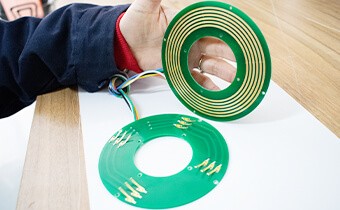

PCB slip ring is a kind of pancake slip ring, also called ultrathin flat slip ring. A common form of flat slip rings and made up of two parts, ring surface and brush assembly. The ring surface circuit board with an ultra-thick copper layer, then copper plating, and hard gold plating, so the PCB slip rings have high hardness and wear resistance features.

What is PCB Slip Ring?

PCB Slip Rings - HPC Series

Available for Custom, Standard ID 12.7-60mm, 1~12 Rings

GRAND developed a series of PCB slip rings for limited space. With a separate structure, low-cost and easy to install. The brush assembly is made up of military-grade brushes and heat-treated copper springs.

Although GRAND offers modularized & standardized designs for various application solutions as an original slip ring manufacturer. To create your most suitable PCB slip ring connector, please feel free to contact us.

Feature

◆ Min 6mm thickness

◆ Integrated structure design for easy installation

◆ Low contact resistance, no friction debris

◆ Standard model supports 1-12rings power or signal(0~10A/ring)

◆ Can be combined to transmit precision signal and supply power

◆ Free maintenance

Options

◆ Center hole size

◆ The circuits

◆ The protective housing

◆ Custom external diameter size

Model Breakdown

PCB Slip Rings Everything You Want to Know is Here

PCB slip rings, also known as printed circuit board slip rings, are specialized electrical devices designed to transmit power, signals, or data between rotating and fixed components of a system. These components play a critical role in applications that require continuous rotation while maintaining reliable electrical connections. By facilitating seamless communication between stationary and moving parts, PCB slip rings are essential in numerous modern technological applications.

Design and Functionality

The traditional slip rings PCB consists of a set of conductive rings attached to a rotating shaft, where electrical contact is made through brushes or contacts. In contrast, pcb ring utilize a more compact and integrated design, eliminating the need for traditional brushes. Instead, they combine conductive wires and a brushless approach on printed circuit boards to achieve efficient electrical connections. This design not only enhances reliability but also minimizes maintenance requirements.

Key Characteristics and Advantages

Compact and Space-Saving:

Compact and Space-Saving:

Compared to traditional flat slip ring, PCB slip rings are engineered to be compact, allowing them to fit seamlessly into smaller spaces. This makes them ideal for applications where space is a premium.

Low Maintenance:

The absence of brushes or moving parts significantly reduces wear and tear, resulting in lower maintenance needs and extending the service life of the slip ring. This reliability makes them a preferred choice for continuous operation.

Reliable Electrical Connections:

The printed circuit boards ensure consistent and dependable electrical connections, effectively minimizing signal loss and interference. This characteristic is crucial for applications requiring high data integrity.

Customizable Configuration:

PCB slip rings can be customized to meet specific requirements, including the number of rings, current capacity, and signal type. This flexibility allows engineers to design solutions tailored to unique applications.

Applications of PCB Slip Rings

PCB slip rings are versatile components that find applications across various industries, effectively enabling the transmission of power and signals between rotating and fixed parts. Here are some key applications:

Surveillance & Video:

PCB slip rings are essential in rotating camera systems, allowing continuous rotation while transmitting video signals and power, critical for monitoring applications.

Wind Turbines:

They play a vital role in wind turbines, facilitating the transmission of power and signals between a fixed base and rotating blades or engine rooms, ensuring efficient energy generation.

Stage Lights:

In the entertainment industry, PCB slip rings are used in stage lighting systems, allowing for seamless rotation and control of lighting fixtures while maintaining electrical connections.

Entertainment Equipment:

These slip rings are commonly used in various entertainment devices, ensuring reliable power and signal transmission in rotating platforms, such as turntables or stage props.

Packing Machines:

PCB slip rings are employed in packaging machinery, enabling continuous rotation during the packaging process while ensuring consistent electrical connections for sensors and actuators.

Robotic Arms:

In robotics technology, PCB slip rings facilitate the transmission of power and control signals between fixed and rotating components, enhancing the functionality of robotic arms and joints.

Construction Machinery:

They are utilized in construction equipment, providing reliable electrical connections for rotating parts, which is essential for the operation of cranes and other machinery.

Medical Devices:

PCB slip rings are critical in medical applications, including MRI machines, CT scanners, and robotic surgical systems, where continuous rotation and stable electrical connections are required.

Marine Applications:

In marine environments, PCB slip rings are used in systems like radar and communication devices, allowing for reliable transmission of power and data while the components rotate.

Cable Reels:

PCB slip rings are integrated into cable reel systems to maintain electrical connections while the reel rotates, ensuring efficient operation.

Automation:

In automated systems, PCB slip rings facilitate communication and power transmission between stationary and moving parts, contributing to improved efficiency and reliability.

Measuring Equipment:

They are used in measuring devices that require continuous rotation, ensuring that power and signals are transmitted reliably while the equipment operates.

Military Applications:

PCB slip rings are employed in military systems for radar and antenna technologies, providing crucial connections that support operational effectiveness in various environments.

Temperature Range and Repair Considerations

The operational temperature range for PCB slip rings is typically between -30 °C to +80 °C for all versions, making them suitable for a variety of environments.

Regarding maintenance, while pancake slip rings can be dismantled and theoretically repaired, it is advisable to avoid makeshift repair attempts due to their precision nature. Occasional cleaning with a suitable acidifying agent may be performed, but no major maintenance should be conducted on the slip rings. Each slip-ring,including circuit board ring,comes with a defined service life, and low-cost components can be easily replaced, restoring functionality and reliability until the next scheduled replacement.

Leading Slip Ring Manufacturers

As a leading player in the industry, Grand stands out among slip ring manufacturers by offering high-quality electrical slip rings、rotary joints、Optical Transmitter and Receiver that are essential for a wide variety of applications.The current market competition is fierce, e.g. Many slip ring manufacturers in India are focusing on advanced technologies to meet the growing demands of various industries.However,We understand that reliable performance is critical in today’s fast-paced technological landscape, and our slip rings are designed to meet those demands with precision and durability.Our commitment to excellence and innovation has positioned us as a trusted slip ring supplier for clients across multiple sectors.

Choose Grand as your reliable slip ring manufacturer, and experience the performance and quality that sets us apart in the industry. Our dedication to innovation, quality, and customer support ensures that we are equipped to meet your specific needs.

Innovation and Patents

With more than 50 national patents, Grand is at the forefront of innovation in the slip ring industry. Our three dedicated R&D centers focus on developing cutting-edge technologies that enhance the functionality and efficiency of our products. We continuously invest in research to explore new materials and designs that can improve performance and extend the lifespan of our slip rings. Our team of experienced professionals is always available to respond promptly to your inquiries about slip rings, rotary unions, and slip ring assemblies, ensuring you receive the support you need.

Commitment to Quality Control

We pride ourselves on our rigorous quality control processes, which include multiple standard steps to ensure that every product meets the highest industry standards. Our quality control measures encompass Incoming Quality Control (IQC), In Process Quality Control (IPQC), Final Quality Control (FQC), and Outgoing Quality Control (OQC). Each slip ring manufactured undergoes thorough testing to guarantee reliability and performance in real-world conditions. This meticulous attention to detail not only solidifies our reputation as a trusted slip ring supplier in the industry but also ensures that our clients can operate with confidence knowing they are using top-quality components.

Diverse Product Range

Grand offers an extensive product range that caters to the unique needs of our clients, from bespoke designs to standard models. Our slip rings are engineered for seamless connectivity in critical sectors such as aerospace, defense, telecommunications, and industrial automation. Each product is designed to handle specific operational requirements, ensuring optimal performance under varying conditions. Whether you need compact slip rings for a small device or a robust solution for heavy machinery, our diverse offerings can meet your specifications and help enhance your systems.

Recognition and Expertise

We are recognized as one of the premier slip ring suppliers in the market, known for our unwavering commitment to quality and customer satisfaction. Our products are trusted by industry leaders and have been successfully implemented in numerous high-stakes applications. Our expertise in the field allows us to understand the specific challenges faced by our clients and develop effective solutions that address those challenges. We strive to maintain our reputation through continuous improvement and innovation.

Specialization in Custom Solutions

In addition to our wide array of products, we specialize in slip ring assembly manufacturing, providing tailored solutions that meet specific operational requirements. Understanding that each application has unique demands, our engineers work closely with clients to design and manufacture customized slip rings that fit their exact specifications. As a prominent slid ring supplier, we recognize the importance of customization and are dedicated to delivering innovative solutions that enhance operational efficiency and effectiveness.

Comprehensive Selection

For those seeking slip ring assembly manufacturers or through hole slip ring manufacturers , Grand offers a comprehensive selection of products designed to meet the most demanding applications. Our through hole slip rings provide reliable electrical connections while allowing for additional wiring or other integrations, making them ideal for complex systems. We are committed to ensuring that our clients have access to the latest technology and features that can improve their applications’ performance.

Bespoke Slip Ring Solutions for Versatile Applications

At Grand, we recognize that different industries utilize various slip rings tailored to their specific environments and signal requirements. Our expertise as a premier slip ring manufacturer allows us to address the unique challenges faced by each sector, ensuring optimal performance across a wide range of applications.

Understanding Industry Variability

Different industries use different slip rings in diverse environments, and the manufacturers have not unified the important performance parameter requirements. This variability often leads to a need for customized solutions that can accommodate the specific demands of each application. For instance, slip rings used in Surveillance & Video applications must handle high data transmission rates, while those in Wind Turbines must endure extreme weather conditions.

Customized Solutions for Every Need

Customized products account for almost 50% of our offerings, demonstrating our commitment to providing tailored solutions. Despite having over 200 standard molds as an original slip ring manufacturer, we understand that many applications require unique designs. Our focus on delivering bespoke slip ring solutions ensures that we can meet the specific needs of industries such as Entertainment Equipment, Packing Machines, Robotic Arms, and Construction Machinery.

Commitment to Quality and Innovation

At Grand, we believe that the right cost, the right quality, and the right features are essential to developing custom solutions. Our engineering team works diligently to ensure that each custom slipring is designed with precision, using high-quality materials that enhance durability and performance. This commitment to quality is evident in the more than 1,500 innovative custom slip ring solutions we provide each year, ensuring that no two solutions are identical.

Comprehensive Application Range

Our bespoke slip ring solutions cater to a diverse array of applications, including Surveillance & Video, Wind Turbines, Stage Lights, Entertainment Equipment, Packing Machines, Robotic Arms, Construction Machinery, Medical Devices, Marine Equipment, Cable Reels, Automation Systems, Measuring Equipment, Military Technologies, and Radar Antenna. Each solution is meticulously crafted to address the specific challenges of its intended use, enhancing operational efficiency and reliability.

Contact Us for Tailored Solutions

If you require a custom slip ring for a specific application or a tailored solution for complex systems, Grand is here to assist you. Our dedication to innovation and customer satisfaction positions us as a leader in the slip ring industry. Contact us today to discuss how our bespoke slip ring solutions can enhance your operations and provide reliable connectivity in your projects.

FAQs about PCB Slip Ring

What is the problem with the slip ring?

Slip rings can experience several common problems that may affect their performance and longevity. One frequent issue is wear and tear on the brushes or contacts, which can lead to intermittent signal loss or complete failure of electrical connections. This is often exacerbated in environments with high levels of dust, moisture, or contaminants, which can degrade the electrical contacts. Additionally, if the slip ring is not properly designed or installed for its specific application, it may not be able to handle the required voltage or current, leading to overheating or electrical arcing. Regular maintenance and inspection are essential to identify these issues early and ensure that slip rings continue to function effectively. Users should also be aware of the importance of choosing a slip ring that meets their operational requirements, as substandard products can lead to performance issues and increased costs in the long run.

What does a slip ring do?

A slip ring is an electromechanical device that allows the transmission of electrical power and data signals from a stationary structure to a rotating one. This functionality is essential in various applications where continuous rotation is required, such as in wind turbines, robotics, and rotating cameras. Slip rings eliminate the need for wires that could twist or break during movement, ensuring a seamless connection while allowing components to rotate freely. By providing a reliable way to transfer power and signals, slip rings enable the efficient operation of machinery and equipment across multiple industries. They can be found in applications ranging from industrial automation and aerospace to medical devices and military systems. In summary, slip rings are crucial for maintaining connectivity in systems that involve rotational motion.

Why are slip rings so expensive?

The cost of slip rings can vary significantly based on several factors, including the complexity of the design, materials used, and the level of customization required. High-quality slip rings are often made from durable materials that can withstand harsh environmental conditions, which contributes to their higher price. Additionally, advanced manufacturing processes and precision engineering are necessary to ensure optimal performance and reliability, especially in critical applications. Custom slip rings tailored to specific operational requirements may also increase costs due to the design and development time involved. Furthermore, the need for rigorous testing and quality control during production ensures that the final product meets industry standards and performs reliably. While slip rings may seem expensive, investing in high-quality components ultimately leads to lower maintenance costs and improved operational efficiency in the long run.

What is the difference between split ring and slip ring?

The terms “split ring” and “slip ring” refer to different types of components with distinct functions in electrical systems. A split ring is typically a type of electrical contact used in devices like commutators, which are found in DC motors. The split ring allows for the reversal of current direction as the motor rotates, enabling continuous operation. In contrast, a slip ring is designed specifically for transferring power and data between stationary and rotating parts without interruption. Slip rings provide a more versatile solution for various applications, as they can handle multiple circuits and signals simultaneously. Additionally, slip rings are used in applications where rotation is continuous, while split rings are more commonly associated with applications requiring periodic reversal of current. Understanding these differences is crucial for selecting the right component for a specific application.