checking the condition of brushes and rings for wear and tear, ensuring proper lubrication, and periodically testing electrical continuity to ensure optimal performance.

See What We Can Do