This concise guide offers an in-depth look at the rotor resistance starter, a key device for optimizing motor efficiency and control. Beginning with its definition and importance, the article systematically breaks down the essential aspects of the rotor resistance starter: how it operates, its advantages like smoother motor startups and minimized electrical stresses, and its applicability across various industries. Further, it provides valuable tips on installation, maintenance, and troubleshooting to maximize device longevity. The overview concludes by considering future advancements in rotor resistance starter technology, underscoring its enduring relevance in electrical engineering.

What is rotor resistance starter

The rotor resistance starter serves as a pivotal component in the realm of motor control, especially when it comes to the management and adjustment of high-power electric motors. At its essence, this device plays a critical role in initiating the operation of a motor by controlling the motor’s acceleration during the start-up phase. This method of startup is crucial as it significantly reduces the inrush current, minimizing mechanical stress on the motor and the electrical stress on the power supply. The beauty of the rotor resistance starter lies in its simplicity and effectiveness, making it a preferred choice for industries looking to optimize the performance and longevity of their electric motors.

In the industrial arena, the importance of rotor resistance starters cannot be overstated. Industries that depend heavily on large machinery for their operations, such as manufacturing plants, mining operations, and utilities providers, find immense value in these devices. These starters are particularly beneficial in applications where the load varies significantly, or where a soft start is necessary to prevent damage to mechanical components, reduce inrush current, and maintain stability in the power supply. This controlled approach to starting motors not only enhances operational efficiency but also contributes to substantial energy savings and reduced maintenance costs.

Through the application of rotor resistance starters, industries can achieve a more sustainable operation, reducing wear on equipment and extending the lifespan of valuable machinery. This introduction to rotor resistance starters sets the stage for a deeper dive into their mechanics, benefits, applications, and the latest advancements in starter technology. By exploring real-world examples and addressing common questions, this article aims to shed light on the multifaceted role of rotor resistance starters in modern industrial applications, underscoring their significance in ensuring smooth, efficient, and cost-effective operations.

The Basics of Rotor Resistance Starters

What are Rotor Resistance Starters

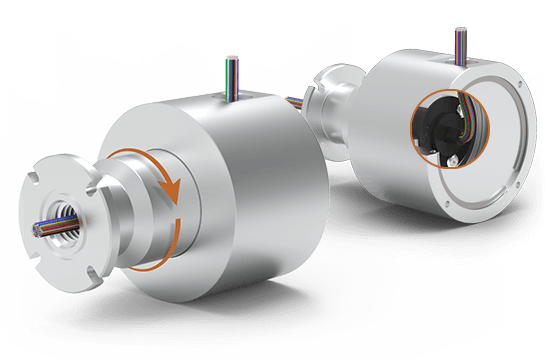

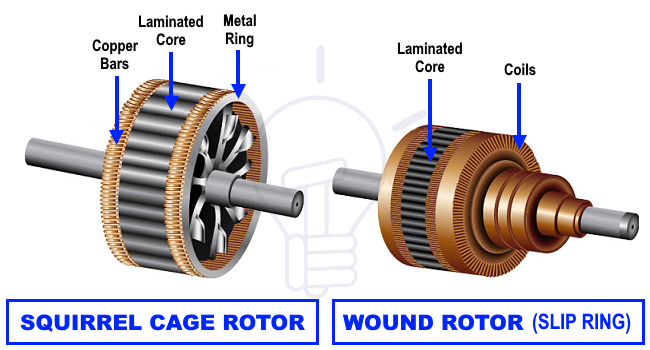

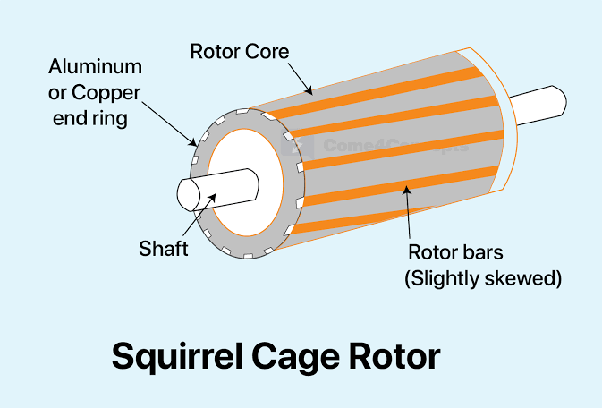

A rotor resistance starter is fundamentally designed to manage the starting of an induction motor, particularly a wound rotor motor. Unlike standard induction motors, wound rotor motors have windings connected to slip rings. These slip rings provide an external circuit where resistors can be connected to add resistance in the rotor circuit. By controlling this resistance, rotor resistance starters precisely manage the motor’s starting torque and current.

When an induction motor starts, the starting current can be very high, sometimes up to 7-8 times the full load current. This high current can lead to electrical and mechanical stresses that shorten the motor’s life. A rotor resistance starter mitigates these effects by inserting variable resistances gradually into the rotor circuit. As the motor accelerates, these resistances are sequentially reduced and eventually eliminated once the motor reaches close to its operating speed. This method not only reduces the initial surge current but also provides a smooth start which is less taxing on the mechanical components of the motor.

Comparison with Other Motor Starters

To appreciate the unique characteristics of a rotor resistance starter, it is beneficial to compare it with other common types of motor starters:

- Direct Online Starters (DOL): The simplest form of a motor starter that connects the motor directly to the power supply. While DOL starters are uncomplicated and cost-effective, they do not offer any form of current control, leading to a high inrush current.

- Star-Delta Starters: Used primarily for larger motors, these starters initially connect the motor windings in a star configuration reducing the voltage applied to each phase. After a preset time, it switches to a delta configuration, allowing full voltage to the motor. Though this reduces the starting current, the transition can be abrupt and may cause mechanical stresses.

- Soft Starters: These employ solid-state devices to control the voltage applied to the motor, gradually ramping it up to the full operational level. Soft starters offer good control over the start but can be more expensive and complex.

Rotor resistance starters distinguish themselves in scenarios where a fine control over the torque is necessary, particularly useful in heavy-load starts or where the mechanical systems connected to the motors are sensitive to torque spikes. Additionally, because rotor resistance starters mechanically adjust resistance, they are often more robust and suitable for harsh industrial environments where electronic devices might fail.

Real-World Example

Consider a large conveyor system used in a mining operation—a sector known for its harsh conditions and the need for reliable and rugged equipment. By employing a rotor resistance starter, the mining company can ensure that the huge motors driving the conveyor start smoothly, minimizing wear on belts and drive trains. This not only prolongs the life of the equipment but also reduces downtime and maintenance costs, leading to better operational efficiency and profitability.

Key Benefits of Using a Rotor Resistance Starter

The choice of a motor starter is pivotal in enhancing the efficiency, longevity, and reliability of industrial motor applications. Among the various starting methods, rotor resistance starters stand out by offering significant advantages, particularly in terms of energy efficiency and motor lifespan. This chapter delves into these benefits, substantiating the value of rotor resistance starters in both operational efficiency and the long-term sustainability of motor-driven systems.

Energy Efficiency and Improved Control Over Motor Starting and Stopping

Rotor resistance starters enhance energy efficiency by significantly improving the control over the motor’s starting and stopping phases. Unlike direct online starters, which cause a high inrush current leading to energy waste and potential damage to electrical circuits, rotor resistance starters moderate the inrush current by incrementally reducing the applied resistance. This control over the starting process not only leads to energy savings but also stabilizes the electrical load on the power supply network, minimizing disturbances that can affect other equipment.

Real-World Example:

Consider a water treatment facility where large pumps are critical for operations. These pumps need to start and stop based on demand without causing pressure surges in the piping system, which could lead to leaks or pipe bursts. Implementing rotor resistance starters, the facility can smoothly ramp up the motor speed, reducing mechanical stress and avoiding sudden power spikes. This translates to lower operational costs and energy consumption, highlighting how rotor resistance starters directly contribute to the efficiency and reliability of critical infrastructure.

Increased Lifespan of Motors by Minimizing Wear and Tear During Startup

The application of rotor resistance starters also bears significant implications for the lifespan of motors. Starting a motor, especially under heavy load, subjects it to mechanical and electrical stresses that can cause wear and tear over time. By inserting resistance into the rotor circuit at startup, these starters allow the motor to gain speed gradually. This gradual increase in speed considerably reduces the mechanical stress on the motor shaft, bearings, and other components, thereby increasing the motor’s overall lifespan.

Case Study:

A cement manufacturing plant faced frequent downtimes and maintenance issues with conveyer belt motors, which operated under heavy load. The installation of rotor resistance starters allowed for controlled startups, significantly reducing mechanical shocks. As a result, the plant observed a marked reduction in maintenance calls and an increase in motor service life, with the investment in rotor resistance starters paying off through decreased operational costs and enhanced productivity.

Design and Components of a Rotor Resistance Starter

A deep understanding of the components and design choices of rotor resistance starters shines a crucial light on the practical aspects of their operation in industrial settings. This chapter outlines the structures and functions of the primary components of rotor resistance starters—including resistors, contactors, and switching mechanisms—and exalyses how particular design elements can influence both performance and reliability in real-world applications.

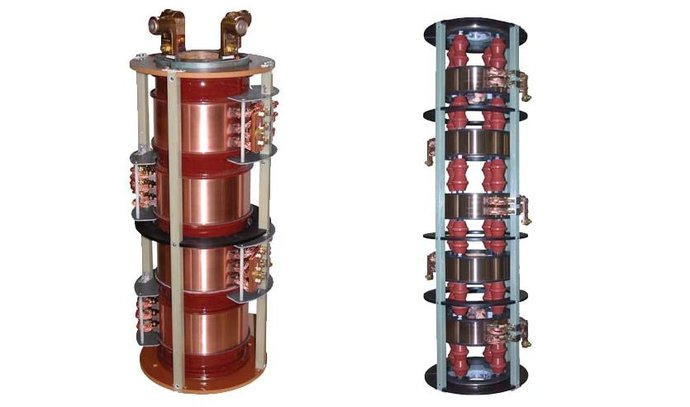

The Main Components of a Rotor Resistance Starter

Understanding each component’s role within a rotor resistance starter is vital for optimizing the device’s function and enhancing the performance of industrial motors. Let’s delve into the characteristics of these components:

Resistors

The resistors in a rotor resistance starter are crucial for controlling the initial inrush current when a motor starts. These components act by inserting a controlled resistance into the rotor circuit, which limits the starting current and allows for a smoother, more gradual increase in motor speed. They are designed to be both robust and responsive, capable of handling and dissipating significant amounts of heat generated during operation. Depending on specific needs, the material makeup and resistance level of these components can vary, directly influencing the starter’s efficiency and the motor’s acceleration profile.

Contactors

Contactors in a rotor resistance starter operate as powerful, electrically-controlled switches. Their function is to connect and disconnect the resistors from the rotor circuit as needed during the startup process. The reliability and efficiency of contactors are paramount as they must endure frequent operation and potential electrical arcing, which can wear down lesser materials over time. Higher-quality contactors improve the overall reliability of the starter, reducing maintenance needs and increasing operational uptime.

Switching Mechanisms

The switching mechanism governs how and when the contactors activate and deactivate the resistors during the startup. This can be manual, semi-automatic, or fully automatic, depending on the complexity of the system and the required precision for the application. In high-end systems, sophisticated automatic controllers, often integrated with programmable logic controllers (PLC), oversee this process, providing precise control based on specific performance parameters and ensuring the optimal ramp-up speed for the motor.

Impact of Design Elements on Starter Performance and Reliability

The integration and design choice of each component in a rotor resistance starter fundamentally influence the device’s effectiveness and durability.

Design Customization for Specific Applications

Consider a mining operation where equipment must frequently start under heavy loads in a dusty environment. A rotor resistance starter designed with encapsulated resistors and heavy-duty contactors, combined with a dust-resistant housing, increases both performance under load and resilience against environmental factors. The tailored design ensures minimal downtime and extends the life of the motor and starter system.

Quality and Configuration Choices

The choice of component materials, the configuration of the resistor bank, and the sophistication of the switching mechanism also play crucial roles in maximizing operational performance and minimizing maintenance. For instance, using silver alloy in contactors might increase upfront costs but significantly enhances their longevity and reliability, reducing the overall life cycle costs.

Installation Considerations for Rotor Resistance Starters

Ensuring a smooth and efficient startup for industrial motors lies not only in the design and components of rotor resistance starters but equally in their proper installation. This chapter demystifies the installation process, offering guidelines to navigate the complexity of setting up these systems while steering clear of common pitfalls that could lead to operational inefficiencies or potential hazards.

Guidelines for Proper Installation

The installation of a rotor resistance starter is a critical step that requires attention to detail, knowledge of electrical systems, and an understanding of the specific application requirements. Below are key considerations to ensure a successful installation:

Assess Environmental Conditions

Before installation, evaluate the environmental conditions of the intended setup location. Temperature, humidity, dust levels, and potential corrosive agents in the air can significantly affect the starter’s operation and longevity. Selecting an optimal location and, if necessary, implementing environmental controls (such as cooling systems or enclosures) can mitigate the impact of harsh conditions.

Plan for Adequate Space and Ventilation

Rotor resistance starters, especially for high-power motors, can generate substantial heat during operation. Ensure there’s enough space around the starter for air circulation to dissipate heat efficiently. In confined spaces, additional cooling or ventilation systems might be necessary to prevent overheating.

Electrical Connection and Grounding

Proper electrical connections are paramount for the safe and efficient operation of rotor resistance starters. Incorrect wiring can lead to malfunctions, inefficiencies, or dangerous electrical faults. Moreover, grounding the starter system is crucial for safety, preventing potential electrical shock hazards and protecting equipment from surge damages.

Common Installation Pitfalls and Avoidance Strategies

Awareness of common installation errors can prevent issues that might compromise the performance or safety of rotor resistance starter systems. Some typical pitfalls include:

Ignoring Manufacturer’s Guidelines

Each rotor resistance starter comes with a set of installation and operation guidelines provided by the manufacturer. Ignoring these instructions can lead to improper installation, risking both performance and safety. Always follow the manufacturer’s recommendations and consult with their support teams if clarification is needed.

Underestimating Environmental Impacts

Failure to account for the environmental conditions can lead to overheating, corrosion, or other forms of degradation. For instance, a starter installed in a high-humidity environment without adequate protection might experience accelerated wear and electrical issues. Assessing and mitigating environmental factors during the installation planning phase is essential.

Inadequate Wiring and Poor Grounding

Incorrect or sloppy wiring can lead to inefficient operation or dangerous conditions. Similarly, inadequate grounding poses a significant safety risk. Ensuring that all connections are secure, correctly configured, and that the entire system is properly grounded is crucial.

Real-World Example: Ensuring Success in Harsh Conditions

Consider a case where a rotor resistance starter was installed in a mining operation deep underground. The environmental challenges—high humidity, varying temperatures, and dust—were significant. By following strict guidelines for environmental assessment, the team chose an installation site that minimized exposure to these conditions and used enclosures designed to protect the starter from dust and moisture. The attention to detail in planning and adherence to installation best practices ensured the longevity and reliability of the starter system under harsh conditions.

Operating a Rotor Resistance Starter

Mastering the operation of a rotor resistance starter is not merely about turning a motor on and off. It requires an understanding of the intricate balance between electrical control, mechanical performance, and long-term equipment health. This chapter delineates the operational phases of a rotor resistance starter and shares tips for maintaining peak performance and troubleshooting common hurdles, ensuring your industrial motor applications run smoothly and efficiently.

Step-by-Step Process to Operate a Rotor Resistance Starter

The operation of a rotor resistance starter is a highly controlled process designed to protect the motor and ensure efficient performance. Here’s a breakdown of the steps involved:

Initial Setup and Inspection

Before operation, ensure that the starter and motor connections are secure, and the system is correctly configured according to the instructions. Inspecting the physical condition of the starter, checking for any signs of wear or damage, and verifying that all safety systems are operational are critical first steps.

Powering Up the Starter

Engage the main power supply to the starter. This should be done using the designated switch or control interface that comes as part of the system. At this stage, the starter begins monitoring the motor but doesn’t initiate its start sequence yet.

Initiating Motor Start

Activate the starter’s motor start sequence through the control panel. This triggers the first stage of resistance engagement, where the pre-calculated resistance is inserted into the rotor circuit to limit the starting current and control the initial torque.

Step-Down Resistance Stages

As the motor accelerates, the starter methodically reduces the resistance in the rotor circuit according to its preprogrammed settings or operator inputs. This step-down process is crucial for gradually increasing the motor’s speed and torque in a controlled manner until it reaches its operational speed.

Monitoring and Adjustment

Throughout the start cycle, continuously monitor the motor’s performance and the starter’s operation. Adjustments may be necessary to optimize the start process or accommodate changing load conditions on the motor.

Entering Run Mode

Once the motor reaches its full operational speed, the starter disconnects the rotor circuit resistances, allowing the motor to run under its own electrical and mechanical characteristics.

Maintaining Optimal Performance and Troubleshooting

To ensure the rotor resistance starter continuously operates at its best, routine maintenance and an understanding of common issues are essential.

Maintenance Tips:

- Regular Inspections: Conduct visual inspections for signs of damage or wear and perform electrical tests to ensure the system functions correctly.

- Cleaning: Keep the starter and its components clean from dust, dirt, and debris that can accumulate and cause overheating or electrical malfunctions.

- Calibration: Periodically check and recalibrate the starter settings and resistances to ensure they align with the motor’s operational needs.

Troubleshooting Common Issues:

- Starter Fails to Initiate: Check power supply connections and circuit breakers to ensure the system is properly energized. Verify that command and control signals are reaching the starter.

- Motor Starts Slowly or Weakly: Adjust the resistance settings. Insufficient resistance can cause a slow start, while too much resistance can weaken the motor’s torque.

- Overheating: Ensure adequate ventilation and cooling. Overheating can be a sign of excessive load, insufficient cooling, or environmental factors.

Real-World Example: Smooth Operations in a Textile Mill

Consider a textile mill where motor startups are frequent and must be smoothly managed to prevent damage to delicate machinery. By following a strict operational protocol for their rotor resistance starters and adhering to regular maintenance schedules, the mill minimized downtime and maximized productivity. Their meticulous attention to step-down resistance stages and continuous monitoring allowed for precise control over motor acceleration, ensuring the longevity and efficiency of their equipment.

Applications of Rotor Resistance Starters in Industry

Rotor resistance starters play a pivotal role in a multitude of industries, safeguarding equipment from the stresses of direct starts by controlling the current and providing a smooth acceleration to operational speed. This chapter delves into the sectors most reliant on this technology and highlights real-world applications, demonstrating their indispensable value in modern industry.

Pivotal Industries for Rotor Resistance Starters

Heavy Manufacturing

Industries involved in heavy manufacturing—such as steel, automotive, and machinery—depend on high-torque equipment that requires rotor resistance starters to mitigate the mechanical strain and electrical demands during startup. Controlled acceleration not only extends the life of machinery but also conserves energy and reduces operational costs.

Mining Operations

Mining operations utilize large conveyors, crushers, and grinders that face significant stress during startup. Rotor resistance starters ensure these machines start efficiently and safely, reducing wear and tear, which is critical in environments where downtime can lead to substantial financial losses.

Water and Wastewater Treatment

Pumps and blowers are the heart of water and wastewater treatment facilities. Ensuring these machines start under controlled conditions is vital to maintain operational continuity and manage the substantial inrush currents involved, which is where rotor resistance starters become essential.

Power Generation

In power generation plants, especially those using coal or gas, the turbines and auxiliary pumps must start smoothly to ensure the stability of the entire power grid. Here, rotor resistance starters play a crucial role in achieving a harmonious balance between demand and supply.

Case Studies and Examples

A Triumph in the Steel Industry

Background: A leading steel manufacturing plant faced challenges with frequent motor failures and downtime, attributed to harsh startup conditions.

Solution: Implementation of rotor resistance starters for their heavy rolling mills.

Outcome: The plant witnessed a dramatic reduction in motor failures and energy costs. The controlled starting mechanism of the rotor resistance starters extended the lifespan of the rolling mills and improved overall production efficiency.

Revolutionizing Wastewater Treatment

Background: A municipal wastewater treatment facility struggled with pump failures and erratic water flow rates.

Solution: The facility upgraded its pumps with rotor resistance starters.

Outcome: This change led to a smoother startup of pumps, reducing mechanical stress and nearly eliminating downtime. Moreover, the energy efficiency gains contributed to lower operational costs and a more reliable treatment process.

Need Assistance with Rotating Joints? Our Experts Are Ready to Help.

Advancements in Rotor Resistance Starter Technology

As industries evolve, so do the technologies that support them. Rotor resistance starters, pivotal in protecting and efficiently managing the startup of heavy-duty motors, have seen significant technological advancements. This chapter explores recent innovations in rotor resistance starter technology and provides insights into what the future might hold for these indispensable industry tools.

Recent Technological Improvements

Advanced Material Use

Modern rotor resistance starters leverage novel materials and components that offer superior performance and durability. For instance, the use of high-resistance alloys in rotor circuits improves efficiency and longevity, reducing maintenance needs and operational costs.

Integration with IoT

The Internet of Things (IoT) has transformed how rotor resistance starters operate. These devices can now be monitored and controlled remotely, providing real-time data on motor performance, energy consumption, and potential issues. This integration enables predictive maintenance, significantly reducing downtime and extending equipment life.

Enhanced Control Systems

Recent advancements include more sophisticated control systems that precisely manage the resistance levels based on varied operational parameters. These systems use algorithms to optimize startups under different load conditions, enhancing overall motor efficiency and reducing electrical stress.

Energy Regeneration Capabilities

Some modern rotor resistance starters are designed to capture and reuse the energy dissipated during the startup process. This regenerative feature represents not only an advancement in starter technology but also a step towards more sustainable industrial operations.

The Future Outlook and Potential Innovations

Artificial Intelligence and Machine Learning

The future of rotor resistance starters lies in the integration of Artificial Intelligence (AI) and Machine Learning (ML). These technologies can analyze data collected from multiple startups, learning to adjust resistance levels optimally for each situation, thereby achieving unprecedented levels of efficiency and reliability.

Advanced Diagnostics and Self-Healing

Emerging technologies will enable rotor resistance starters to predict failures before they occur and initiate corrective measures autonomously. This could include adjusting operational parameters or ordering parts and service automatically, epitomizing the shift towards truly intelligent systems.

Sustainable and Eco-Friendly Solutions

As global emphasis on sustainability grows, future rotor resistance starters will likely incorporate eco-friendly materials and designs. Innovations may focus on minimizing energy loss and reducing the carbon footprint of industrial operations.

Choosing the Right Rotor Resistance Starter for Your Needs

The process of selecting the ideal rotor resistance starter (RRS) for your application is a pivotal decision that can significantly influence the efficiency, longevity, and operational costs of your heavy-duty machinery. This chapter provides a comprehensive guide to understanding the critical factors that should influence your selection process and offers insights into assessing quality and compatibility with existing systems.

Factors to Consider

What are Motor Specifications

The first step in identifying the appropriate RRS is to thoroughly understand the specifications of the motors in question, including power ratings, torque requirements, and operational environment. For instance, motors that operate under constant heavy loads, like those in the mining industry, may require more robust starters with higher resistance capacities.

Operational Requirements

Consideration of the specific operational needs of your application is crucial. Factors such as the frequency of starts, the necessity for speed control, and the demand for energy efficiency should guide the selection process. For example, water treatment facilities, which often require pumps to start and stop frequently, may benefit from an RRS that offers enhanced control features and energy efficiency.

System Compatibility

Evaluating the compatibility of the RRS with your existing system infrastructure is essential to ensure seamless integration. This includes electrical compatibility, physical space requirements, and the ability to interface with existing control systems. Ignoring these factors can lead to increased costs and complications during installation.

Future Expansion Plans

Planning for future expansion or changes in operational requirements can save significant time and expense. Selecting an RRS that is scalable or adaptable to future modifications in your systems can be a wise long-term investment.

Assessing Quality and Compatibility

Quality Indicators

High-quality RRS units typically exhibit certain characteristics, including robust construction, reliability under various operational conditions, and compliance with industry standards. Manufacturers with a proven track record, positive reviews, and the provision of comprehensive warranties are often reliable indicators of quality.

Compatibility Checks

Assessing the compatibility of an RRS with your existing system requires a detailed analysis of electronic and mechanical interfaces. Consultation with engineers or the manufacturing company can provide valuable insights into compatibility issues. Utilizing pilot projects or test installations can also offer practical evidence of how well the RRS integrates with your system.

Case Study: Cement Manufacturing Plant

Background: A cement manufacturing plant was facing frequent downtimes and high energy costs due to inappropriate RRS units that were not suited to the harsh operating conditions and heavy start-stop cycles of their kiln motors.

Solution: The plant conducted a comprehensive review of their operational requirements and selected a new RRS based on motor specifications, operational needs, and future expansion plans. The chosen system provided enhanced control features, energy efficiency, and was compatible with their existing systems.

Outcome: The new RRS led to a significant reduction in downtimes, energy costs, and improved the overall efficiency of the cement kiln operations.

The Pivotal Role of Rotor Resistance Starters

A Reflection on Benefits

Rotor resistance starters are unsung heroes in the industrial world, and their deployment brings several advantages. These include the protection of motor winding from the stress of high starting currents, the provision of controlled acceleration to mechanical systems, and the reduction of wear on mechanical components, leading to extended equipment life. The benefits extend to cost savings—both immediate, through reduced power consumption at startup, and long-term, through improved operational efficiency and decreased maintenance costs.

Real-World Successes

To illustrate these benefits in action, let’s revisit the case study of the previously mentioned cement manufacturing plant. Through the implementation of a well-chosen RRS, the plant achieved a significant reduction in energy consumption, mechanical stress, and overall operational costs. This transformation showcases the critical importance of an RRS to the plant’s success and underlines the potential such technology holds across diverse applications.

Evolution of Motor Starters and Industry Impact

The Journey of Innovation

The evolution of motor starters is a saga of innovation and adaption, with technological advances spurring a continuous refinement of performance. From simple manual switches to sophisticated digital interfaces, motor starter technology has advanced to meet the increasing complexity and demands of modern industrial systems.

Industry Revolutionized

Motor starters—and RRS in particular—have revolutionized various industries by facilitating the operation of machinery in a safer, more efficient manner. Industries such as manufacturing, mining, and utilities have seen a substantial positive impact on their operations. They’ve been able to achieve more precise control over machinery, minimize disruptions due to breakdowns, and optimize production processes as a result of advancements in motor starter technologies.

Preparing for the Future

As industries become more interconnected and automated, the role of motor starters, especially RRS, is bound to evolve further. Integration with smart systems and IoT devices will provide real-time data and analytics, driving efficiency to new heights. Keeping abreast of these changes and preparing for the integration of new technologies will be critical for future developments and success.

Reflections

It is clear that rotor resistance starters are more than simple components; they are fundamental in optimizing industrial operations. The evolution of starters reflects a greater narrative of progress, a testament to humanity’s relentless pursuit of improved efficiency and reliability in industrial processes. As the journey continues, we can expect motor starters to become increasingly sophisticated, ensuring that industries keep pace with the demands of an ever-changing technological landscape.

Moreover, as society continues to emphasize energy conservation and sustainability, the importance of selecting and utilizing the right motor starters becomes all the more apparent. Efficient starters such as RRS not only contribute to the bottom line but also support broader environmental goals by reducing energy wastage.

In the chapters of this guide, we aimed to address vital concerns, debunk common myths, and provide you with actionable insights and information. Whatever the future holds, the fundamental principles and pragmatic wisdom encapsulated here will be a perpetual resource for those who wish to understand and leverage the power of rotor resistance starters as part of their industrial toolkit.

FAQs about rotor resistance starter

Q: Why not use a soft starter instead of a rotor resistance starter for every application?

A: While soft starters are excellent for controlling the start-up current and are energy-efficient, they may not offer the same level of robustness required in environments exposed to extreme conditions. Rotor resistance starters, with their simple and rugged design, often outlast soft starters in harsh industrial settings.

Q: Are rotor resistance starters suitable for all types of motors?

A: Rotor resistance starters are specifically designed for wound rotor motors and may not be applicable to standard squirrel cage motors. It’s crucial to understand the motor type before deciding on the starter.

Q: Can rotor resistance starters be used in energy-critical applications?

A: Absolutely. Rotor resistance starters are particularly suited for applications where energy efficiency is a priority. By providing a controlled start and minimizing electrical surges, these starters can help in optimizing energy use and reducing the overall operational costs.

Q: How significant is the effect of rotor resistance starters on motor lifespan?

A: The impact can be substantial. Motors often fail due to mechanical stresses and overheating from abrupt starts or stops. By ensuring a smooth transition during these phases, rotor resistance starters can extend the motor’s operational lifespan by reducing wear and tear, ultimately translating to cost savings and enhanced reliability.

Q: How frequently should components of a rotor resistance starter be replaced or maintained?

A: The lifespan of the components varies based on the design quality and operational conditions. Regular maintenance checks are recommended, with component replacements as needed based on wear and performance testing results.

Get Detailed Specifications on Our Rotating Joints. Contact Us!