RF rotary joint is the abbreviation of radio frequency, used to transmit radio frequency signals between rotor and stator parts in a rotary system. RF rotary joints can be divided into three types, coaxial rotary joints, waveguide rotary joints, and waveguide to coaxial rotary joints. The possible applications range from radar antennae to military, air traffic control, and space. It is often necessary to receive and send multiple-frequency signals.

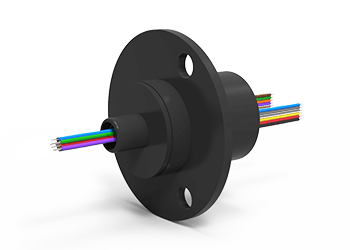

RF Rotary Joints - HR Series

Available for Custom, DC-4.5, DC-18, 14-14.5 Frequency Rate(GHz)

GRAND HR Series RF rotary joints are designed according to the skin effect of high-frequency signals and the structure of the coaxial cable. Support single or multi-channel to transfer DC~18GHz RF signals, also can be integrated with electric and other signals. HF rotary joint high-frequency signal uses 50Ω characteristic impedance RF coaxial structure.

With almost 10 years experience of in high-frequency slip rings, and RF slip rings. GRAND offers rotary joints with compact design, excellent VSWR, low insertion loss, and minimal fluctuation.

Although GRAND offers modularized & standardized designs for various application solutions as an original slip ring manufacturer. To create your most suitable RF rotary joint connector, please feel free to contact us.

Feature

◆ Frequency: DC~18GHz

◆ Can be combine with power and signal transmission

◆ Low insertion loss and voltage standing wave ratio

◆ Support 1 or 2 RF channels

Options

◆ Option for separate transfer single or multi channels high frequency signals

◆ Option for integrated transfer electric and HF signals

◆ Option for connector type

Model Breakdown

What is the Use of RF Rotary Joint?

RF Rotary Joints, often referred to within the industry as rotary couplings or swivels, are sophisticated electromechanical devices. They are typically used to transfer RF signals – a range of radio frequencies on the electromagnetic spectrum where electromagnetic waves are extensively applied for communication or radar signals – from stationary to rotating systems. As coupling devices, they are integral components in machinery handling the transmission of the RF energy while maintaining the rotational integrity of mechanical systems. To provide a deeper understanding, here are further elaborations on where these devices are typically used:

Radar Systems

In radar systems, RF Rotary Joints perform a pivotal role where antenna rotation is necessary to perform sweeping scans of a geographical area. Typically used in both ground-based and airborne radar systems, they allow for precise and clear data transmission of radar signals from the rotating antenna to stationary ground equipment.

Satellite Communication Systems

In satellite communication systems, RF Rotary Joints are vital in tracking satellites. Communication dishes need to move continuously to maintain lock with a specific satellite, or to move from one satellite to another. The RF Rotary Joint facilitates the transmission of RF signals between the stationary ground system and the moving antenna system.

Medical Equipment

In advanced medical technologies, like MRI machines, RF Rotary Joints are used to transmit signals while allowing relative movement between different parts of the equipment. This ensures a continuous imaging process without data interruption or loss.

Defense and Aerospace

For defense and aerospace applications, RF Rotary Joints ensure seamless communication and signal transmission in continuously rotating systems. They are used in a wide array of military equipment, including missile guidance systems, surveillance systems, and vehicular communication systems.

Industrial Applications

Various industrial scenarios involve rotating sensors or antennas that are used for measurement or communication purposes. Here, RF Rotary Joints are instrumental in fulfilling the accuracy requirements.

RF Rotary Joints are designed to provide consistent, high-quality, and low-loss connections in rotating systems. The kind of rotary joint used depends on factors including frequency range, power level, loss and VSWR requirements, mechanical constraints, and environmental conditions. Their complex designs and versatile functionality have positioned RF Rotary Joints as a fundamental component across industries where handling RF signals and ensuring operational efficiency is paramount.

The Versatility and Benefits of RF Slip Rings

Key Features of RF Slip Rings

Innovative Contactless Technology for Enhanced Signal Integrity

RF slip rings utilize contactless signal transfer technology through radio frequency transceivers. This ensures reliable and efficient signal transmission without physical contact, maintaining performance over the product’s lifespan. They can transfer various signals, including CAN and Ethernet protocols, making them versatile for diverse applications and high-speed data needs.

Customizable and Durable Slip Rings for Harsh Environments

These RF slip rings can be customized to meet specific IP ratings up to IP69, making them suitable for harsh environments exposed to dust, water, and other elements. Their robust PCB-based design enhances reliability, ensuring uninterrupted signal transfer with minimal downtime.

Compact Design for Versatile Integration and Extreme Durability

Engineered for compact spaces, RF slip rings can be as small as 0.7 inches wide and 0.6 inches high. They integrate seamlessly into existing setups, including through bore or enclosed within conventional power slip ring. Customizable enclosures made from materials like nylon or steel ensure consistent performance under various operational conditions.

Radio Frequency (RF) Slip Rings

Innovation is crucial for meeting the increasing demands of signal transfer in modern technology. While traditional slip rings perform well in many applications, radio frequency slip rings offer added design versatility. They can function alongside traditional slip rings or serve as standalone solutions, providing significant advantages.

Benefits of Radio Frequency Slip Rings

Contactless Signal Transfer: Eliminates wear and tear, ensuring long-term reliability.

Contactless Signal Transfer: Eliminates wear and tear, ensuring long-term reliability.

Scalable Data Transfer Rates: Supports various protocols with flexibility in design.

Maintenance-Free Long Life: Designed for durability and minimal upkeep.

High-Speed Signal Capability: Capable of transferring data at speeds up to 5 GBPS.

Minimal Size Impact: Compact designs fit easily into tight spaces.

Extreme Temperature Resilience: Operates effectively in temperatures ranging from -40°F to 320°F (-40°C to 160°C).

Customizable Enclosures: Adaptable to specific environmental needs.

Adaptability in Integration: Easily integrates into existing systems.

No Carbon Dust: Enhances cleanliness and reduces maintenance issues.

Coax Capsule Slip Ring

Coax Capsule Slip Rings are essential for transferring high frequency signals between stationary and rotating platforms. Their capsule structure guarantees higher protection rates.

What is a Coax Capsule Slip Ring?

Coax Capsule Slip Rings provide excellent transmission, high-speed data rates, and robust integrity. They enable uninterrupted rotation between coaxial cables, allowing RF signals to be transmitted without disruption. This technology ensures optimal crosstalk attenuation between channels and optimized VSWR. High frequency signals can be analog (GHz) or digital (Giga bits).

Based on advanced gold-to-gold contact technology or contactless solutions, operation is extremely reliable and maintenance-free for several hundred million rotations without component change or lubrication. Coax Capsule Slip Rings can also be combined with other rotary joints, such as FORJ, hydraulic, or hyper frequency.

Coax Capsule Slip Ring Applications

Typical applications for coaxial slip ring include communication systems such as radars, air traffic control, SATCOM antennas, and high-end cameras. This versatility makes them indispensable in various industries requiring reliable signal transmission.

Types of RF Rotary Joints

RF rotary joints are essential components for efficient signal transmission in rotating systems, available in non-contacting and contacting designs. Non-contacting RF rotary joints, including RF ring, are available in coaxial and waveguide configurations, supporting frequency ranges up to 100 GHz. They feature a long service life and can transmit signals at about 20% of the highest frequency, making them ideal for narrow-band applications. Special coupling structures allow the same module to handle multiple frequency bands, enhancing versatility in various applications, including RF multi channel rotary joints that facilitate efficient signal routing.

Contacting Rotary Joints

Contacting rotary joints, including RF contacting rotary joints, connect the inner and outer conductors of the stator and rotor directly. This design supports broadband applications, allowing signal transmission from DC up to 92 GHz. The maximum frequency depends on the coaxial line’s diameter, providing reliable performance across a wide frequency spectrum. Additionally, these joints can be designed to handle low frequencies, ensuring adaptability for different operational requirements, making them suitable for various industrial applications.

Interface Styles

rotary joint rf are available in several interface styles, including I, U, and L configurations. The orientation of input and output connections varies based on the style chosen. In the I style, both connections align with the rotational axis, facilitating straightforward installation. The U style positions the connections perpendicularly, while the L style features one aligned and one perpendicular connection, providing flexibility in design. Understanding these styles is crucial for selecting the right RF joint for specific applications.

Coaxial Rotary Joints

Coaxial rotary joints have coaxial input and output terminals, allowing one connector to rotate while the other remains fixed. Their performance is determined by the power and frequency limits of the connectors used, making them suitable for a range of applications. These joints ensure stable signal transmission while minimizing the risk of twisting or tangling, which is especially important in high-frequency environments. Coaxial rotary joints are commonly used in communications, radar systems, and various industrial processes.

Waveguide Rotary Joints

Waveguide rotary joints utilize waveguide interfaces at their input and output terminals. Similar to coaxial designs, one terminal rotates while the other is stationary. The operating frequency is constrained by the waveguide size, ensuring efficient signal transmission. These joints are ideal for high-frequency applications where maintaining signal integrity is critical. Waveguide rotary joints are often employed in advanced communication systems and radar technology, where precise signal handling is essential for performance.

Waveguide to Coaxial Rotary Joints

Waveguide to coaxial rotary joints feature a waveguide interface on one side and a coaxial interface on the other. The operating frequency is influenced by both the waveguide size and the type of coaxial connector used, providing flexibility for diverse applications. These joints are particularly useful in systems requiring both high-frequency performance and reliable power handling. Their design allows for seamless integration into existing systems, making them a valuable choice for engineers seeking efficient signal transmission solutions.

Overview of Grand in the RF Slip Ring Market

Grand, established in 2011, has swiftly risen to prominence as a manufacturer specializing in slip rings, rotary joints, and slip ring assemblies. With a robust manufacturing complex spanning 6,000 square meters, Grand is recognized as an expert in the RF slip ring market. The company focuses on delivering innovative and reliable solutions tailored to meet the specific needs of various industries, ensuring that its products enhance the efficiency and performance of rotating systems.

Certifications and Quality Assurance

Grand places a strong emphasis on quality assurance, having obtained several key certifications, including ISO9001, RoHS, CE, and GJB9001B. These certifications reflect Grand’s commitment to maintaining high standards in product manufacturing. The company also holds numerous patents for its slip rings and rotary joints, which ensures that its offerings meet stringent military-grade standards, thus providing customers with reliable and durable solutions in demanding applications.

Collaborative Innovations

Grand actively engages in collaborations with leading universities, research institutions, and major industry players, including Panasonic, Siemens, CSIC, Samsung, and Huawei. These strategic partnerships not only foster innovation but also facilitate the development of advanced technologies in the RF slip ring sector. By leveraging the expertise and resources of its collaborators, Grand enhances its product offerings and stays at the forefront of technological advancements in signal transmission solutions.

Advanced Manufacturing Capabilities

Grand’s workforce consists of hundreds of skilled technicians proficient in handling a diverse range of manufacturing tasks. The company has made substantial investments in automation technologies, which have significantly improved productivity, repeatability, and overall product quality. This focus on modern manufacturing processes allows Grand to reduce lead times while meeting customer demands effectively, ensuring that its products are both reliable and available in a timely manner.

Testing and Reliability

Grand boasts a state-of-the-art testing center that incorporates standard operating procedures (SOPs) and a dust-free laboratory environment. This facility is equipped with comprehensive testing equipment for high and low temperature conditions, salt spray tests, impact assessments, and vibration tests. Such rigorous testing ensures the reliability and performance of Grand’s RF slip rings, confirming that they can withstand various operational challenges while maintaining optimal functionality and longevity.

For further details or personalized inquiries regarding Grand’s RF slip ring products, potential customers are encouraged to reach out directly.

Related Posts

FAQs about RF Rotary Joint

What is a rotary joint?

A rotary joint is a mechanical device that allows the transfer of fluids, gases, or electrical signals between stationary and rotating parts of machinery. Rotary joints are used in a variety of applications, including industrial machinery, robotics, and aerospace systems. They can accommodate multiple media, such as hydraulic fluids, air, and electrical signals, facilitating seamless operation while preventing leaks or damage. Rotary joints come in different designs, such as contacting and non-contacting types, each suitable for specific applications. The contacting types use physical connections to transmit signals or fluids, while non-contacting variants employ advanced technology to achieve transfer without wear and tear. Overall, rotary joints are critical components in ensuring smooth and efficient operation in rotating systems.

How does a radar rotary joint work?

A radar rotary joint is a specific type of RF rotary joint designed for radar systems. It enables the seamless transfer of RF signals from a stationary base to a rotating radar antenna. The joint consists of multiple conductors that are aligned to transmit the radar signals effectively while allowing for continuous rotation. As the radar antenna turns, the rotary joint maintains signal integrity, preventing cable twist or damage that could compromise performance. The design often includes features to minimize insertion loss and maintain high-frequency performance. By ensuring a reliable connection, radar rotary joints are essential for accurate target detection and tracking in various applications, including aviation, maritime, and military radar systems.

How does a waveguide rotary joint work?

A waveguide rotary joint operates on the principles of waveguide technology, which is used to transmit high-frequency signals. In a waveguide rotary joint, the input and output interfaces are designed as waveguides, allowing for efficient signal propagation with minimal loss. As the rotary joint rotates, the waveguide structure ensures that the RF signals can pass through without interruption. This design is particularly effective for microwave and millimeter-wave applications, where maintaining signal integrity is crucial. The waveguide joint’s design minimizes reflection and crosstalk, making it ideal for high-performance communication systems. By integrating waveguide rotary joints into various technologies, users can achieve reliable signal transfer in rotating systems, enhancing overall system performance and efficiency.

Enhance Your System’s Performance with Our RF Rotary Joints – Contact Us Now!