The servo encoder slip ring is an electrical slip ring that works for the servo encoder signal and servo motor power supply. The servo encoder slip ring can save many cables and installation works to transmit data and power. Suitable for all kinds of servo/stepper motors. Supplies usually use gold contacts to avoid external interference and internal interference.

What Is Servo Encoder Slip Ring?

Servo Encoder Slip Rings - BH Series

Available for Custom, Standard 1~4 Motor

GRAND does special treatment for internal shielding and wiring to make sure no packet loss and a low bit error rate.

Although GRAND offers modularized & standardized designs for various application solutions as an original slip ring manufacturer. To create your most suitable servo encoder slip ring connector, please feel free to contact us.

Feature

- Special internal shielding and wiring design

- Permanently lubricated bearing

- Gold to gold contacts

- Easy installation

Options

- No. of rings

- Current &voltage

- Inner, out diameter and length

- Operating speed

- Wire length

- Position of wire outlet

- Connector

- Housing material

Model Breakdown

Servo Encoder Slip Ring: An Innovative Solution

The Servo Encoder Slip Ring is an advanced component designed to facilitate seamless power and data transmission between stationary and rotating parts in various applications. This innovative solution is especially beneficial in scenarios requiring precise motion control and reliable feedback. Below, we explore the key features and benefits of this unique product.

Integration of Technologies: The encoder servo slip ring combines the functionalities of a slip ring encoder with a servo system. This integration allows for uninterrupted electrical and data connections, crucial for applications where rotation and data transmission occur simultaneously.

Precision Motion Control: With its servo encoder capabilities, the slip ring provides accurate position and speed monitoring. This precision is vital in applications such as robotics, industrial automation, and CNC machinery, where operational efficiency and responsiveness are paramount.

Continuous Rotation: The design of the slip ring with encoder ensures that data can be transmitted continuously while the system is in motion. This feature eliminates the limitations associated with traditional connections, allowing for 360° rotation without interruptions.

Compact Design: The ring encoder configuration offers a space-saving solution for installations where physical space is limited. By integrating the functions of both slip rings and encoders, the overall system can maintain a smaller footprint while still providing high performance.

Dynamic Feedback Mechanism: Utilizing ring encoders enables real-time feedback, which is essential for maintaining operational accuracy. The data collected by the encoder ring informs the servo motor about its position and speed, allowing for precise adjustments and control.

Enhanced System Performance: The combination of a servo with encoder provides a dynamic and responsive system that can adapt to changing conditions. This adaptability is crucial in high-speed and high-precision applications, ensuring optimal performance and reducing the risk of errors.

Applications: The Servo Encoder Slip Ring is ideal for various applications, including robotics, automated manufacturing, packaging systems, and any equipment requiring both power transmission and data feedback. Its ability to operate effectively in demanding environments makes it a reliable choice for engineers and manufacturers.

The Servo Encoder Slip Ring represents a significant advancement in the integration of slip ring technology and encoder functionality. By providing continuous power and data transmission alongside precise motion control, this component enhances the efficiency and effectiveness of modern automation systems, making it an essential tool in the field.

Who is Grand Technology?

Industry Leadership: Grand Technology is a pioneering company in the slip ring and rotary joint industry, recognized for its commitment to quality and innovation. We are a leader in the power slip ring market, catering to the HD video slip rings market with an industry-leading quality system.

Quality Assurance: Our quality system is integrated throughout the entire supply chain, from raw materials to final delivery. We adhere to strict standard operating procedures to ensure consistent quality and timely delivery of our products.

ISO Compliance: We operate in full compliance with ISO-9001 standards, providing complete traceability in all processes. Our S.Q.D.I.P. system—Safety, Quality, Delivery, Inventory, Performance—drives excellence across our organization.

Innovative Labs: Our state-of-the-art laboratories are equipped for testing and verification solutions, ensuring that all products meet the highest industry standards. We guarantee the reliability and accuracy of our products through rigorous testing.

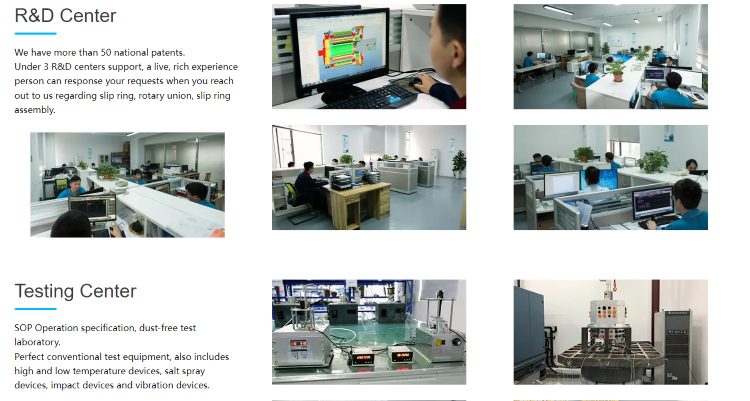

Research and Development: With over 50 national patents and three dedicated R&D centers, we are at the forefront of innovation. Our experienced professionals address inquiries related to slip rings, rotary unions, and slip ring assemblies, continuously improving our products.

Testing Facilities: Our testing center features standard operation specifications and a dust-free laboratory, equipped with advanced testing devices for high and low temperatures, salt spray, impact, and vibration tests, ensuring exceptional performance.

Commitment to Quality: We are dedicated to delivering quality and innovation, as evidenced by our attainment of ISO9001, RoHS, CE, and GJB9001B certifications, confirming our products exceed military-grade standards.

Collaborations and Partnerships: We actively collaborate with prestigious universities, research institutes, and renowned factories across Asia and Europe. Partnerships with industry giants such as Panasonic, SIEMENS, CSIC, SAMSUNG, and HUAWEI enhance our product development capabilities.

Comprehensive Supply Chain Management: Our comprehensive approach to quality assurance covers the entire supply chain, ensuring each product meets rigorous standards.

Reliable Solutions: Whether you’re looking for Grand slip products, we are committed to providing the highest quality solutions for your needs. Our innovative labs rigorously assess product performance to ensure reliable results across diverse applications.

FAQs about Servo Encoder Slip Ring

What does a slip ring do?

A slip ring is an electromechanical device that enables the transmission of electrical power and data signals between stationary and rotating parts of a machine. It consists of conductive rings and brushes that make contact with these rings, allowing for continuous rotation without losing connectivity. Slip rings are commonly used in applications where rotating machinery needs to maintain electrical connections, such as in wind turbines, rotary tables, and industrial robots. By providing a reliable way to transfer power and signals, slip rings facilitate smooth and uninterrupted operation of rotating systems, improving efficiency and performance in various applications.

What is the purpose of the slip ring commutator?

The slip ring commutator serves a critical role in converting alternating current (AC) generated in a rotor into direct current (DC) for the external circuit in certain types of electrical machines, such as DC motors and generators. It consists of segmented copper rings connected to the rotor and brushes that maintain contact with these rings as the rotor spins. The primary purpose of the slip ring commutator is to ensure that the electrical output remains stable and directed, preventing the back-and-forth flow of current associated with AC. This allows the device to deliver a consistent power supply to the load while facilitating the operation of the motor or generator.

What is the purpose of slip rings in synchronous motors?

In synchronous motors, slip rings play a vital role in enabling the transfer of power to the rotor windings. Unlike induction motors, synchronous motors require an external DC power supply to energize the rotor, creating a magnetic field that interacts with the stator’s rotating magnetic field. Slip rings allow for continuous electrical connectivity, enabling the DC power to flow to the rotor while it is spinning. This setup ensures that the rotor maintains synchronous speed with the rotating magnetic field, which is essential for the motor’s efficient operation. By facilitating this power transfer, slip rings contribute to the performance and reliability of synchronous motors in various applications, including industrial drives and generators.

How does a slip ring sensor work?

A slip ring sensor is a device that utilizes slip ring technology to continuously transmit signals from a rotating element to a stationary system. The sensor typically consists of a rotating shaft equipped with conductive rings, which are connected to the sensor’s output circuitry. As the shaft rotates, stationary brushes maintain contact with the conductive rings, allowing electrical signals generated by the sensor (such as position, speed, or temperature) to be transmitted without interruption. This design enables the slip ring sensor to provide real-time data to the control system, ensuring accurate monitoring and feedback in applications like robotics, aerospace, and industrial automation. By eliminating the need for complex wiring solutions, slip ring sensors enhance the flexibility and efficiency of systems that require continuous rotation.