This article offers a thorough exploration of slip ring connectors, covering everything from their basic principles to the latest innovations and future trends. Aimed at professionals, enthusiasts, and newcomers to the field, this guide demystifies slip ring connectors, showcasing their importance across various industries.

Introduction to Slip Ring Connectors

Slip ring connectors, often simply referred to as “slip rings,” are electromechanical devices that play a crucial role in systems involving rotating structures. Their primary function is to provide a continuous electrical connection between stationary and rotating components. In other words, they enable the transfer of power or signals from a stationary source to a part that is rotating, without obstruction or disruption, paving the way for continuous 360-degree rotation.

Usually comprised of a rotating ring and stationary brushes, these slip rings, when connected to the source and the receiver, facilitate a steady flow of electricity or data. It is through this establishment of a dependable, unfaltering connection that these connectors become pivotal in mitigating the otherwise impending issues such as breaking circuits or entangling wires, which would halt the functioning of the rotating mechanism altogether.

The essence of slip ring connectors is incredibly prominent in numerous rotary applications. From small-scale rotary platforms to large industrial machinery, they oversee the efficient transmission of power or data, contributing to the effective operation of the respective device or system.

Consider the examples of wind turbines or rotary tables in manufacturing; the blades of a wind turbine need to rotate freely to capture wind from all directions, necessitating the use of slip ring connectors to transmit generated electricity to the grid. Similarly, in a medical CT scanner, slip ring connectors enable the scanner’s inner parts to rotate continuously, sending vital image data back to stationary computers for analysis.

From the view of everyday technology to the perspective of massive-scale industrial machinery, slip ring connectors consistently play an integral, almost silhouetted role. Fully understanding their function and significance can unlock a deeper appreciation for these essential elements and the technological marvels they support.

Historical Development of Slip Ring Connectors

The journey of slip ring connectors through history is a fascinating chronicle of human ingenuity and the relentless pursuit of technological advancement. Tracing back to the early stages of electrical engineering, the need for slip ring connectors emerged alongside the development of machinery and devices requiring rotation. Initially, these connectors were simplistic, designed to meet basic requirements and overcome the fundamental challenge of transmitting power and signals to rotating platforms without interruption.

In their formative years, slip ring connectors were bulky and limited in functionality, offering a rudimentary solution that was prone to wear and inefficiency. These early models used basic materials for contacts and insulation, which significantly limited their lifespan and reliability. However, the pivotal role they played in enabling the operation of rotating machines and equipment ensured their continued development and refinement.

As the Industrial Revolution gained momentum, the demand for more sophisticated machinery and equipment skyrocketed, pushing the boundaries of slip ring technology. The 20th century marked a period of intense innovation, during which slip ring connectors underwent significant transformations. Technological advancements in materials science introduced new insulating and conductive materials, leading to slip rings capable of handling higher currents and voltages more efficiently and reliably. The introduction of precious metal contacts, for instance, drastically reduced wear and improved the quality of electrical connections.

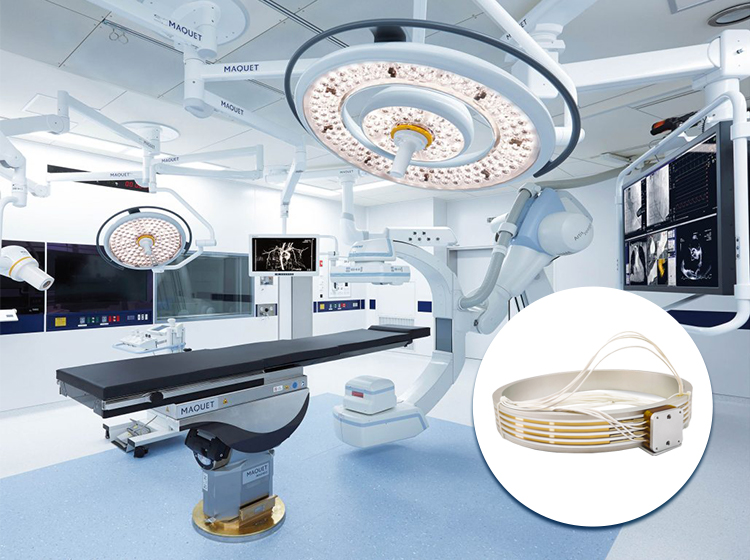

Moreover, the advent of computers and digital technology in the latter half of the 20th century brought about precision engineering techniques. These advancements allowed for the miniaturization of slip ring connectors, making them suitable for a broader range of applications, including medical equipment like MRI and CT scanners, where space is at a premium and reliability is non-negotiable.

In recent years, the focus has shifted towards integrating slip ring connectors with advanced signal handling capabilities, catering to the growing demand for the transmission of not just power but also complex data signals across rotating interfaces. Innovations such as fiber optic rotary joints and wireless power transfer technologies are pushing the boundaries of what’s possible, enabling slip ring connectors to meet the needs of high-speed data transmission and high-frequency operations in aerospace and telecommunications, among other high-tech industries.

The historical development of slip ring connectors is not just a narrative of mechanical and electrical engineering evolving; it’s a testament to the adaptability and innovation required to keep pace with the relentless advancement of technology. From their humble beginnings to their critical role in modern machinery and devices, slip ring connectors have significantly impacted several facets of technological progress, improving design, functionality, and efficiency along the way. As we look to the future, the ongoing evolution of slip ring connectors promises to underpin yet more technological breakthroughs, maintaining their status as indispensable components in the seamless operation of rotational equipment.

Slip Ring Connectors: Basic Principles and Working Mechanism

At the heart of the operation of slip ring connectors lies a basic yet ingenious principle: the seamless transfer of electricity or signals between a stationary structure and a rotating one. This fundamental objective is achieved through two primary components: the slip ring and the brush, each playing a pivotal role in the mechanism of these connectors.

Slip Rings: In essence, slip rings are conductive rings that are mounted on the rotating part of a machine. Made from durable and electrically conductive materials, these rings are designed to maintain a physical and electrical connection as they rotate. Their surfaces are meticulously engineered to allow for smooth contact with the brushes, ensuring minimal wear and reliable conductivity.

Brushes: Acting as the counterpart to the slip rings, brushes are stationary electrical contacts that lightly press against the slip rings’ rotating surfaces. Typically constructed from materials that balance conductivity with wear resistance, such as graphite or precious metal alloys, brushes are designed to maintain constant contact with the slip rings without hindering the rotation. They serve as the conduit through which electrical power or signals are transferred from a stationary source to the slip ring and, consequently, to the rotating part of the system.

Working Together for Continuous Electrical Connection:

The interplay between slip rings and brushes is what facilitates the uninterrupted flow of electricity or signals. Here’s how the mechanism unfolds: as the machine or device begins to rotate, so do the slip rings attached to the moving part. Despite the rotation, the brushes remain in constant contact with the slip rings due to their stationary mounting and the physical pressure applied. This contact ensures that electrical current or data signals flow steadily from the stationary brushes, through the rotating slip rings, and into the rotating part of the machine.

To visualize this process, imagine the rotor of a wind turbine, which turns to face the wind’s direction. Slip ring connectors installed within the turbine allow for the transmission of generated electrical power from the moving rotor down through the stationary tower to the grid. Similarly, in the realm of entertainment, complex stage lighting rigs use slip ring connectors to supply power and control signals to lights that can rotate continuously, creating dynamic lighting effects without tangling cables.

This basic principle — a stationary brush maintaining contact with a rotating ring — is simple yet effective, enabling countless applications where rotational motion is necessary. The beauty of the slip ring connector system lies in its elegant solution to what would otherwise be a complex problem of transmitting power and signals in rotating systems. Through continuous development and refinement, these connectors ensure not just the transfer but the dependable and efficient transmission of electrical power and data, pivotal to the functionality and reliability of modern rotating machinery and devices.

Types of Slip Ring Connectors

Slip ring connectors are available in an array of types and designs, each tailored to meet the unique demands of various applications. The size of the system, the speed of rotating parts, and the complexity of the signals being transmitted – all these factors contribute to the type of slip ring connector best suited for the job. Among the various types of slip ring connectors, three of the most commonly used are capsule, through-bore, and pancake slip ring connectors.

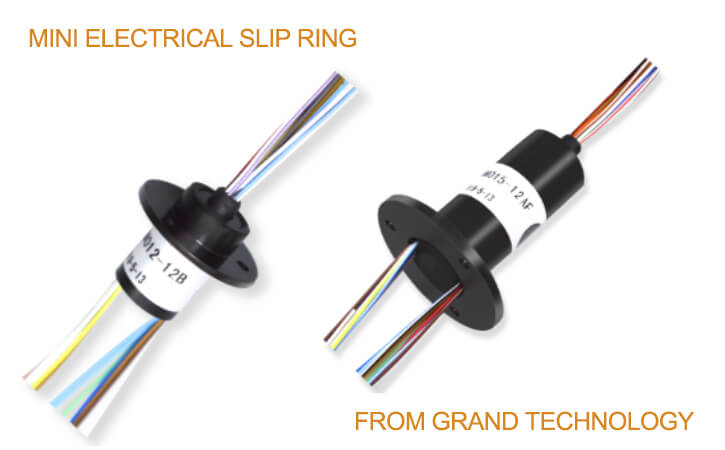

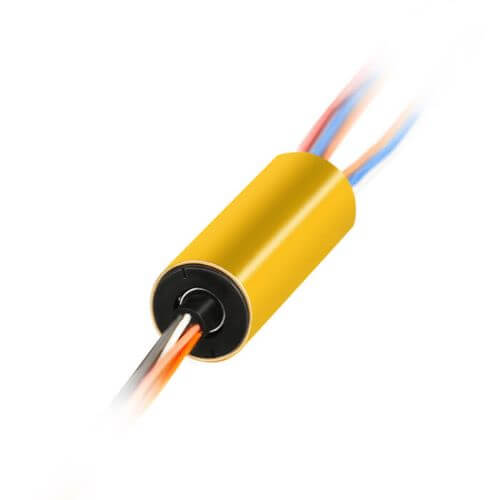

Capsule Slip Ring Connectors:

Restricted spaces often demand compact solutions, and that’s where capsule slip ring connectors come into the picture. Designed for lighter, smaller, and slower rotating applications, these connectors encapsulate the conductive rings within a compact cylindrical housing. Capsule slip ring connectors are best suited for applications that require support for both power and signal transmission but do not have the luxury of large space or high load capacities. Common uses include CCTV cameras, medical equipment, and robotics.

Through-Bore Slip Ring Connectors:

Through-bore slip ring connectors are characterized by their hollow shaft design, which allows cables, shafts, or other feed-throughs to pass through the center. This design is particularly advantageous in applications requiring both rotational movement and a central passage, such as packaging machines and industrial turntables. Through-bore slip ring connectors are generally larger and capable of handling higher loads and speeds than their capsule counterparts.

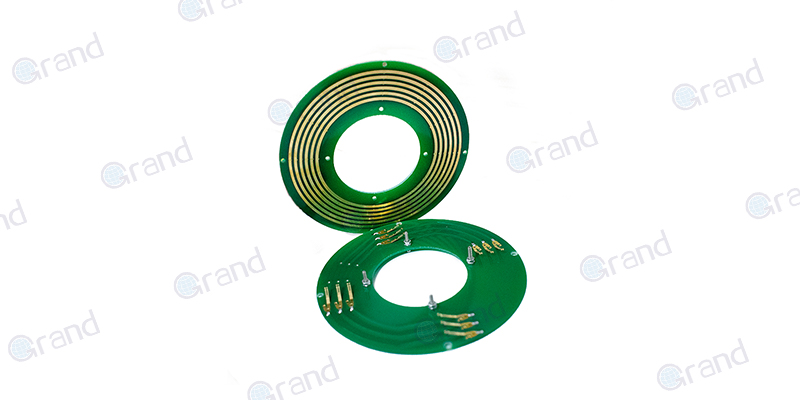

Pancake Slip Ring Connectors:

As their name suggests, pancake slip ring connectors feature a flat, disc-like design, in contrast to the cylindrical shapes of capsule and through-bore connectors. This flat design helps reduce the connector’s axial length, making it an excellent choice when installation space is limited in the vertical direction. Pancake slip ring connectors find their application in areas such as rotating displays, cable reels, and other environments where space is vertically constrained.

Sound selection of slip ring connectors hinges on understanding the unique challenges and requirements of each application. Be it high-speed operations, space constraints, or the need for a central passage, various types of slip ring connectors serve specific purposes tailored to the unique demands of these scenarios. By achieving the delicate balance of design optimization and functional adaptability, slip ring connectors continue to advance, keeping pace with the evolving landscape of industrial machinery and related applications.

Slip Ring Connectors: Key Specifications and Features

When selecting slip ring connectors for specific applications, understanding the key technical specifications and features is crucial. These details not only determine the connector’s compatibility with the intended system but also directly impact its performance and lifespan. Specifications such as current and voltage capacity, the number of circuits, and speed, alongside features like insulation materials, housing types, and bearings, are essential considerations.

Technical Specifications:

- Current and Voltage Capacity: Slip ring connectors are designed to carry different load capacities, measured by their ability to handle specific current (Ampere) and voltage (Volt) levels. These capacities can vary significantly, from low-power signals to high currents for power transmission. High-power slip rings are used in industrial machinery, while lower-power rings find their niche in delicate electronics where signal integrity is paramount.

- Number of Circuits: This specification indicates how many independent electrical paths are available in a slip ring connector. Applications requiring multiple signal transfers, such as combined power and data in robotic arms or medical equipment, necessitate slip rings with a higher number of circuits to support diverse connections simultaneously.

- Speed: The operational speed (RPM – revolutions per minute) refers to how fast the slip ring can rotate while maintaining a reliable connection. High-speed applications demand slip rings engineered for minimal contact friction and wear, ensuring longevity and consistent performance.

Key Features:

- Insulation Materials: The choice of insulation material in a slip ring connector is critical for preventing electrical leakage and short circuits between adjacent circuits. High-quality slip rings utilize advanced polymers or ceramics that offer superior insulation properties, high-temperature resistance, and durability against wear and environmental factors.

- Housing Types: The housing of a slip ring connector protects its internal components from dust, moisture, and mechanical impact. Materials such as aluminum alloys, stainless steel, or engineered plastics are commonly used, each offering different benefits in terms of strength, weight, and resistance to corrosion or electrical interference.

- Bearing Types: Bearings play a vital role in supporting the rotational movement of slip ring connectors. The selection between ball bearings, roller bearings, or other types depends on factors like required operation speed, load capacity, and service life expectancy. High-grade bearings enhance the performance of slip ring connectors by ensuring smooth rotation, reducing friction, and extending the lifespan of the unit.

In conclusion, the technical specifications and features of slip ring connectors outline the blueprint for their performance capabilities and application potential. From power and signal transmission needs to operational conditions like speed and environmental exposure, every aspect plays into selecting the right slip ring connector. With advancements in materials science and engineering, modern slip ring connectors offer a balance of high functionality, durability, and efficiency, tailored to the specific demands of a wide range of industrial, commercial, and technical applications.

Slip Ring Connectors: Application Areas

Slip ring connectors find their utility in an astonishingly diverse range of sectors, with each application leveraging the ability of these devices to provide a continuous electrical connection in systems that need to rotate uninhibitedly. Let’s delve into some of these sectors and understand the pivotal roles slip ring connectors play.

In the renewable energy sector, specifically in wind turbines, slip ring connectors are integral. They serve a dual purpose – transmitting power generated by the turbine blades as they rotate, and allowing for the transfer of control signals for pitch control systems. These rings enable the rotor to turn freely concerning the tower, mitigating the risk of cable twisting and ensuring efficient operation regardless of wind direction.

Rotating Cameras:

In security and surveillance systems, rotating cameras frequently rely on slip ring connectors to maintain the transmission of video signals as well as power while allowing for 360-degree uninterrupted rotation. This is critical to maintain constant power and ensure data integrity, allowing for continuous panoramic surveillance without the need to reset the camera’s position.

In the medical field, particularly in diagnostic imaging machines like (CT) scanners, slip ring connectors are crucial. These scanners require the gantry to rotate around the patient, and slip ring connectors facilitate the transfer of power and the retrieval of data from the detectors on the rotating part of the machine. This capability is paramount for producing detailed images required for accurate diagnoses without compromising functionality due to rotation limits.

Manufacturing Machinery:

The manufacturing sector employs slip ring connectors in various types of machinery, including rotary tables, robotic arms, and automated packaging systems. Here, slip rings provide power and control signals to the moving parts of the machinery, ensuring that production processes are smooth, continuous, and efficient. For instance, in a bottling plant, rotating turntables use slip ring connectors to keep the assembly line moving, powering conveyor belts and sensors while transmitting data regarding the position and status of the bottles.

The utility of slip ring connectors across these sectors is a testament to their versatility and essentiality. As industries evolve and demand more complex and high-performing machinery, slip ring connectors will continue to be a key component, enabling innovation and efficiency. Their application in these diverse sectors illustrates how slip ring connectors are not merely components but critical enablers of modern technology across a vast array of industries.

Selection Criteria for Slip Ring Connectors

Selecting the right slip ring connector is pivotal to ensuring that your application operates efficiently, safely, and reliably. These connectors are foundational components in various applications enabling the transmission of power and data between stationary and rotating parts. To guide through this selection process, it’s essential to consider several critical factors that can significantly impact the connector’s performance and suitability for the intended application. These factors include size, load capacity, environment, among others.

Size:

The physical dimensions of the slip ring connector are among the first considerations. The size is determined by the space available for the slip ring in the application assembly. For compact applications with limited space, such as in certain types of medical equipment or small-scale robotics, capsule slip rings with a small form factor might be ideal. Conversely, larger machinery like wind turbines might accommodate through-bore or larger capsule slip rings to meet their requirements. Thus, measuring the available space and understanding the limitations is critical in choosing a slip ring that fits both physically and functionally.

Load Capacity:

Load capacity encompasses both the electrical and mechanical load that the slip ring will bear. Electrically, it is about the current and voltage that the slip ring needs to transmit. Applications involving high-power transmission, such as in industrial machinery, demand slip rings with high current and voltage ratings. Mechanically, the load capacity involves the bearing load and rotational speed. It’s crucial to choose a slip ring that can withstand the expected mechanical stresses to maintain operational integrity and longevity.

Environment:

The operating environment significantly influences the selection of slip ring connectors. Factors such as temperature, humidity, dust, and potential exposure to corrosive substances must be considered. For harsh environments, such as outdoor applications or those within industrial plants where exposure to elements like dust and moisture is common, slip rings with robust housing materials and seals are required to protect the internal components and ensure reliable operation. Environmental consideration also extends to the type of material used for contacts and insulation, as they must resist corrosion and wear under the expected conditions.

Signal Type and Quality:

Depending on whether the application involves transferring power, data, or both, the slip ring selected must be capable of handling the required signal types without degradation over time. Applications involving sensitive data transmissions, such as high-definition video in rotating cameras or critical sensor data in aerospace applications, require slip rings with excellent signal integrity features. These might include shielding for electromagnetic interference (EMI) and specially designed contact materials that maintain a stable connection.

Maintenance and Service Life:

Finally, the expected maintenance intervals and service life are crucial considerations. Slip rings designed with longevity in mind and those that offer easy access for maintenance can significantly reduce downtime and operational costs. Understanding the life expectancy of the slip ring under normal operating conditions and the availability of replacements and support from the manufacturer is also important.

In summary, the selection of slip ring connectors is a nuanced process that requires a comprehensive understanding of the application’s specific needs and constraints. By carefully evaluating factors such as size, load capacity, environmental conditions, signal type, and quality, along with maintenance requirements, one can ensure the selection of a slip ring connector that not only meets the operational demands but also contributes to the system’s longevity and reliability.

Slip Ring Connectors: Installation and Maintenance

Proper installation and regular maintenance of slip ring connectors are paramount to securing their operational efficiency and prolonging their lifespan. These connectors are pivotal in facilitating uninterrupted power and signal transmission in systems requiring rotation. Failing to correctly install or maintain these components can lead to poor performance, increased wear and tear, and even system failures. Here are best practices for installation, alongside maintenance tips and troubleshooting steps to ensure the longevity and reliability of your slip ring connectors.

Installation Best Practices

Read the Manufacturer’s Instructions: Always start with a thorough review of the installation instructions provided by the manufacturer. These directions include specific details about mounting requirements, wiring guidelines, and other critical considerations unique to the slip ring model.

Ensure Proper Alignment: Misalignment during installation can cause uneven wear, increased resistance, and ultimately lead to failure. Ensure that the stationary and rotating parts of the slip ring are perfectly aligned according to the manufacturer’s specifications.

Secure Electrical Connections: Loose wires or improperly secured connections can result in intermittent signals or power loss. Make sure all electrical connections are tight, well-insulated, and correctly matched to their respective circuits.

Avoid Tension on Wires: Ensure that cables connected to the slip ring are free from tension or excessive bending. Strain relief methods can be used to prevent stress on the connections, which could dislodge contacts or damage the wires.

Maintenance Tips and Troubleshooting

Regular Inspections: Conduct routine visual inspections to check for signs of wear, corrosion, or damage. Look specifically at the contact surfaces for excessive wear or pitting, which could indicate the need for cleaning or part replacement.

Cleaning Contacts: Keeping the contact surfaces clean is vital. Over time, debris or oxidation can form, leading to poor electrical conductivity. Use a soft, dry cloth or appropriate contact cleaner for removing contaminants, following the cleaner manufacturer’s guidance to avoid damage.

Monitoring Electrical Performance: Regularly test the electrical performance of the slip ring, checking for consistent power delivery and signal integrity. Sudden changes in performance can indicate issues such as worn contacts, dirt buildup, or electrical faults.

Lubrication: If the slip ring design allows for lubrication, ensure it’s done with the correct type and amount of lubricant as specified by the manufacturer. Incorrect lubrication can attract dirt or lead to excessive wear.

Common Troubleshooting Steps

Intermittent Signals or Power Loss: This issue is often due to loose connections or worn contacts. Check and secure all connections, and inspect the contacts for wear, cleaning, or replacing as necessary.

Increased Electrical Noise: If experiencing heightened electrical noise, inspect the slip ring for dirt or debris buildup on the contacts. Ensure proper shielding and grounding of the unit to mitigate electromagnetic interference.

Rough Operation or High Resistance: This can be caused by misalignment, inadequate lubrication, or damaged bearings. Verify the alignment according to the installation guide, lubricate as the design permits, and check bearings and other moving parts for signs of failure, replacing if necessary.

Adhering to these installation and maintenance guidelines will significantly enhance the performance and longevity of slip ring connectors. Regularly scheduled maintenance, coupled with prompt troubleshooting and corrective actions, will ensure these components continue to function as intended, supporting the seamless operation of the systems they are part of.

Slip Ring Connectors: Innovations and Technological Advancements

Slip ring connectors, essential for electrical connectivity in rotating systems, have seen significant technological progress over the years. These advancements aim not only at enhancing the basic functionality of these components — enabling continuous power and data transmission — but also at improving their longevity, reliability, and efficiency even in the most challenging conditions. This evolution reflects the growing demands of industries such as renewable energy, aerospace, defense, and automation, which require robust solutions for their dynamic environments. Let’s delve into the recent technological innovations and advancements that have marked the domain of slip ring connectors.

Recent Technological Innovations in Slip Ring Connector Design

One of the significant innovations is the integration of fiber optic technology with traditional slip ring design. Fiber optic slip rings provide a solution for high-speed data transmission without electromagnetic interference (EMI), crucial in environments with strict EMI requirements like aerospace and medical imaging. These slip rings use light to transmit data between the rotating and stationary parts of the system, ensuring higher bandwidth and data integrity.

The development of wireless slip rings represents a leap towards eliminating physical contact in power and data transmission. Using inductive coupling for power and RF signals for data, these slip rings drastically reduce wear and tear, minimizing maintenance needs and prolonging service life. This technology is particularly beneficial in applications where minimal interference and maintenance are paramount.

High-Density Packaging

Advancements in miniaturization and high-density packaging have allowed for more compact slip ring designs without compromising performance. Such innovations enable slip rings to carry more circuits and higher currents within a smaller footprint, essential in applications with space constraints like robotics and small satellites.

Advancements That Have Increased Performance and Durability

Advanced Contact Materials: The introduction of advanced materials for contact points, such as gold-gold contacts, has significantly improved the performance and durability of slip ring connectors. These materials offer excellent conductivity, low electrical noise, and resistance to wear and corrosion, extending the connectors’ lifespans and reliability in harsh environments.

Sealing and Encapsulation Techniques: Enhancements in sealing and encapsulation techniques have led to slip rings capable of withstanding extreme environmental conditions, including high humidity, dust, and corrosive atmospheres. These improvements ensure the protection of internal components, maintaining optimal performance in outdoor applications, such as wind turbines or marine equipment, and in demanding industrial settings.

Customization and Modular Design: The shift towards customizable and modular slip ring designs allows for greater flexibility in addressing the specific needs of various applications. Users can select the number of circuits, and the type of signal (power, data, or both), and even incorporate additional modules for RF or fiber optic transmission. This adaptability ensures that the slip rings can evolve alongside the technological advancements of the systems they serve.

In conclusion, the landscape of slip ring connectors is continually evolving, driven by the need for higher performance, greater reliability, and adaptability to new and demanding applications. The innovations and technological advancements in this field not only enhance the current capabilities of slip ring connectors but also pave the way for future developments, ensuring that these critical components remain at the forefront of technology, ready to meet the challenges of tomorrow’s advanced systems.

Slip Ring Connectors: Challenges and Limitations

Slip ring connectors serve as a critical interface in countless applications, bridging the gap between stationary and rotating systems to enable the continuous transmission of power and signals. Despite their indispensable role and the significant advancements in their design and materials, slip ring connectors are not without their inherent limitations and challenges. Understanding these challenges is crucial for optimizing the design and maintenance of systems that rely on slip rings, ensuring they meet the demanding requirements of modern applications in various industries, from wind energy to aerospace.

Acknowledging the Limitations Associated with Slip Ring Connectors

Slip ring connectors, by their very design, are subject to physical contact between their rotating and stationary components. This contact, necessary for the transmission of power and data, inherently leads to friction. Over time, this friction contributes to wear and tear on the contacts, affecting the connector’s performance and longevity. The very nature of this mechanical interaction limits the lifespan of slip ring connectors compared to non-contact forms of data and power transmission, such as wireless technologies.

Additionally, the performance of slip ring connectors can be significantly impacted by environmental factors. Dust, moisture, and chemical contaminants can infiltrate the slip ring, leading to corrosion, increased electrical resistance, and eventual failure. For applications in harsh environments, this necessitates the use of specially designed slip rings with enhanced protective measures, which can increase costs and complexity.

Common Challenges Users May Face

The most prevalent challenge with slip ring connectors is wear and tear on the contact surfaces. As the connector operates, the constant friction between the rotating and stationary parts causes the material of the contacts to degrade over time. This degradation can lead to increased electrical resistance, reduced efficiency, and, eventually, the need for maintenance or replacement. Selecting materials with high wear resistance and proper lubrication can mitigate this issue but not eliminate it.

Noise and Signal Interference

Another significant challenge is electrical noise and signal interference. The friction between contacts not only leads to physical wear but can also generate electrical noise, which can interfere with the transmission of delicate data signals. Furthermore, slip ring connectors can be susceptible to external electromagnetic interference (EMI), affecting signal integrity. Advances in materials science and shielding techniques have improved the situation, yet maintaining high signal quality remains a challenge, especially in environments with high EMI.

Environmental Susceptibility

Slip ring connectors, especially those utilized in outdoor or industrial settings, must contend with the ingress of contaminants such as dust, water, and corrosive chemicals. These contaminants can cause corrosion, increase wear, and degrade electrical performance. While sealing and encapsulation technologies have advanced, achieving complete protection in the most extreme environments poses a continuous challenge. Designing connectors that balance protective measures with performance, maintenance accessibility, and cost-efficiency is a complex endeavor.

In summary, while slip ring connectors are irreplaceable in many applications, their inherent limitations and the challenges they present, such as wear and tear, noise and signal interference, and environmental susceptibility, demand ongoing attention. Addressing these issues requires a multifaceted approach involving advancements in materials, engineering design, and perhaps even rethinking the fundamental ways in which these essential components operate. As technology progresses, the continuing evolution of slip ring connectors will be paramount in meeting the ever-growing demands of modern and future systems.

Slip Ring Connectors: Energy Efficiency and Environmental Considerations

Slip ring connectors, given their key role in empowering a multitude of rotating systems, stand at the intersection between technology and sustainability. Their capacity to facilitate uninterrupted energy transfer and signal transmission in various applications, from wind energy turbines to industrial equipment, mandates a close examination of their efficiency and environmental footprint. As the global imperative to conserve energy and reduce environmental impact intensifies, the performance of slip ring connectors and their associated manufacturing and recycling processes come under scrutiny.

Efficiency of Slip Ring Connectors in Energy Transfer

The conductivity of the materials used in the contacts of slip ring connectors plays a vital role in determining their energy efficiency. Advanced materials, such as precious metal alloys, often used for their low electrical resistance, facilitate efficient energy transfer with minimal losses. However, friction between the stationary and rotating components of the slip ring can lead to energy loss as heat. Ensuring high-conductivity materials, optimal alignment, and adequate lubrication can mitigate these losses to ensure efficient energy transfer.

That said, it’s also important to acknowledge that slip rings, by their very nature, may not be as energy-efficient as non-contact methods of power transmission, such as wireless or inductive systems. These methods, while often more efficient, may not always be feasible due to constraints related to cost, compatibility, and application-specific requirements. Balancing efficiency with practicality is often necessary when selecting the most appropriate solution for power transmission in rotating systems.

Environmental Impacts and Considerations in Manufacturing and Recycling

The manufacturing process of slip ring connectors, like any other electronic device, inevitably has environmental implications. The mining and processing of raw materials, particularly precious metals used in contact, contribute to resource depletion and environmental pollution. Manufacturers are, therefore, challenged to source materials responsibly and adopt sustainable practices in their manufacturing processes.

Subsequently, in the product lifecycle, end-of-life management of slip ring connectors can lead to environmental impacts if not appropriately handled. Given that these devices contain valuable and often scarce metals, their recycling offers an opportunity to recover these materials, reducing the demand for virgin resources. However, not all parts of the slip ring may be recyclable, which poses an additional challenge in waste management.

Additionally, slip rings used in outdoor or harsh environments are often designed with robust encapsulation and protective measures. While such measures are crucial for performance and durability, they can add to the complexity of recycling the device, potentially necessitating specialized recycling processes.

In response to these environmental challenges, some manufacturers are turning to greener practices, such as adopting circular economy principles, minimizing the use of hazardous substances, and designing their products with recycling and disposal in mind.

In conclusion, while slip ring connectors play a critical role in enabling diverse technological applications, their energy efficiency and environmental impact present ongoing challenges. Nevertheless, these challenges also provide opportunities for innovation and progress. Through continued research, responsible sourcing, smart design, and embracing sustainable practices, manufacturers can improve the energy efficiency of slip ring connectors and reduce their environmental impact, contributing to a more sustainable future.

Slip Ring Connectors: Future Trends and Market Outlook

As the technological landscape continues to evolve at an unprecedented pace, slip ring connectors, which sit at the core of numerous rotating systems, are no exception to this tide of innovation. The future developments in the slip ring connector industry are likely to be shaped by advances in material science, digitalization, and the rising demands of sustainable and smart technologies. Concurrently, analyzing current market trends reveals much about future demand for these components, highlighting areas of growth and the changing requirements of industries that depend on these essential devices.

Predicting Future Developments in the Slip Ring Connector Industry

Integration of Smart Technologies: Future slip ring connectors are poised to become ‘smarter’ through the integration of sensors and digital communication capabilities. These enhancements would enable real-time monitoring of performance metrics such as wear, temperature, and electrical resistance. Such data could be used not only for predictive maintenance, and reducing downtime, but also for optimizing system performance through adaptive control algorithms.

Advancements in Materials and Design: Ongoing research in nanotechnology and novel alloys promises the development of slip rings with even lower electrical resistance, higher wear resistance, and reduced susceptibility to environmental conditions. Furthermore, modular and scalable slip ring designs could become more prevalent, catering to a wider range of applications and making custom solutions more cost-effective and accessible.

Focus on Sustainability: As the global emphasis on sustainability intensifies, the slip ring industry is expected to prioritize eco-friendly materials, manufacturing processes, and recycling practices. This shift will likely influence the entire lifecycle of slip ring connectors, from design to disposal, encouraging the adoption of principles from the circular economy.

Analyzing Current Market Trends and Future Demand

Renewable Energy Sector Growth: The global push towards renewable energy sources, particularly wind power, suggests a robust demand for high-quality, durable slip ring connectors. These components are essential for wind turbines, which rely on slip rings for electrical connectivity between the nacelle and the rotating blades. The growth of the offshore wind sector, with its harsh operating environments, further underscores the need for connectors that ensure reliability and longevity.

Expansion into New Applications: Market trends indicate that slip ring connectors are finding new applications in emerging fields such as robotics, drones, and space exploration. The increasing automation of industrial processes and the burgeoning exploration of both space and the deep sea will drive demand for sophisticated slip ring solutions capable of operating in extreme conditions.

Demand for High-Performance Data Transmission: As the world becomes increasingly digitalized, the demand for slip ring connectors capable of high-speed, high-fidelity data transmission is set to rise. This trend is particularly evident in the aerospace and defense sectors, where reliable data transfer is critical for the operation of complex systems in challenging environments.

In conclusion, the future of slip ring connectors is bright, shaped by technological advancements, sustainability efforts, and expanding markets. As these components evolve to meet the rigorous demands of modern applications, their role as enablers of innovation in rotating systems is set to grow. Manufacturers and designers who stay ahead of these trends, focusing on smart, sustainable solutions, will be well-placed to lead the market into the future.

Conclusion

Slip ring connectors stand as a testament to the ingenuity of electrical engineering, enabling technologies that make modern life possible. Their evolution, marked by both challenges and breakthroughs, points towards a future where they continue to play a pivotal role in technological advancement.

See What We Can Do