This article thoroughly examines the critical role of slip rings and their applications in medical equipment. Beginning with an essential introduction to slip rings and their different types, the article navigates through their key applications in medical equipment such as diagnostic imaging systems, surgical tools, and patient monitoring systems. It highlights the user concerns and regulatory standards for their use in medical technology, discusses current technological advancements, and aspects to consider when selecting slip rings for medical applications. The article provides a comprehensive understanding of how slip rings contribute to the advancement and functionality of medical devices while underscoring the importance of continuous innovation in this arena.

The Intricacies of Slip Ring Applications in Medical Equipment

In the intersection where electrical engineering meets biomedical technology, slip rings have emerged as indispensable components. Fundamentally, slip rings are electromechanical devices designed to transmit power and electrical signals from a stationary part of a machine to a rotating part. Essentially, they consist of conductive rings mounted on a rotating shaft, with brushes or contact wires that maintain an electrical connection as the shaft spins. This seamless transmission is paramount in complex machinery where rotation is inherent to its operation, and it is where slip rings shine due to their ability to provide continuous power and data flow without hindering movement.

In the medical sector, the presence and application of slip rings become profoundly significant. Medical devices and machinery, such as computer tomography (CT) scanners and magnetic resonance imaging (MRI) machines, rely on the functional dexterity of slip rings. These rotating interfaces bridge the gap between mobility and functionality, thereby facilitating the rotational movements of gantries or beds while simultaneously handling the critical transmission of signals and power. This balance is paramount in the high-stakes realm of healthcare, where the data integrity and operational reliability provided by slip rings can quite literally make the difference between life and death.

Thus, the importance of slip rings extends beyond their physical function; they represent a union of dependability and innovative engineering within medical equipment. They are not merely accessories but are essential elements that guarantee the precision, safety, and efficacy of medical diagnostics and procedures. It is in this nexus of reliability and sophistication that slip rings underscore their value, ensuring that as medical technology progresses, these devices evolve in tandem to meet the increasing demands of modern medicine.

Understanding Slip Rings in Medical Equipment: Their Types and Impactful Differences

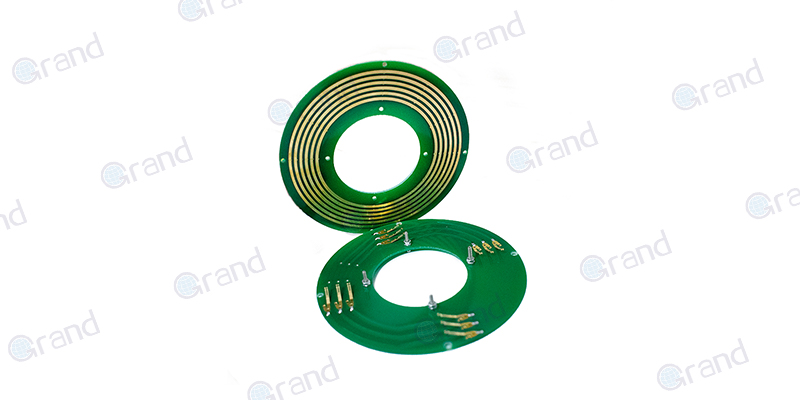

The functioning of a slip ring is central to its essence as an electromechanical device – it facilitates the transmission of power and electrical signals from a stationary body to a rotating one. Slip rings operate by maintaining an uninterrupted electrical connection between brushing contacts and conductive rings that spin with the device’s rotor. It is this unbroken link that makes slip rings invaluable in the operation of various electrical machinery, including many essential medical devices.

Delving deeper into the types of Slip Rings, there are three primary categories: Conventional, Mercury-Wetted, and Wireless slip rings.

Conventional Slip Rings employ mechanical brushes against a rotating surface, allowing for consistent energy and data flow. While reliable and versatile, these are subject to potential brush-related wear and noise. Therefore, their usability often depends on the application’s requirement for revolutions per minute (RPM) and the need for regular maintenance.

Mercury-wetted slip Rings are a specialized type where the conductive fluid mercury replaces the mechanical brush. This type offers low electrical noise and is well-suited for high-speed, sensitive data applications. However, they are not as widely used due to ethical concerns related to mercury’s potential environmental hazard and health risks.

Wireless Slip Rings, also known as rotary transformers or inductive slip rings, transmit power and signals electromagnetically, ensuring a no-contact, wear-free transmission. This lack of physical contact minimizes wear and tear, leading to potentially longer operational life, but necessitates proximity between the transmitter and receiver which might limit their application.

When contemplating their use in the medical field, careful consideration of these advantages and disadvantages is necessary. Conventional slip rings are a robust and economical choice, but they may require more maintenance due to their mechanical nature. Mercury-wetted slip rings offer low electrical noise which is beneficial for delicate, high-quality data transmission, like in medical imaging, but their use must be weighed against potential health and environmental risks. Wireless slip rings offer the benefit of less maintenance and longer durability, presenting an attractive choice for medical devices requiring uninterrupted, long-term operation. This core understanding of slip rings and the characteristics of their various types enable their effective adaptation in designing and engineering state-of-the-art medical equipment.

Slip Ring Applications in Medical Equipment: Key Applications in Medical Equipment

Diagnostic Imaging Systems (MRI, CT Scanners): Within the advanced arena of diagnostic imaging systems, slip rings play a pivotal role that is often understated. These systems, including Magnetic Resonance Imaging (MRI) and Computed Tomography (CT) scanners, involve complex rotating parts that are integral to their functionality. Slip rings facilitate seamless power transmission and real-time data exchange between the stationary and rotating parts of these machines. For example, in an MRI machine, the slip ring enables the continuous rotation of the gantry without interrupting the power supply or the flow of data. This uninterrupted operational capability is crucial for acquiring high-resolution images that medical professionals rely on for accurate diagnoses, making slip rings indispensable for the integrity and efficiency of these imaging procedures.

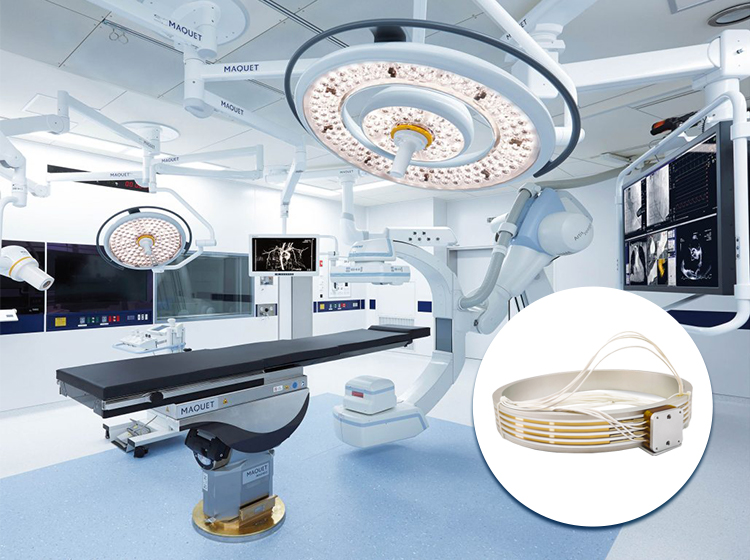

Surgical Tools and Tables: The realm of modern surgery requires an unprecedented level of precision and adaptability, attributes that slip rings help to provide. Surgical tables, often equipped with built-in electrical features for adjustability and comfort, utilize slip rings to maintain electrical connectivity regardless of the table’s orientation. Similarly, in powered surgical tools that must remain operational while being fully maneuverable, slip rings ensure reliable electrical contact. This continuous power and data transmission capacity contribute significantly to the functionality and flexibility of surgical equipment, enabling surgeons to perform complex procedures with greater efficiency and safety. The inherent capabilities of slip rings, therefore, are not just contributing to the operational efficacy of surgical instruments but are also enhancing the surgical environment’s adaptability and responsiveness.

Patient Monitoring Systems: In the critical care and monitoring domain, slip rings find applications that are vital for patient care. Devices dedicated to patient monitoring, such as rotating beds in intensive care units or advanced telemetry equipment, require constant, reliable data transmission to ensure uninterrupted patient observation and data logging. Slip rings enable these devices to rotate or adjust without losing connectivity, ensuring that vital signs and other critical patient information are continuously monitored and recorded. This real-time data transmission is essential for healthcare providers to make informed decisions and provide timely care, illustrating how slip rings are not only facilitating advanced medical device functionality but are also directly contributing to patient care and safety.

In each of these key applications, the unique properties of slip rings—providing reliable, continuous transmission of power and data across moving components—play a critical role. Whether in the detailed imaging necessary for accurate diagnoses, the precision and adaptability demanded in modern surgical procedures, or the constant vigilance required in patient monitoring, slip rings significantly impact the functionality and effectiveness of medical equipment. This versatility underscores their indispensable role in the evolution and operation of medical technology.

Slip Ring Applications in Medical Equipment: User Concerns and Considerations

In the field of medical technology, user concerns and considerations are particularly paramount, given the high stakes involved in patient health and safety. The deployment of slip rings in medical equipment is no exception, and several key factors must be taken into account:

Reliability and Durability: In the critical environment of medical settings, equipment failure is not an option. The reliability and durability of slip rings are paramount because they directly impact the functioning of vital diagnostic and therapeutic devices. Users need slip rings that can withstand high-speed rotations and prolonged use without degradation in performance. For instance, in an MRI machine, a slip ring failure could lead to incomplete or inaccurate imaging data, potentially leading to misdiagnosis. Thus, manufacturers design these components to meet stringent reliability standards, often employing advanced materials and engineering innovations to extend their life cycles and minimize maintenance frequency.

Precision and Safety: The precision of slip rings in transmitting electrical signals directly correlates to data accuracy. In medical equipment, accurate data transmission is not just about performance—it’s a matter of patient safety. For example, in surgery, equipment powered through slip rings must operate with precise control, as any fluctuation or interference could impact the surgeon’s work. Moreover, these devices need to be constructed with biocompatible materials that do not adversely affect the patient or the sterile field. The safety concern extends to ensuring that slip rings shield sensitive electronic components from electromagnetic interference, which is especially critical in the controlled medical environment.

Miniaturization: As medical devices become more sophisticated and compact, the components within them, including slip rings, must also shrink in size without compromising performance. The demand for miniaturized slip rings is driven by both the need for more portable medical equipment and the increasing complexity of devices such as endoscopes and miniature surgical instruments. The challenge lies in designing slip rings that not only fit into smaller spaces but also provide the same level of reliable connectivity as their larger counterparts.

Compliance and Standards: Medical equipment manufacturers must navigate a complex framework of regulatory standards and compliance requirements, and slip ring components are no exception. These standards, which vary by region and application, typically cover aspects like biocompatibility, reliability, safety, and electromagnetic compatibility. For example, in the United States, the Food and Drug Administration (FDA) sets forth regulations that medical equipment must meet, and similar directives exist in the European Union, like the Medical Devices Regulation (MDR). Slip ring manufacturers must therefore ensure that their products adhere to these rigorous standards, often implementing quality control systems and undergoing strict testing and certification processes to demonstrate compliance.

Overall, these concerns—reliability and durability, precision and safety, miniaturization, and compliance with regulatory standards—paint a comprehensive picture of the requirements that slip rings must fulfill to serve the medical industry effectively. Manufacturers and designers are continually addressing these demands through innovative solutions, ensuring that slip rings contribute positively to the medical field’s dynamic and life-saving technology landscape.

Slip Ring Applications in Medical Equipment: Technological Advancements

The medical field is constantly advancing, with technology pushing the boundaries of what’s possible in patient care and treatment. Slip rings, as crucial components in many medical equipment systems, have evolved alongside these advances, seeing significant improvements and innovations that enhance their application.

Innovations in Slip Ring Technology

The innovations in slip ring technology have focused on increasing their reliability, performance, and suitability for sensitive applications. For instance, fiber optic slip rings (FORJ) represent a significant breakthrough, providing high-speed data transfer capabilities essential for today’s digital diagnostic equipment. Moreover, the development of modular slip rings has allowed for easy customization and scaling according to specific equipment needs, whether handling more circuits or integrating additional features like RF (Radio Frequency) rotary joints.

The introduction of contactless slip rings, which use inductive coupling for power and data transmission, is another revolutionary step, virtually eliminating mechanical wear and tear, thereby extending the life of the equipment. This is especially crucial in medical settings where equipment needs to operate with minimal downtime and undergo rigorous sterilization processes that can degrade mechanical components.

The Role of Materials Science

Materials science has played a significant role in enhancing the performance and safety of slip rings in medical applications. Researchers and engineers have developed new conductive materials that reduce electrical noise, allowing for clearer signal transmission – a must for the accurate diagnostics and monitoring of patient health.

Biocompatible coatings are also a critical advancement. Materials that resist corrosion and are compatible with human tissues, such as gold and platinum group metals, have become essential in surgical environments. These materials minimize the risk of adverse reactions and ensure that medical equipment can be safely used inside or in direct contact with the human body.

Regarding safety, there is a continued emphasis on developing materials and designs that are easy to clean and sterilize, thus adhering to strict hygiene and infection control standards.

Future Directions

Looking to the future, it’s expected that slip rings will find new uses in medical technology through the burgeoning fields of robotics and telemedicine. Slip rings could become integral in power and data transmission for robotic surgical systems, enabling smoother and more dynamic movement while maintaining uninterrupted operation during procedures.

In telemedicine, as the demand for home diagnostic equipment and remote monitoring grows, slip rings could enable the development of more sophisticated, reliable devices that patients can use in the comfort of their homes. This would broaden the scope of patient data collection, fostering a more connected and proactive healthcare framework.

Moreover, the ongoing miniaturization trend may create opportunities for slip rings in nanotechnology and micro-electromechanical systems (MEMS), where they could play a role in tiny diagnostic or surgical devices, once thought impossible.

Advancements in slip ring technology continue to reflect the ever-evolving nature of the medical field. With each technological stride, slip rings are refined and reimagined to meet the demands of cutting-edge medical equipment, ensuring that they help, rather than hinder, the quest for better patient outcomes.

Choosing the Right Slip Ring for Medical Equipment

Selecting the ideal slip ring for medical applications is a critical decision that impacts not only the functionality of the equipment but also its safety and longevity. Key considerations and strategic partnerships play vital roles in this selection process, ensuring that medical equipment operates reliably in high-stakes environments.

Factors to Consider When Selecting a Slip Ring

Get in touch with us for customized solutions and pricing on Medical Slip Rings by filling out the inquiry form.

When choosing a slip ring for medical equipment, several crucial factors come into play. Firstly, the electrical requirements of the application—such as current and voltage ratings, signal types, and data transmission needs—must be clearly understood. This ensures the slip ring can handle the electrical loads and provide the necessary data integrity for the equipment’s operation.

Environmental conditions represent another essential consideration. Medical equipment can be subject to a range of conditions, including sterilization processes, exposure to biological fluids, or operation within magnetic fields in the case of MRI equipment. The chosen slip ring must withstand these conditions without degradation in performance or safety.

Moreover, the physical constraints of the medical device play a significant role. The size, installation space, and movement dynamics of the equipment influence the design and type of slip ring required. For instance, compact medical devices necessitate miniaturized slip rings that can fit into constrained spaces without sacrificing performance.

The Importance of Working with Reputable Manufacturers

The complexity and critical nature of medical applications underscore the importance of sourcing slip rings from reputable manufacturers. Experienced manufacturers can provide not only high-quality products that meet stringent medical standards but also valuable expertise in selecting the right slip ring for specific medical applications.

Reputable manufacturers are also more likely to have robust quality control processes and adherence to medical industry regulations, ensuring that their slip rings contribute to the safety and reliability of medical equipment. The ability to provide comprehensive technical support and customization options is another benefit of working with established providers, making the integration of slip rings into medical devices as seamless as possible.

Custom Solutions for Unique Medical Applications

Given the diverse and often highly specialized nature of medical equipment, off-the-shelf slip ring solutions may not always meet every criterion of a particular application. In such cases, custom slip ring solutions become invaluable. Working closely with manufacturers, medical equipment designers can develop slip rings tailored to their devices’ exact specifications and constraints.

Custom solutions can address unique electrical, mechanical, and environmental challenges, ensuring that the slip ring fully complements the device’s functionality and design. For instance, custom configurations can optimize the placement of power, signal, and data channels within the slip ring, enhance the integration of additional features like fluid rotary joints for cooling systems, or incorporate specific materials and coatings to meet rigorous hygiene standards.

Choosing the right slip ring for medical equipment involves a delicate balance of technical, environmental, and regulatory considerations. By factoring in the specific requirements of the application, partnering with reputable manufacturers, and exploring custom solutions when necessary, medical equipment designers can ensure their devices achieve optimal performance, safety, and reliability, ultimately contributing to better patient care.

Conclusion

Slip rings indisputably serve a vital role in the effective operation of various medical equipment. As technical advancements surge forward, these devices remain at the heart of innovation—propelling medical technology to the vanguard of modern healthcare.

See What We Can Do